Low-odor low-VOC glass fiber reinforced polypropylene composite material and preparation method thereof

A composite material, low-odor technology, applied in the field of polymer material modification, can solve the problems of large difference in shrinkage rate of glass fiber reinforced polypropylene composite materials, uneven glass fiber arrangement, limited glass fiber fluidity, etc. Low odor and low VOC, the effect of reducing odor and VOC content, improving process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

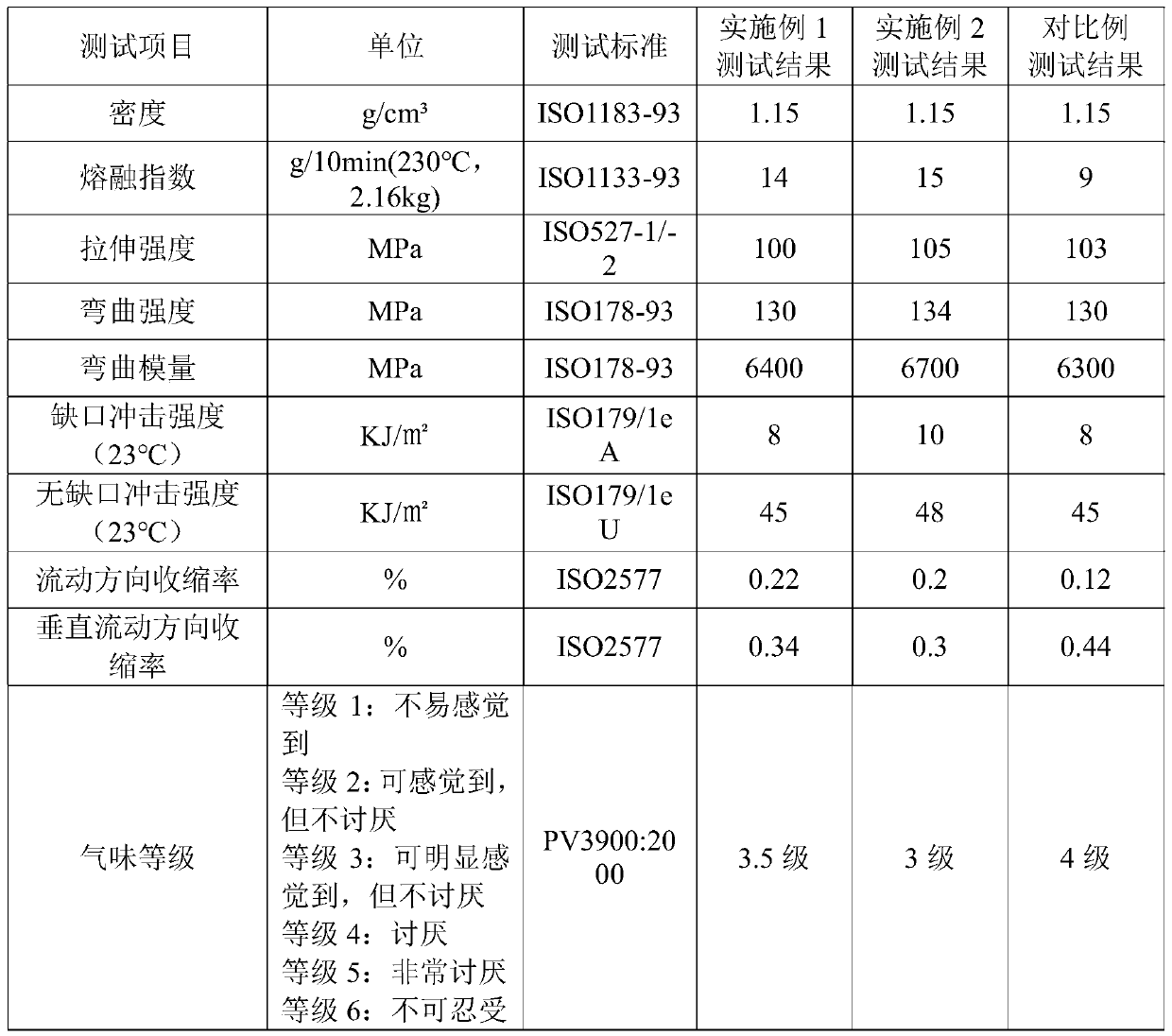

Examples

Embodiment 1

[0022] Low odor and low VOC glass fiber reinforced polypropylene composite material 1, including the following raw materials:

[0023] 66.5 kg of PP (polypropylene) resin, model PP-HP500P;

[0024] 30 kg chopped flat glass fiber, model ECS305K-3-M4, the cross-section is flat, the cross-section width-thickness ratio is 4:1, and the surface is coated with low-odor and low-VOC sizing;

[0025] 0.14 kg polypropylene wax lubricant;

[0026] 2.8 kg of common compatibilizer, formed by grafting PP with maleic anhydride groups (PP-g-MAH);

[0027] 0.14 kg of phenolic antioxidant, model Irganox 1010, and 0.14 kg of phosphite antioxidant, model Irganox 168;

[0028] 0.28 kg of black masterbatch, the model is CABOT-UN2014.

[0029] The preparation method of glass fiber reinforced polypropylene composite material 1 with low odor and low VOC, prepares raw materials according to the above weight,

[0030] Step 1: Confirm whether the chopped flat glass fiber model ECS305K-3-M4 is a low-od...

Embodiment 2

[0035] Low odor and low VOC glass fiber reinforced polypropylene composite material 2, including the following raw materials:

[0036] 67.2 kg of PP (polypropylene) resin, model PP-HP500P;

[0037] 30 kg chopped flat glass fiber, model ECS305K-3-M4, the cross-section is flat, the cross-section width-thickness ratio is 4:1, and the surface is coated with low-odor and low-VOC sizing;

[0038] 0.14 kg polypropylene wax lubricant;

[0039] 2.1 kg of low-odor and high-activity oligomer compatibilizer, the high-activity oligomer compatibilizer is formed by grafting PP (PP-g-MAH) with maleic anhydride groups and high-reactivity groups, and maleic anhydride groups The grafting rate of the group and the grafting rate of the highly reactive group are 1.3%-1.6%, and the melt index is 150g / 10min (230°C, 2.16kg);

[0040] 0.14 kg of phenolic antioxidant, model Irganox 1010, and 0.14 kg of phosphite antioxidant, model Irganox 168;

[0041] 0.28 kg of black masterbatch, the model is CABOT...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com