Method for laser-assisted polishing of CVD diamond

A laser-assisted and diamond-based technology, which is applied to surface polishing machine tools, grinding/polishing equipment, metal processing, etc., can solve the problems that laser-assisted polishing technology has not been researched, so as to improve polishing efficiency and polishing quality, and improve polishing The effect of surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A CVD diamond laser-assisted polishing method, the steps are as follows:

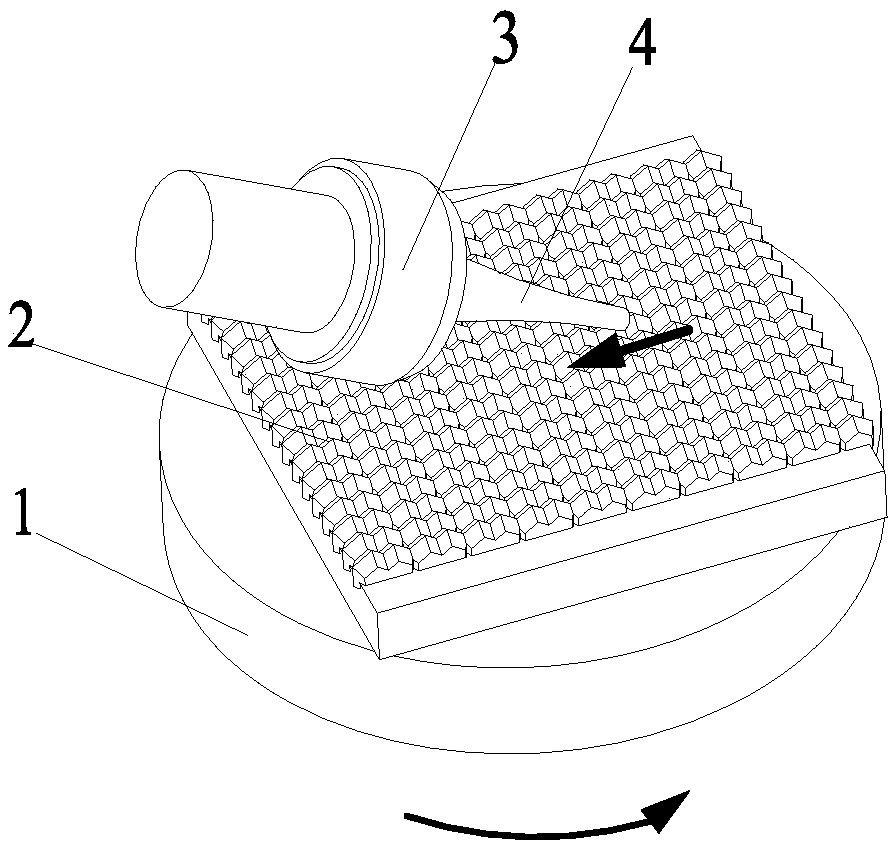

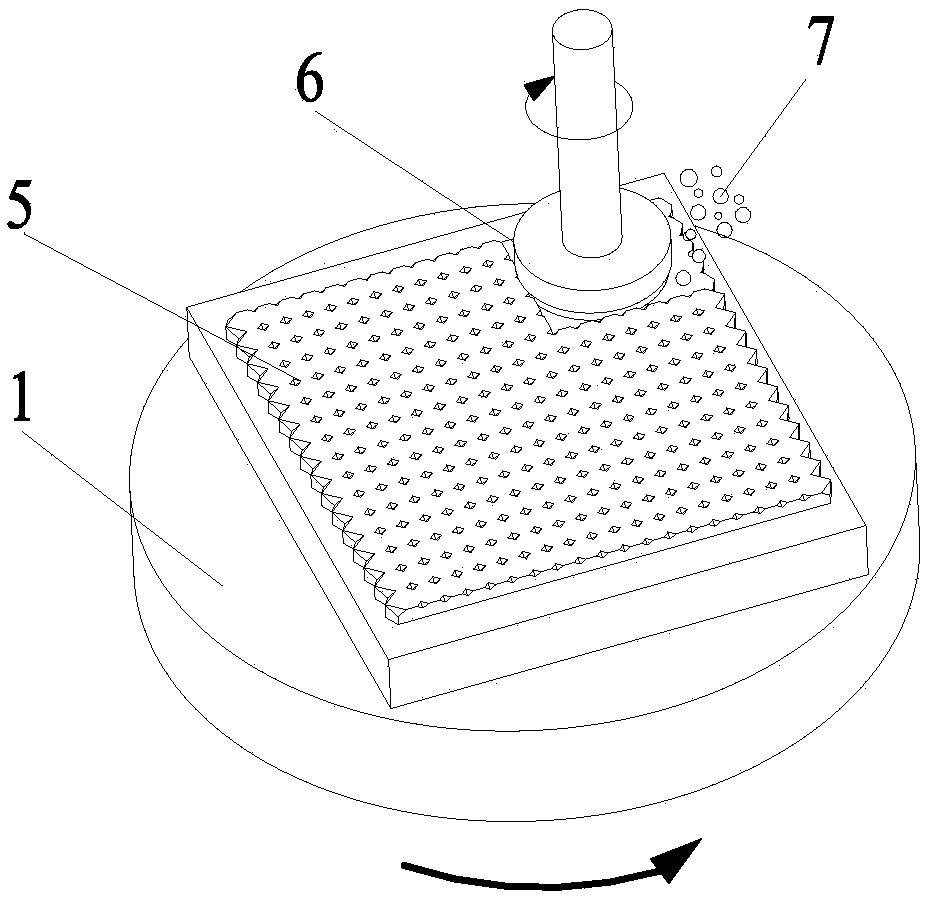

[0030] Adjust the laser ablation parameters, the rotating speed of the rotary table, and the incident angle of the laser to build a polishing platform, and clamp the CVD diamond workpiece 2 on the rotary table 1. The scanning path of the laser beam 4 and the rotation direction of the turntable are as follows: figure 1 As shown in , the turntable rotates counterclockwise while the laser beam translates.

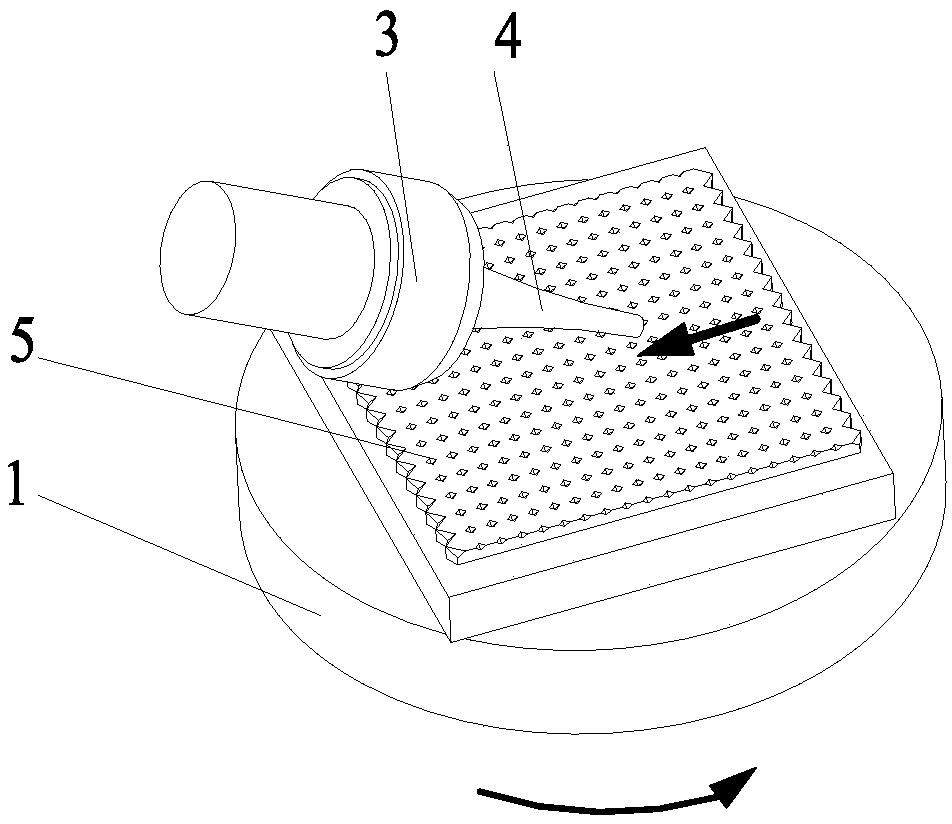

[0031] In the process of laser polishing CVD diamond, such as Figure 4 The schematic diagram of laser ablation diamond is shown, because the surface roughness of CVD diamond before polishing is relatively high, and the laser beam 4 is polished at an incident angle θ (the range of θ is 0° to 85°), which is beneficial to maximize the laser energy density. Improve material removal rate.

[0032] The laser beam is polished along the incident angle, and the protrusion height h of the polished CVD ...

Embodiment 2

[0041] Investigate the relationship between the laser incident angle and the surface roughness after polishing, as the laser incident angle increases, the polished surface roughness tends to decrease, and when the incident angle is greater than 60°, the surface roughness decreases rapidly. Therefore, the present invention chooses The selection range of the incident angle is: 0°-85°, preferably, the incident angle is 45°-85°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com