Preparation method of molded line used for stranded conductor

A technology of stranded conductors and wire conductors, applied in cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of increased transmission power consumption, low production efficiency, and high manufacturing costs, and can improve the area deformation ratio and production efficiency. , The effect of good production operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

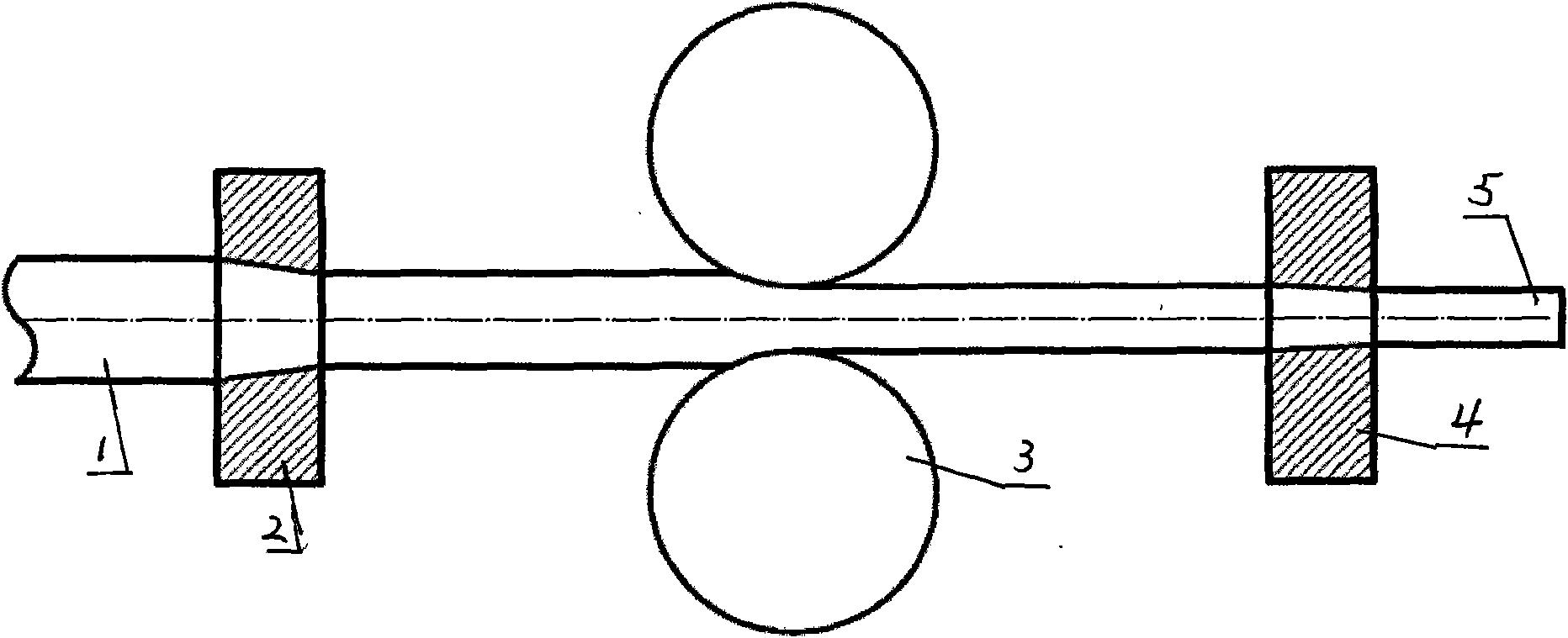

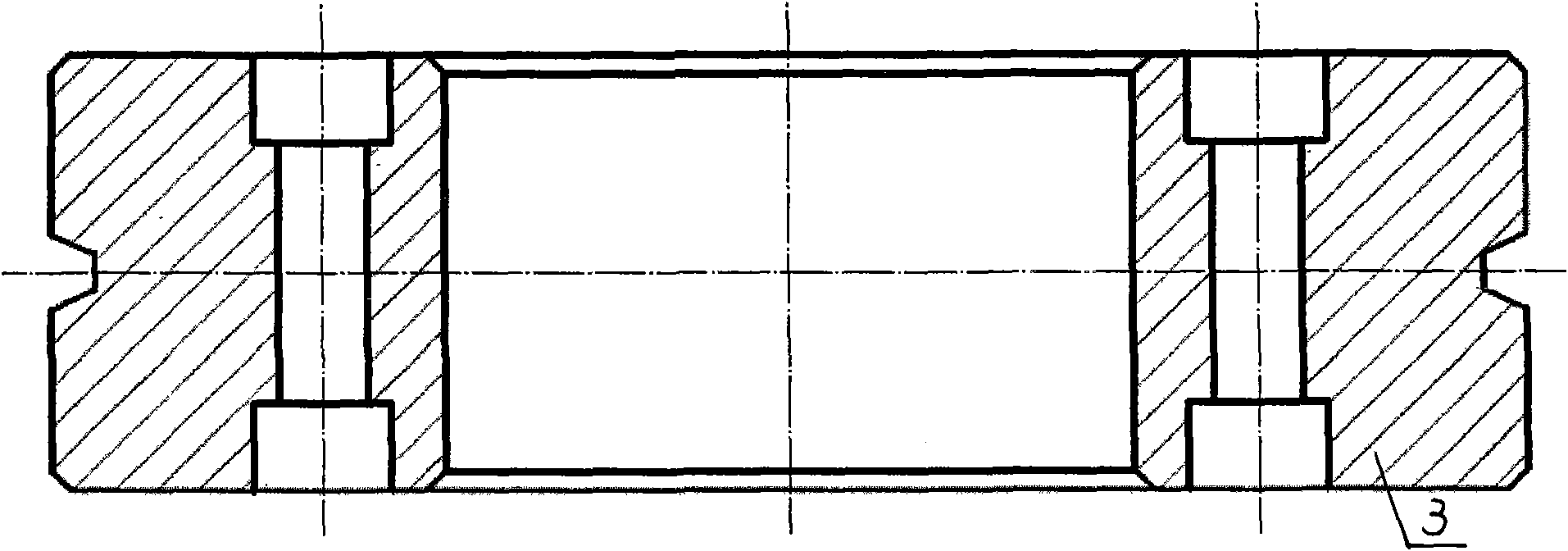

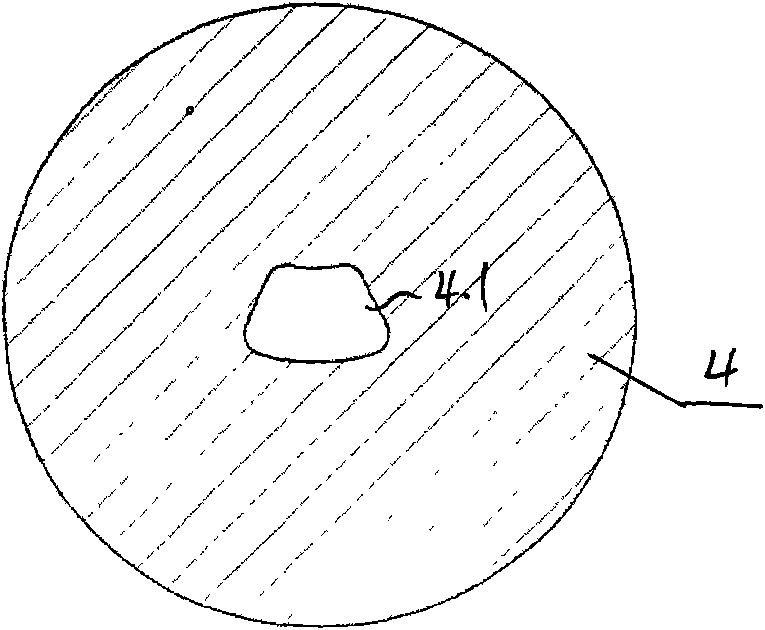

[0016] Embodiment 1: see Figure 1-3 , φ12.0mm circular aluminum rod 1, drawn by 5 circular drawing dies 2, to obtain a cross-sectional area of 30.65mm 2 The circular conductor, through rolling die 3 (embodiment rolling groove is trapezoidal) that roller is formed, obtains cross-sectional area and is 23.0~24.0mm 2 The trapezoidal conductor is finally shaped by the drawing die 4 with a hole shape of trapezoidal 4.1 to obtain a smooth and neat trapezoidal line 5.

[0017] Changing the groove shape of the rolling wheel and the shape of the shaping die can produce such as Figure 4-Figure 6 Said Z-shape, fan-shape, trapezoid, and the molded lines of the shapes thereof.

Embodiment 2

[0018] Embodiment 2: As mentioned above, two parallel rolling grooves are processed on the roller, which can cooperate with two drawing lines, or roll two kinds of non-standard and dimensioned lines.

[0019] According to requirements, the formed wire can be obtained through subsequent annealing or no annealing to obtain soft aluminum type wire conductors or hard aluminum type wire conductors respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com