Machining device for full-surface micro-pit structure of thin-wall spherical shell type micro-component

A processing device, full-surface technology, applied in positioning devices, clamping devices, feeding devices, etc., can solve the problems of unstable fluid mechanics, surface asymmetry, material non-uniformity, etc., achieve compact structure design, improve processing accuracy, Configure flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

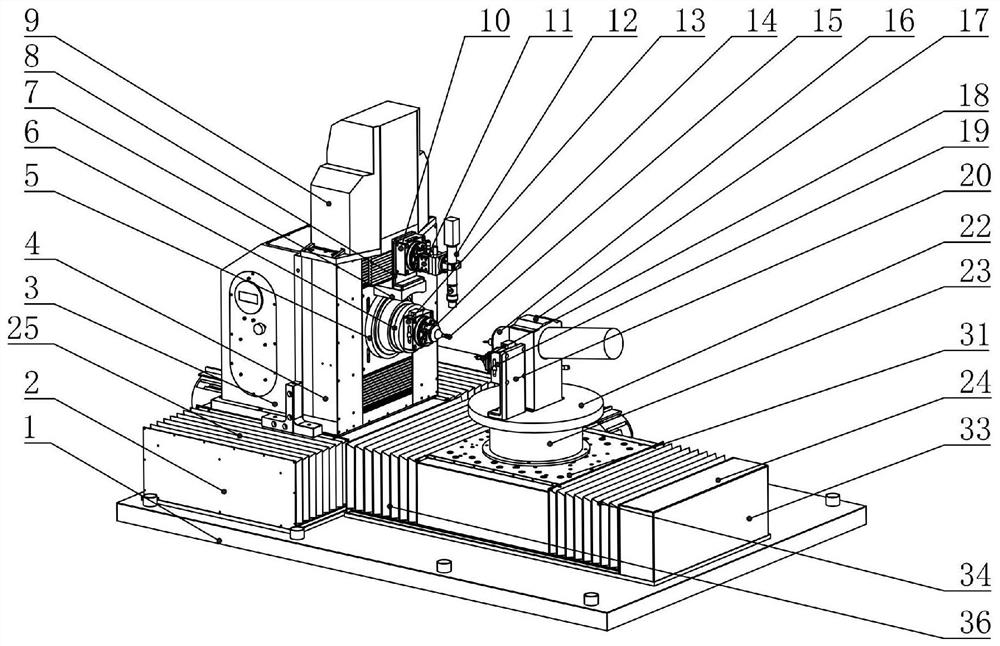

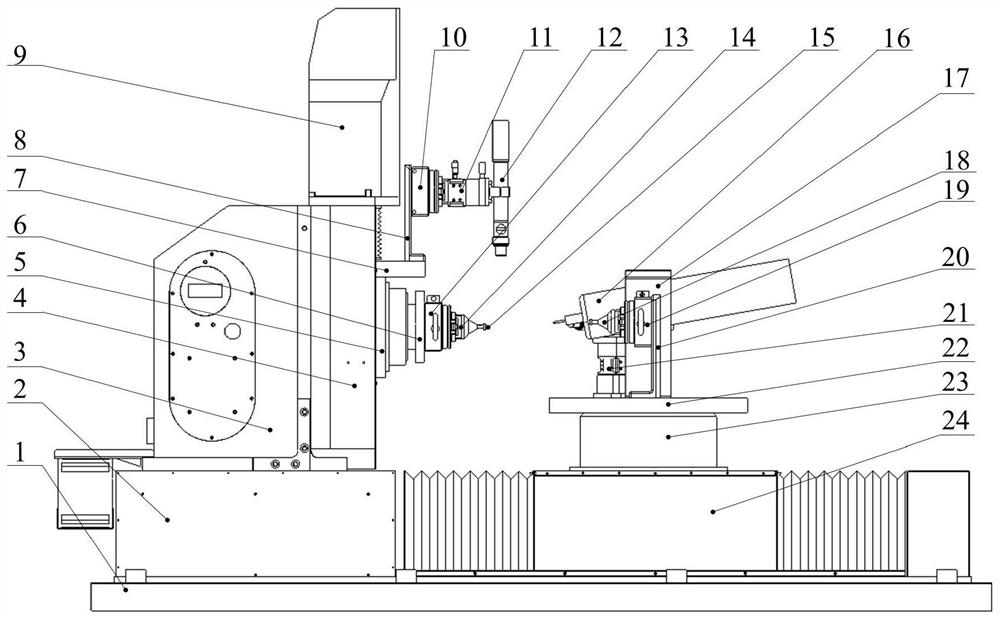

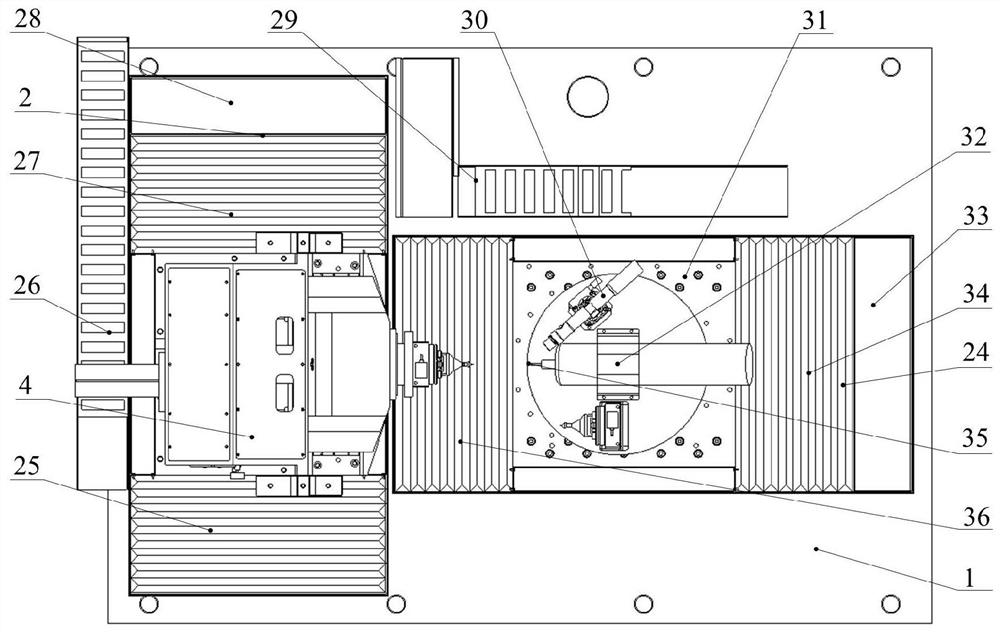

[0055]In a further embodiment of the present invention, a special vacuum adsorption fixture and adsorption method are used to adsorb and clamp thin-walled spherical shell micro-components 15 to reduce clamping deformation, and use a zero point positioning system for quick change and U-turn secondary clamping to realize High-precision repeated clamping and positioning, through the arrangement of two high-resolution CCD cameras to achieve precise tool setting under the constraints of micro-space scales, identification and capture of secondary clamping track points, determination of characteristic micro-pit structure coordinates, and a complete overview of the machining process Azimuth monitoring, due to the oblique placement of the milling axis 16, can effectively avoid the zero vertex speed of the ball end milling cutter 35 and reduce the quality of the processed surface, especially suitable for the cross-scale characteristic micro-pit uniformly distributed on the entire surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com