Long-distance-leaving steel billet positioning control system for roughing mill

A positioning control and billeting machine technology, applied in rolling mill control devices, metal rolling, manufacturing tools, etc., can solve problems such as affecting the inlet temperature of the billet into the continuous rolling, affecting the billeting progress and rolling rhythm, and affecting the process quality. , to achieve the effect of facilitating realization, simple design, and speeding up production rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The features of the present invention and other related features will be described in detail below in conjunction with the accompanying drawings. The embodiments are implemented on the premise of the technical solutions of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited. Limited to the following examples.

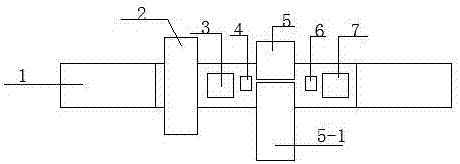

[0017] Such as figure 1 As shown, a blanking machine running steel positioning control system specifically includes: a roller table 1, an entrance turning machine 2, an entrance pusher 3, an entrance hot metal detector 4, a blank opening machine 5, and an exit hot metal detector 6 , Export push bed 7. The inlet hot metal detector is connected with the roller table, and the outlet hot metal detector is connected with the main motor 5-1 of the blanking machine and the roller table at the same time.

[0018] The steel billet is turned over by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com