A single-stand reversing rolling mill ultra-thin steel strip rolling process

A single-frame, ultra-thin technology, applied in the field of cold rolling of steel sheets and strips, can solve problems such as large thickness fluctuations, low production efficiency, and large rolling forces, and achieve the effects of greatly improving motor load, increasing production capacity, and stabilizing product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1. In this example, Q195LD material, 2.75*760 slit hot-rolled coil is used as the raw material. After pickling, the rolling force is 9000KN, and in the 1150 rolling mill unit, it is rolled into a 0.165mm steel strip through six passes. During the six-pass rolling process, the rolling speed gradually increases from 210 to 712 m / min, and the total reduction rate reaches 94.5%.

[0017] The specific rolling process is shown in Table 1.

[0018] Table 1 Six-pass rolling process parameters of Example 1

[0019]

Embodiment 2

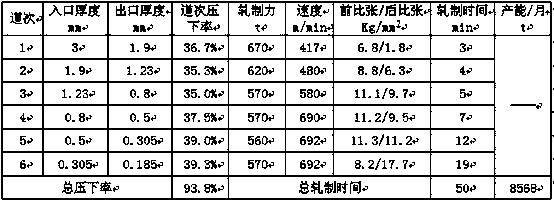

[0023] Embodiment 2, in this example, use SPHC material, 3.0*910 specification hot-rolled coil as raw material, after pickling, in rolling force 9000KN, 1150 rolling mill units, through six pass rolling into the steel strip of 0.185mm thickness . During the six-pass rolling process, the rolling speed gradually increases from 417 to 692 m / min, the total reduction rate is 93.8%, and the rolling force and main engine load are reasonable. The specific rolling process parameters are shown in Table 3.

[0024] Table 3 Six-pass rolling process parameters of embodiment 2

[0025]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com