Roughing-rolling reversable mill strand continuous rolling process

A rolling mill and rough rolling technology, applied in the field of rough rolling reversing rolling mill rolling process, can solve the problems of low hourly output of the unit, many rolling passes, and high investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

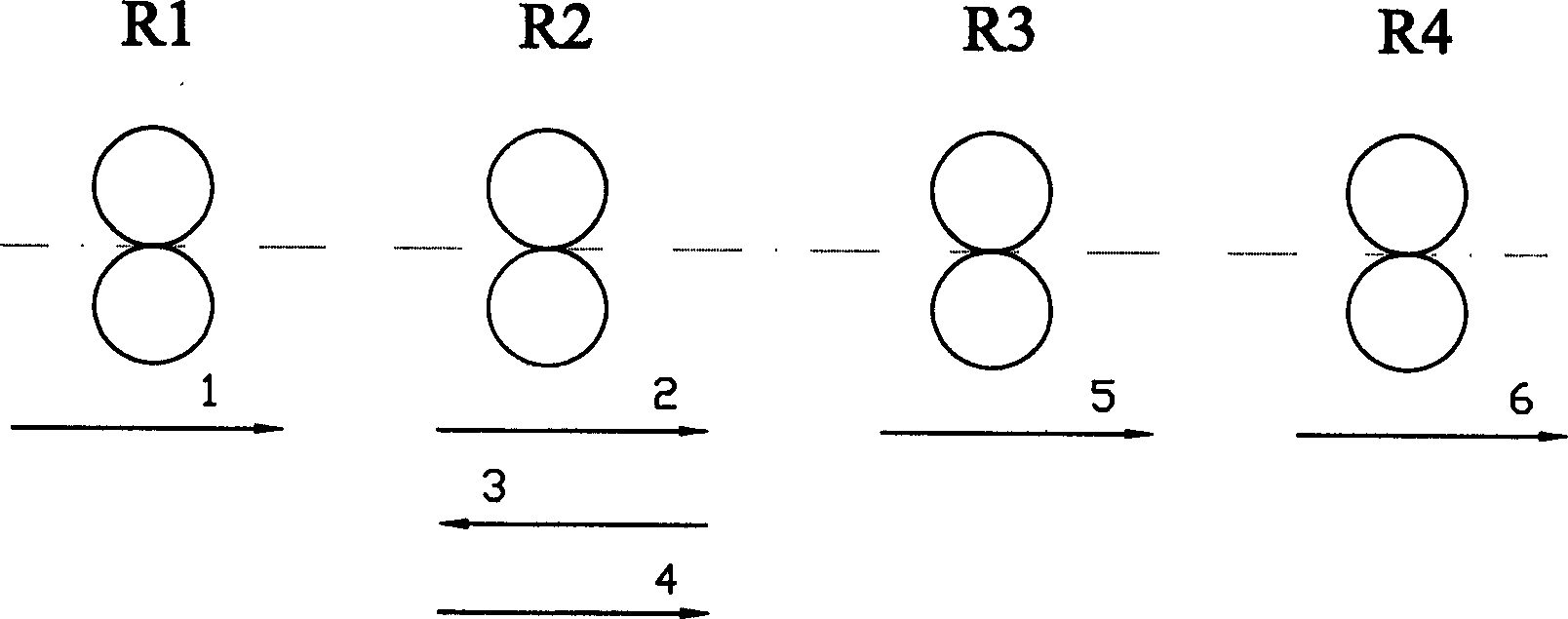

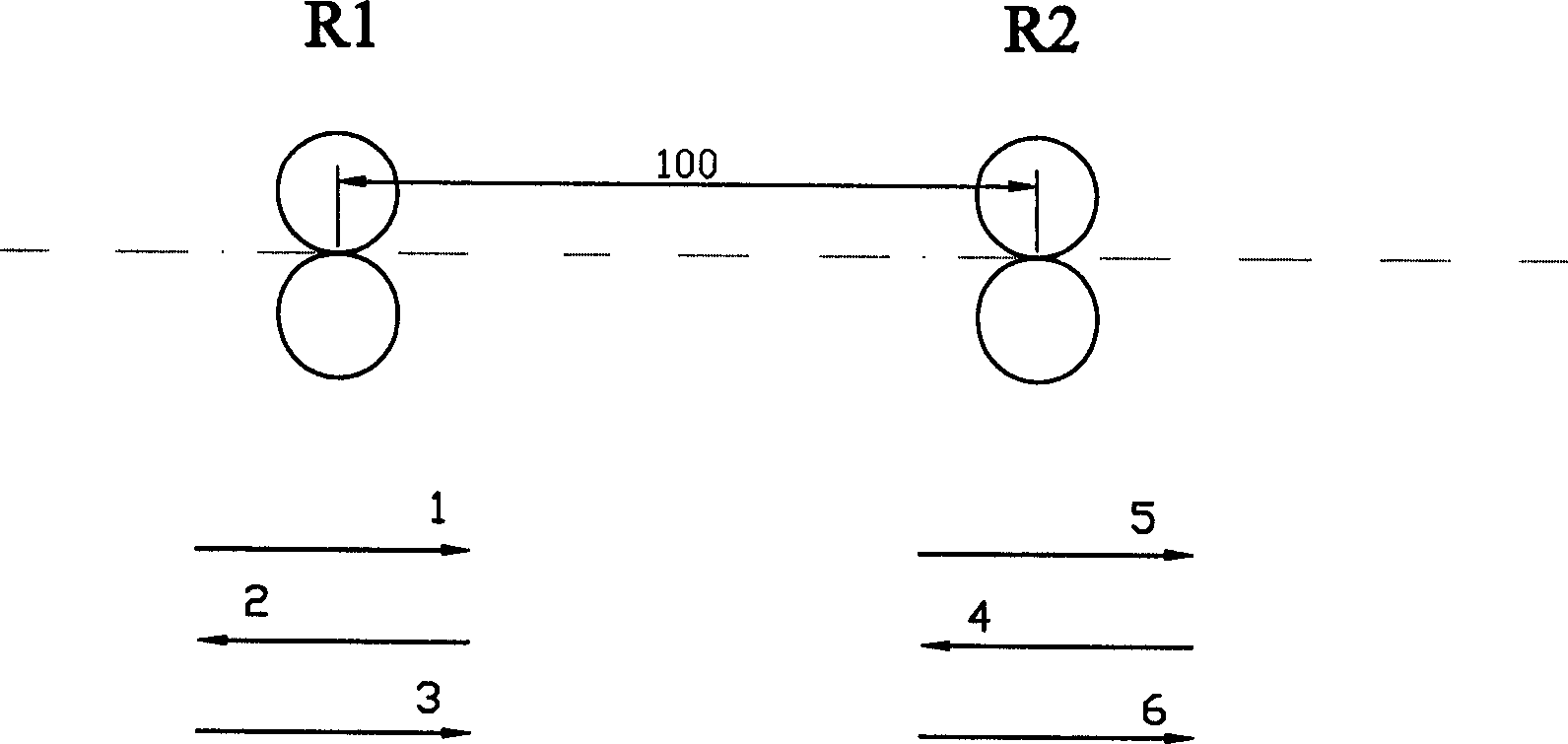

[0033] The tandem rolling process of the rough rolling reversible rolling mill of the present invention adopts the layout form of two stands in series, the distance between the two stands is 25 meters, the unit coil weight of the steel coil is 23kg / mm, and the rolling is carried out in 6 passes. The 5th pass of R1 and the 6th pass of rack R2 are continuous rolling, and the rest of the passes are series rolling. see Figure 4 And Tables 1 to 6:

[0034] It can be seen from Tables 1 to 6 that,

[0035] (1) Due to the series mode, the second pass and the sixth pass do not need to carry out reverse control of the speed, and the adjustment time is reduced by 5.2 seconds and 8.3 seconds respectively;

[0036] (2) Also due to the tandem method, the distance between R1 and R2 is reduced from 102 meters to 25 meters, and the slab handling time is shortened by 25 seconds.

Embodiment 2

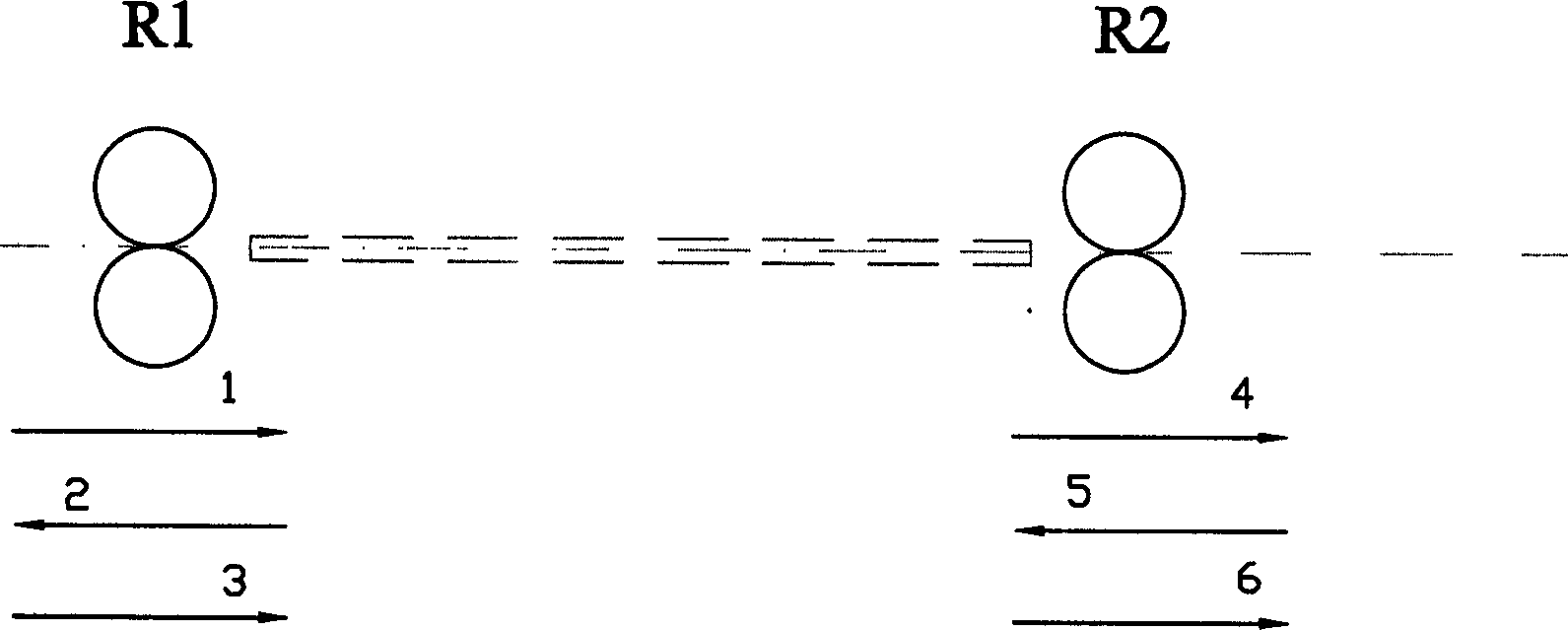

[0049] The rough rolling reversible mill serial rolling process of the present invention adopts the layout form of two racks connected in series, the distance between the two racks is 60 meters, and the rolling is carried out in 6 passes, wherein all the passes are string rolling. see image 3 And Table 7~11:

[0050] (1) Due to the string rolling method, the sixth pass does not need to perform reverse control of the speed, reducing the adjustment time by 8.3 seconds; but because the distance reaches 60 meters, the second pass loses 9.3 seconds

[0051] (2) Also due to the string rolling method, the distance between racks R1 and R2 is reduced from 102 meters to 60 meters, and the slab handling time is shortened by 14 seconds

[0052] The typical time for rough rolling a coil of steel by the original method is 124.5 seconds, which is reduced to 111 seconds by the method of the present invention. That's 13.3 seconds off.

[0053] In the method of the present invention, when r...

Embodiment 3

[0062] Rough rolling reversible rolling mill tandem rolling process is adopted, the distance between R1 and R2 is 40 meters, the unit coil weight of steel coil is 23kg / mm, rolling 6 passes, among which, the 5th pass of R1 and the 6th pass of R2 are Continuous rolling, and series rolling between the rest of the passes. see Figure 4 And Table 12 to Table 16.

[0063]

[0064] Table 13 is the calculation table of rolling time, temperature loss, rolling rhythm, and available monitoring time between passes for different layouts.

[0065] pass

[0066] Distance from SP to R1

[0067] First 3 passes

[0068] 1 pass ends

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com