Multi-rolling device for LED soft light bars

A technology of LED flexible light strips and equipment, which is applied in the direction of winding strips, sending objects, thin material processing, etc., and can solve the problems of cumbersome and inefficient single-line LED flexible light strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

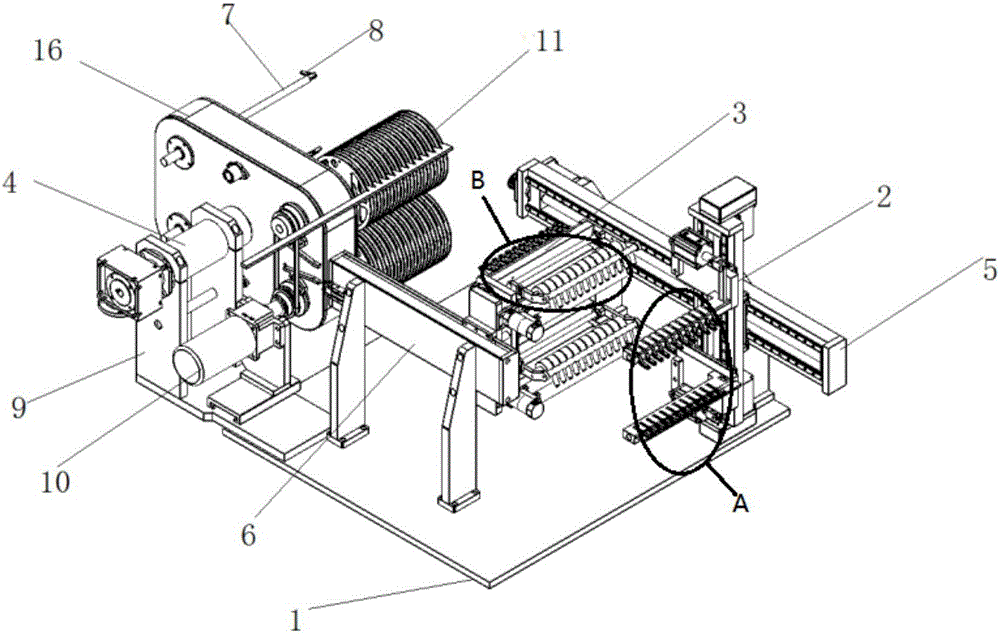

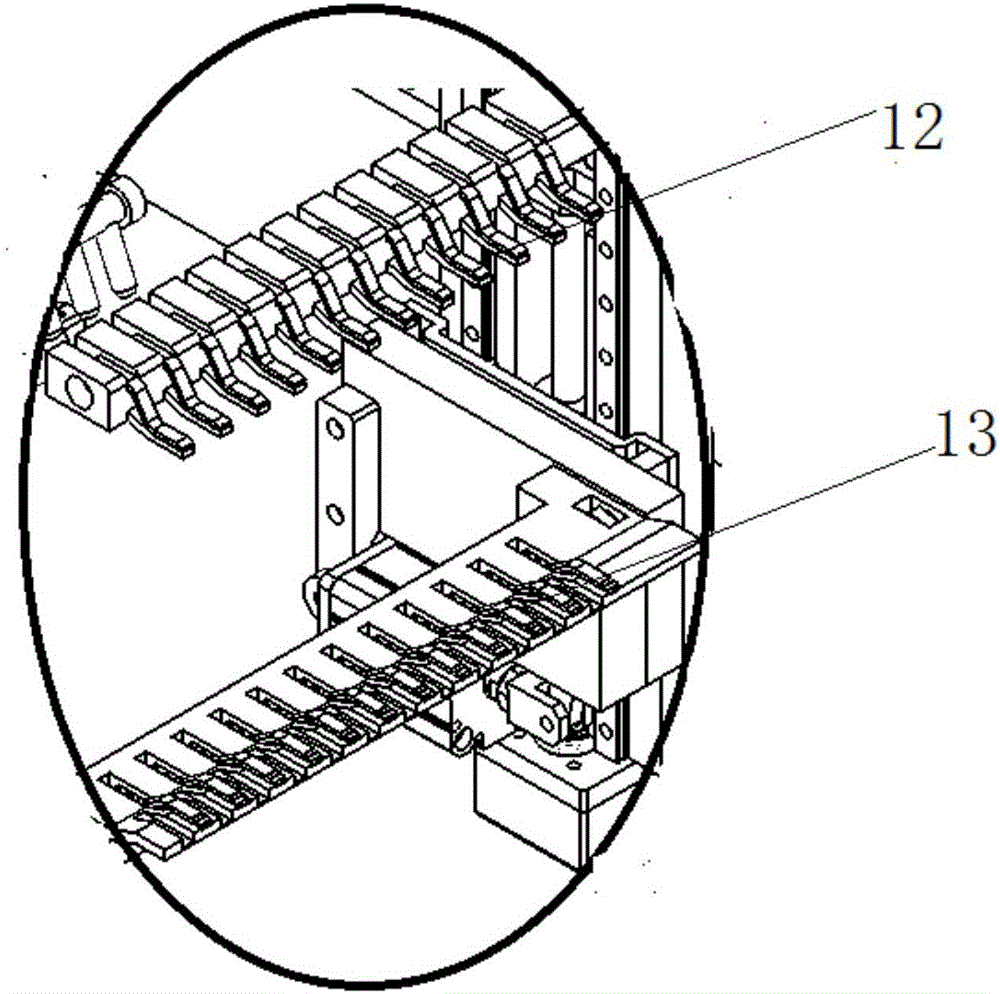

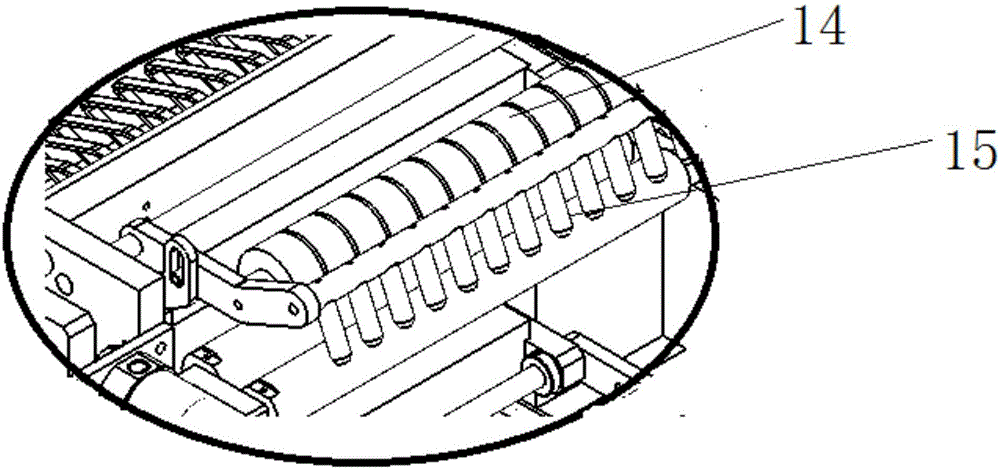

[0023] combine figure 1 , figure 2 and image 3 , a multi-strip rolling device for LED flexible light strips of the present invention, including a bracket 1, a strip-pulling layered manipulator 2, a strip-feeding reel manipulator 3, a strip winding reel rotating machine 4; on the support 1 Including the first support arm 5 and the second support arm 6; guide rails are provided on the first support arm 5 and the second support arm 6; The manipulator 2 for pulling out and layering the light strip can reciprocate in the guide rail; the manipulator 3 for sending the light strip into the reel is installed in the guide rail of the second support arm 6, and the manipulator 3 for sending the light strip into the reel can reciprocate in the guide rail; The rotation of the light strip winding reel includes a base 9, an indexing winding part 16, a motor 10, a rotating shaft 7 and a reel 11; the rotating shaft 7 is installed on the indexing winding part 16; the rotating shaft 7 is driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com