Rolling method capable of improving biting condition in rolling process of reversible rolling mill

A technology of rolling process and conditions, applied in metal rolling and other directions, can solve the problems of increasing the size of the rolling mill arch, motor power, increasing the investment in rolling mill equipment, and reducing the surface quality of the steel plate, reducing energy consumption, saving rolling time, The effect of reducing the number of passes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

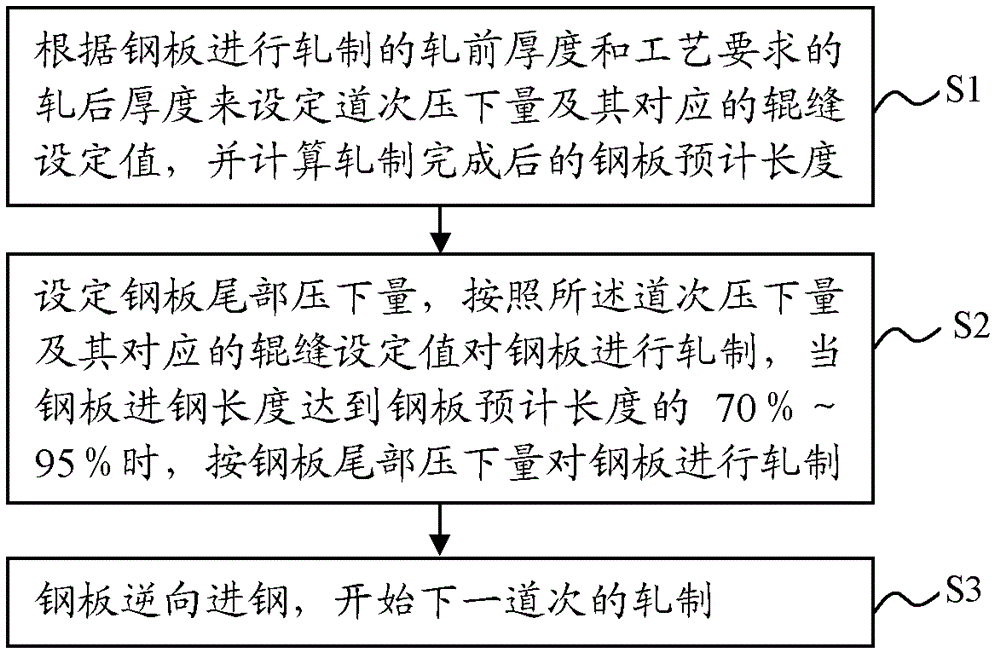

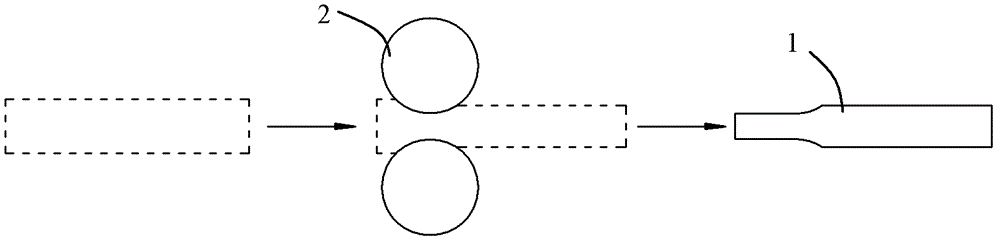

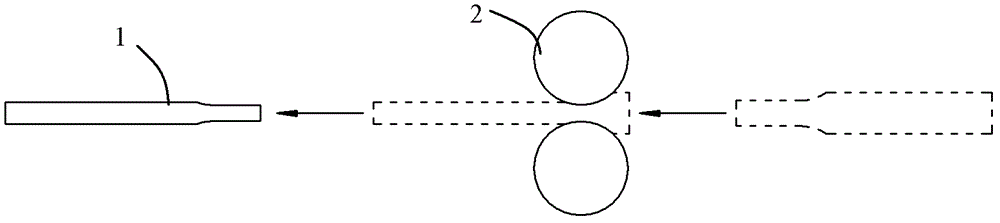

[0022] see Figure 1 ~ Figure 4 In the figure, 1 is a steel plate, and 2 is a roll. The steel plate 1 is rolled by using the rolling method of the present invention to improve the biting condition in the rolling process of a reversible rolling mill. Include the following steps:

[0023] Step 1. Setting of pass reduction and roll gap (S1)

[0024] When the steel plate is rolled for one pass on the reversible rolling mill, the pass reduction dh and the corresponding roll gap setting are set according to the thickness before rolling of the steel plate for this pass and the thickness after rolling required by the process value gap, and calculate the estimated length length of the steel plate after the pass rolling is completed using the pass reduction dh and the corresponding roll gap setting value gap. The pass reduction dh is the difference between the pre-rolling thickness of the steel plate and the post-rolling thickness required by the process. Existing rolling mills are u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com