Cold straightening process for improving straightening capability through reduction of number of working rolls of straightener

A technology of work rolls and straightening machines, applied in the field of steel rolling, which can solve the problems of increased straightening force of the straightening machine and the inability to continue straightening, etc., to achieve the effects of increasing plastic deformation, expanding straightening capacity, and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

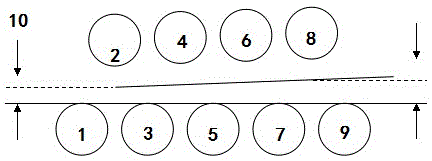

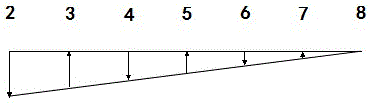

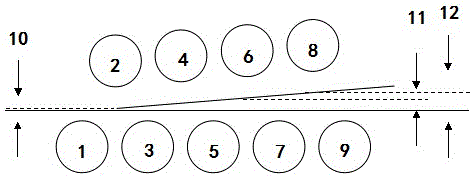

[0020] A straightening process for medium-thick plates with a yield strength of 30 mm and a yield strength of 400 MPa (elastic modulus of 205800 MPa). The roll diameter and roll distance of the straightening machine used in this process are 285 mm and 300 mm respectively. This process requires two straightening passes: In the first straightening pass, 80% of the plastic deformation is used to calculate the roll gap at the entrance of the straightener, and the roll gap at the exit = 2*steel plate thickness - the roll gap at the entrance; in the second pass, 65% of the plastic deformation is used to calculate the roll gap at the entrance of the straightener , the exit roll gap is the thickness of the steel plate. The flatness of the steel plate after straightening is less than 5mm / 2m.

[0021] In this example, a medium-thick plate with a yield strength of 30mm and a yield strength of 400MPa is selected as the straightening object. The straightness is less than 4mm / 2m, straighte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com