Patents

Literature

46results about How to "Increase the amount of plastic deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Differential-speed extrusion forming method of magnesium alloy high performance cup-shaped piece

ActiveCN106607468AIncrease the number of deformationsIncrease the amount of plastic deformationExtrusion diesChinese charactersHigh density

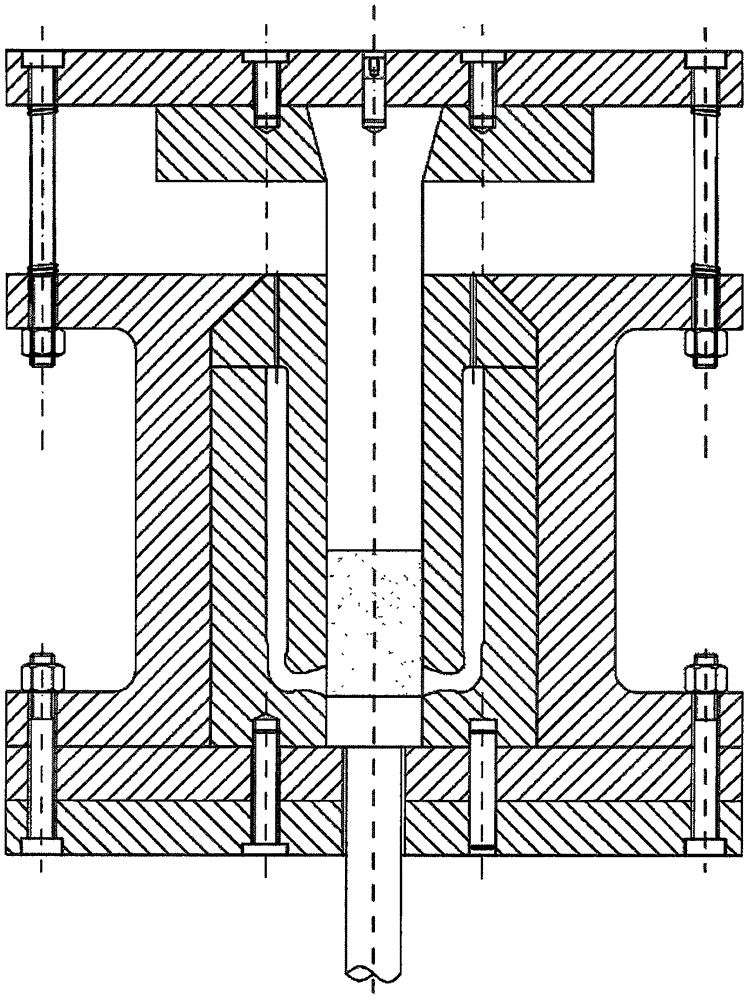

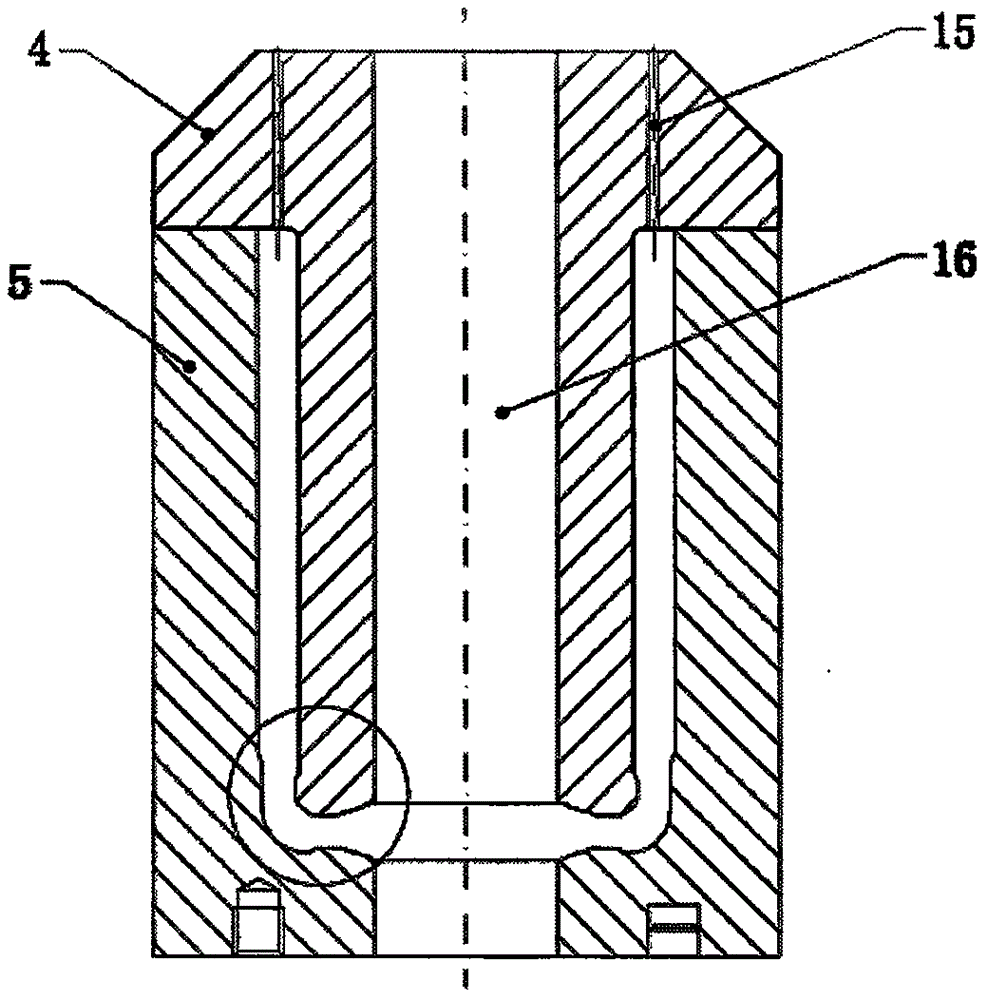

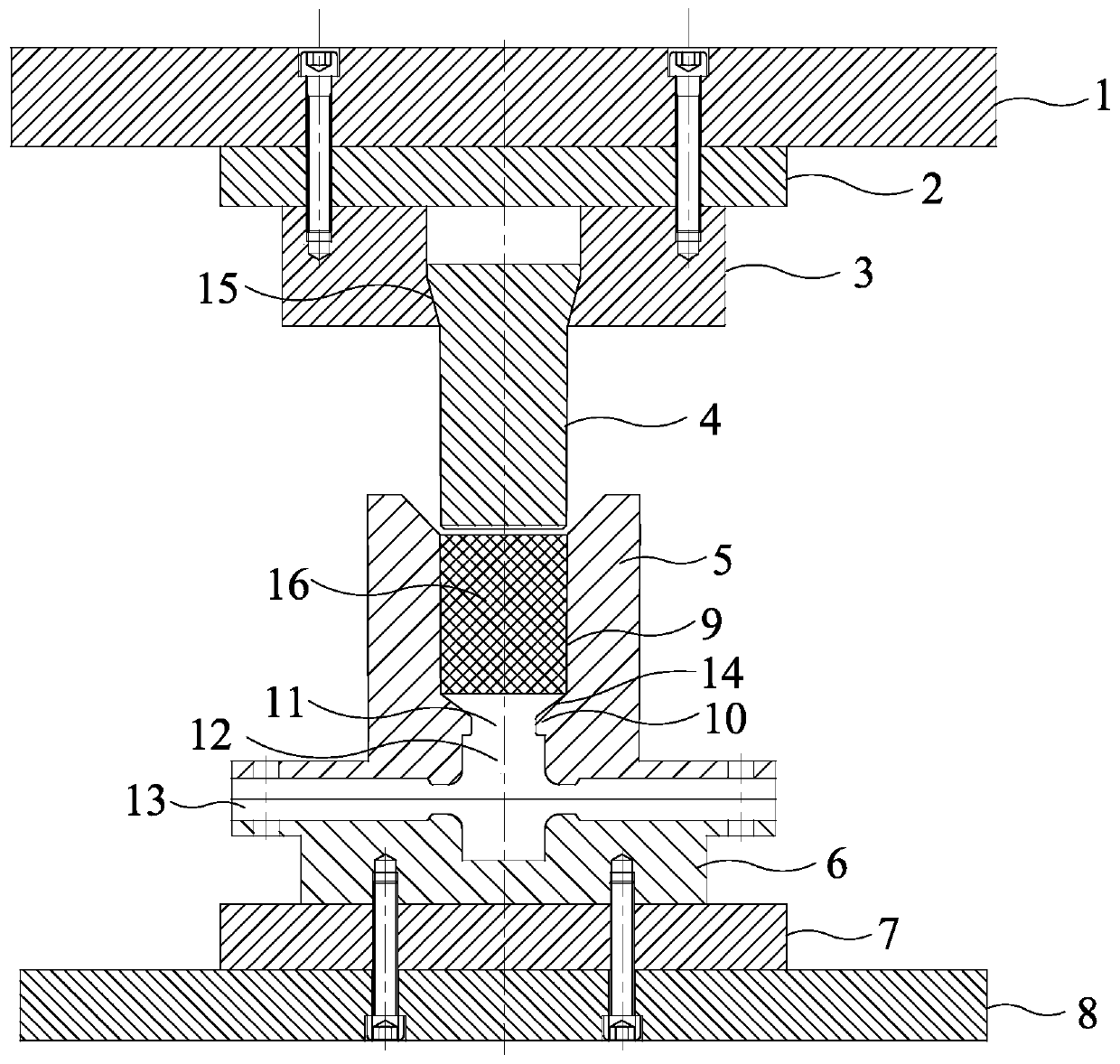

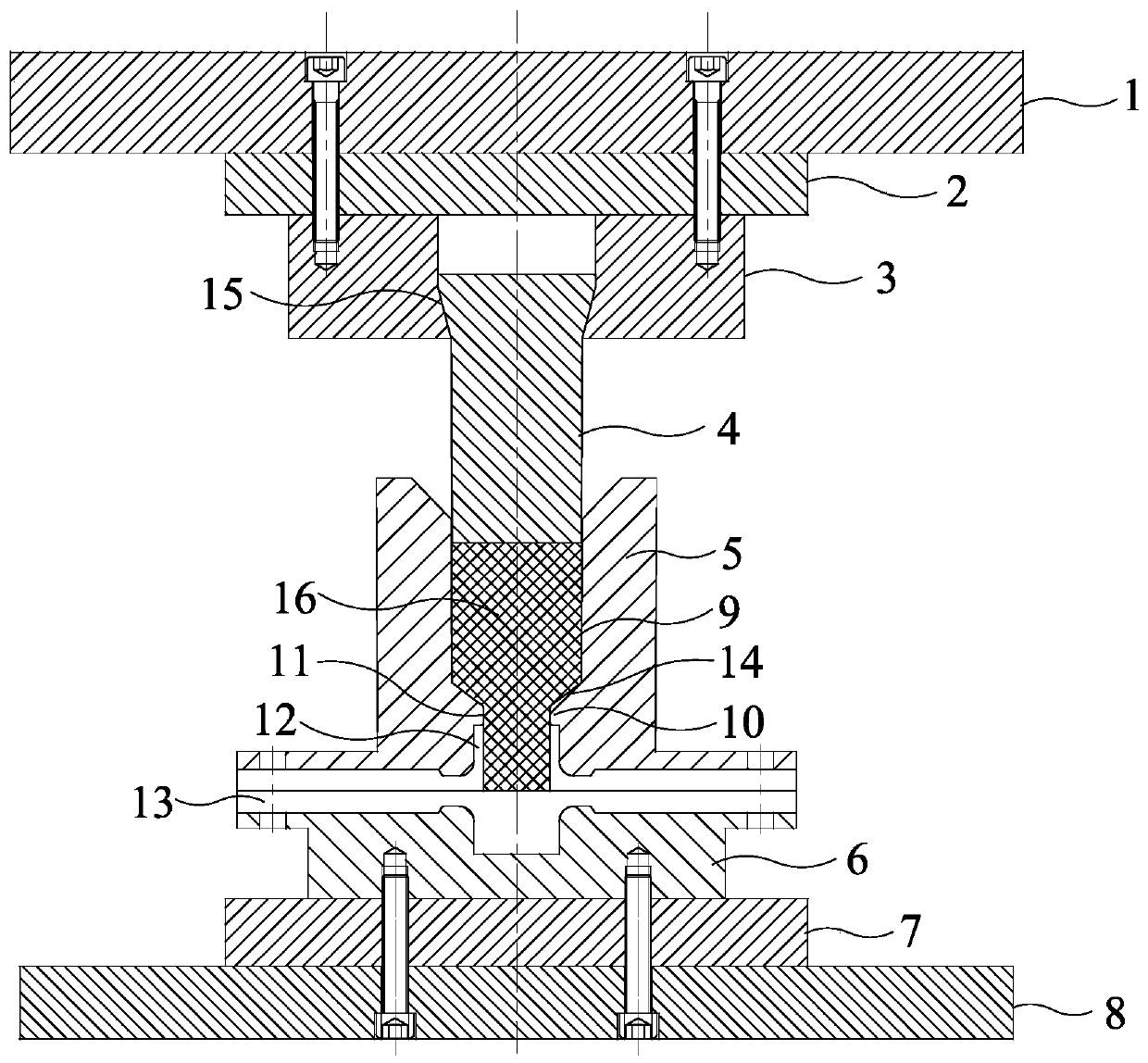

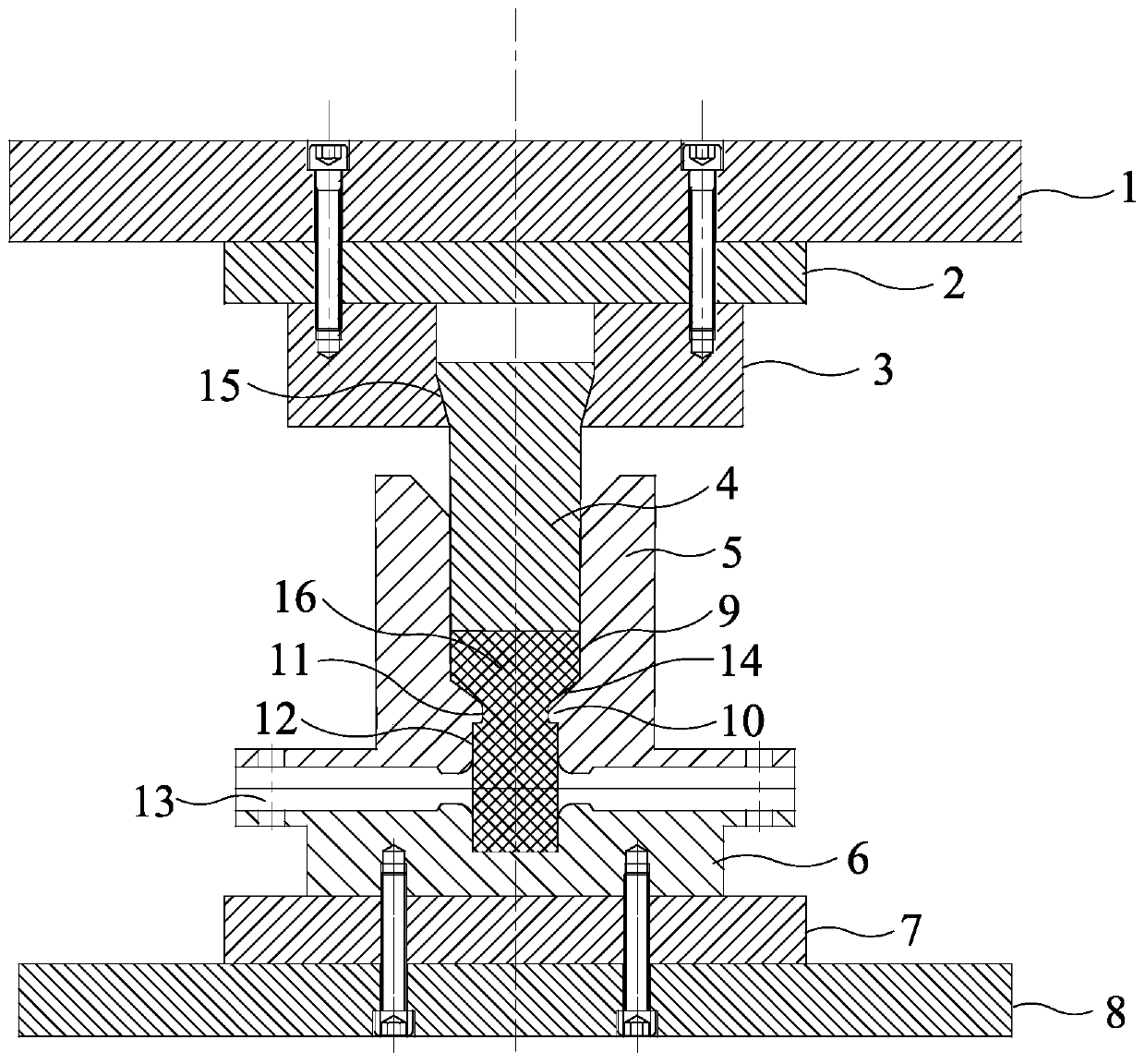

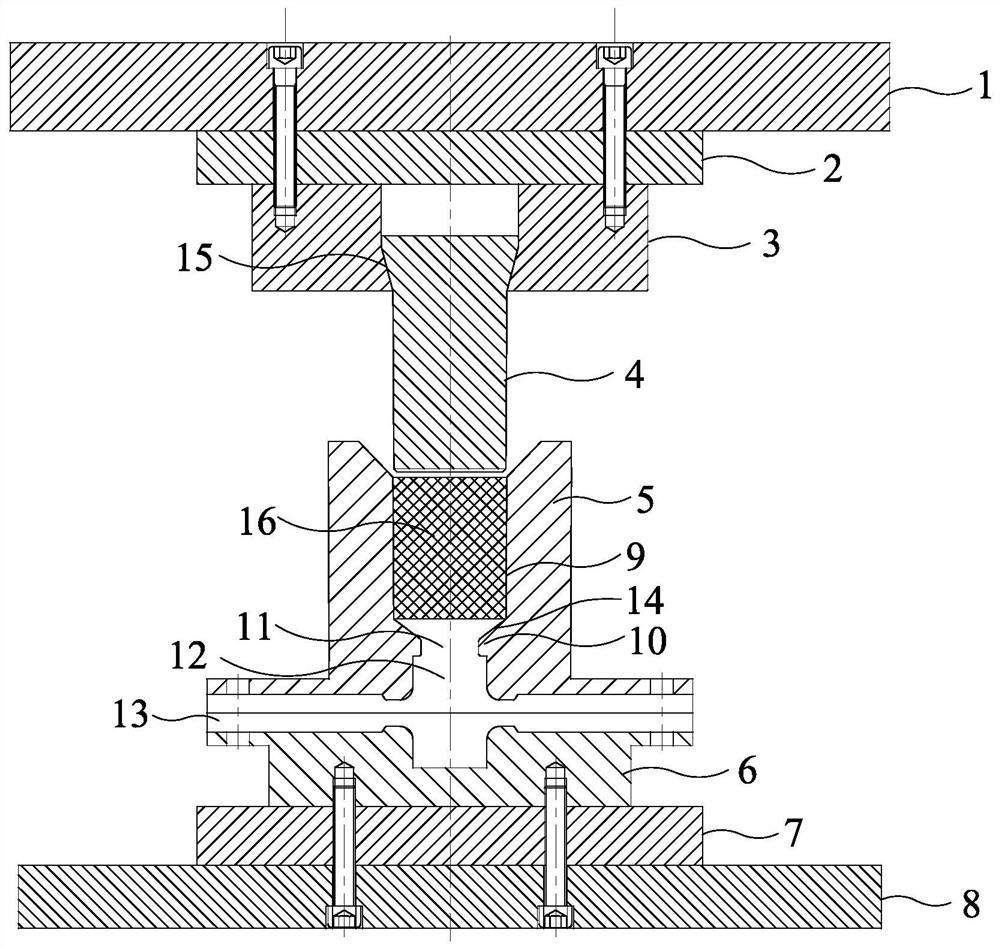

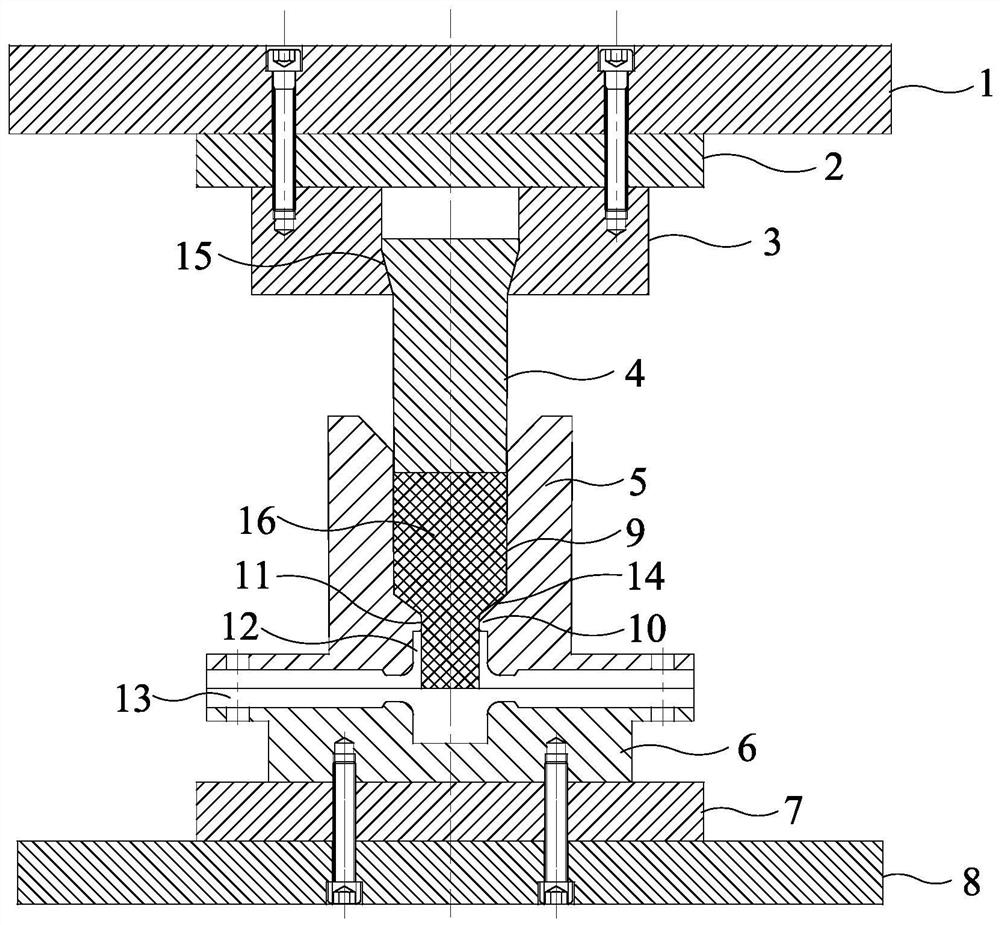

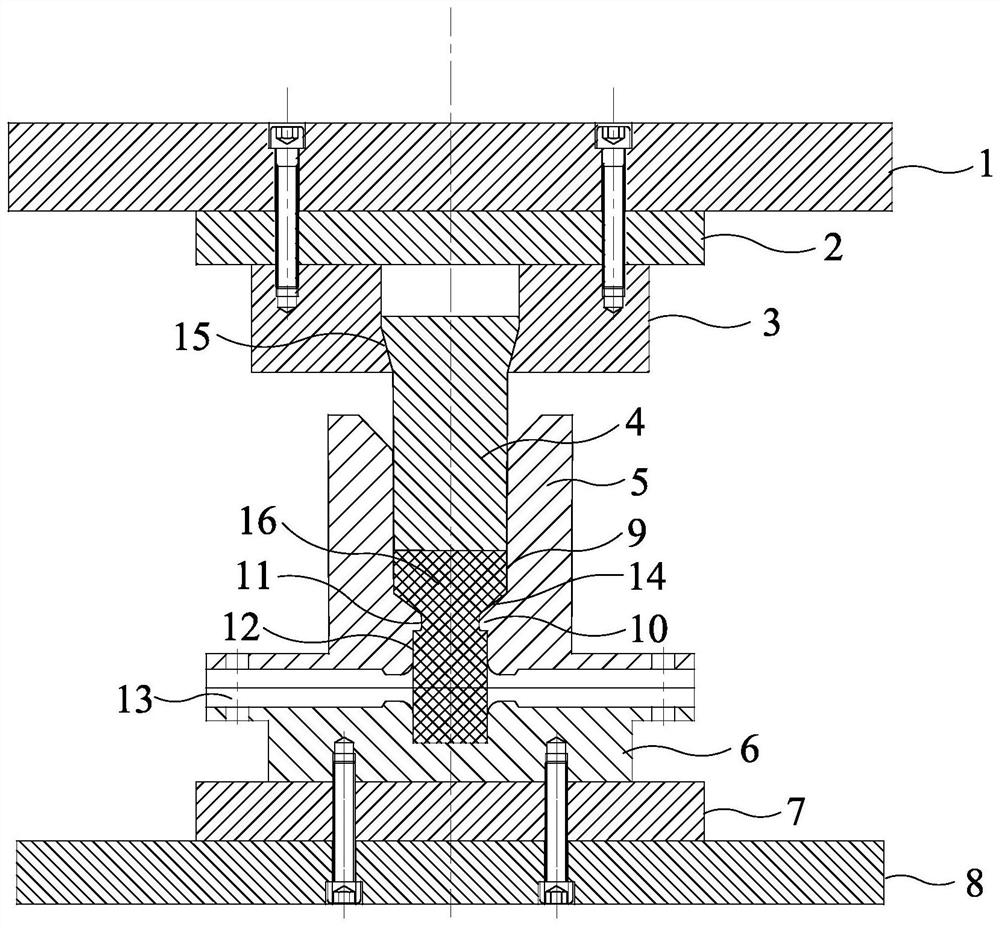

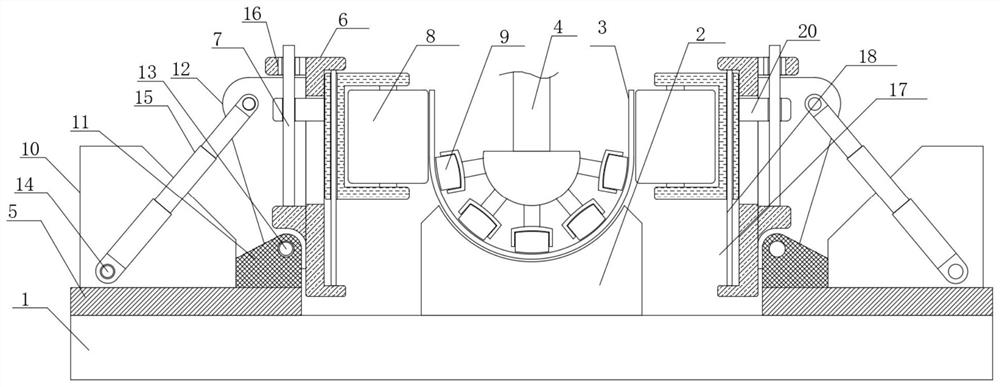

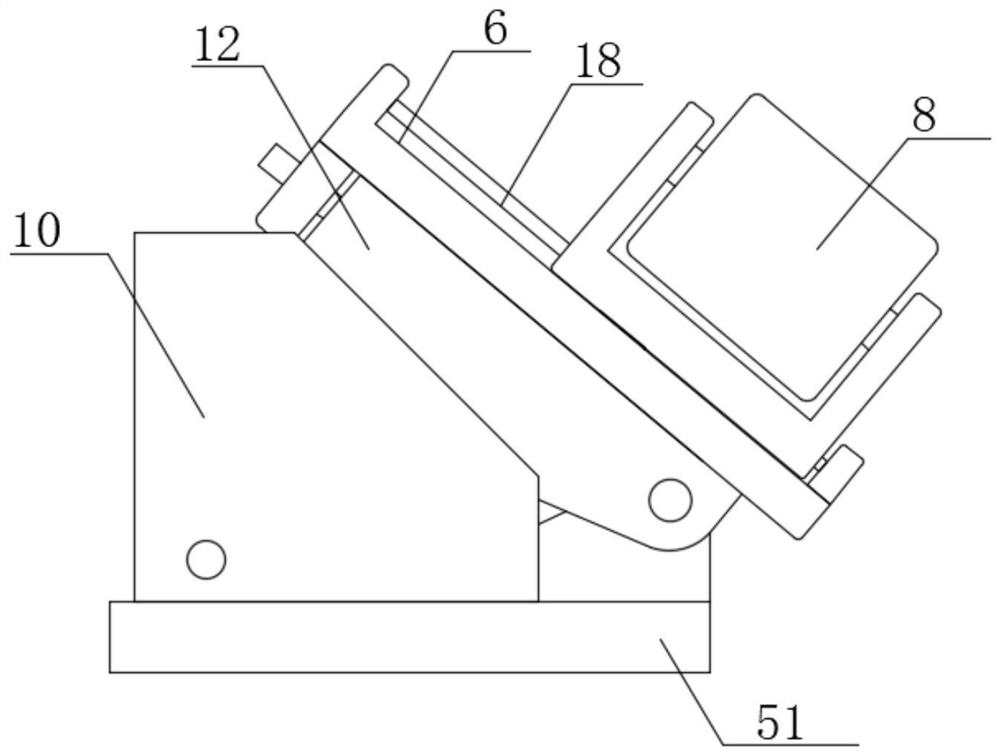

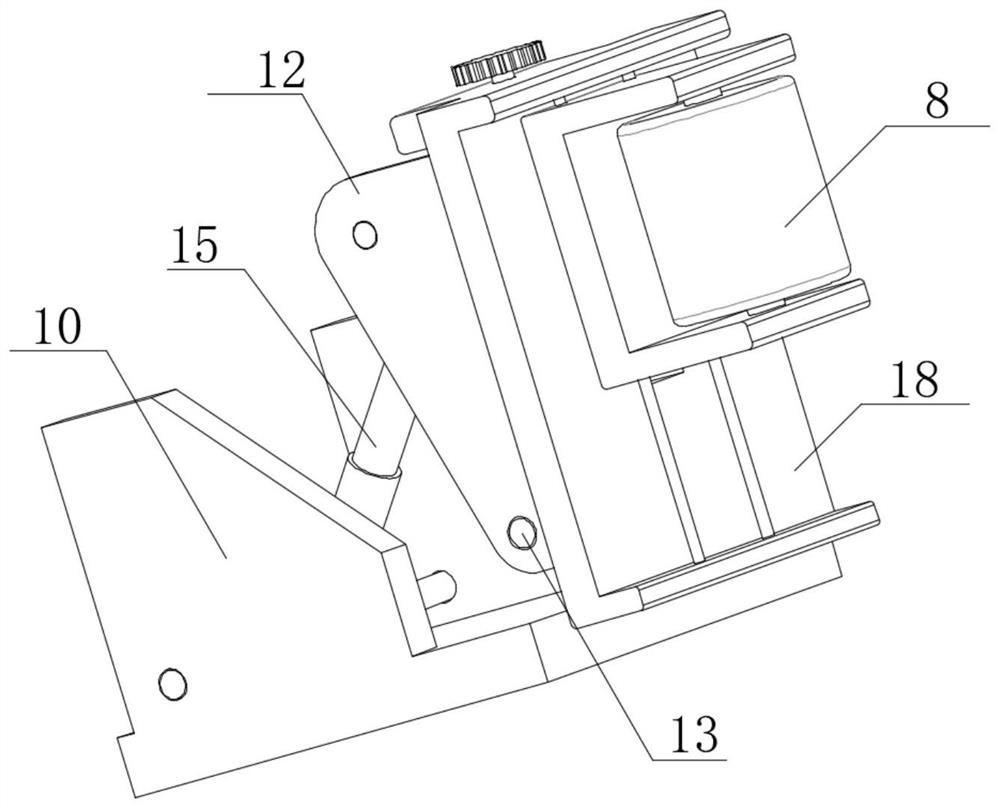

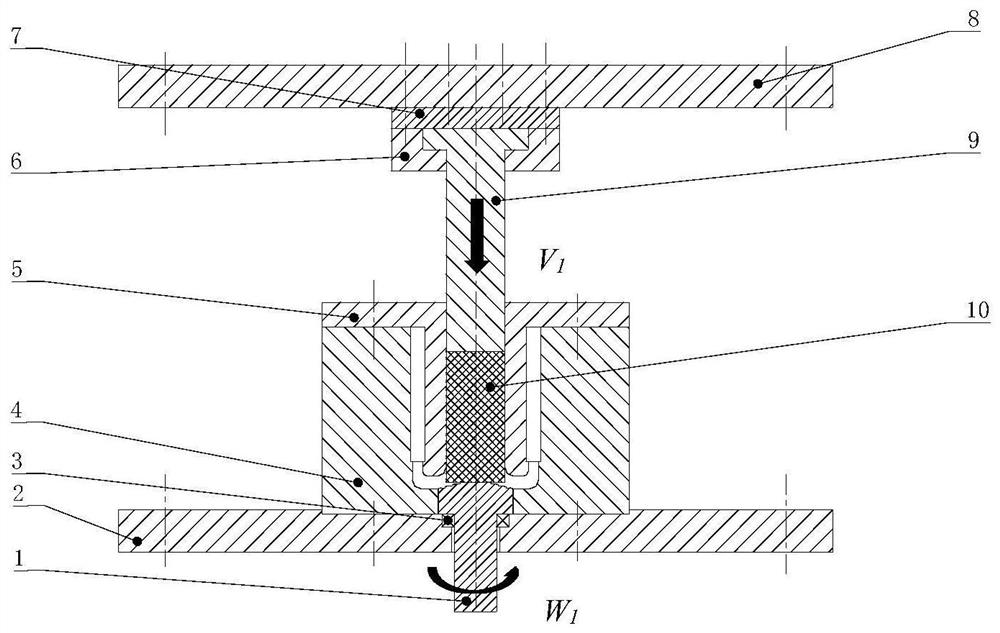

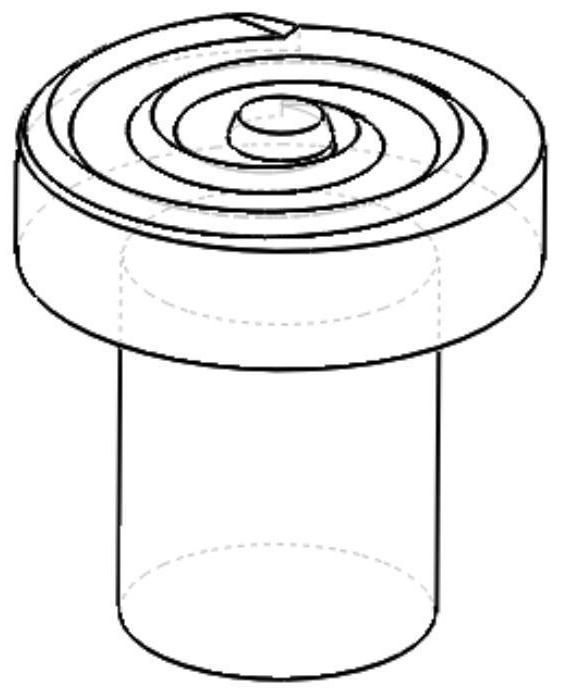

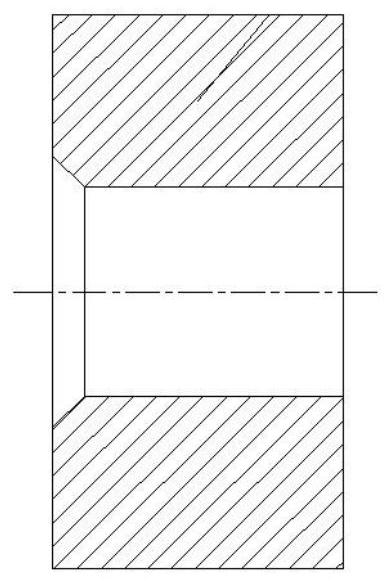

The invention provides a differential-speed extrusion forming method of a magnesium alloy high performance cup-shaped piece and relates to the technical field of metal and plastic machining and forming. A combined concave die is adopted and comprises a T-shaped upper concave die body and a U-shaped lower concave die body. The T-shaped upper concave die body is internally provided with a cylindrical cavity and installed on the U-shaped lower concave die body, and the section of a formed revolved cavity is shaped like a Chinese character 'shan'. Staggered 'ladder' type differential-speed extrusion steps are adopted for the bottom of the extrusion cavity shaped like the Chinese character 'shan'. Three stages of deformation are conducted, the first stage is the axial similar cylinder pier coarse deformation stage, the second stage is the radial extrusion large deformation stage, and the third stage is the corner extrusion and shearing deformation stage. The extrusion cavity shaped like the Chinese character 'shan' and the staggered 'ladder' type differential-speed extrusion steps at the cavity bottom are adopted for extruding the magnesium alloy high performance cup-shaped piece, the magnesium alloy material forming capacity is greatly improved, a high-density structure is obtained, great plastic deformation is obtained, the grain refining effect is remarkable, the effect of eliminating grain dual-mode distribution of the barrel wall of the cup-shaped piece is obvious, and the fabrication procedure of the high performance magnesium alloy cup-shaped piece is shortened.

Owner:ZHONGBEI UNIV

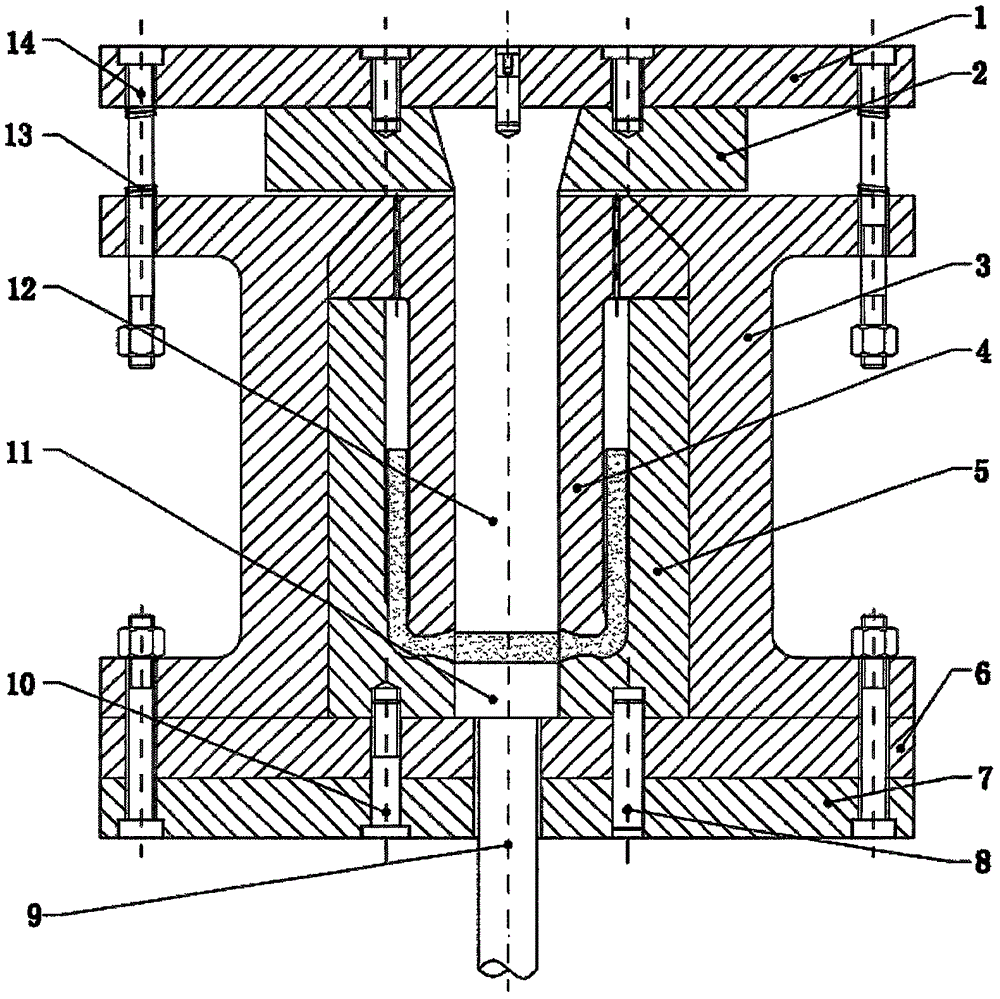

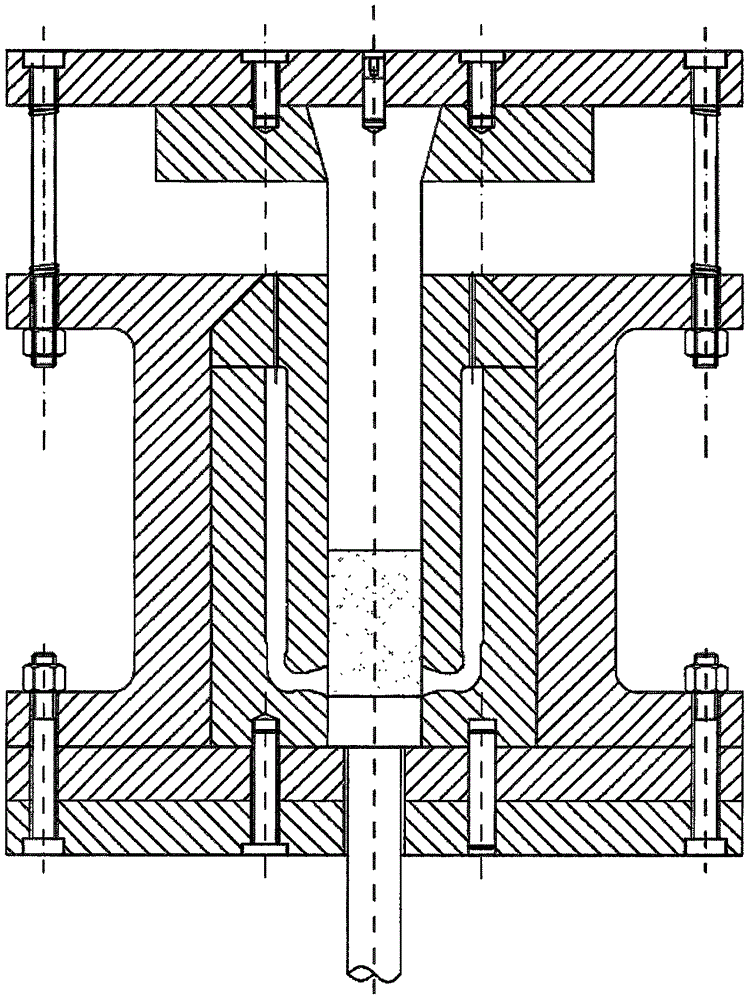

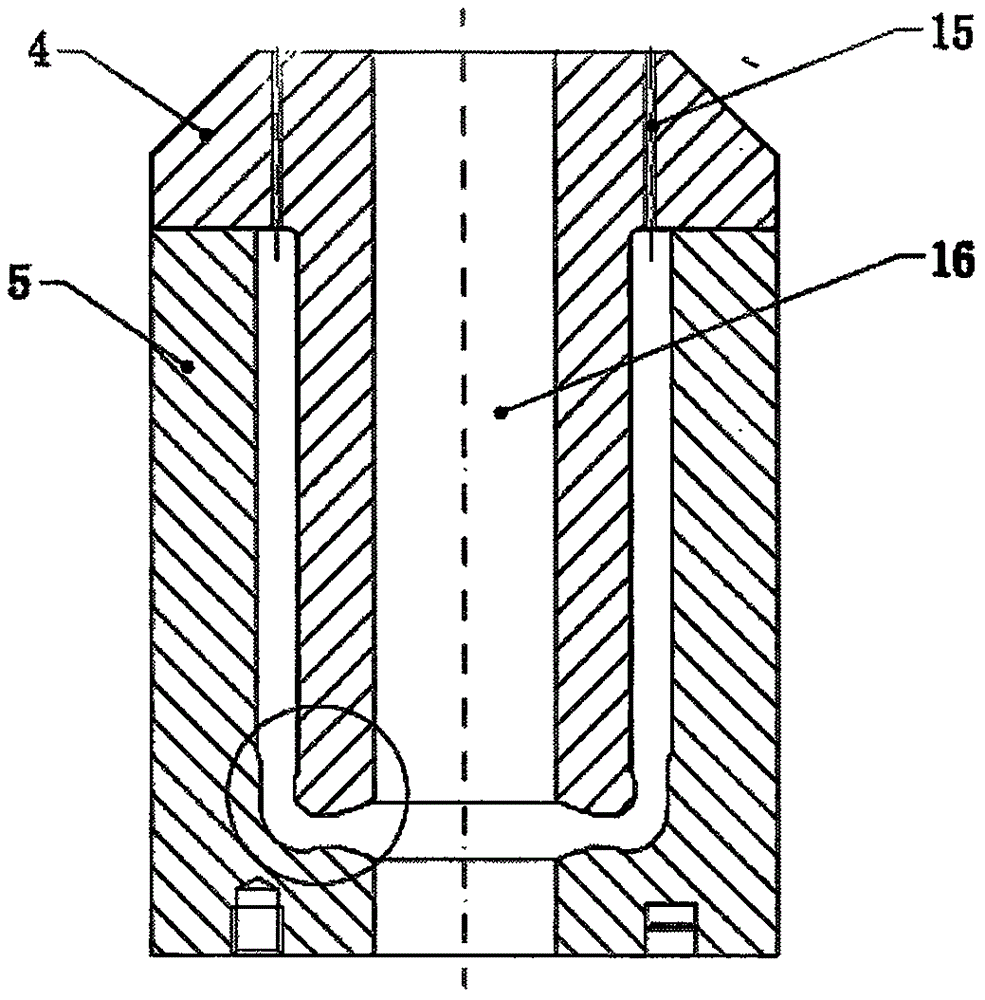

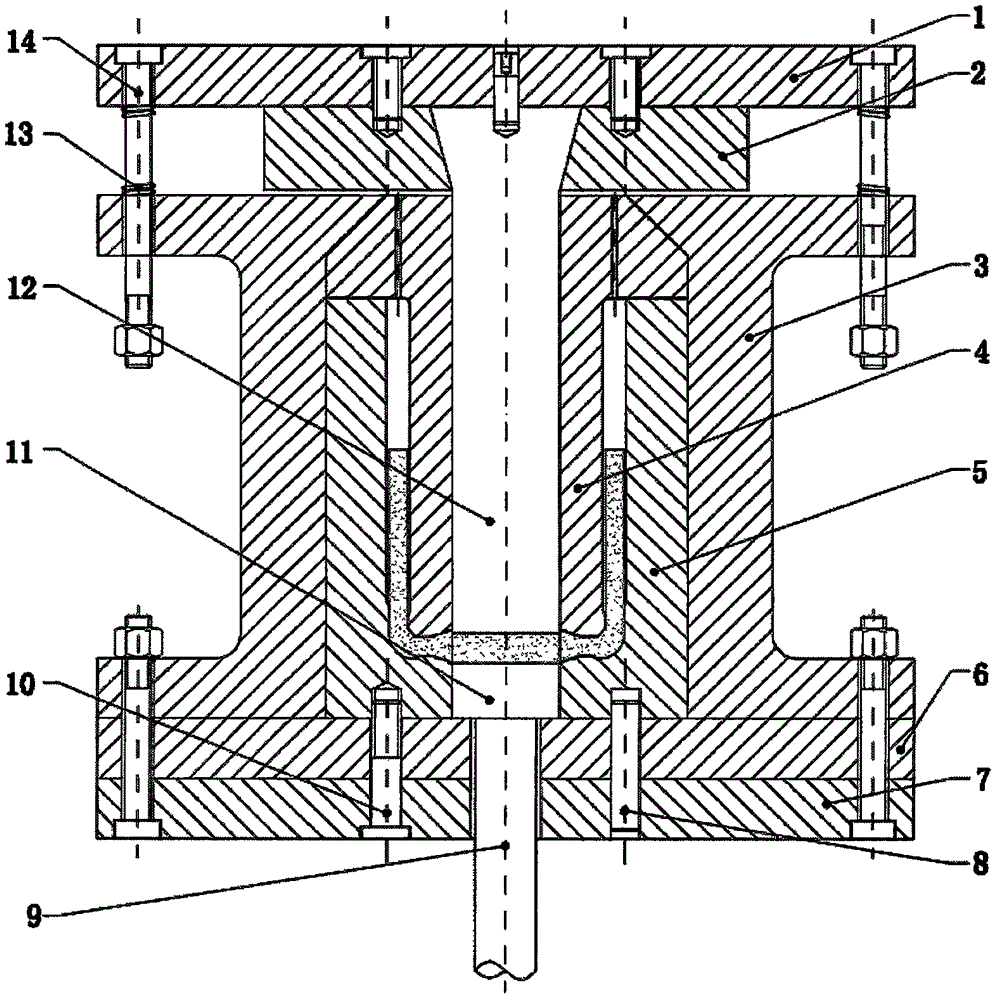

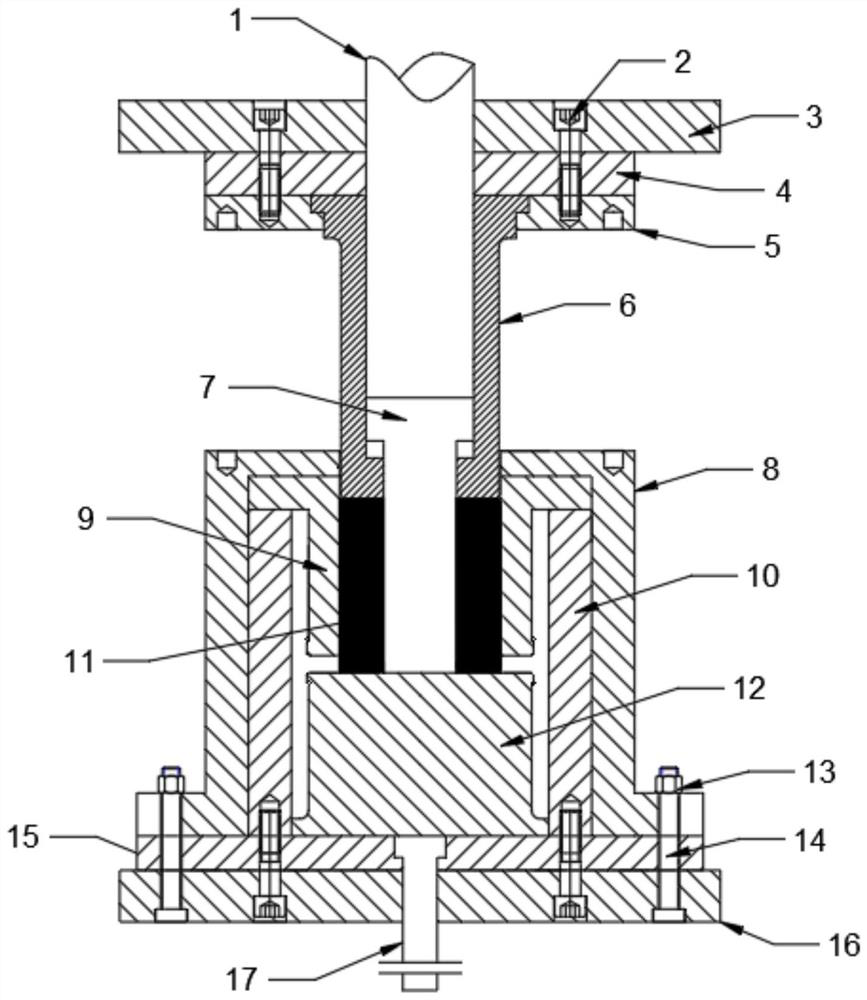

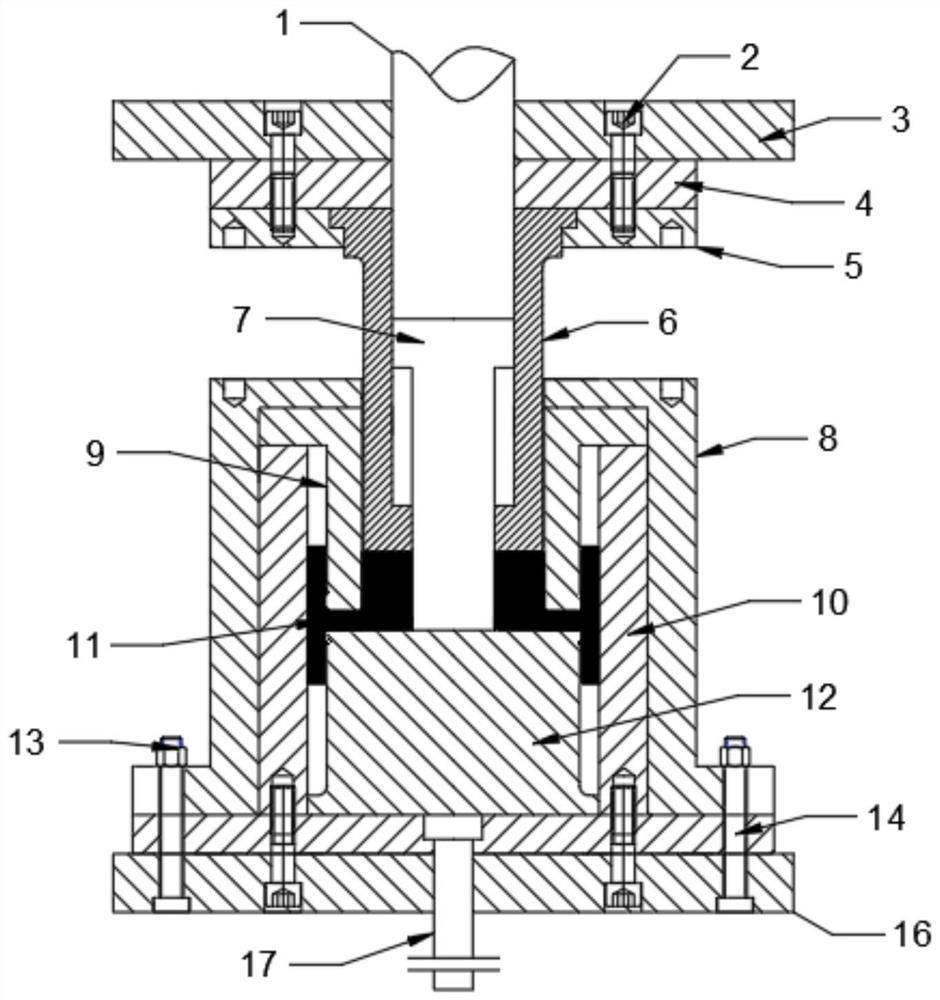

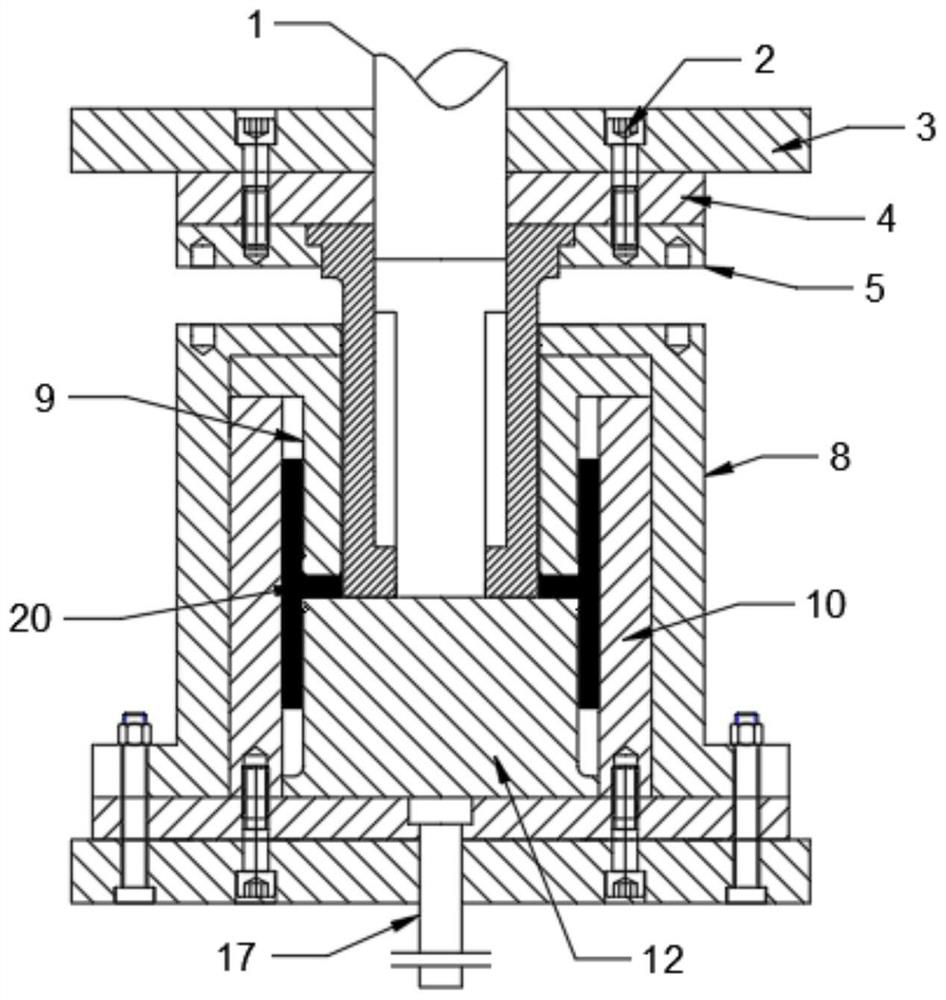

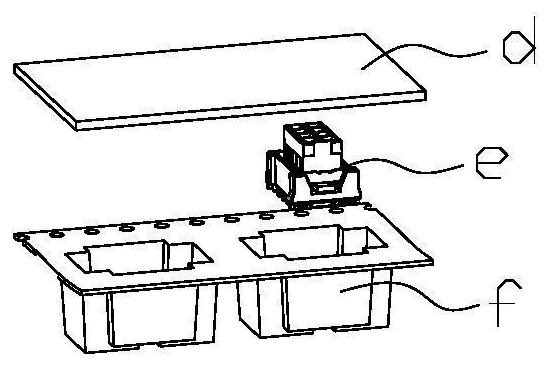

Differential extrusion forming die of high-performance magnesium alloy cup-shaped part

ActiveCN106825098AIncrease the number of deformationsIncrease the amount of plastic deformationExtrusion diesExtrusion mandrelsChinese charactersMachining process

The invention discloses a differential extrusion forming die of a high-performance magnesium alloy cup-shaped part and relates to the technical field of metal plastic machining processes and forming. A combined type female die comprising a T-shaped upper female die body and a U-shaped lower female die body is adopted. A cylindrical cavity is formed inside the T-shaped upper concave die body mounted on the U-shaped lower concave die body, and the cross section of a formed revolution body cavity is shaped like the Chinese character 'shan'. Staggered ladder type differential extrusion steps are arranged at the bottom of the extrusion cavity shaped like the Chinese character 'shan'. The magnesium alloy cup-shaped part is extruded through the extrusion cavity shaped like the Chinese character 'shan' and the staggered ladder type differential extrusion steps at the bottom of the cavity, so that the forming capacity of a magnesium alloy material is improved greatly, a high compact structure and large plastic deformation are obtained, the grain refining effect is significant, the effect of removing grain dual modality distribution of the cylinder wall of the cup-shaped part is obvious, and the manufacturing process of the high-performance magnesium alloy cup-shaped part is accelerated.

Owner:ZHONGBEI UNIV

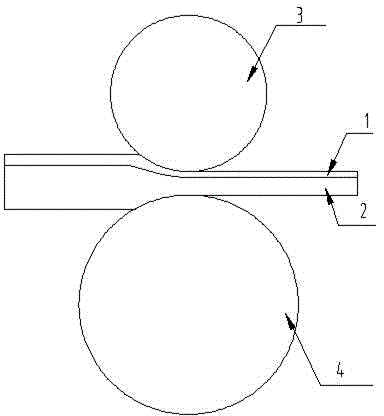

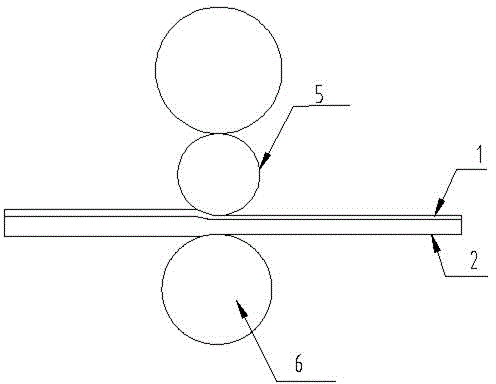

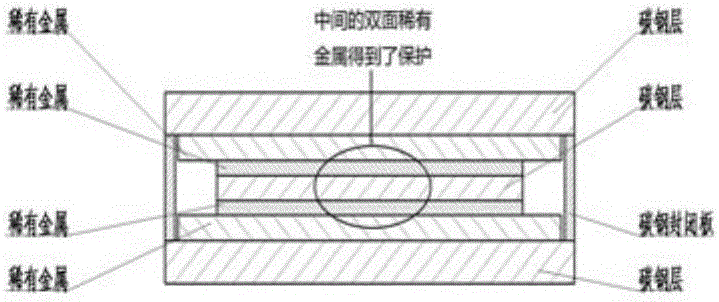

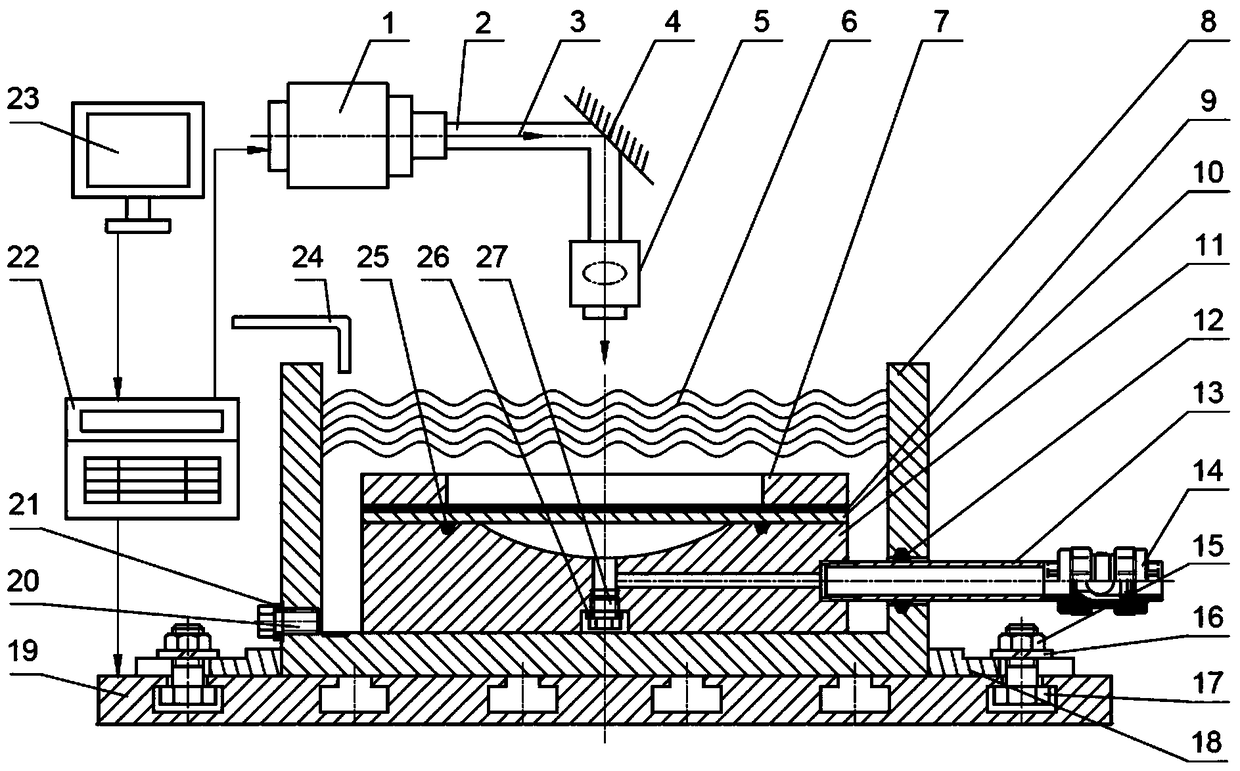

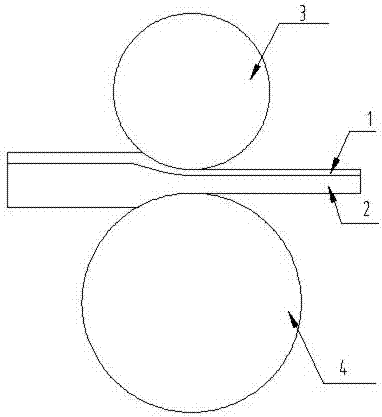

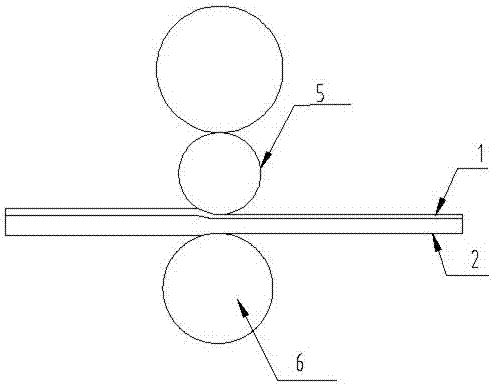

Method for rolling copper-aluminum double-layer composite plate

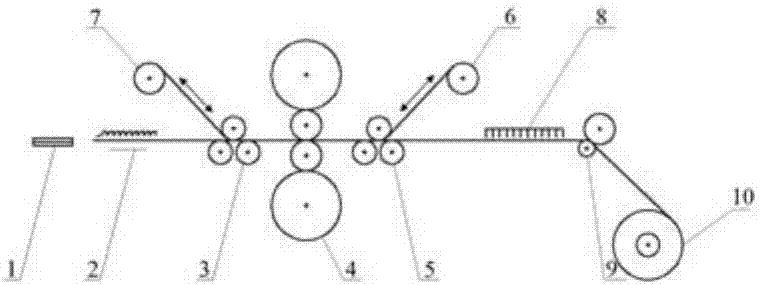

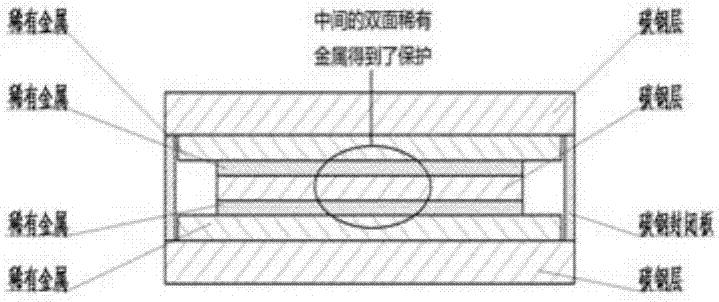

ActiveCN104959382AReduce residual stressIncrease the amount of plastic deformationAuxillary arrangementsMetal rolling arrangementsComposite plateCopper

The invention discloses a method for manufacturing a copper-aluminum double-layer medium-thick composite plate through a cold rolling manner. The method comprises following steps: 1) cleaning an aluminum plate and a copper plate in an immersion manner, removing oil of the plates, drying the plates, and cleaning the composite surfaces of the plates; 2) stacking and compressing the copper plate and the aluminum plate, and riveting the plates at a rolling bite end; 3) rolling the copper-aluminum composite plate blank through a two-roller roughing mill; 4) rolling the copper-aluminum composite plate through a three-roller intermediate mill; 5) rolling the copper-aluminum composite plate through a four-roller finishing mill; 6) rolling the copper-aluminum composite plate through a six-roller finishing mill to reach the required thickness; and 7) annealing the copper-aluminum composite plate. According to the invention, rolling is carried out through the rolling mills provided with working rolls having different roll diameters, so that the plastic deformation is increased, the composite ratio is improved, and a plate shape problem of the copper-aluminum double-layer medium-thick composite plate is solved as the working rolls are different in linear speed.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

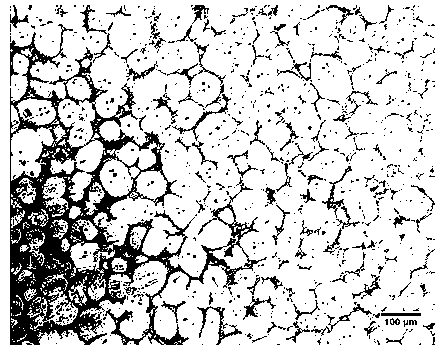

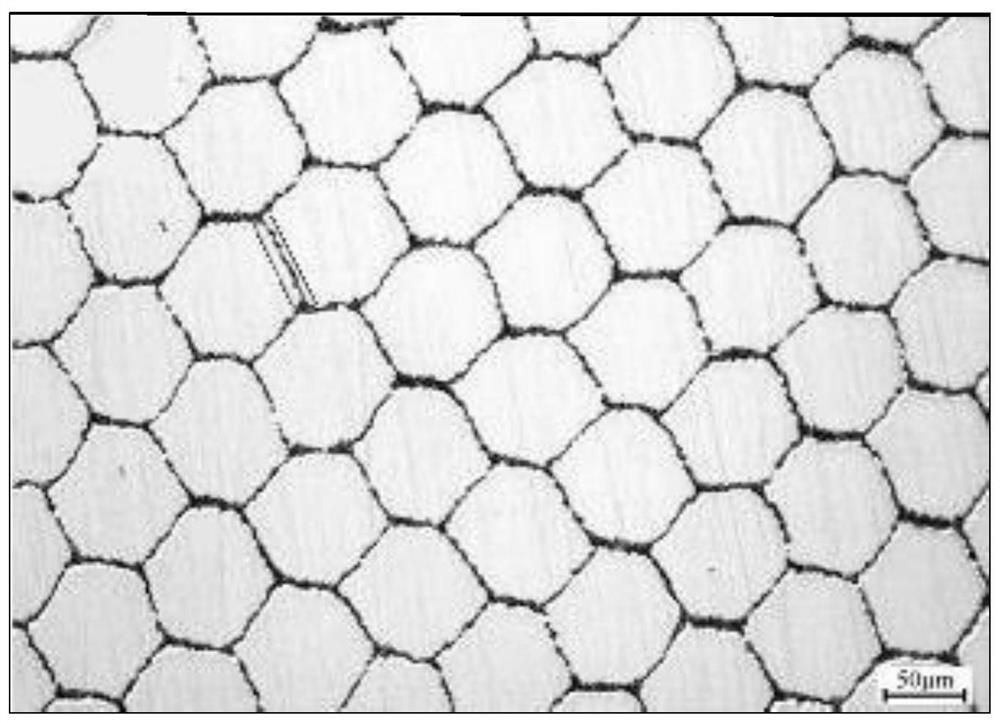

Method for preparing semisolid blank

The invention relates to a method for preparing a semisolid blank, utilizes an improved SIMA (strain induced melt activation) method to prepare the semisolid blank, and belongs to the technical field of metal semisolid blank. The method comprises the following steps of: firstly, measuring a liquid solid phase line point of the semisolid alloy to be prepared, then, heating an alloy blank so as to carry out asynchronization multitrack rolling or pillar squeezing transformation, finally, remelting, and carrying out heat preservation for a long time so as to obtain the required semisolid blank. The asynchronization rolling or pillar squeezing transformation is capable of generating large deformation amount, group bough crystal formed in the blank is destroyed, the asynchronization rolling is utilized to replace pre-deformation processes such as the existing upset, compression, equal diameter angle compression, and the semisolid blank is prepared and has the advantages of uniform formation, high nodularity, and accurate control solid phase rate.

Owner:KUNMING UNIV OF SCI & TECH

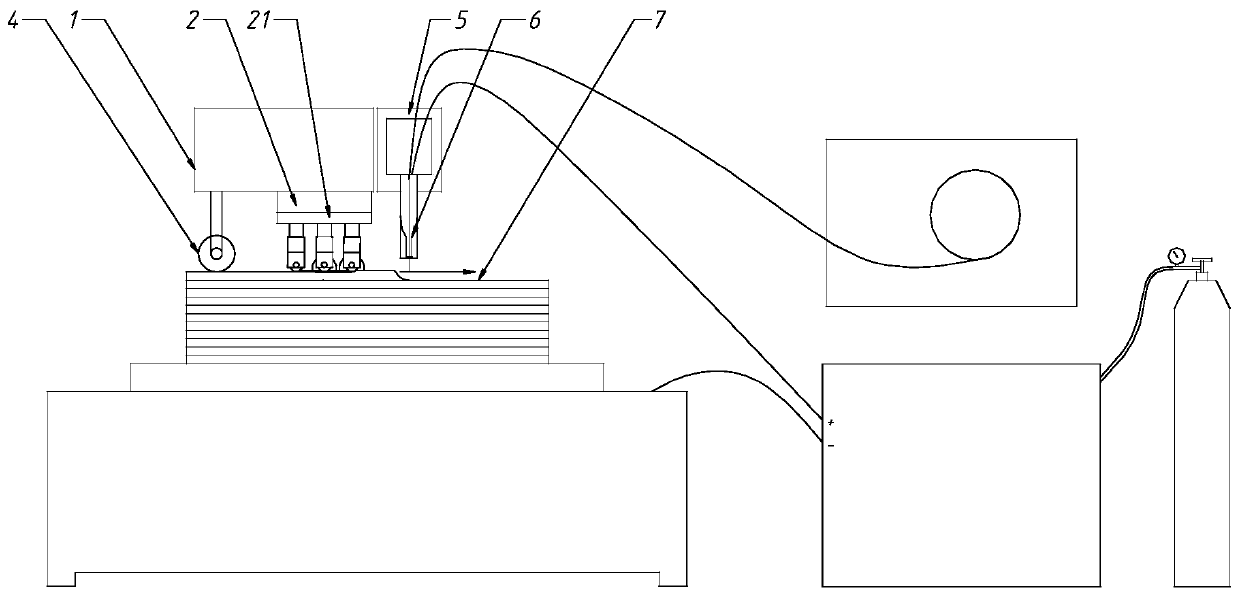

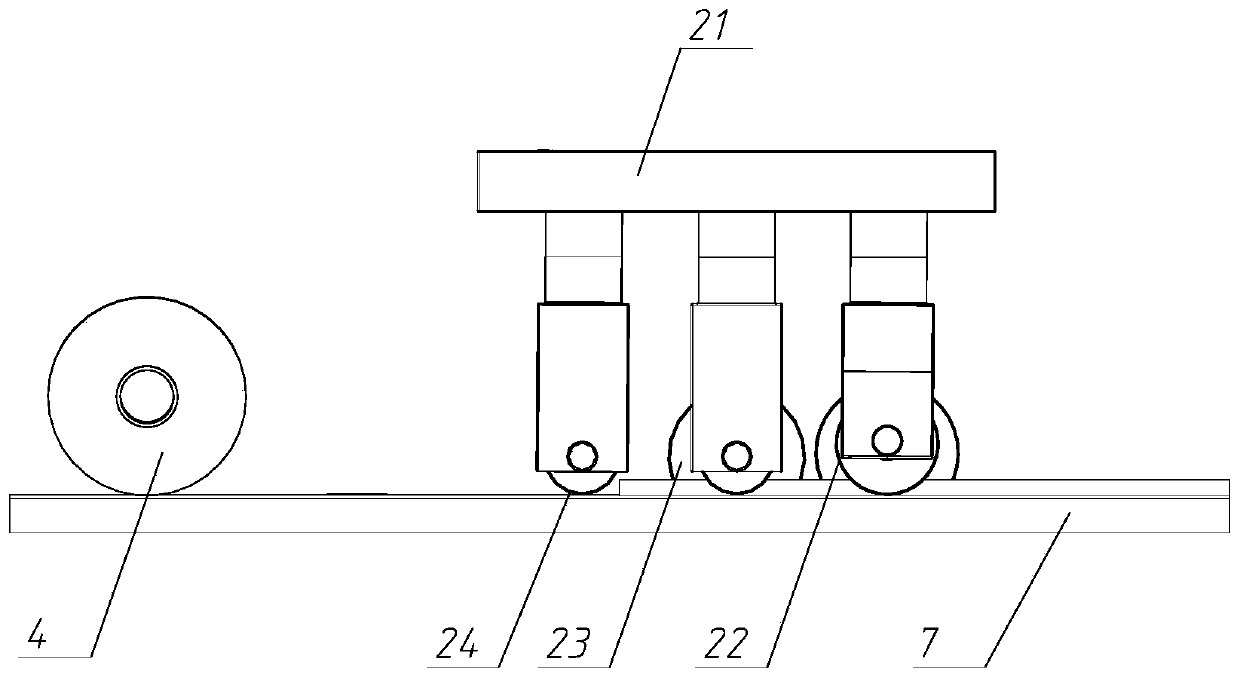

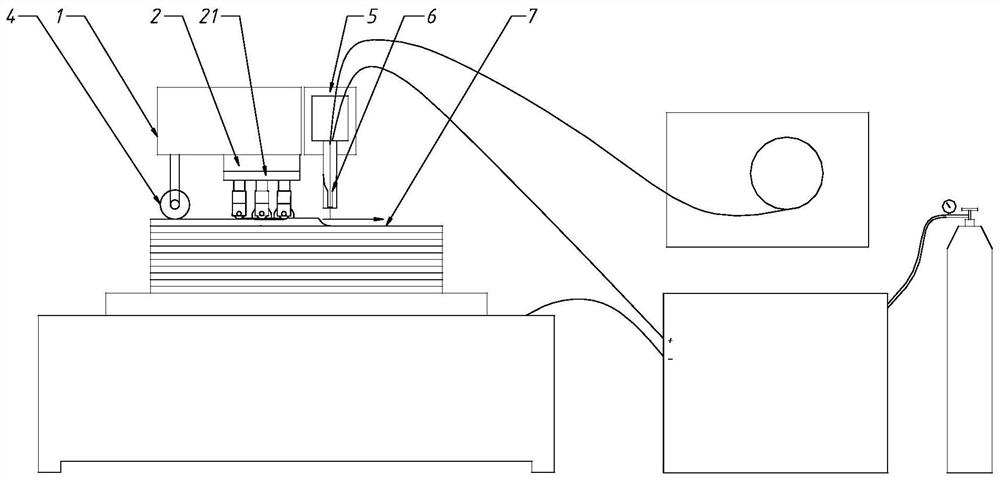

Arc wire feeding additive oblique roller combined wheel hot rolling manufacturing method and device

ActiveCN111215843ARapid coolingPreventing Dimensional Distortion ProblemsAdditive manufacturing apparatusOther manufacturing equipments/toolsEngineeringShearing deformation

The invention discloses an arc wire feeding additive oblique roller combined wheel hot rolling manufacturing method and device, and relates to the technical field of 3D printing. The wire feeding additive oblique roller combined wheel hot rolling manufacturing method and device are exquisite in structure, high in processing efficiency and good in processing effect, and can refine crystal grains ofan arc additive manufacturing formed part, improve compactness and reduce internal defects, thereby finally improving mechanical properties. The technical scheme of the invention is as follows: the manufacturing method comprises the following steps: (1) initialization; (2) arc wire feeding and material adding; (3) rolling; (3.1) strong shear deformation of an oblique roller; (3.2) primary flattening; (3.3) full flattening; (4) cooling; and (5) cutting of waste edges. The crystal grains of the arc wire feeding additive manufacturing formed part can be refined, the compactness is improved, internal defects are reduced, and the mechanical properties of the part are finally improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

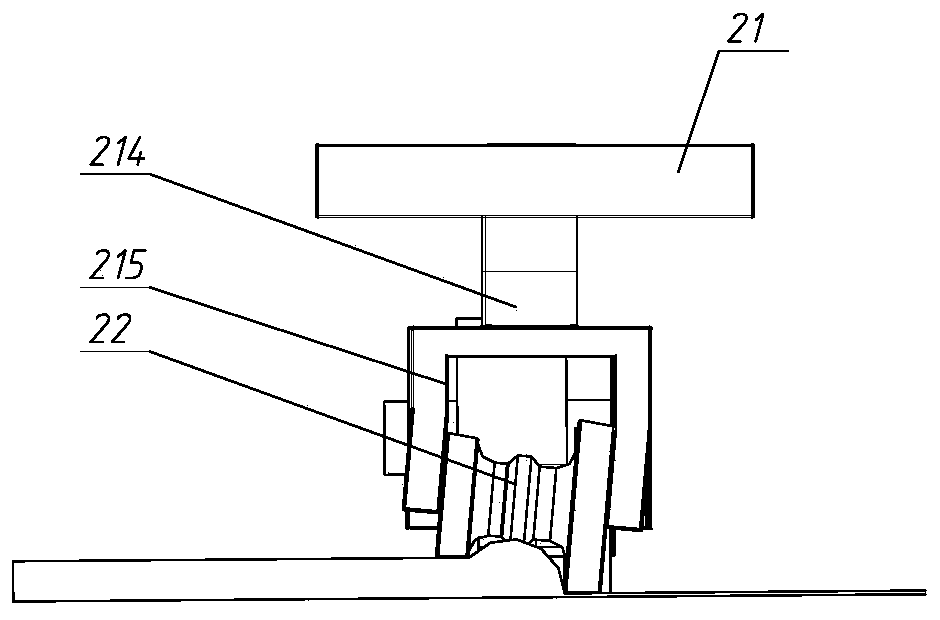

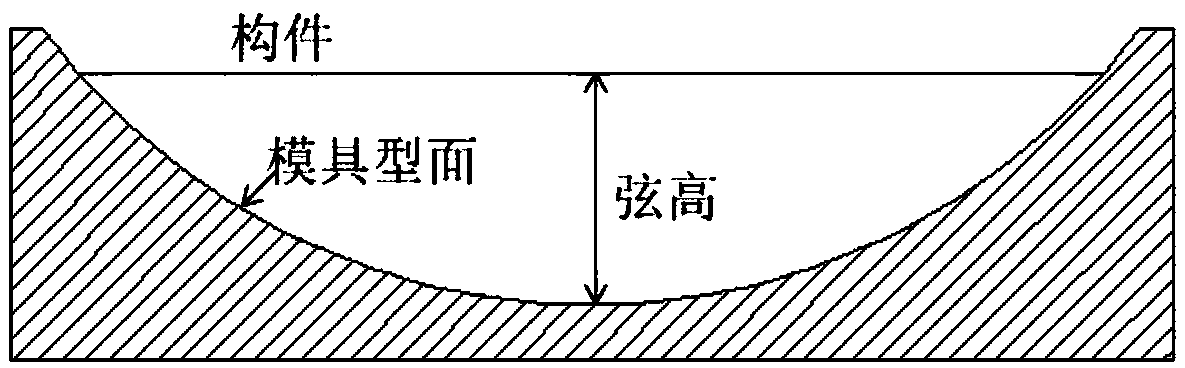

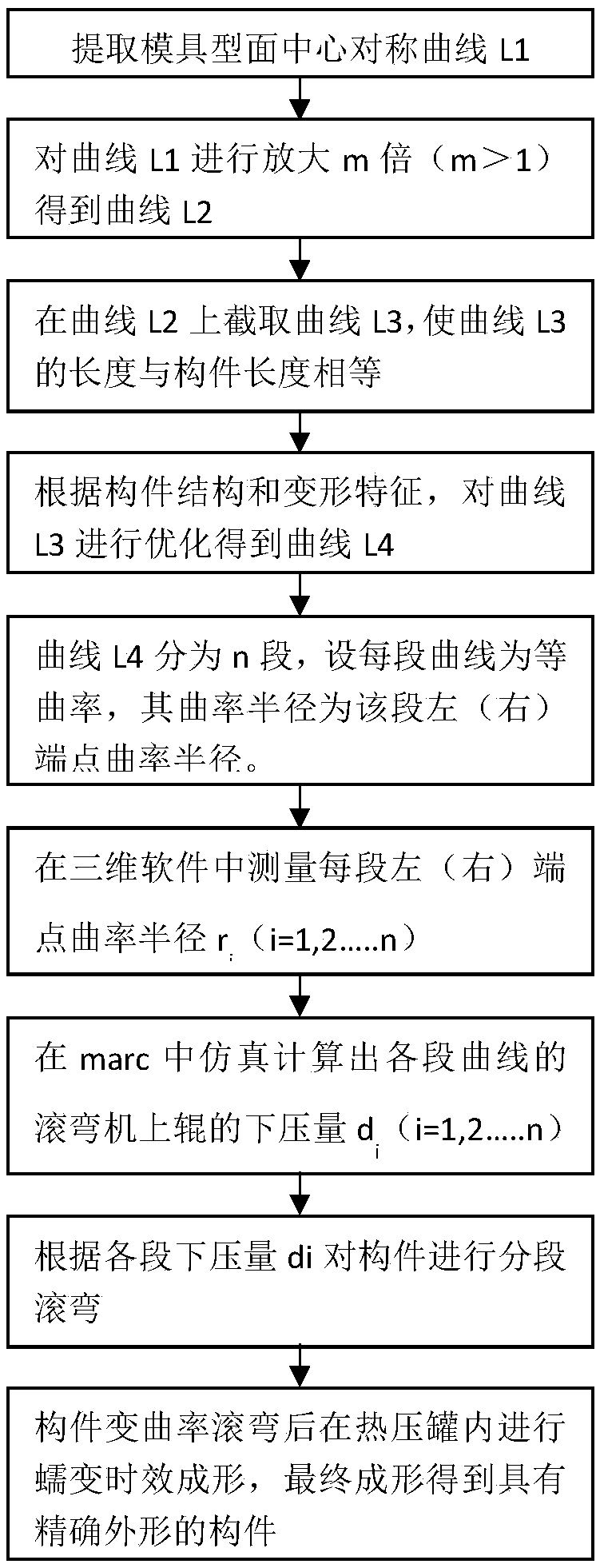

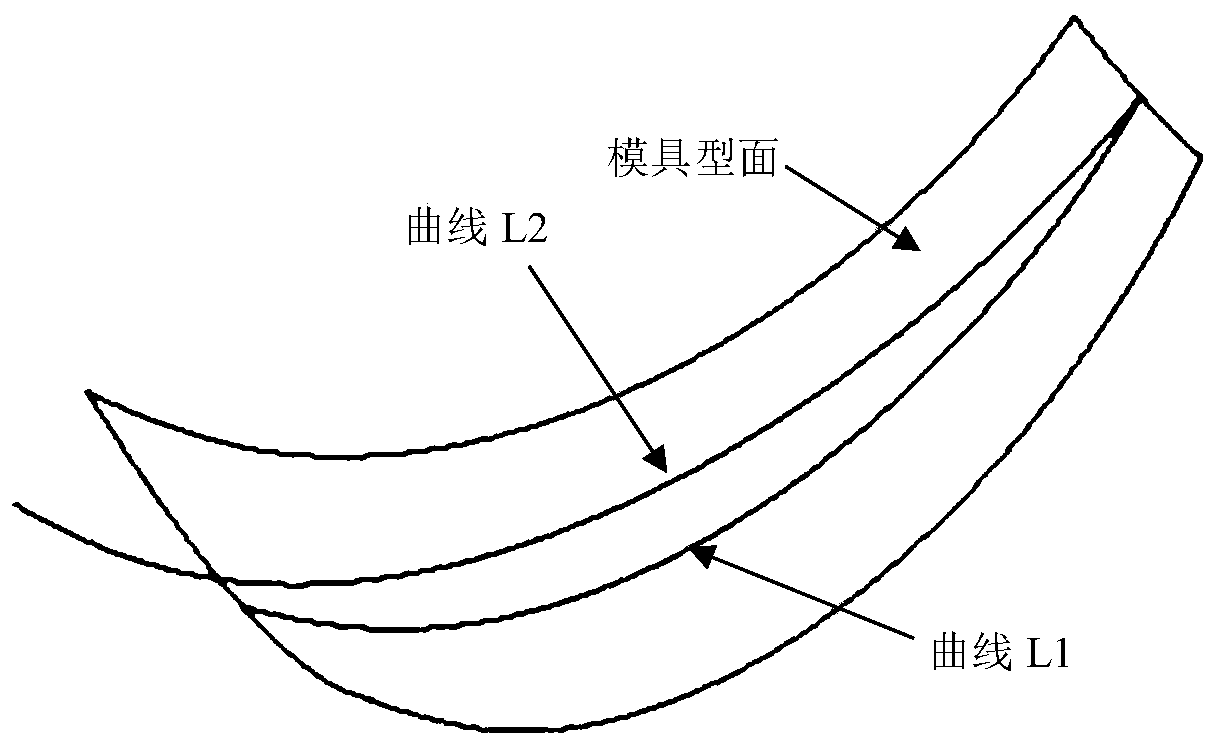

Large complex curvature component accurate forming method

ActiveCN109092944AHigh precisionIncrease the amount of plastic deformationManufacturing technologyMetal sheet

The invention belongs to the technical field of metal sheet manufacturing, and relates to a large complex curvature component accurate forming method. The large complex curvature component accurate forming method comprises the following steps of 1) performing roll bending treatment on the original plate of the large complex curvature component to be machined on the basis of the following variablecurvature of a mold profile; and 2) carrying out creep aging forming on the original plate after the original plate is subjected to the roll bending treatment so as to obtain the high-precision forming large complex curvature component. By virtue of the large complex curvature component accurate forming method, the creep aging forming operation is simple, and a phenomenon of breakage of a vacuum bag in the forming process can be avoided; and meanwhile, the potential safety hazard of hurting people caused by rebounding of the component can be eliminated.

Owner:CENT SOUTH UNIV

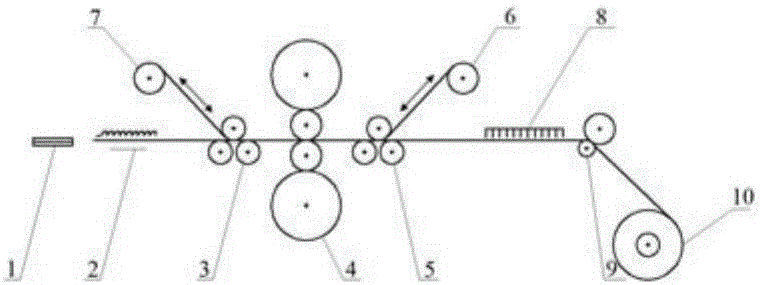

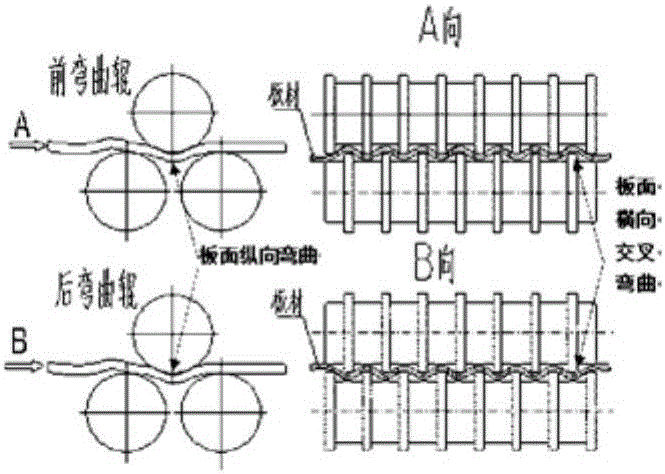

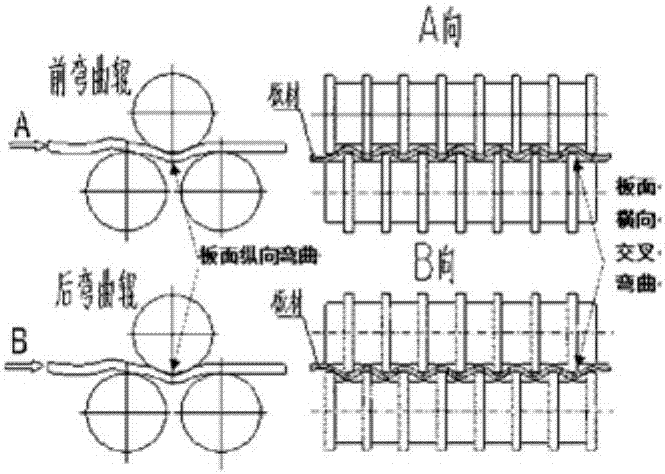

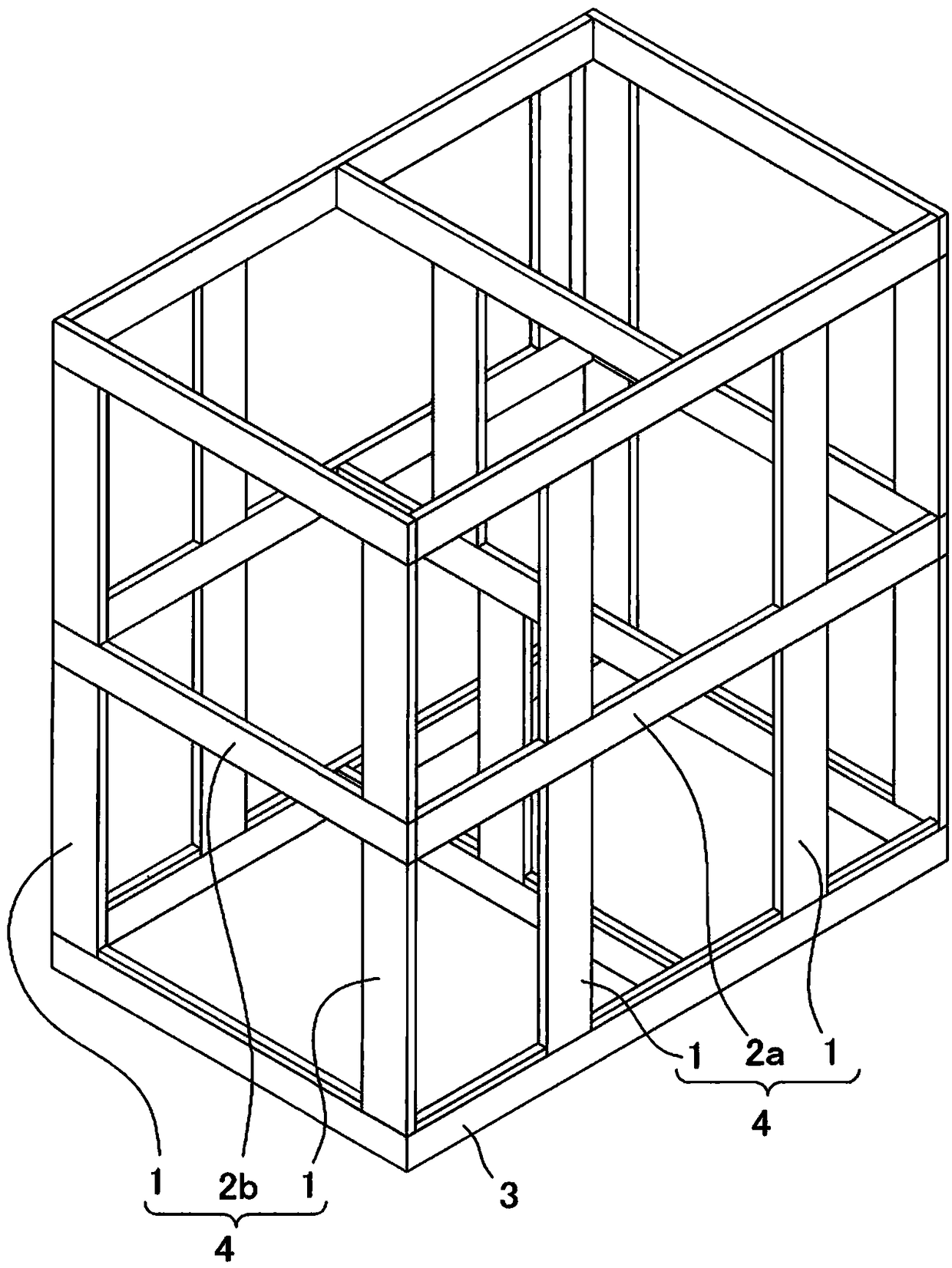

Multilayer metal coupling deformation rolling combined method and device

ActiveCN106001110AReduce the number of rolling millsLess investmentTemperature control deviceAuxillary arrangementsCombined methodHigh pressure water

The invention provides a multilayer metal coupling deformation rolling combined method and device. The device comprises a compound blank heating furnace, a high-pressure water descaling machine, a four-roller reversible rolling mill, a front reeling holding furnace, a rear reeling holding furnace, a front board criss cross bending deformation unit, a rear board criss cross bending deformation unit, a laminar cooling unit and a finished product reeling machine. According to the method, the reeling heating furnaces are equipped in front of and in rear of the single-frame four-roller reversible rolling mill, and the tension bending units are arranged between the front reeling furnace and the rear reeling furnace, the tension bending rollers are flower rollers of which the surfaces are of a convex and concave structure, three flower rollers form a reverse bending deformation unit, and a convex-concave structure of a front roller surface and a convex-concave structure of a rear roller surface are arranged in a staggered mode, so that a temperature controlling reeling coupling deformation rolling combined mechanism used for applying tension and achieving board criss cross bending deformation is formed, residual stress of a compound interface is remarkably reduced, and board shape quality is ensured; and meanwhile, the bonding strength and binding rate of the compound interfaces are greatly improved, the structure performance and comprehensive mechanical performance of composite boards are improved, and the production efficiency and yield are remarkably improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Large-deformation composite extrusion preparation method for magnesium alloy profile for vertical hydraulic machine

ActiveCN111438213AIncrease profitSpeed up the flowExtrusion diesLarge deformationUltimate tensile strength

The invention discloses a large-deformation composite extrusion preparation method for a magnesium alloy profile for a vertical hydraulic machine. The large-deformation composite extrusion preparationmethod comprises the steps that (1) blanking is conducted; (2) homogenization treatment is conducted; (3) a blank and a die are heated and subjected to heat preservation; (4) a lubricant is smeared,and the blank is placed into a forward extrusion cavity; (5) the blank is forwards extruded into a storage cavity through a calibrating straight; (6) the blank continuously bears pressure to flow tillmaking contact with the bottom of the storage cavity, the blank radially flows, the space in the storage cavity is gradually and fully filled with the blank, and in the process, the blank is subjected to upsetting deformation; (7) under the downward pressing effect of the male die, blank metal starts to flow towards a radial cavity extrusion opening communicating with the two sides of the storagecavity to be subjected to lateral extrusion deformation, and when the stroke of the male die is completed, the lateral extrusion process is also completed; and (8) die release is conducted. Accordingto the large-deformation composite extrusion preparation method, one-time forming of large plastic deformation of forward extrusion, upsetting and lateral extrusion is achieved, thus the strain amount is increased, the stress strain state is enriched, the structure is improved, the structure strength is weakened, production processes are effectively reduced, and the large-deformation composite extrusion preparation method adapts to market economic prospects in China.

Owner:ZHONGBEI UNIV

Photosensitive resin composition for photosensitive clearance material

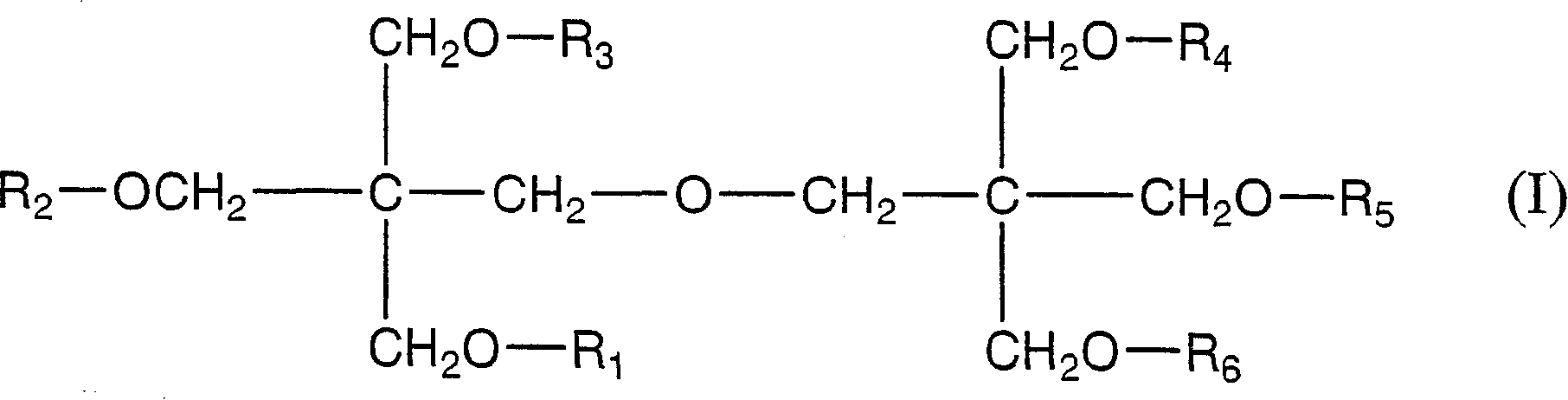

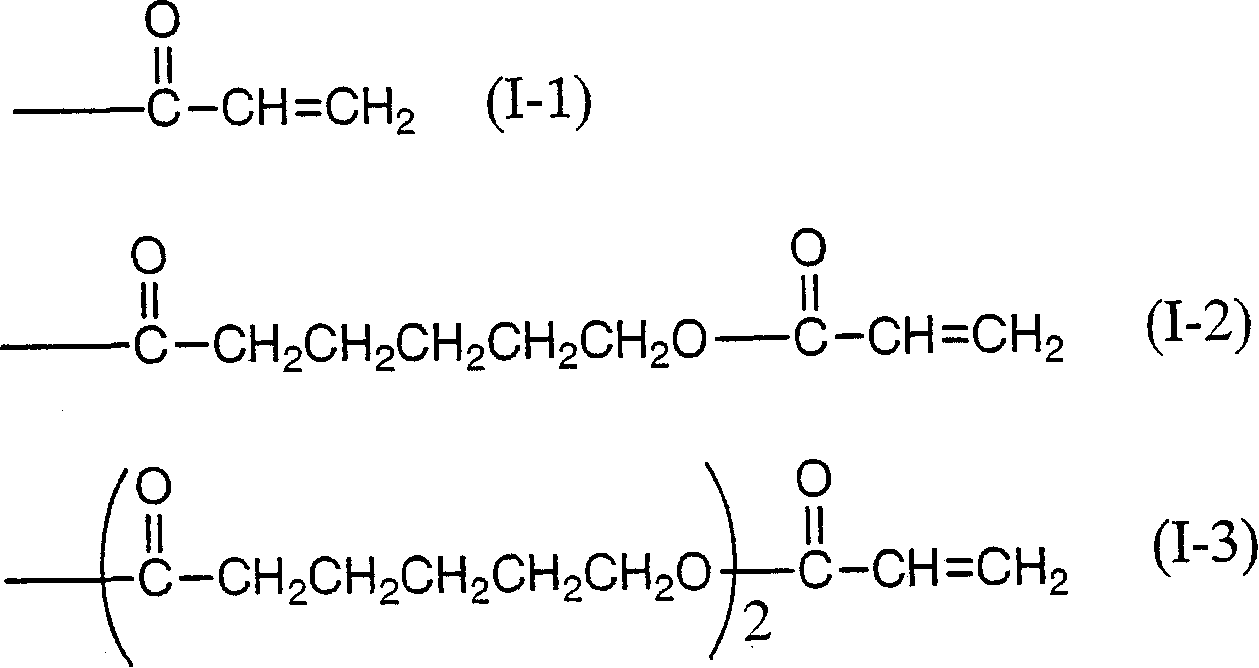

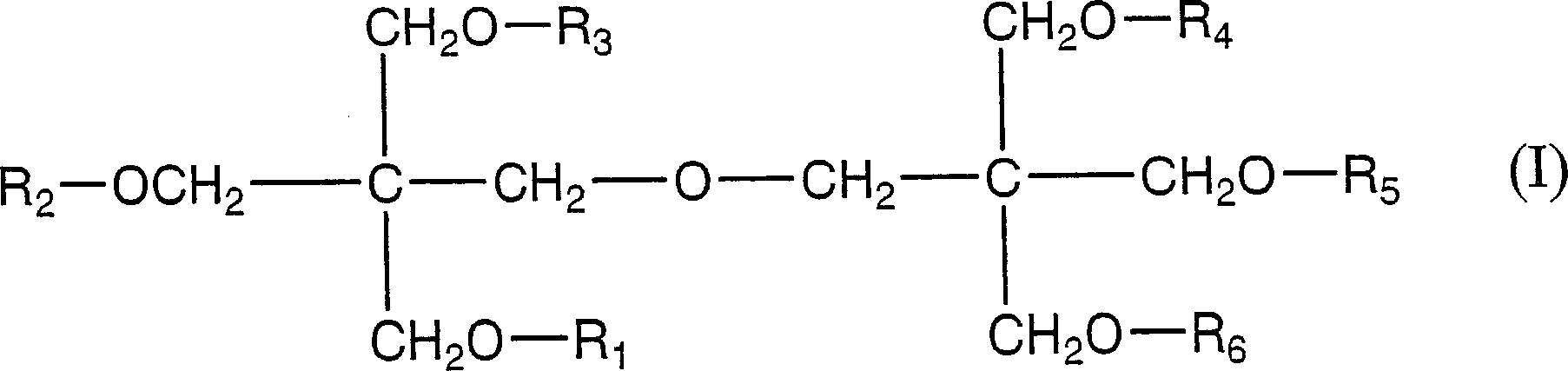

ActiveCN1904732AIncrease the amount of plastic deformationPhotosensitive materials for photomechanical apparatusNon-linear opticsSolventPolymerization

A photosensitive resin composition for photosensitive clearance material comprises a resin binder (A), a photo-polymerization compound (B), a photo-polymerization initiator (C) and a solvent (D), the photo-polymerization compound (B) contains a compound of the formula (I) with a content of 5-60 w% in a total amount of resin binder, photo-polymerization compound (B) and photo-polymerization initiator (C). In formula (I), R1-R6 are separately represent H or any group of formula (I-1) to (I-3), at least four groups of R1-R6 are selected from the groups of (I-1) to (I-3) and at least one group of R1-R6 is selected from the groups of (I-2) to (I-3).

Owner:SUMITOMO CHEM CO LTD

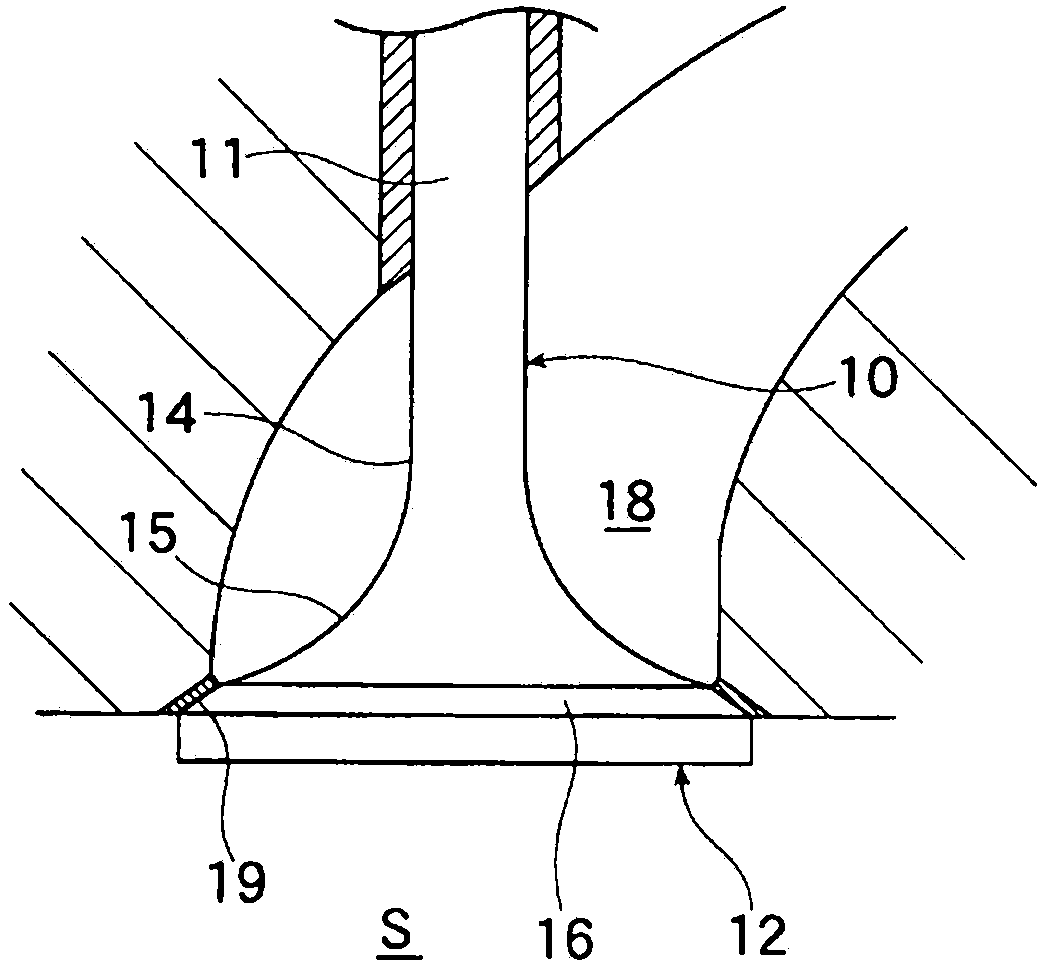

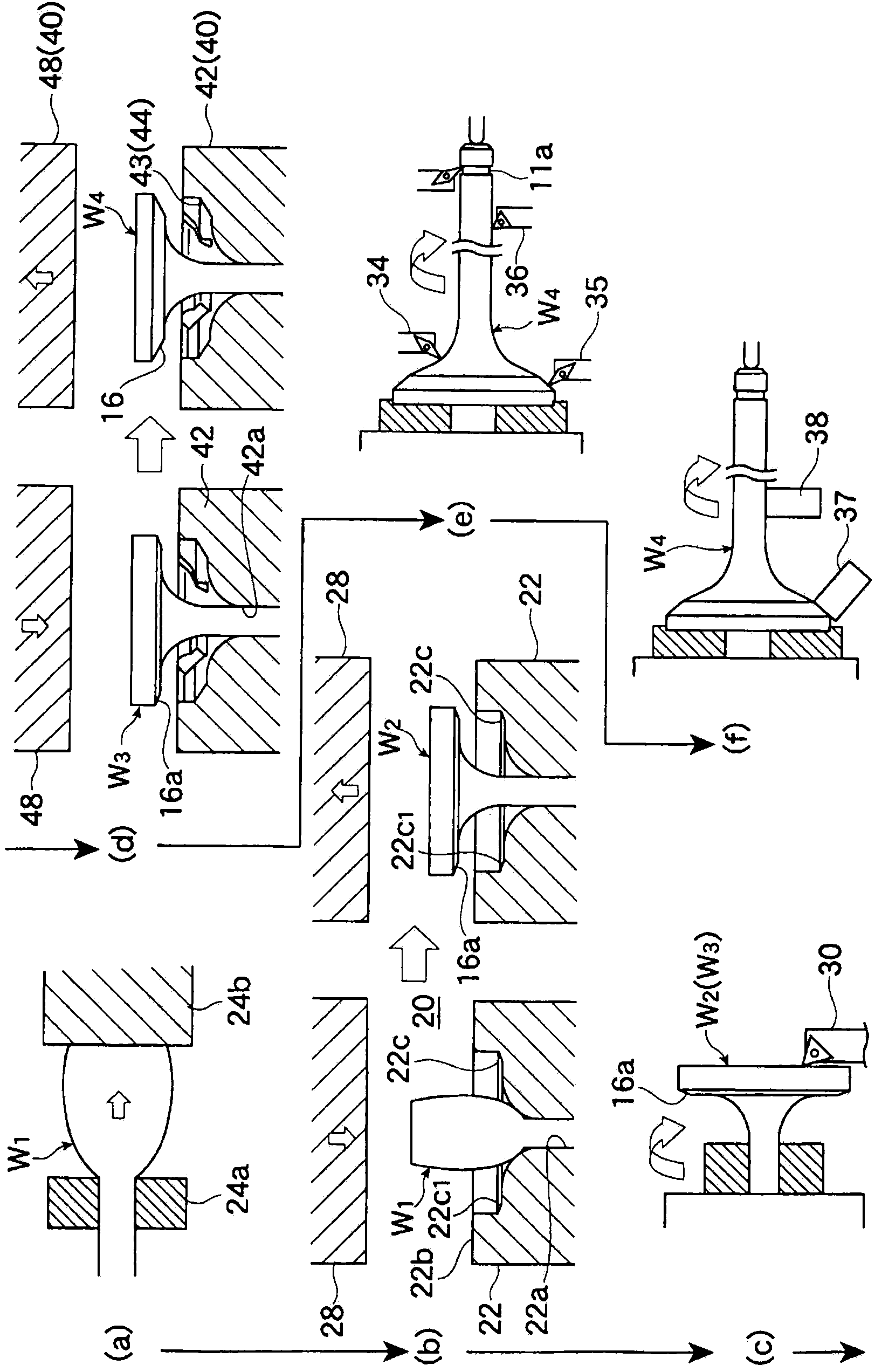

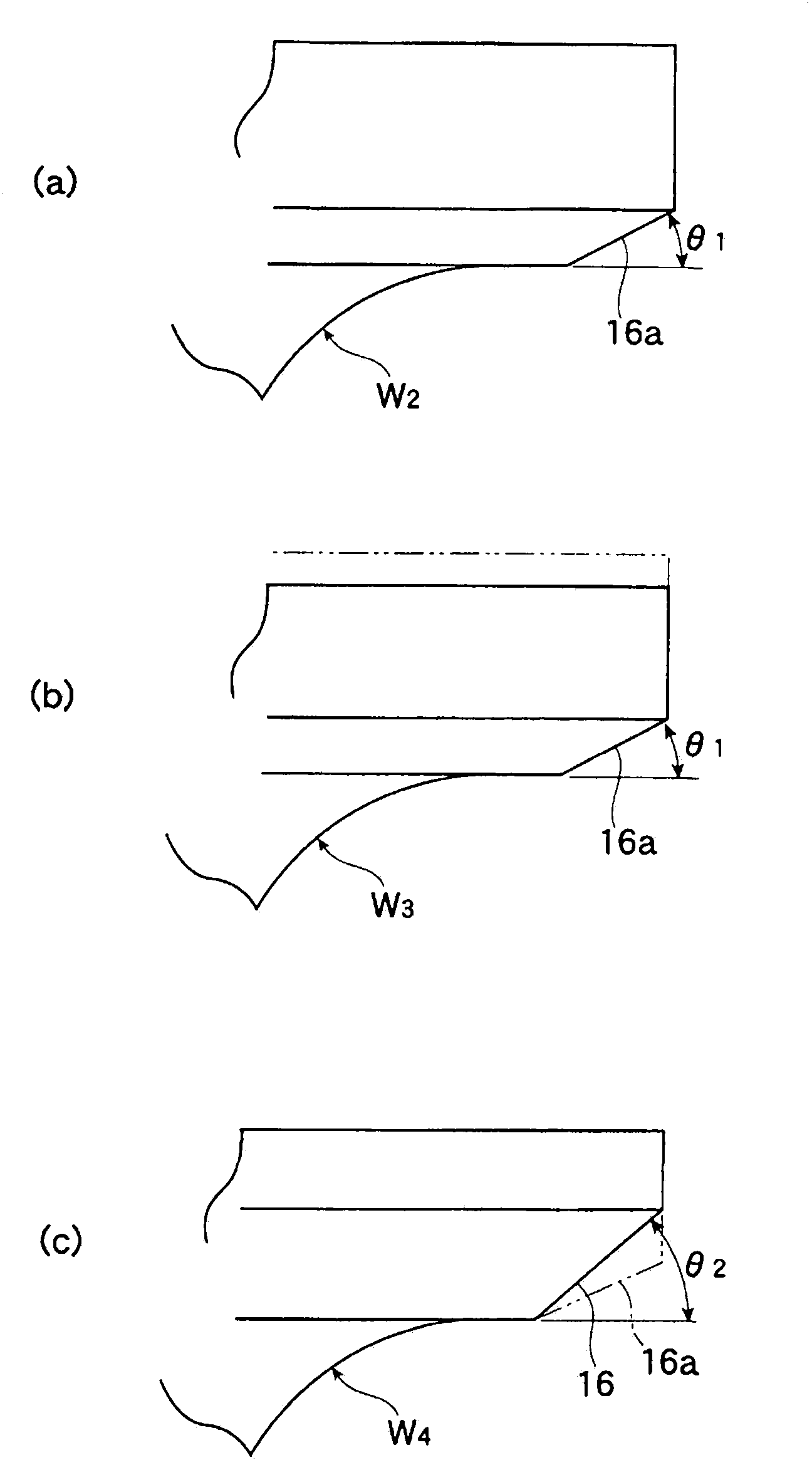

Method for manufacturing valve for internal combustion engine

ActiveCN103797220AImprove wear resistanceHigh hardnessMetal-working apparatusMachines/enginesSource materialWork in process

A method for manufacturing a valve is provided. A mold (40) equipped with a die (42) and a pressing punch (48) is used to perform forging whereby slip deformation is produced from the inner circumferential side toward the outer circumferential side of an umbrella-part face (16). The die (42) is provided with pressing projections (43) that form the umbrella-part face (16). The pressing projections (43) and recessed grooves (46) are provided alternating continuously in the circumferential direction on the die (42), and the umbrella-part face (16) is forged while an intermediate valve product (W3) is rotated at a prescribed angle with respect to the mold (40) in coordination with the pressing operation of the punch (48). The amount of elastic deformation of the source material in the depth direction by means of the pressing projections (43) is greater than with a conventional mold (die), and to that extent a higher hardening of the deep part of the umbrella-part face (16) is enabled. The region of plastic deformation separates in the circumferential direction, but the formed surface (forged surface) of the plastically deformed umbrella-part face (16) is smoothed by shifting the pressing location of the pressing projections (43) in the circumferential direction with each pressing operation of the punch (48).

Owner:NITTAN CORP

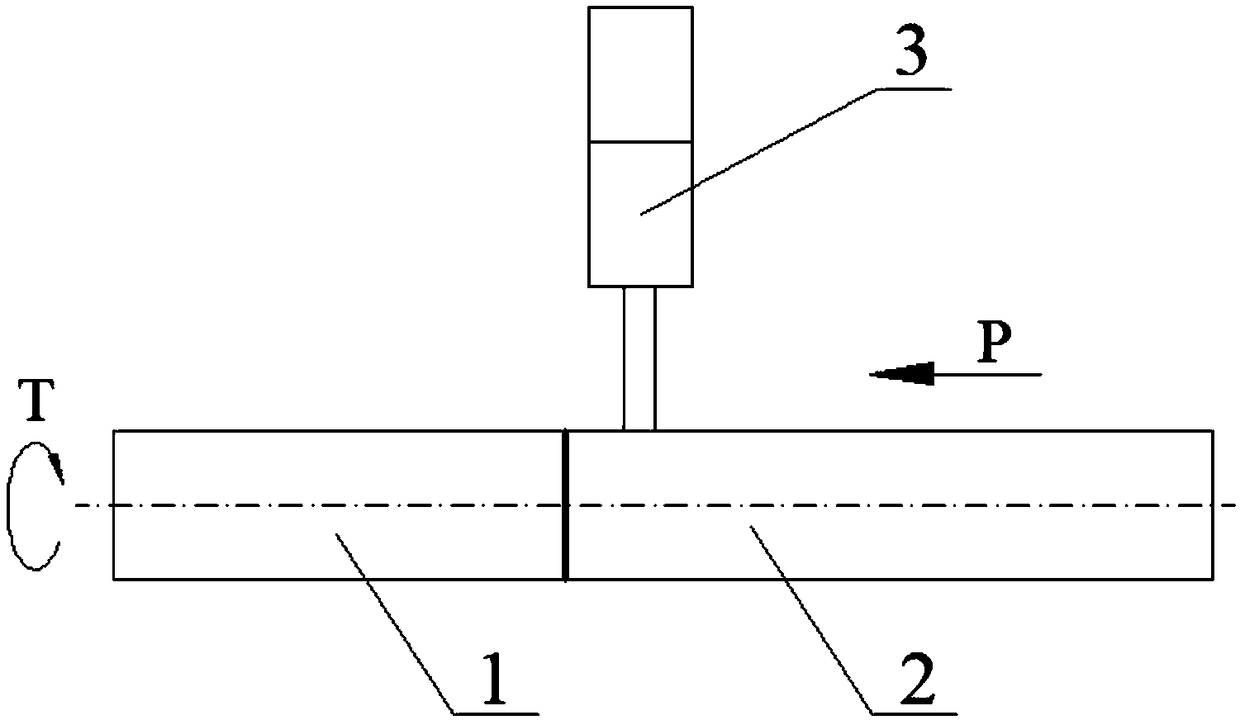

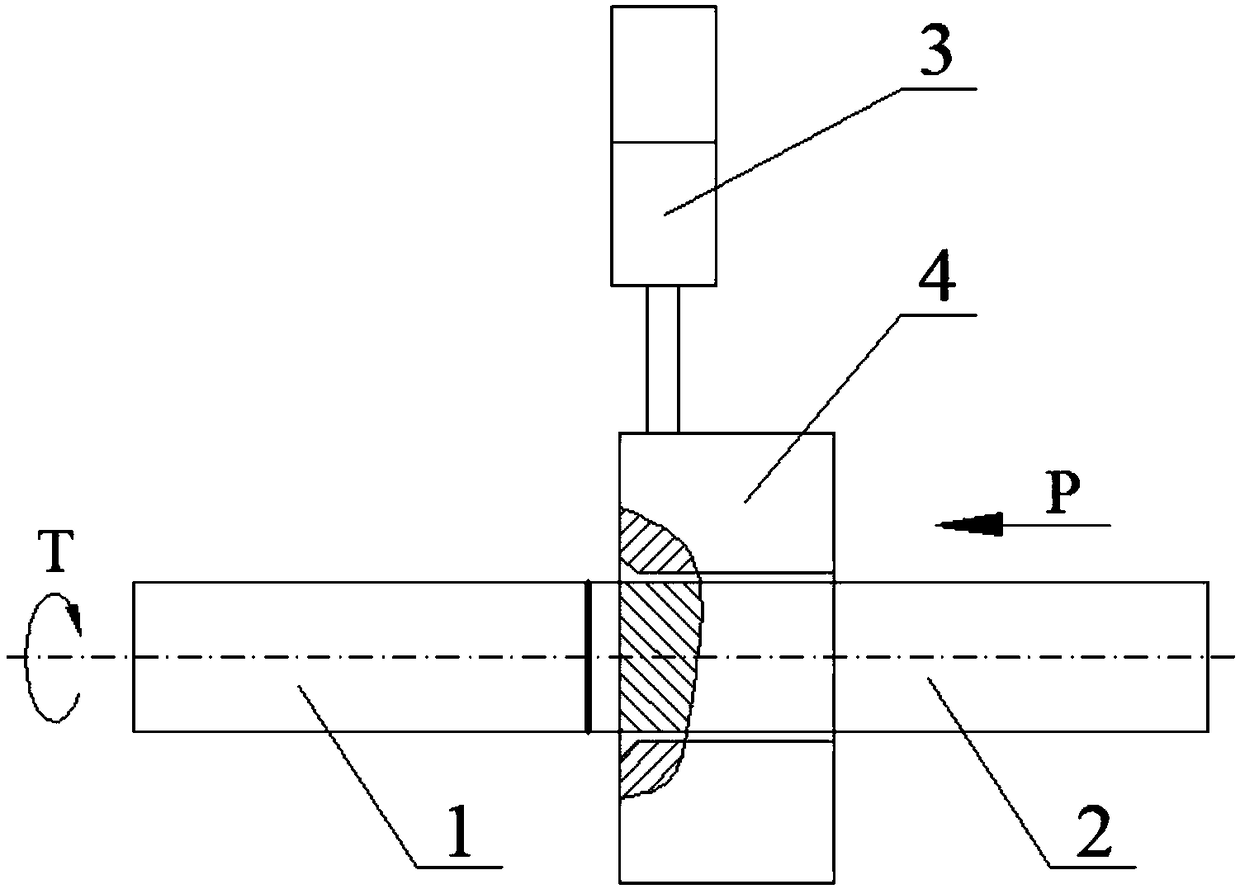

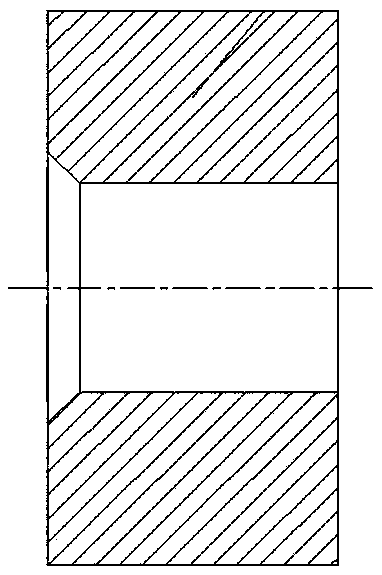

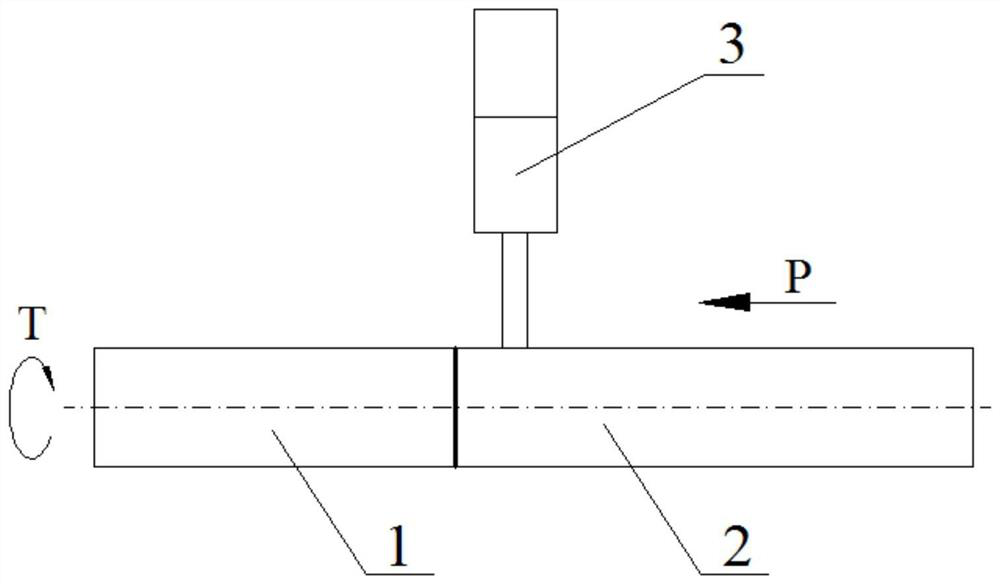

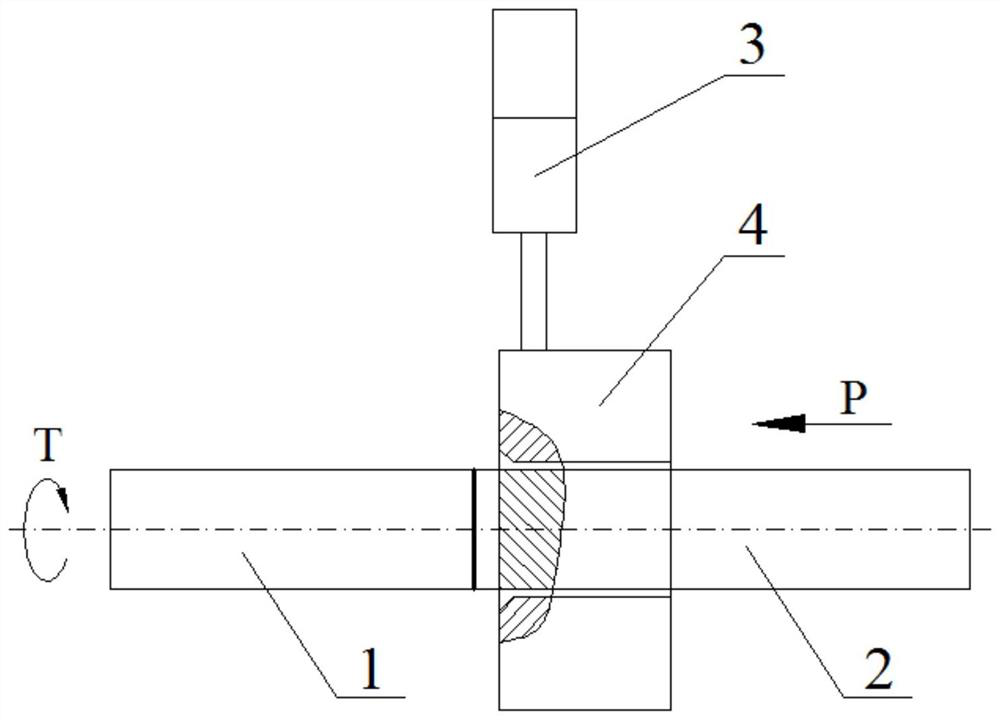

Ultrasonic vibration assisted friction welding method

InactiveCN109226956AReduce deformation resistanceHigh strengthNon-electric welding apparatusFriction weldingPositive pressure

The invention discloses an ultrasonic vibration auxiliary friction welding method, which is used for solving the technical problem of poor strength of a welding joint of the existing auxiliary friction welding method. The technical scheme is that in the process of rotating or linear friction welding, in addition to applying positive pressure and friction shearing force on the friction interface togenerate friction heat and plastic deformation, ultrasonic vibration is applied on the workpiece at the moving end, and the ultrasonic vibration transmitted to the friction interface can reduce the deformation resistance of high-temperature metal on the friction interface and promote the plastic deformation thereof, so that a larger plastic deformation amount can be generated even under a smallerfriction pressure, and finally the effective connection of workpieces at two sides is realized, and the strength of the friction welding joint is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

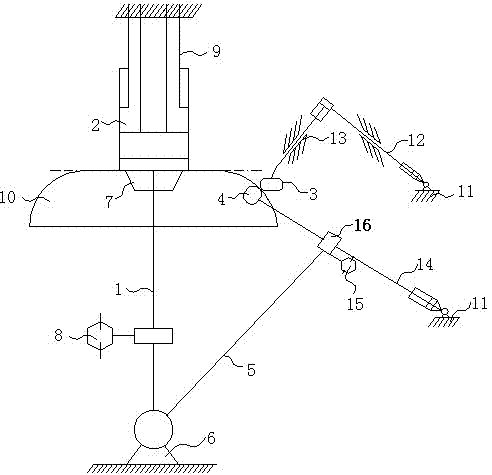

Dieless cold spinning one-step forming device and method for end enclosure

The invention relates to a dieless cold spinning one-step forming device and a dieless cold spinning one-step forming method for an end enclosure. The spinning device consists of a main shaft, a hydraulic jacking shaft, a spinning roller, a forming roller and an arc adjusting arm. The lower end of the main shaft is supported on a base, the upper end of the main shaft is provided with a tray in clearance fit, the main shaft is mechanically connected with a driving motor, the hydraulic jacking shaft is vertically arranged on a frame top beam coaxial with the main shaft, and a circular plate blank is axially clamped between the hydraulic jacking shaft and the tray of the main shaft. The upper part of a frame side post is connected with a spinning roller transverse hydraulic arm, the upper end of the spinning roller transverse hydraulic arm is fixedly connected with the tail end of a spinning roller longitudinal hydraulic arm in a break angle mode, and the lower end of the spinning roller longitudinal hydraulic arm is connected with the spinning roller in clearance fit; and the middle part of the frame side post is connected with a forming roller hydraulic arm, the top of the forming roller hydraulic arm is connected with the forming roller in clearance fit, the lower end of the arc adjusting arm is connected with the base at the root of the main shaft in clearance fit, and the upper end of the arc adjusting arm is hinged with the forming roller hydraulic arm through a displacement mechanism driven by the driving motor. According to the device and the method, the deformation state is greatly improved, plate blank supporting is enhanced, a crease is prevented from stretching to the center of the plate blank, and the device plays a very important role in finally eliminating the crease. Under the action of mutual deformation force, the elastic deformation is greatly reduced, and the plastic deformation is increased, so that the total spinning pass is reduced.

Owner:胡景春

Integral extrusion forming die and method for thin-walled shell with inner ring rib

InactiveCN112453092ARealize plastic formingReduce demandExtrusion diesOther manufacturing equipments/toolsEngineeringMachine

The invention discloses an integral extrusion forming die for a thin-walled shell with an inner ring rib. The integral extrusion forming die comprises a combined male die, a combined female die, a cushion block, an ejector rod, a fixed assembly and a movable assembly, wherein the combined male die is formed by a shaft sleeve and a mandrel in a guiding and sliding fit mode; the mandrel is connectedwith an independent power output shaft of a hydraulic machine; the combined female die comprises an inner female die body, an outer female die body and a fixed sleeve; and a hollow discharging cavityis formed in the middle of the inner female die body. The invention further provides an integral extrusion forming method for the thin-walled shell with the inner ring rib. The integral extrusion forming method comprises the following specific steps that (1) a sawing machine is adopted for cutting a bar; (2) homogenization treatment is conducted, and a hollow blank is prepared; (3) extrusion forming is conducted on the thin-walled shell with the inner ring rib; and (4) heat treatment and machining are conducted. The integral extrusion forming die is reasonable in structure, the defects of a traditional machining method can be effectively overcome, the technological process is short, the material utilization rate is high, extrusion forming of the inner ring rib can be achieved, and the mechanical property and the bearing capacity of a component are greatly improved.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Welding method for aluminum and copper

InactiveCN105665911AImprove welding qualityIncrease the amount of plastic deformationNon-electric welding apparatusButt jointSurface roughness

The invention discloses a welding method for aluminum and copper. The welding method is characterized by comprising the following steps that a, a cold pressure welding method is adopted; b, an aluminum base material and a copper base material are subjected to annealing treatment before welding, and the annealing temperature is 450-600 DEG C; c, metal oxide films and greasy dirt on the two annealed base materials are cleaned up, the joint surfaces of joints are accurately machined, the surface roughness Ra is 0.8-1.6 micrometers, and the axes are accurately perpendicular to the surfaces; d, an LHJ-15-model cold pressure welder and manual welding tongs are adopted; e, a wire of the aluminum and a wire of the copper adopt overlap joints, the pressure is 800-1200 MPa during overlap joint of the aluminum and the copper, and the pressure is 2400-3000 Mpa during butt joint; and f, after cold pressure welding, welding joints are cleaned, and welding quality inspection is conducted. According to the welding method for the aluminum and the copper, the plasticity is good, and the aluminum joint and the copper joint have high welding quality.

Owner:CHONGQING SHANGKE MACHINERY MFG CO LTD

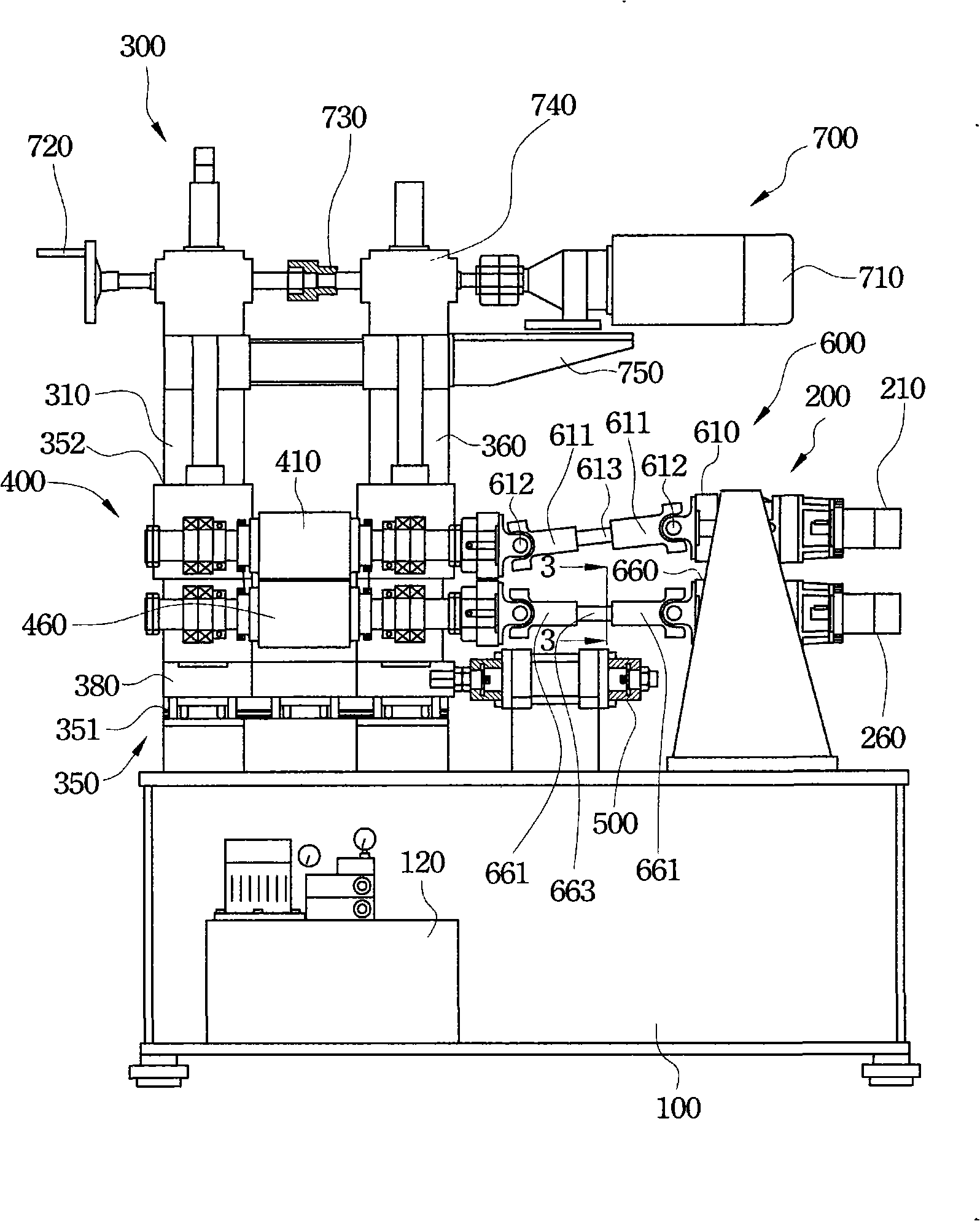

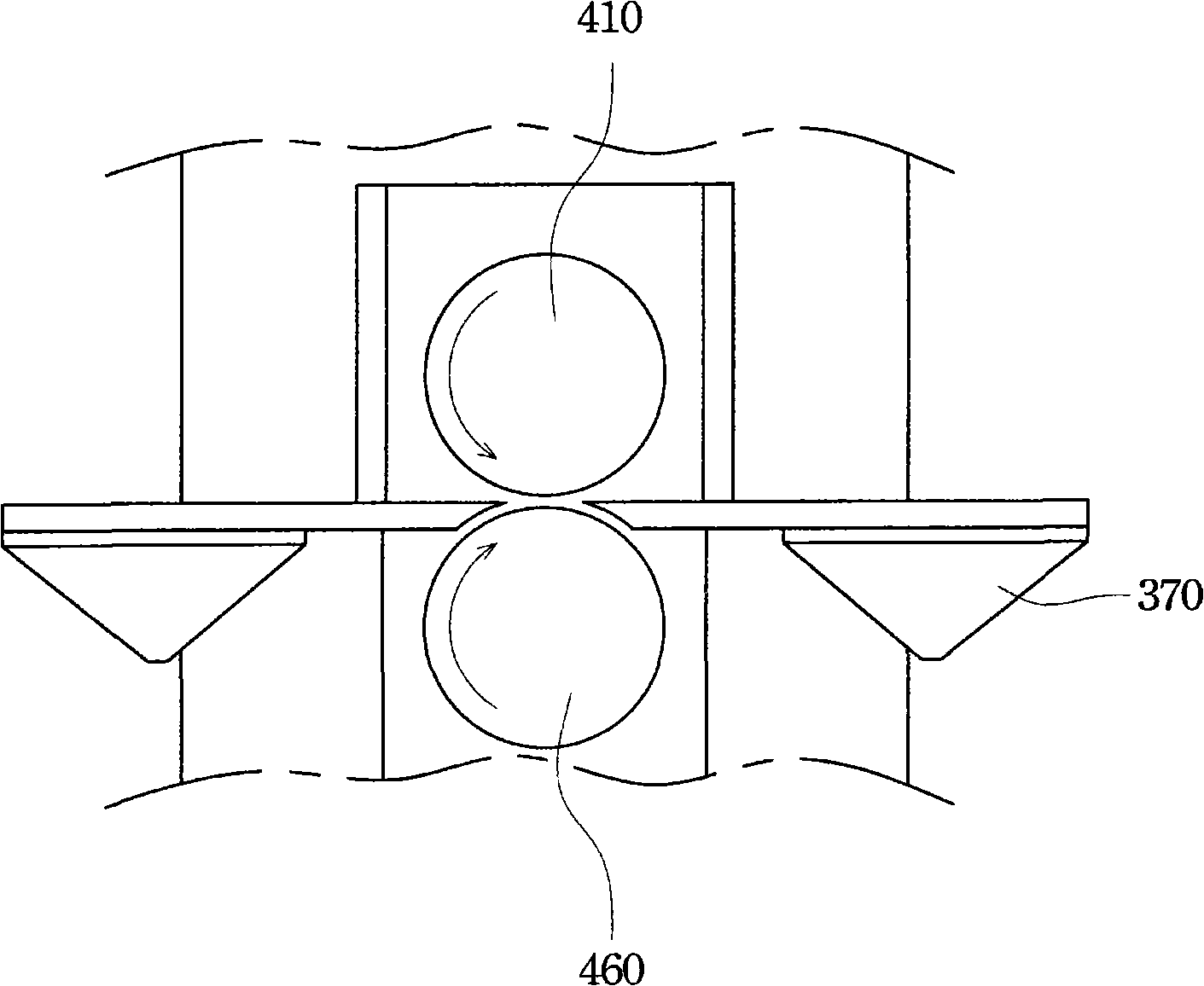

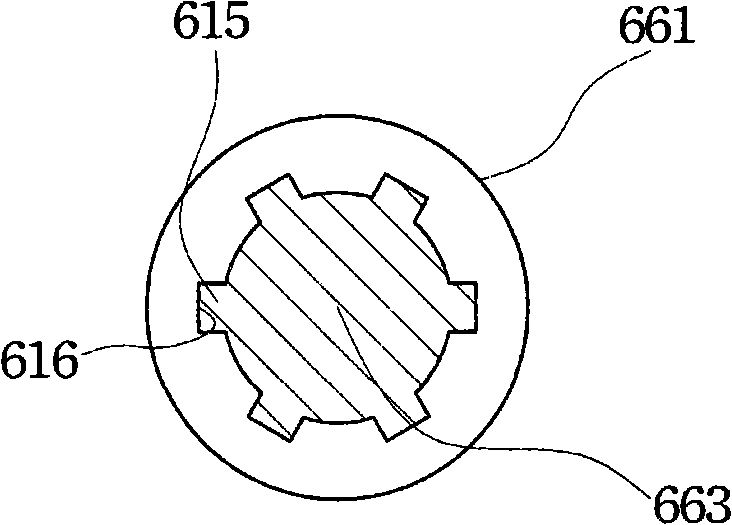

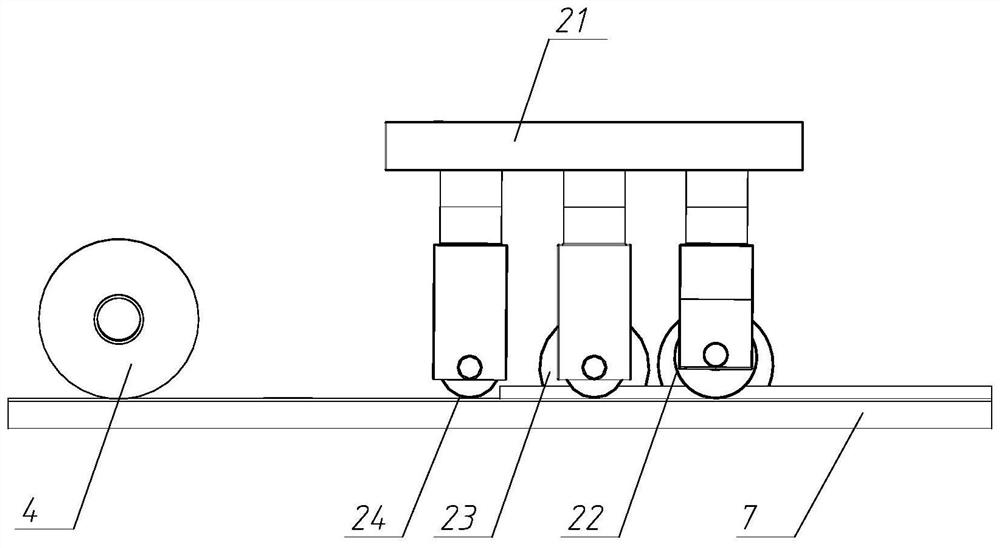

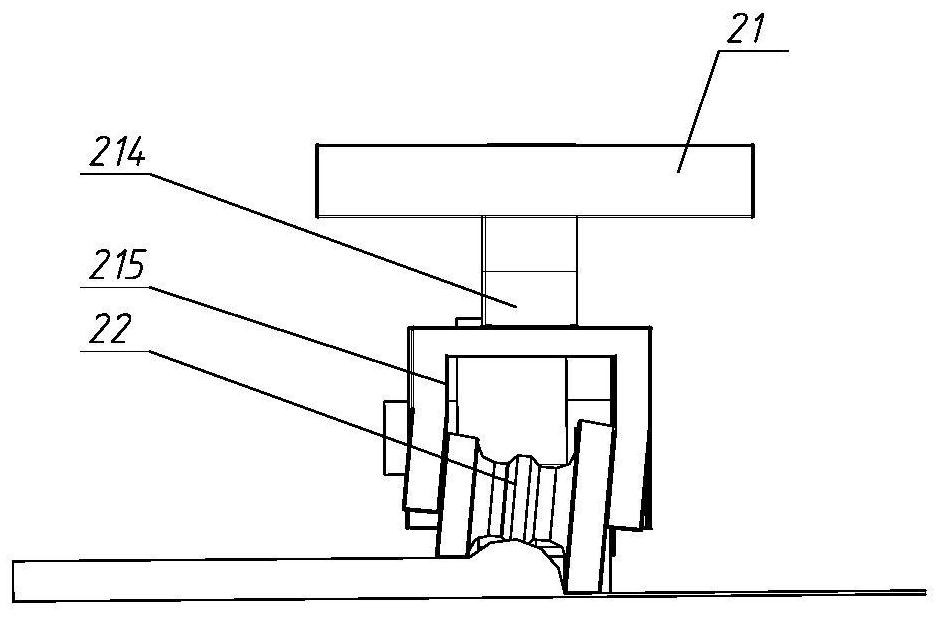

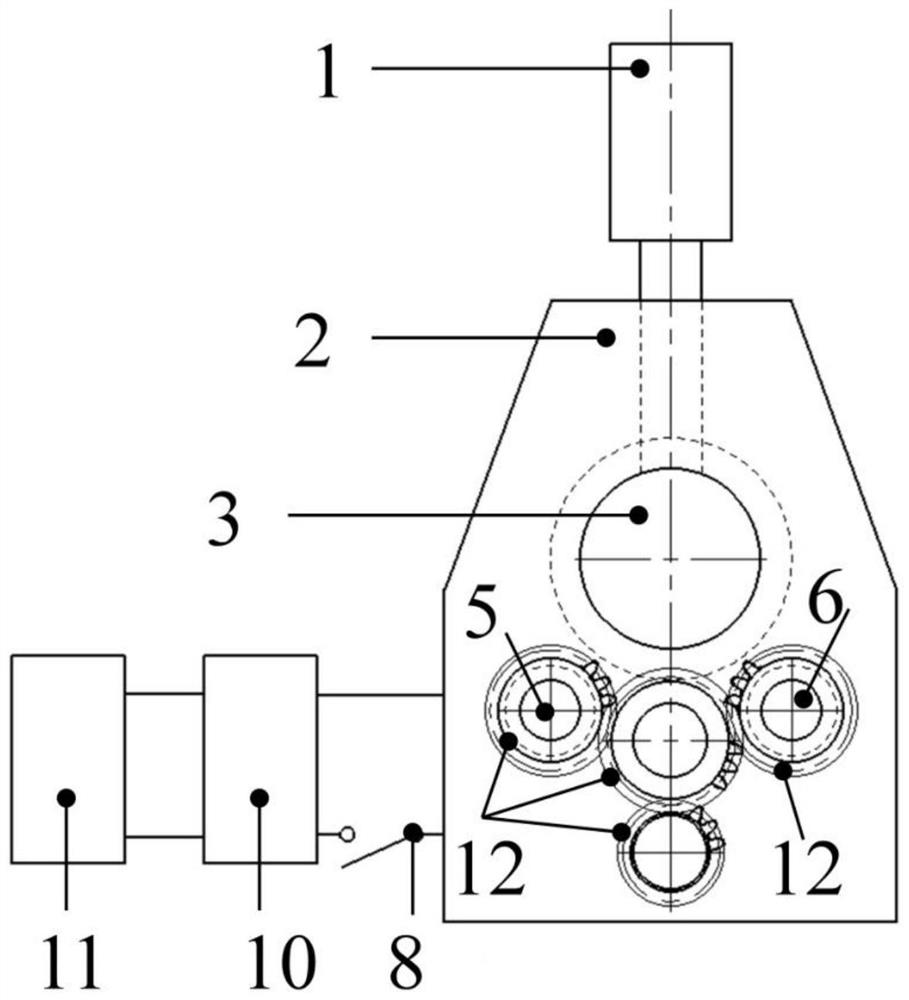

Sheet metal processor

InactiveCN101314164AIncrease the amount of plastic deformationSignificant progressMetal rolling stand detailsRolling mill drivesReciprocating motionMetal sheet

The invention relates to a metal sheet processing machine, which comprises a supporting seat, a driving device, a supporting device, a rolling device and a vibrating device. The driving device and the supporting device are arranged on the supporting seat. The rolling device is arranged on the supporting device, and comprises a first roll wheel device and a second roll wheel device. The vibrating device is connected to the second roll wheel device in order to be matched with a slide rail. Thus the first roll wheel device and the second roll wheel device are driven by the driving device to rotate in opposite directions, wherein, the second roll wheel device even performs reciprocating movement with linear swinging by means of the vibrating device. The metal sheet processing machine ensures that the stress strain inside a material is subject to compression strain between two roll wheels and is also imposed with shearing strain by the two roll wheels to increase the plastic deformation of the material.

Owner:蔡德昌 +1

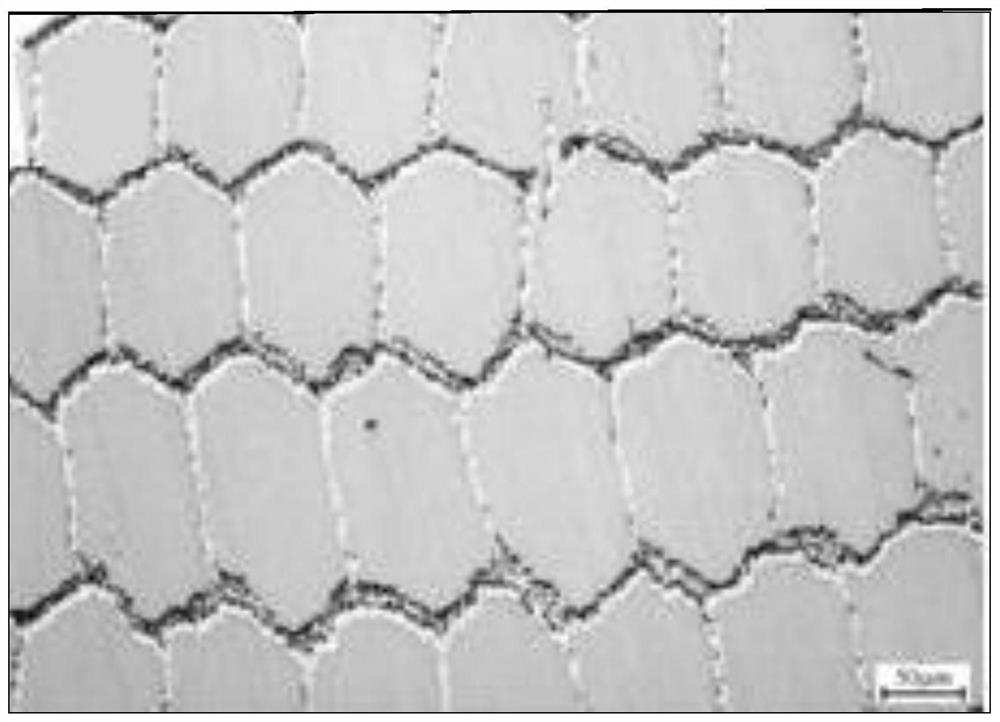

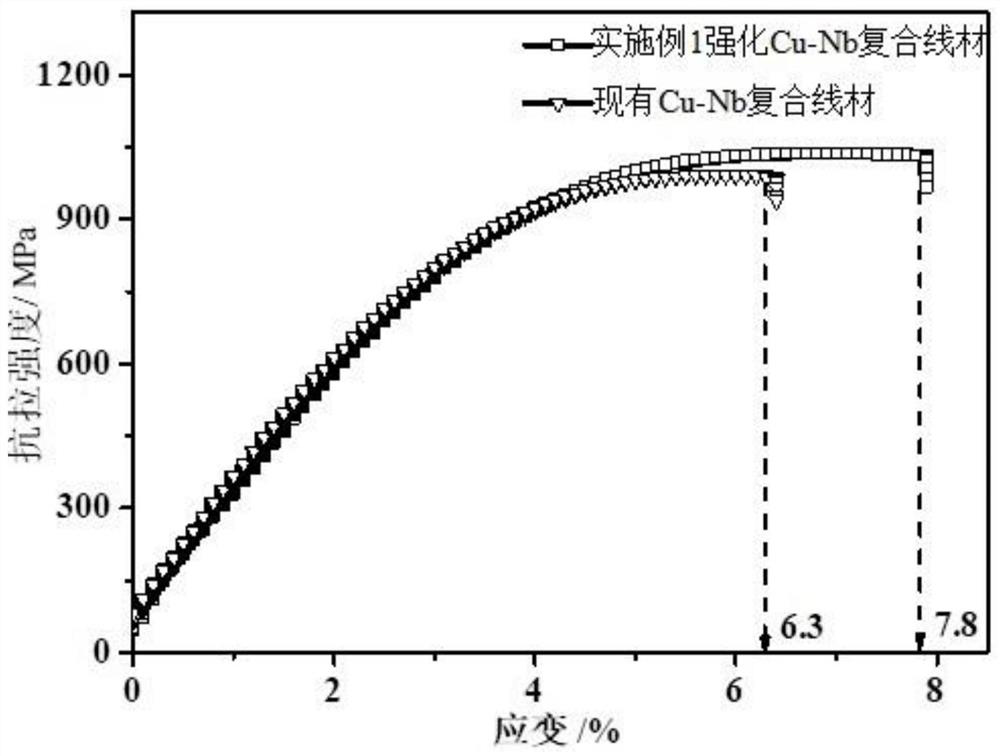

Preparation method of reinforced Cu-Nb composite wire

ActiveCN112007949AFacilitates longitudinal deformationQuality improvementMetal rolling arrangementsWire rodContinuous rolling

The invention discloses a preparation method of a reinforced Cu-Nb composite wire. The method comprises the following steps: 1, carrying out plastic drawing processing on a Cu-Nb three-time compositewire prepared by adopting a bundling drawing method, and then carrying out annealing treatment; 2, carrying out continuous multi-roll pass rolling on the annealed Cu-Nb three-time composite wire to obtain a Cu-Nb composite wire intermediate; and 3, carrying out plastic drawing processing on the Cu-Nb composite wire intermediate to obtain the reinforced Cu-Nb composite wire. According to the preparation method, a multi-roll pass rolling process is adopted for continuous rolling; the longitudinal deformation of the Cu-Nb three-time composite wire is promoted. Compared with the prior art, the plastic deformation is promoted to be improved, the plastic deformation amount is increased, the obtained reinforced Cu-Nb composite wire is more uniform in core wire distribution and deformation, and more obvious in core wire refinement, plastic deformation capacity is enhanced, the quality and performance of the reinforced Cu-Nb composite wire are improved, good matching of the mechanical propertyand the conductivity is achieved, and the engineering application requirement is met.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

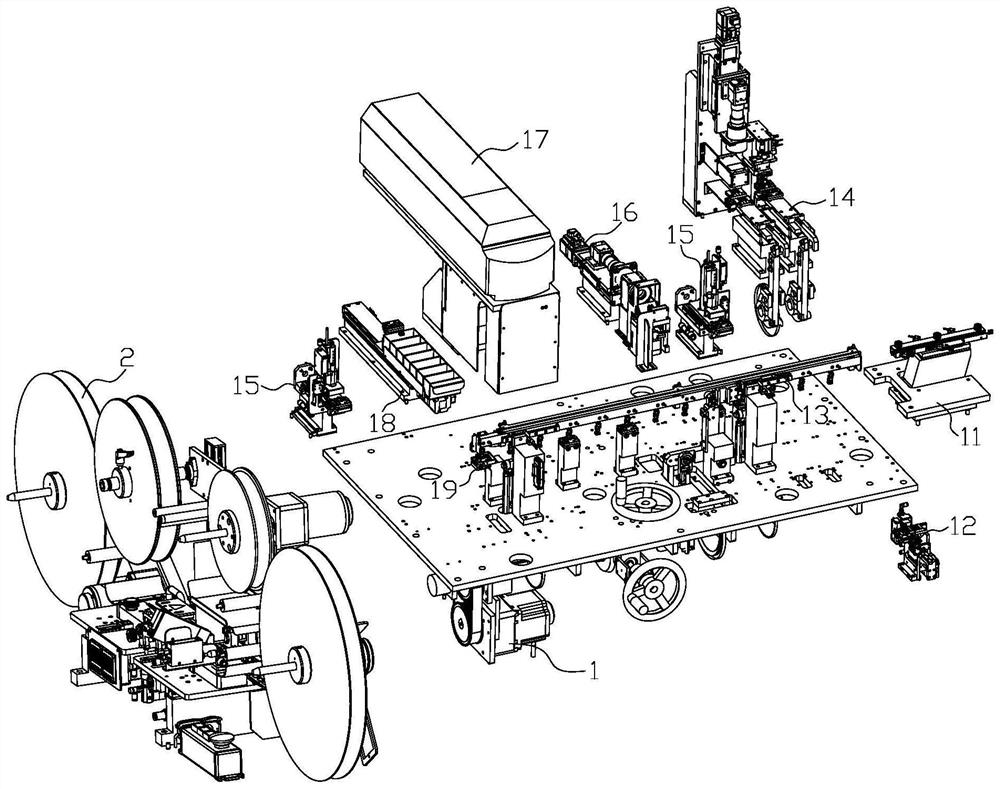

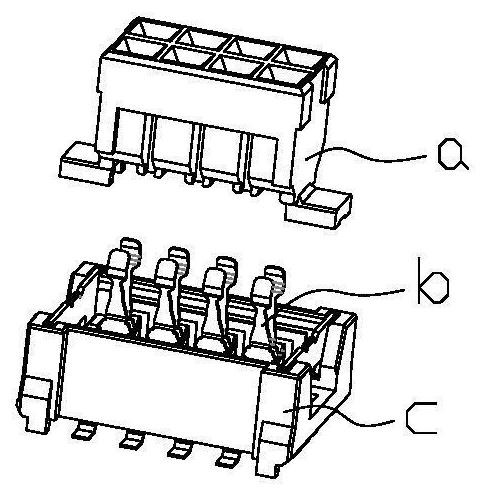

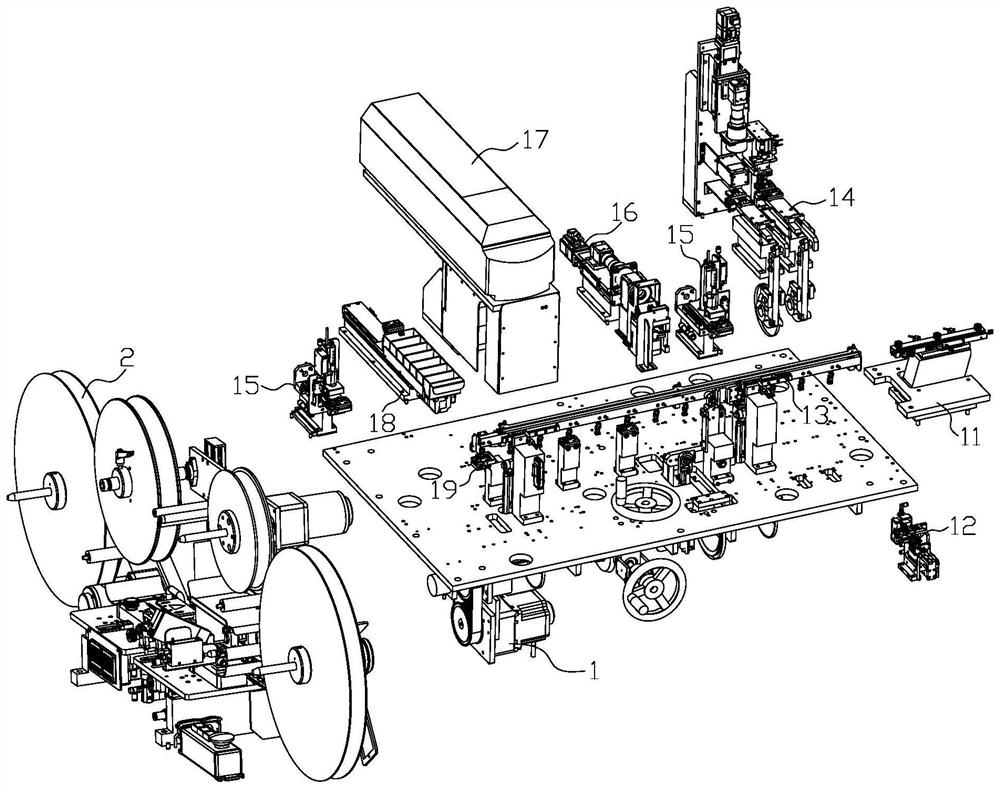

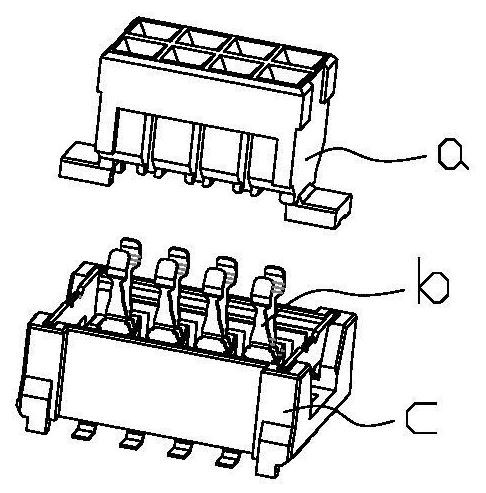

Automatic electronic connector detecting and packaging production line and detecting and packaging method

InactiveCN111846464AAvoid falling phenomenonEnsure stabilityWrapper twisting/gatheringPackaging automatic controlElectrical connectorEmbedded system

The invention relates to the field of electronic connectors. An automatic electronic connector detecting and packaging production line comprises a rack, electronic connector detecting equipment and electronic connector packaging equipment, wherein the electronic connector detecting equipment and the electronic connector packaging equipment are fixed on the rack, a feeding port of the electronic connector detecting equipment is connected with a feeding station, and a discharging port of the electronic connector detecting equipment is connected with a feeding port of the electronic connector packaging equipment. According to the production line, a connector overturning device is arranged to prevent electronic connectors from falling off during overturning, so that the stability of the overturning process of the connectors is guaranteed; by arranging a connector moving mechanism, the control steps of a carrying device are reduced, and the complexity of the mechanism is reduced; accurate moving of the electronic connectors at different stations is guaranteed by arranging a connector clamping mechanisms; due to the arrangement of the electronic connector packaging equipment, firm connection between a diaphragm and a carrier tape is guaranteed, and the packaging quality of the electronic connectors is improved.

Owner:周俊英

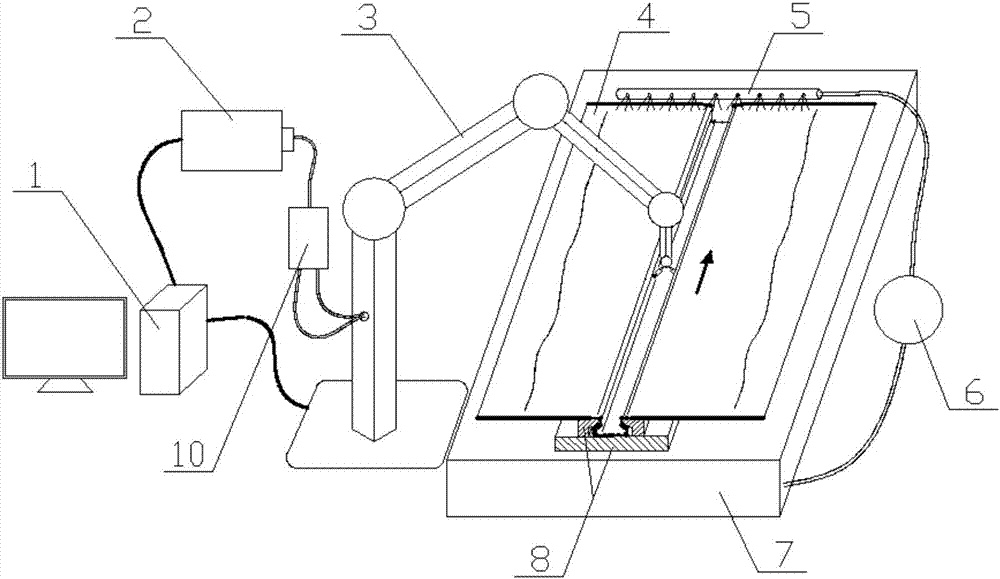

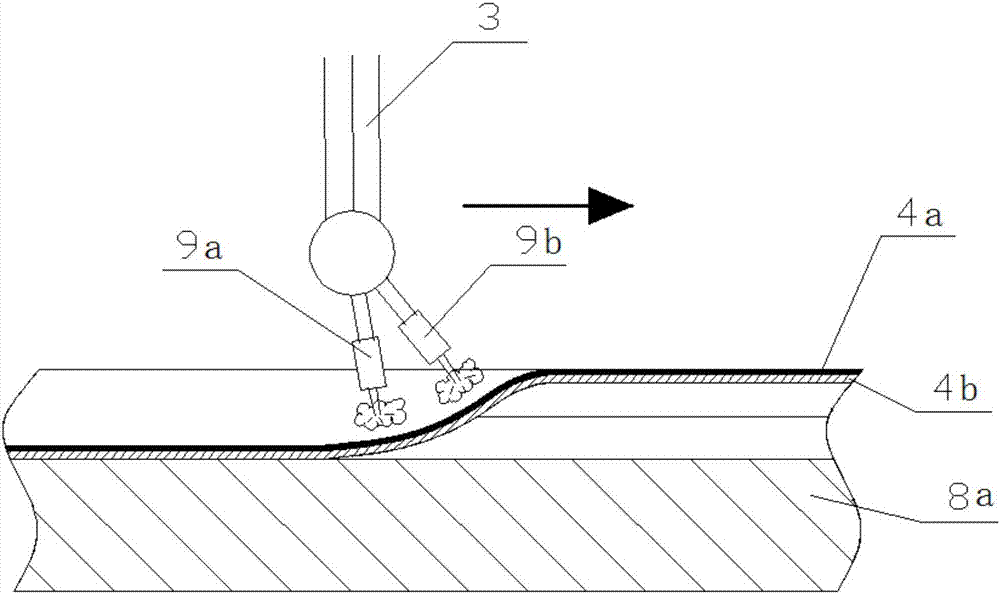

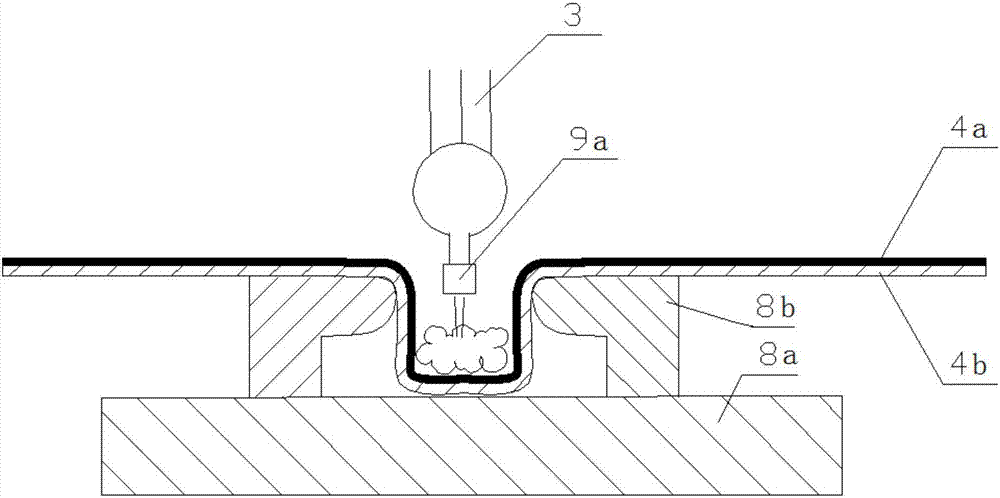

A progressive laser shock continuous riveting method and device

ActiveCN106041298BUniform and continuous linear rivetingImprove connection strengthLaser beam welding apparatusBeam splittingLight beam

The invention relates to a gradual type laser shock continuous riveting method and device and belongs to the technical field of material connection. The method and device are used for linear riveting between boards. The method includes the steps that A, a laser device is used for directly generating multiple beams of lasers or a beam splitting system is used for generating the multiple beams of lasers; B, a V-shaped included angle is formed between the extending lines of every two laser beams, and the boards are swept through the multiple beams of lasers at the same time; C, when the pulse lasers act on the surfaces of the boards, exploding plasma is generated, and each board gradually deforms to be of a groove structure under the shock effect of the exploding plasma and with the cooperation of the restraint of a forming die; D, the arranging manner of the multiple beams of lasers is adjusted, so that the laser beams are aligned with the two sides of the bottom of each groove structure; and E, the multiple beams of lasers move; under the continuous shock effect of the exploding plasma, the laser beams are matched with the restraint of the forming die, so that the groove structures are gradually shocked into interlocking structures; and the step B to the step E are repeated, the boards are gradually shocked, and therefore the boards are riveted together.

Owner:SHANDONG UNIV

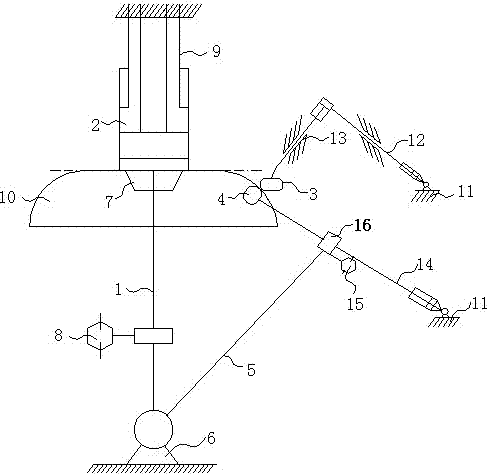

A method and device for hot rolling and rolling of arc wire-feeding additive inclined roller combined wheel

ActiveCN111215843BIncrease the dislocation densityImprove mechanical propertiesAdditive manufacturing apparatusOther manufacturing equipments/toolsAdditive layer manufacturingPhysics

A manufacturing method and device for hot rolling of an arc-feeding wire-feeding additive oblique-roller combination wheel. The invention relates to the technical field of 3D printing. A skewed roller for arc wire-feeding additive manufacturing with compact structure, high processing efficiency and good processing effect is proposed, which can refine grains, increase density, reduce internal defects, and finally improve the mechanical properties of arc additive manufacturing formed parts. Combination wheel hot rolling manufacturing method and device. The technical solution of the present invention is: manufacture according to the following steps; 1), initialization; 2), arc wire feeding additive; 3), rolling processing; 3.1), inclined roller strong shear deformation; 3.2), preliminary flattening; 3.3), complete flattening; 4), cooling; 5), waste edge removal; complete. It can refine the grains, increase the density and reduce internal defects of the formed parts by arc wire feeding additive manufacturing, so as to finally improve the mechanical properties of the parts.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

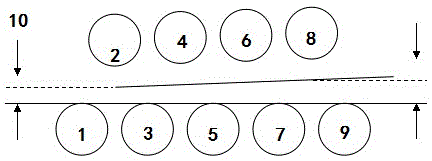

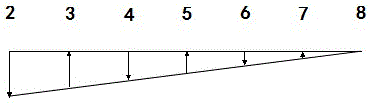

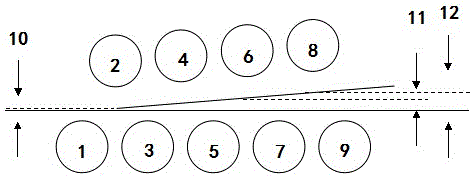

Cold straightening process for improving straightening capability through reduction of number of working rolls of straightener

ActiveCN105107873AIncrease the amount of cuttingExtended Straightening CapabilitiesWork rollEngineering

The invention discloses a cold straightening process for improving the straightening capability through the reduction of the number of working rolls of a straightener. In the step of the first pass large plastic deformation straightening, the number of the working rolls actually performing straightening is determined; one or two upper working rolls on the outlet side do not perform straightening; roll gaps of the inlet and the outlet are set; and the roll gap of the inlet is calculated according to a secondary model and based on a condition that a steel plate plastically deforms by 80%. In the step of the second pass small plastic deformation straightening, all the working rolls perform straightening; the roll gap of the inlet is calculated according to the secondary model and based on a condition that the steel plate plastically deforms by 65%; and the roll gap of the outlet is designed to be the thickness of a plate to be straightened. According to the invention, through the reduction of the number of the working rolls actually performing straightening on the outlet side of the straightener, the load of the straightener is reduced, the rolling reduction of the inlet of the straightener is increased, the maximum bending curvature of the steel plate is increased, the straightening capability of the straightener is enhanced, and the straightening qualified rate of the steel plate is improved.

Owner:NANJING IRON & STEEL CO LTD

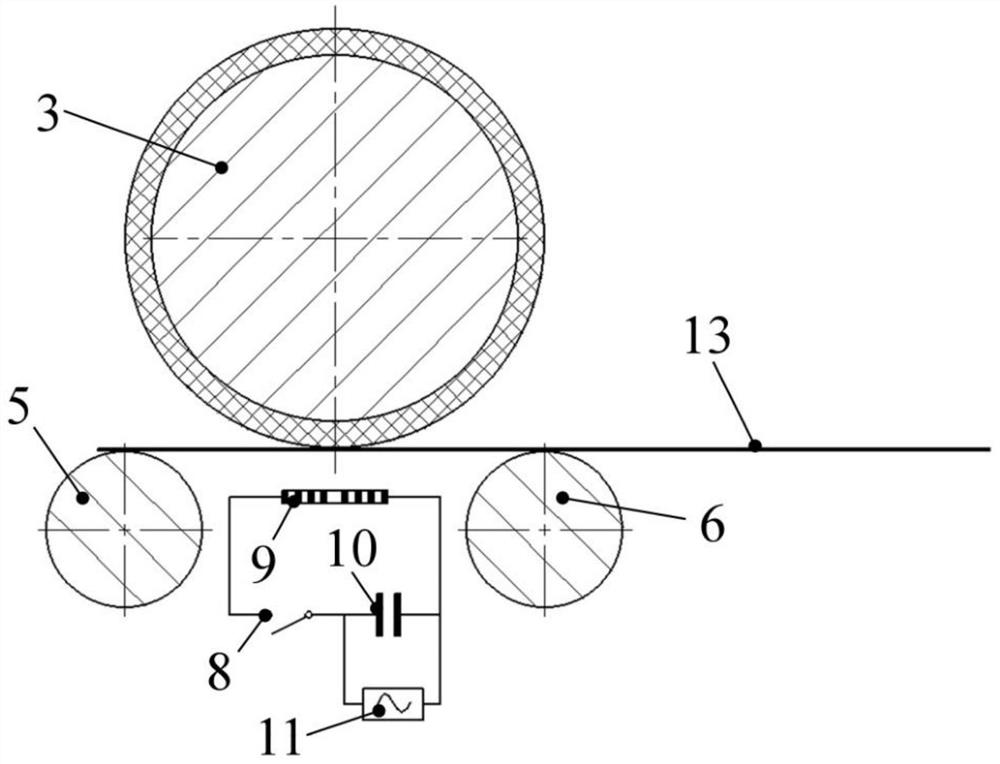

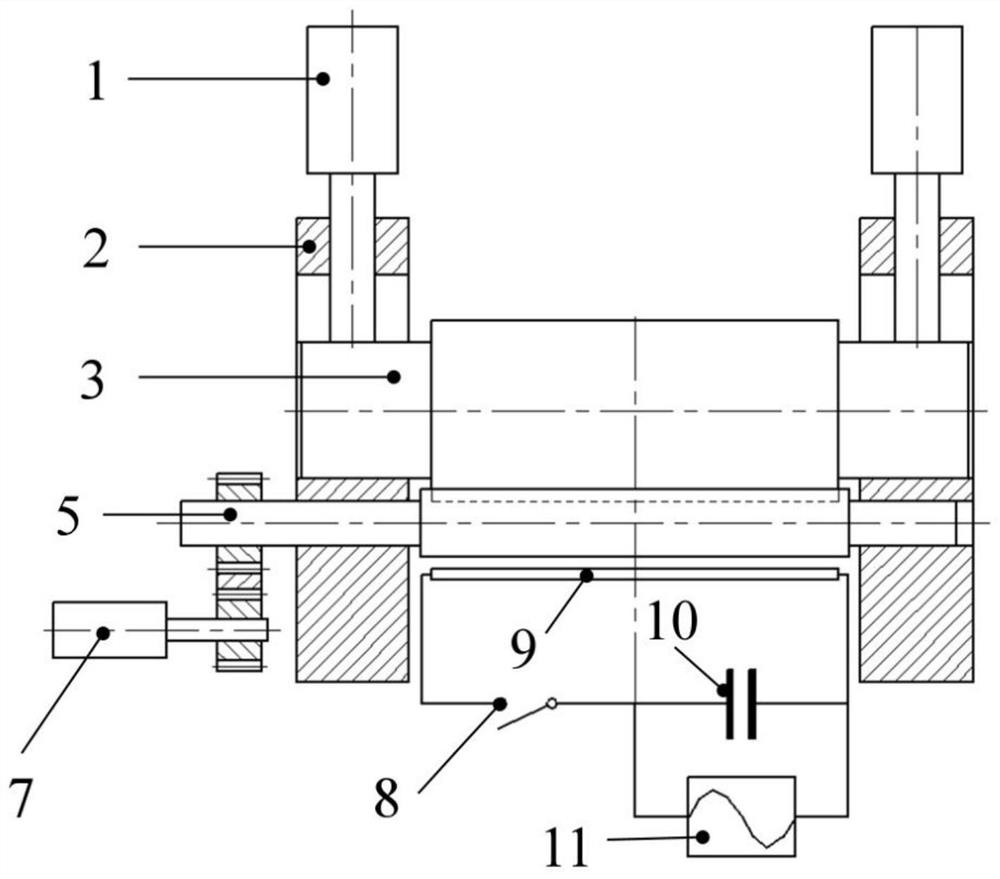

Electromagnetic auxiliary roll bending forming method and forming device thereof

The electromagnetic auxiliary roll bending forming method comprises the following steps that an elastic roller is used for pressing a plate to be bent and deformed, and the plate with an inner arc face and an outer arc face is formed; the downward pressing position of the elastic roller is kept, and periodic electromagnetic pulse discharging is conducted on the plate on the outer cambered surface of the plate; during discharge amplification, the plate is reversely bent and deformed under electromagnetic loading, and meanwhile, the elastic surface of the compression elastic roller is deformed; during discharge attenuation, the elastic surface of the elastic roller recovers deformation and forces the plate to reset; and the plate is driven to continuously move in the roll bending direction, and meanwhile periodic electromagnetic pulse discharging is continuously conducted till the continuous roll bending arc length of the plate is larger than or equal to the forming target arc length. Local reverse bending and local bending are periodically and alternately carried out on the plate, the plastic forming performance of the plate can be improved, rebound of the plate after roll bending is restrained, and the surface quality and forming precision of the formed small-curvature thin-wall bent part are improved.

Owner:NANJING FORESTRY UNIV

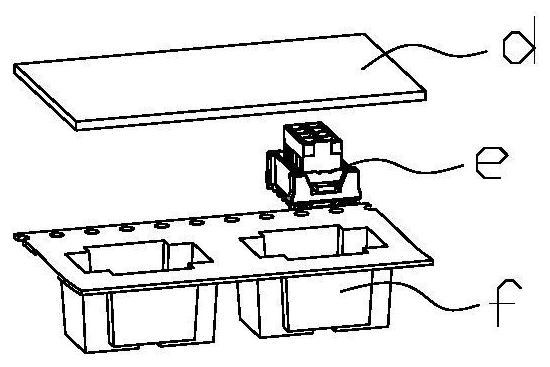

Electronic connector packaging equipment and packaging method

InactiveCN111846463AAvoid falling phenomenonEnsure stabilityWrapper twisting/gatheringPackaging automatic controlEngineeringElectrical connector

Owner:周俊英

A preparation method for large deformation composite extrusion of magnesium alloy profile for vertical hydraulic press

ActiveCN111438213BIncrease profitSpeed up the flowExtrusion diesLarge deformationUltimate tensile strength

The invention discloses a large-deformation composite extrusion preparation method of magnesium alloy profiles for vertical hydraulic presses, including (1) blanking, (2) homogenization treatment, (3) heating and heat preservation of blanks and molds, (4) applying lubricant, and putting the blanks into forward extrusion Cavity, ⑤ Forward extrusion of the billet, the billet is extruded into the storage cavity through the sizing belt, ⑥ The billet continues to flow under pressure until it touches the bottom of the storage cavity, the billet flows radially, and gradually the storage The space in the material cavity is completely filled, and the billet is upset and deformed during this process. ⑦Under the downward pressure of the punch, the metal of the billet begins to flow to the extrusion port of the lateral cavity that communicates with both sides of the storage cavity, and sideways deformation occurs. Lateral extrusion deformation, when the punch stroke ends, the lateral extrusion process also ends, ⑧ demoulding. This case realizes forward extrusion-upsetting-lateral extrusion large plastic deformation forming at one time, increases the strain, enriches the stress-strain state, improves the structure and weakens the texture strength, effectively reduces the production process, and adapts to the prospect of my country's market economy.

Owner:ZHONGBEI UNIV

Sheet metal forming method and device based on laser shock wave and vibration technology

The invention discloses a metal plate forming method and device based on the laser shock wave and vibration technology, and belongs to the technical field of mechanical part fast manufacturing. According to the method and device, a single pulse laser is adopted for induce shock waves underwater to load a metal plate many times; resilience and vibration in the plate forming process are controlled through the one-way exhaust performance of a one-way valve; a vibration method is adopted for weakening resistance of plastic deformation of the metal plate in the forming process; plastic flowing and forming of the metal plate are accelerated; resilience is further reduced; and therefore the metal plate and a molded surface of a mold are attached precisely, and a high-precision formed part is obtained. Adopted equipment is simple, operation is convenient, the induced shock waves are high in pressure and can be utilized many times, and the formed part is small in elastic recovery, large in plastic deformation and high in forming precision.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Cold rolling forming machine and U-shaped suspension arm plate production and manufacturing method

PendingCN114570800AEliminate internal stressMeet normal productionShaping toolsMolding machineThermal deformation

The invention relates to the field of forming equipment, in particular to a cold rolling forming machine and a U-shaped suspension arm plate manufacturing method.The cold rolling forming machine comprises a finishing workbench, a lower die and a plate are arranged in the center of the upper end of the finishing workbench, the plate is arranged at the upper end of the lower die, and an upper die is arranged at the position, located at the upper end of one side of the lower die, of the plate. The method shortens the elastic recovery time, prolongs the rolling time, has good effects of inhibiting stress release, improving plastic deformation and keeping rolling stability, can adapt to material performance changes in a certain range through bend angle adjustment, eliminates internal stress generated by strong rolling after normalizing treatment, and improves the rolling quality. Thermal deformation caused by heat treatment is treated in the finishing section, and the section, longitudinal bending and transverse bending of the profile are further corrected, so that the internal stress of the material of the forming section is effectively controlled, the end springback caused by placement after cutting is reduced, and the new process can meet the production of the U-shaped suspension arm.

Owner:南京图信新材料科技有限公司

A twist-extrusion composite strong-plastic forming method and process device

ActiveCN108714631BImprove refinementAvoid grain growthExtrusion diesRolling-element bearingGrain growth

The invention provides a torsion-extrusion composite strong-plastic forming method and a technological device, and belongs to the technical field of metal plastic processing. The method combines the advantages of high-pressure torsion fine crystal and extrusion forming, the blank is simultaneously subjected to high-pressure torsion and extrusion, the metal at the lower end of the blank is violently sheared, so that crystal grains are mechanically broken, meanwhile, the temperature rise generated by plastic work and friction power enables the dynamic recrystallization to be refined and the metal plasticity is improved; a large extrusion force is applied to enable the metal to generate plastic flow, and then a high-performance component is obtained through corner deformation in a cavity of aprocess device, and accurate control of property forming and shape forming of the technological process is achieved; and the process device mainly comprises a male mould, a combined female mould, a rolling bearing and a rotary head with a special shape. According to the method and the device, crystal grain refining capacity is strong, the crystal grain growth caused by the heating link of the blank can be avoided by shortening the heating process.

Owner:UNIV OF SCI & TECH BEIJING

A compound method and device for multi-layer metal coupling deformation rolling

ActiveCN106001110BProtectAvoid burnsTemperature control deviceAuxillary arrangementsCombined methodHigh pressure water

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

A method for rolling copper-aluminum double-layer composite board

ActiveCN104959382BIncrease the amount of plastic deformationIncrease contact areaAuxillary arrangementsMetal rolling arrangementsCopperComposite plate

The invention discloses a method for manufacturing a copper-aluminum double-layer medium-thick composite plate through a cold rolling manner. The method comprises following steps: 1) cleaning an aluminum plate and a copper plate in an immersion manner, removing oil of the plates, drying the plates, and cleaning the composite surfaces of the plates; 2) stacking and compressing the copper plate and the aluminum plate, and riveting the plates at a rolling bite end; 3) rolling the copper-aluminum composite plate blank through a two-roller roughing mill; 4) rolling the copper-aluminum composite plate through a three-roller intermediate mill; 5) rolling the copper-aluminum composite plate through a four-roller finishing mill; 6) rolling the copper-aluminum composite plate through a six-roller finishing mill to reach the required thickness; and 7) annealing the copper-aluminum composite plate. According to the invention, rolling is carried out through the rolling mills provided with working rolls having different roll diameters, so that the plastic deformation is increased, the composite ratio is improved, and a plate shape problem of the copper-aluminum double-layer medium-thick composite plate is solved as the working rolls are different in linear speed.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Ultrasonic vibration assisted friction welding method

InactiveCN109226956BReduce deformation resistanceHigh strengthNon-electric welding apparatusFriction weldingUltrasonic vibration

The invention discloses an ultrasonic vibration auxiliary friction welding method, which is used for solving the technical problem of poor strength of a welding joint of the existing auxiliary friction welding method. The technical scheme is that in the process of rotating or linear friction welding, in addition to applying positive pressure and friction shearing force on the friction interface togenerate friction heat and plastic deformation, ultrasonic vibration is applied on the workpiece at the moving end, and the ultrasonic vibration transmitted to the friction interface can reduce the deformation resistance of high-temperature metal on the friction interface and promote the plastic deformation thereof, so that a larger plastic deformation amount can be generated even under a smallerfriction pressure, and finally the effective connection of workpieces at two sides is realized, and the strength of the friction welding joint is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com