Sheet metal processor

A metal sheet and processing machine technology, applied in metal processing equipment, metal rolling stands, metal rolling mill stands, etc., can solve the problems of limited processing strain and lack of shear strain, and achieve the effect of increasing the amount of plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, characteristics and effects of the sheet metal processing machine proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. , as detailed below.

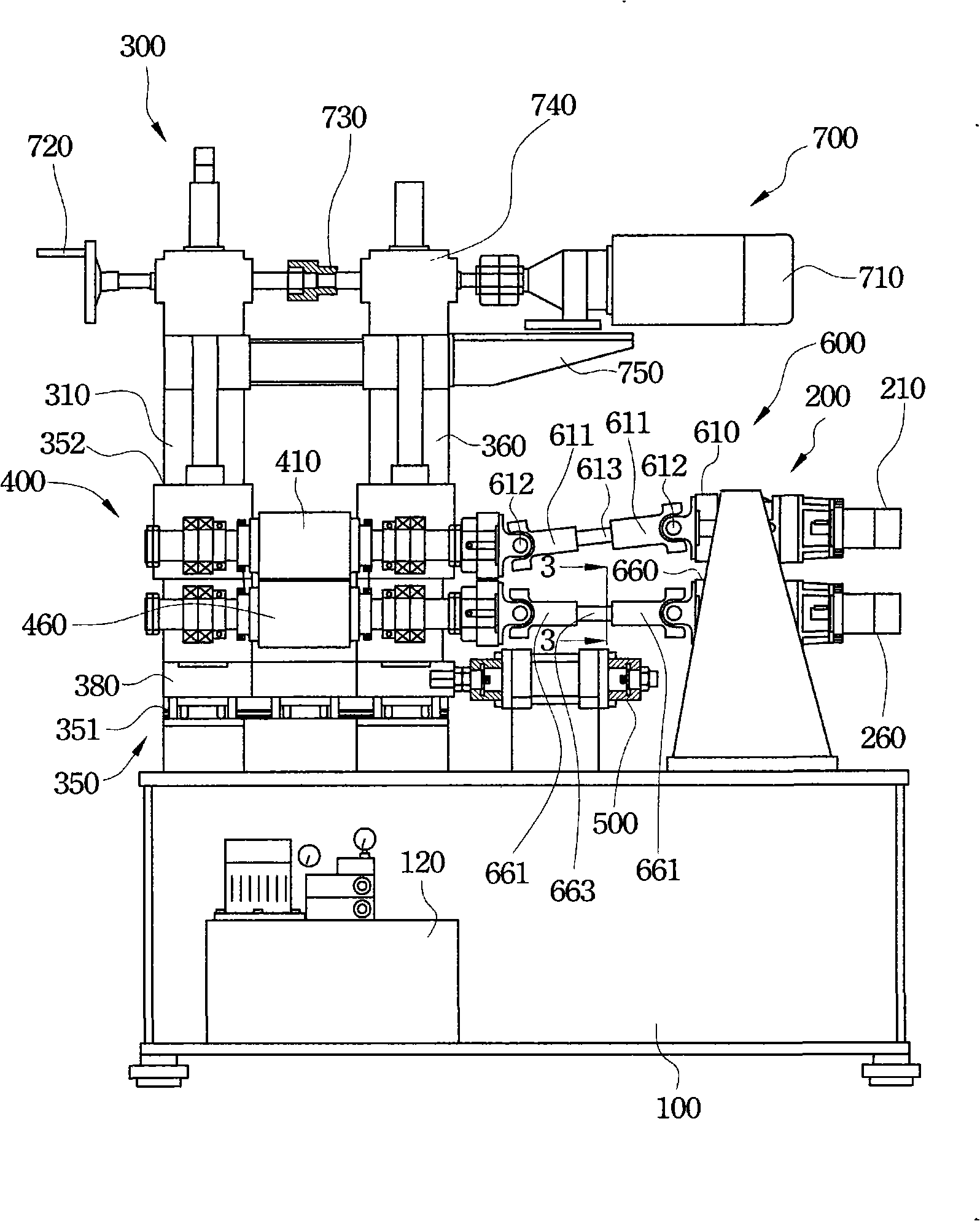

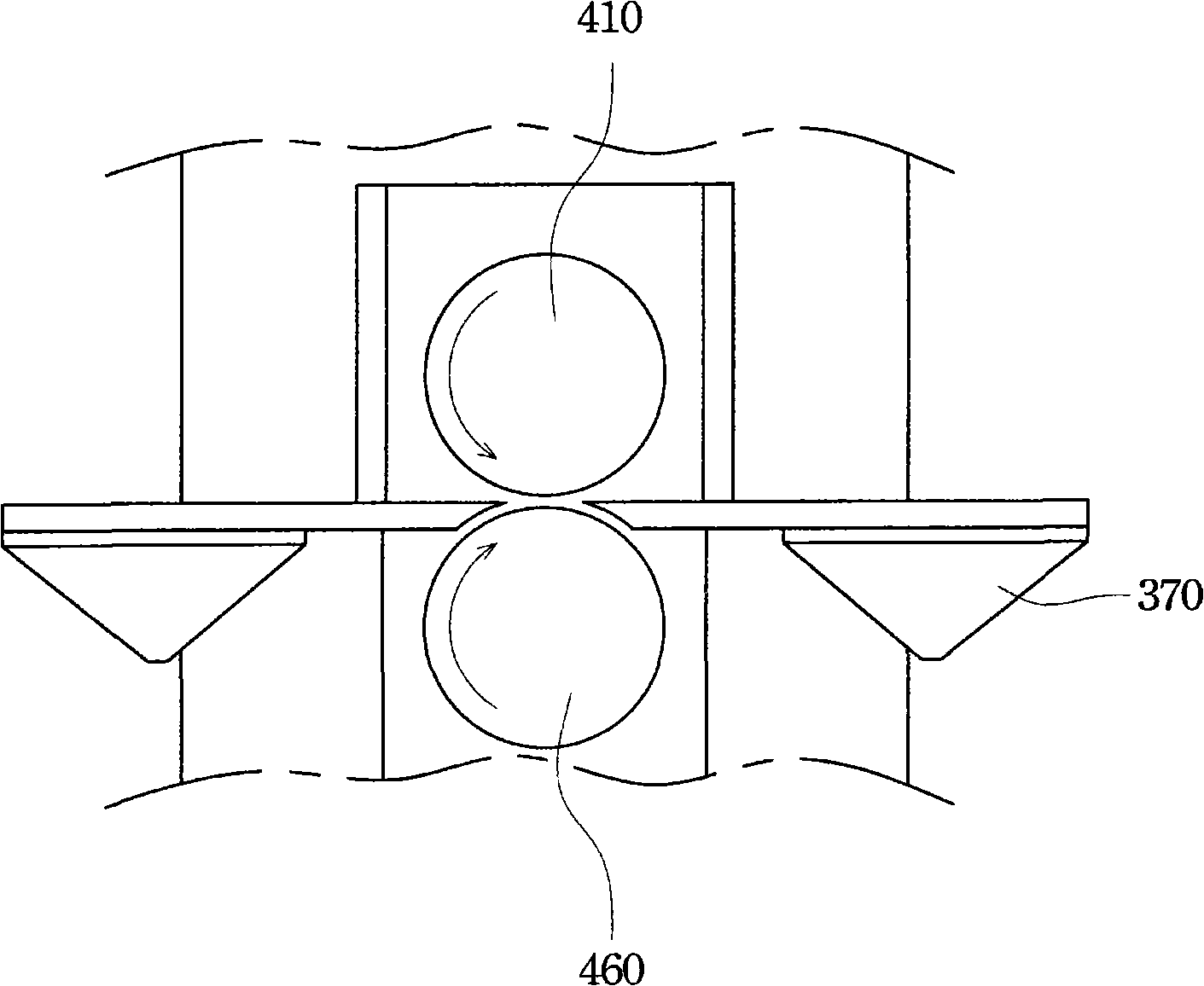

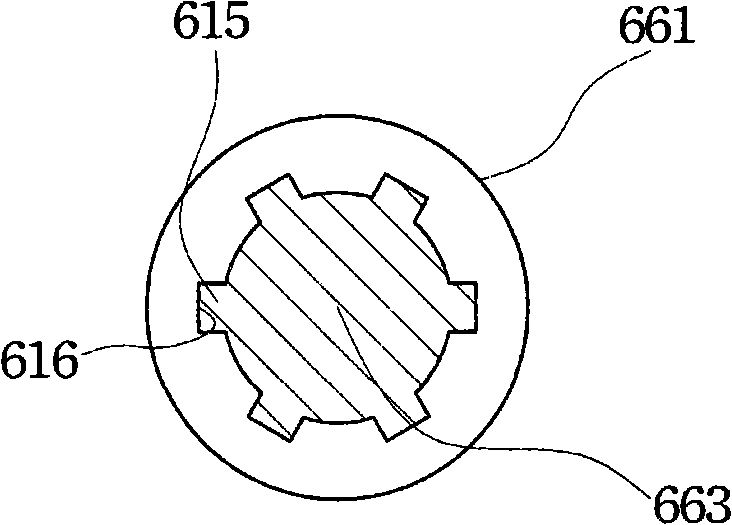

[0055] see figure 1 as well as figure 2 . figure 1 is a schematic structural view of a sheet metal processing machine according to an embodiment of the present invention; figure 2 is to draw figure 1 A partially enlarged schematic view of a sheet metal working machine in operation. The sheet metal processing machine in the embodiment of the present invention includes a seat 100 , a driving device 200 , a supporting device 300 , a rolling device 400 and a vibrating device 500 .

[0056] The driving device 200 is installed on the base 100 and is a hydraulic driving de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com