A twist-extrusion composite strong-plastic forming method and process device

A process device and combined technology, applied in the field of metal plastic processing, can solve the problems of difficult to form high-performance plate/cylinder components, and achieve the effect of avoiding grain growth and large plastic deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

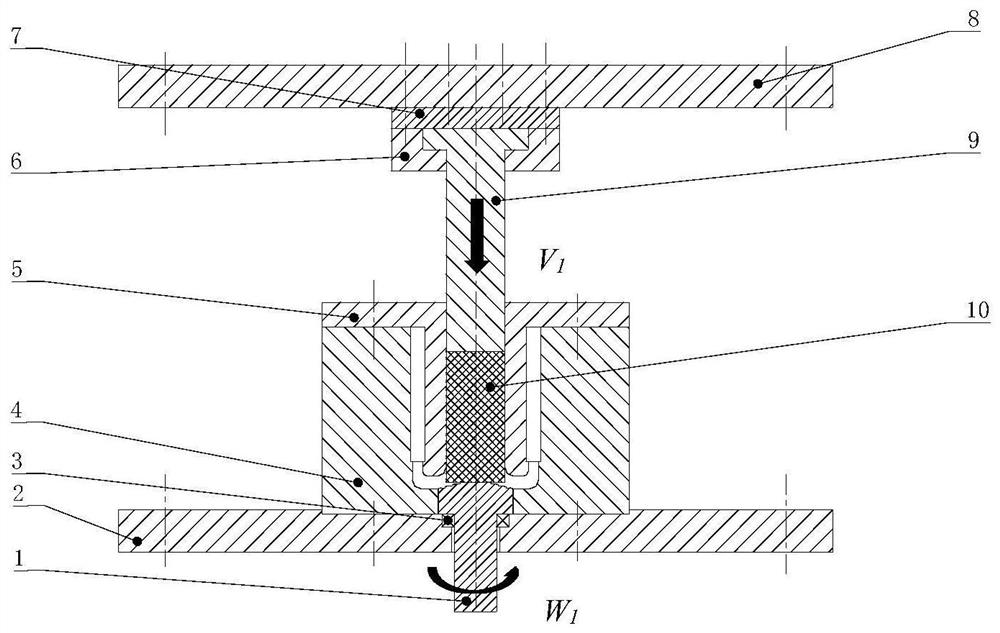

[0030] Example 1: A torsion-extrusion combined strong-plastic forming method and process device for a magnesium alloy cylindrical part are described in detail in conjunction with the accompanying drawings.

[0031] Such as figure 1 As shown, in the twisting-extrusion combined strong-plastic forming process device for a magnesium alloy cylindrical part, the extruded blank is cylindrical, such as image 3 shown. The steps to use the forming process device are:

[0032] The first step: fix the upper mold seat cover 6, the punch 9 and the backing plate 7 on the upper template 8 by bolts;

[0033] Step 2: Fix the upper template 8 to the slider of the hydraulic press, and fix the lower template 2 to the workbench of the hydraulic press;

[0034] The third step: install the rolling bearing 3 in the groove of the lower template 2;

[0035] Step 4: Fix the lower die 4 on the lower template 2;

[0036] Step 5: Install the rotating head 1 on the rolling bearing 3, and place it in th...

example 2

[0043] Example 2: Combine Figure 6 To illustrate this embodiment, in the twisting-extrusion compound strong-plastic forming process device for magnesium alloy plate-shaped parts, the extruded blank is a square block, such as Figure 7 shown. The combined die of this example is composed of an upper die 5 and a lower die 4; the combined die is fixed on the lower template 2 through the lower mold seat cover 12, and when the blank 10 is extruded, the extrusion speed is V 2 , the rotational speed of the rotating head is W 2 , the metal at the lower end of the billet 10 is subjected to the torsional shearing action of the rotary head 1, and can obtain a fine-grained structure. As the extrusion deformation continues, the metal begins to flow along the concave mold cavity to both sides, forming a plate 13, as Figure 8 shown.

example 3

[0044] Example 3: In the seventh step of this example, the blank 10 is aluminum and its alloys, titanium and its alloys, and a light metal material that is difficult to deform and has better plasticity.

[0045] It should be noted that the specific type of components with complex features depends mainly on the cavity characteristics of the combined die.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com