A method for rolling copper-aluminum double-layer composite board

A clad plate and aluminum plate technology, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of large residual stress, low degree of mechanization and uneven surface of copper-aluminum double-layer clad plate, and achieve the elimination of metal plasticity. The difference in deformation, the effect of improving the compounding rate, and the simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

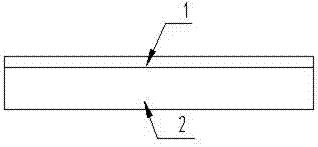

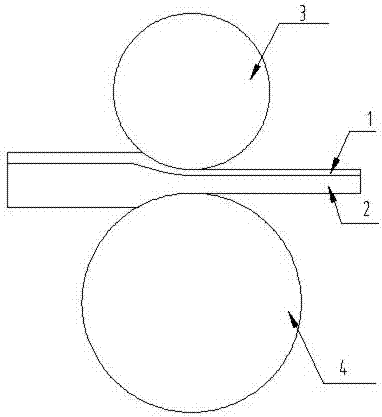

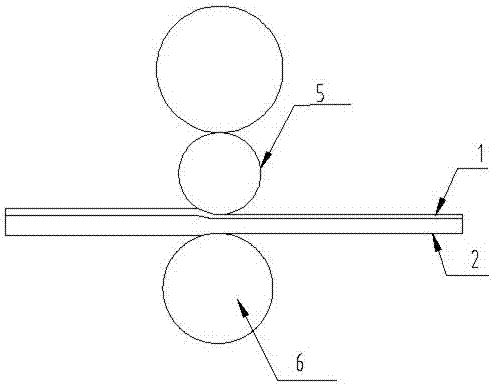

[0030] Embodiment 1: The preparation of L3 aluminum plate-T2 copper plate double-layer medium-thick composite plate has the following steps.

[0031] Billet making: select the copper plate 1 and aluminum plate 2 in the homogenized annealed state to form blanks according to the ratio of 1:4, the size of the copper plate 1 is 5 mm thick * 1000 mm wide * 2000 mm long; the size of the aluminum plate 2 is 20 mm thick * 1000 mm wide * 2000 mm long; the copper plate 1 with 10% H 2 SO 4 Solution soaking and drying, the aluminum plate (2) is soaked and dried with 5% NaOH solution; use a wire brush to clean the composite surface of the copper plate 1 and the aluminum plate 2 until the metal base is seen; stack the copper plate 1 and the aluminum plate 2 Compression, use a drilling machine to drill two holes symmetrically in the width direction of the rolling bite end. In the width direction, the distance between the holes and the symmetrical line is 350mm, and in the rolling direction,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com