Ultrasonic vibration assisted friction welding method

A technology of ultrasonic vibration and friction welding, used in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as poor strength of welded joints, and achieve the effect of improving strength, effective connection, and promoting plastic deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

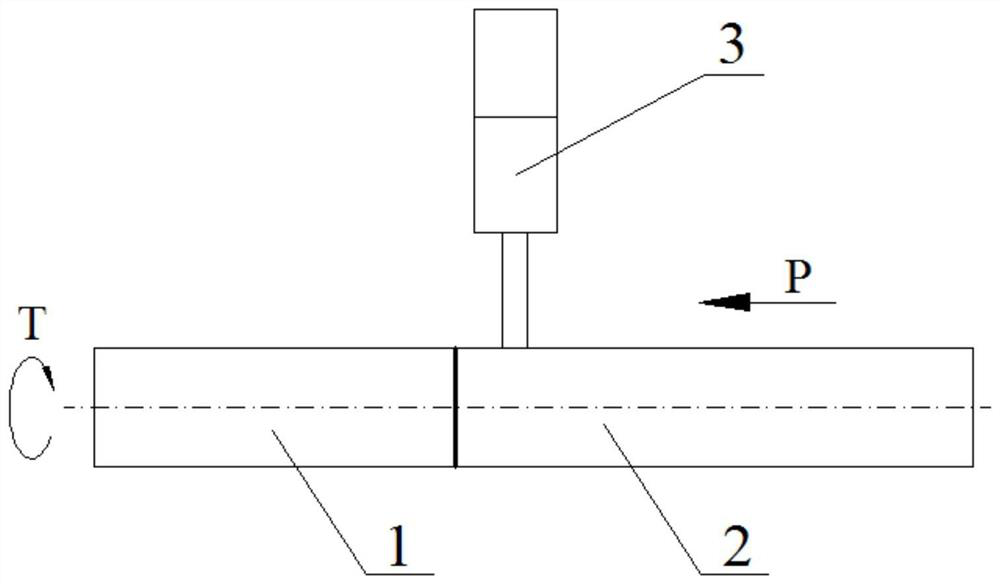

[0024]Example 1: Referencefigure 1 The specific steps of the ultrasonic vibration assisted friction welding method of this embodiment are as follows:

[0025]Step 1. Clamp the rotating end work piece 1 and the moving end work piece 2 respectively on the rotating fixture and the moving fixture of the rotary friction welding machine;

[0026]Step 2. The rotary friction welding machine drives the rotating end workpiece 1 to rotate through the spindle motor and the rotating fixture, and the mobile end hydraulic system drives the mobile end workpiece 2 through the sliding table and the mobile fixture to gradually approach and press on the high-speed rotating rotating end workpiece 1, friction The pressure is 50~350MPa, the friction deformation is 1.0~3.0mm, and the friction time is 3~12s. At the same time, the ultrasonic transducer output head 3 is pressed on the mobile end workpiece 2, and ultrasonic vibration is applied to the mobile end workpiece 2. The frequency is 20-100kHz; when any para...

Embodiment 2

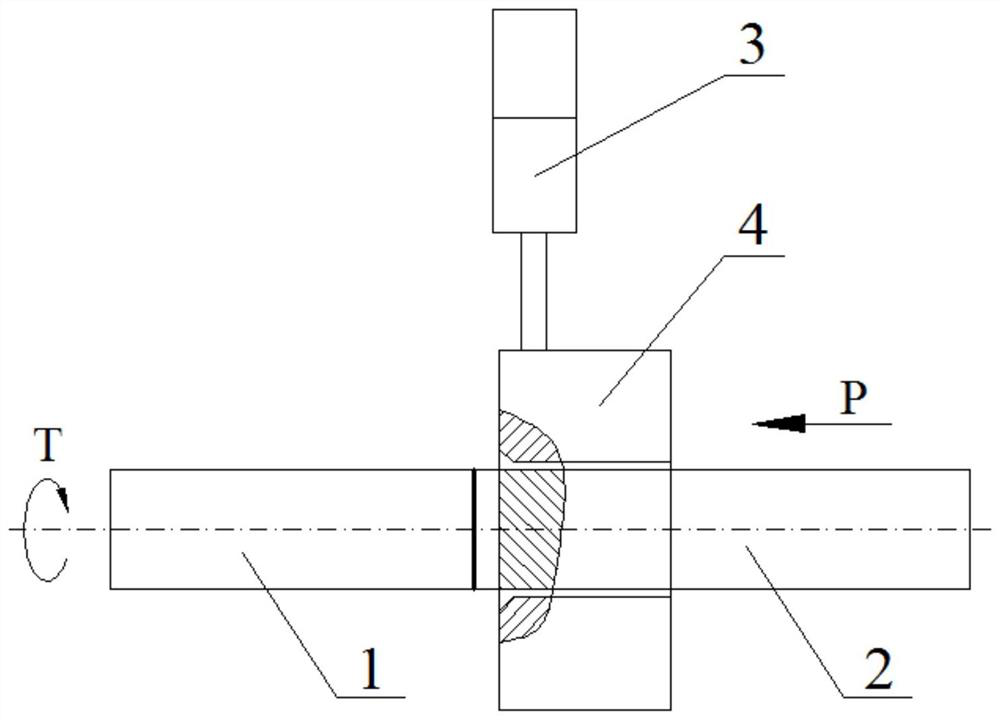

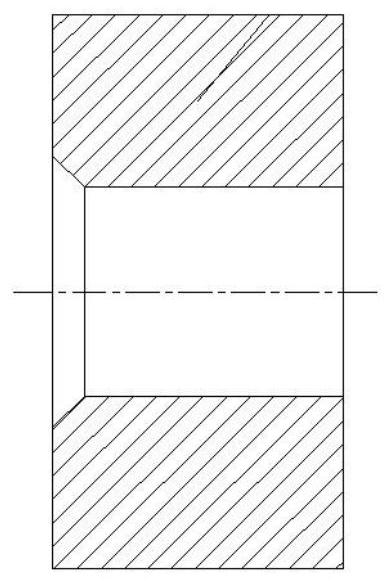

[0027]Example 2: ReferenceFigure 2-3On the basis of embodiment 1, the mobile end workpiece 2 is restricted, and the remaining welding methods are the same. The specific steps of the ultrasonic vibration assisted friction welding method of this embodiment are as follows:

[0028]Step 1. Clamp the rotating end work piece 1 and the moving end work 2 on the rotating fixture and the moving fixture of the rotary friction welding machine respectively, and put the restraint sleeve 4 on the moving end work piece 2, the restraining sleeve 4 and the moving end work piece 2 The gap is 0.2~0.5mm, and the welding surface of the workpiece 2 at the moving end extends out of the restraint sleeve 4 by 4.0~4.2mm;

[0029]Step 2. The rotary friction welding machine drives the rotating end workpiece 1 to rotate through the spindle motor and the rotating fixture, and the mobile end hydraulic system drives the mobile end workpiece 2 through the sliding table and the mobile fixture to gradually approach and pres...

Embodiment 3

[0030]Example 3: ReferenceFigure 4 On the basis of Example 1, the rotary friction welding machine was replaced with a linear friction welding machine, and the rotary clamp was replaced with a vibration clamp. The specific steps of the ultrasonic vibration assisted friction welding method of this embodiment are as follows:

[0031]Step 1. Clamp the vibrating end workpiece 5 and the mobile end workpiece 2 on the vibrating fixture and the mobile fixture of the linear friction welding machine respectively;

[0032]Step 2. The linear friction welding machine drives the workpiece 5 at the vibrating end to vibrate up and down with high frequency and small amplitude through the vibrating end hydraulic system and the vibrating fixture. The vibration frequency is 20-60 Hz and the amplitude is 1 to 3 mm; the mobile end hydraulic system passes through the sliding table and The mobile fixture drives the mobile end workpiece 2 to gradually approach and press on the reciprocating vibration end workpiece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com