Medium thick plate continuously casting and head-less rolling process

An endless rolling and continuous casting technology, which is applied in the field of metallurgical steel rolling, can solve the problems of low production efficiency, long process flow, low yield, etc., achieve less water consumption, help control rolling, and improve metal yield rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

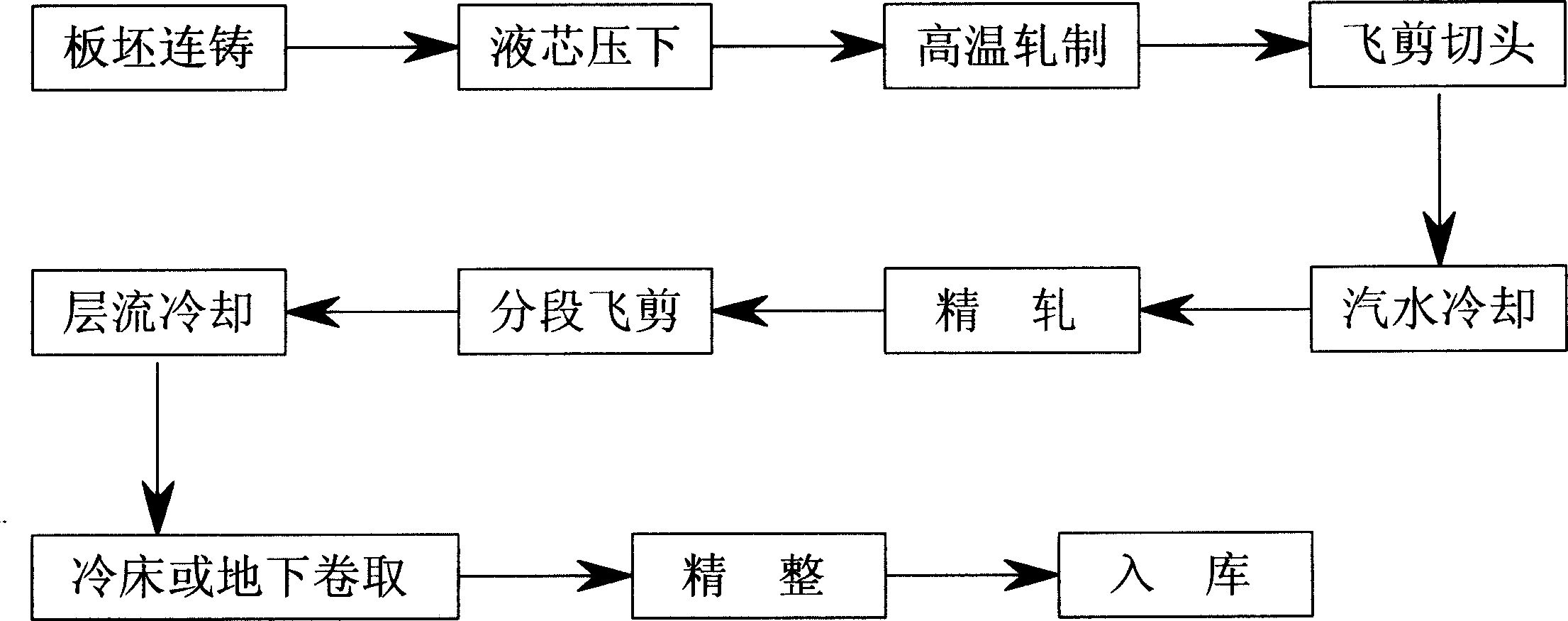

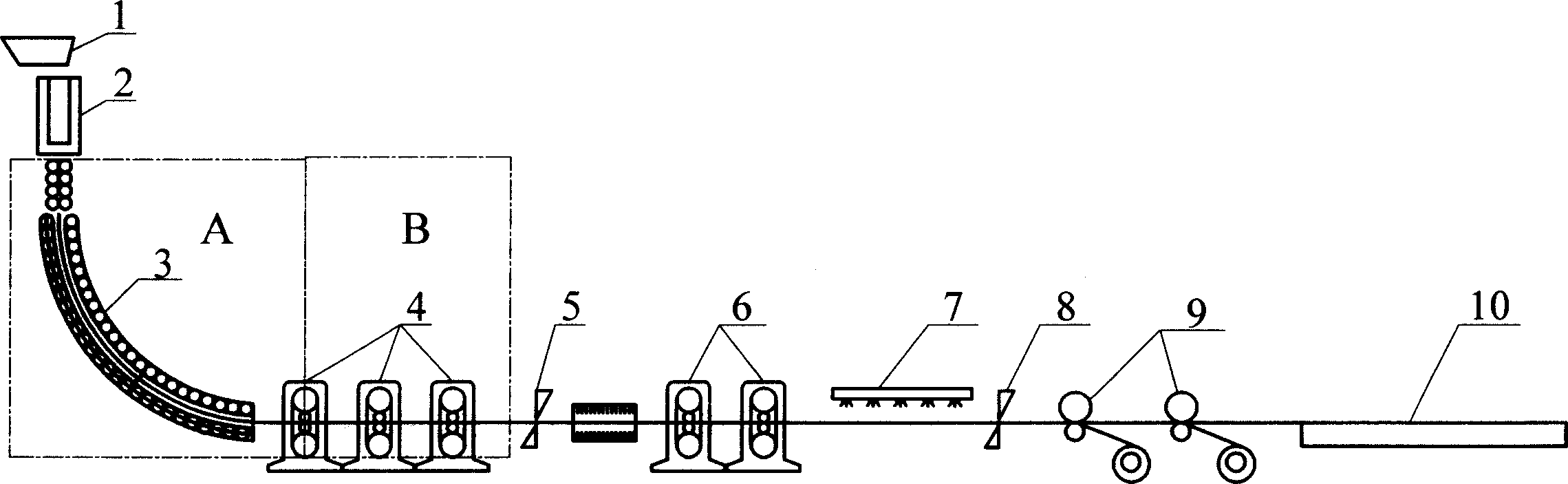

[0022] See figure 1 , the continuous casting endless rolling medium and heavy plate process of the present invention, its technological process is: slab continuous casting→liquid core pressing→high temperature rolling→flying shear head→steam water cooling→finish rolling→segmented flying shear→ Laminar cooling → cooling bed or underground coiling → finishing → storage.

[0023] The specific process is: pour the molten steel through the tundish 1 into the crystallizer 2 for pouring, and then enter the cooling section 3 of zone A, and use nitrogen protection to control cooling, and the surface temperature of the billet will drop to 1200 ° C. According to the following technology, the continuous casting slab is thinned by 15mm, and then the slab directly enters the rough rolling unit 4 in the B area for rolling, and the steam-water cooling 6 is used in the B area to control the surface temperature of the slab. Cut off the cut head brought by the dummy ingot, and then enter the fi...

Embodiment 2

[0025] Embodiment 2 is basically the same as Embodiment 1, the difference is that the start rolling temperature of rough rolling is 1050°C and the finish rolling temperature is 900°C controlled by steam-water cooling device; The temperature of the thick plate was reduced to 600°C.

Embodiment 3

[0027] Embodiment 3 is basically the same as Embodiment 1, the difference is that the start rolling temperature of rough rolling is 1100°C and the finish rolling temperature is 930°C controlled by steam-water cooling device; The temperature of the slab dropped to 620°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com