Patents

Literature

99results about How to "Reduce rolling passes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Superhigh-strength high-toughness steel plate for ocean engineering and production method thereof

The invention discloses a superhigh-strength high-toughness steel plate for ocean engineering and a manufacturing method thereof. The superhigh-strength high-toughness steel plate comprises the following chemical components in percentage by weight: 0.06-0.10% of C, 0.20-0.40% of Si, 1.10-1.65% of Mn, at most 0.010% of P, at most 0.0020% of S, 0.030-0.050% of Nb, 0.020-0.060% of V, 0.006-0.015% of Ti, 0.60-1.30% of Ni, 0.30-0.60% of Cr, 0.20-0.60% of Cu, 0.40-0.60% of Mo, 0.020-0.040% of Alt, and the balance of Fe and inevitable impurities. The production method comprises the following steps: smelting in a converter, rolling on a Steckel reversing mill, and finally carrying out hardening and tempering heat treatment by a TMCP (thermomechanical rolling process) technique. The steel plate has favorable properties: the tensile strength is 770-840 MPa, the yield strength is 710-800 MPa, the elongation percentage is 16-19%, the -40 DEG C low-temperature lateral impact and low-temperature ageing impact properties are greater than or equal to 90J, and the cold bending resistance is qualified; and thus, the steel plate has the advantages of ultrahigh strength, excellent low-temperature impact and low-temperature ageing impact properties, and stable production technique.

Owner:NANJING IRON & STEEL CO LTD

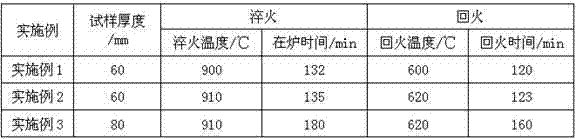

Manufacture method of extremely thick ocean engineering steel plate with low compression ratio and super high-strength strain age

ActiveCN103031498AReduce the compression ratioReduce rolling passesUltimate tensile strengthMechanical engineering

The invention discloses a manufacture method of an extremely thick ocean engineering steel plate with low compression ratio and super high-strength strain age, which performs reasonable setting and optimization to controlled rolling and controlled cooling technology through converter smelting, LF and RH refining, so as to perform quenched-tempered heat treatment. The steel plate has good performance, the tensile strength is 780 to 850 MPa, the yield strength is 720 to 800 MPa, the percentage of elongation is 18 to 21 percent, the low-temperature transverse impact at minus 40 DEG C is larger than or equal to 120J, the low-temperature aging impact property at minus 40 DEG C is larger than or equal to 100J, the steel plate has ultrahigh strength, high tenacity and excellent low temperature aging tenacity, and the production technology is stable.

Owner:NANJING IRON & STEEL CO LTD

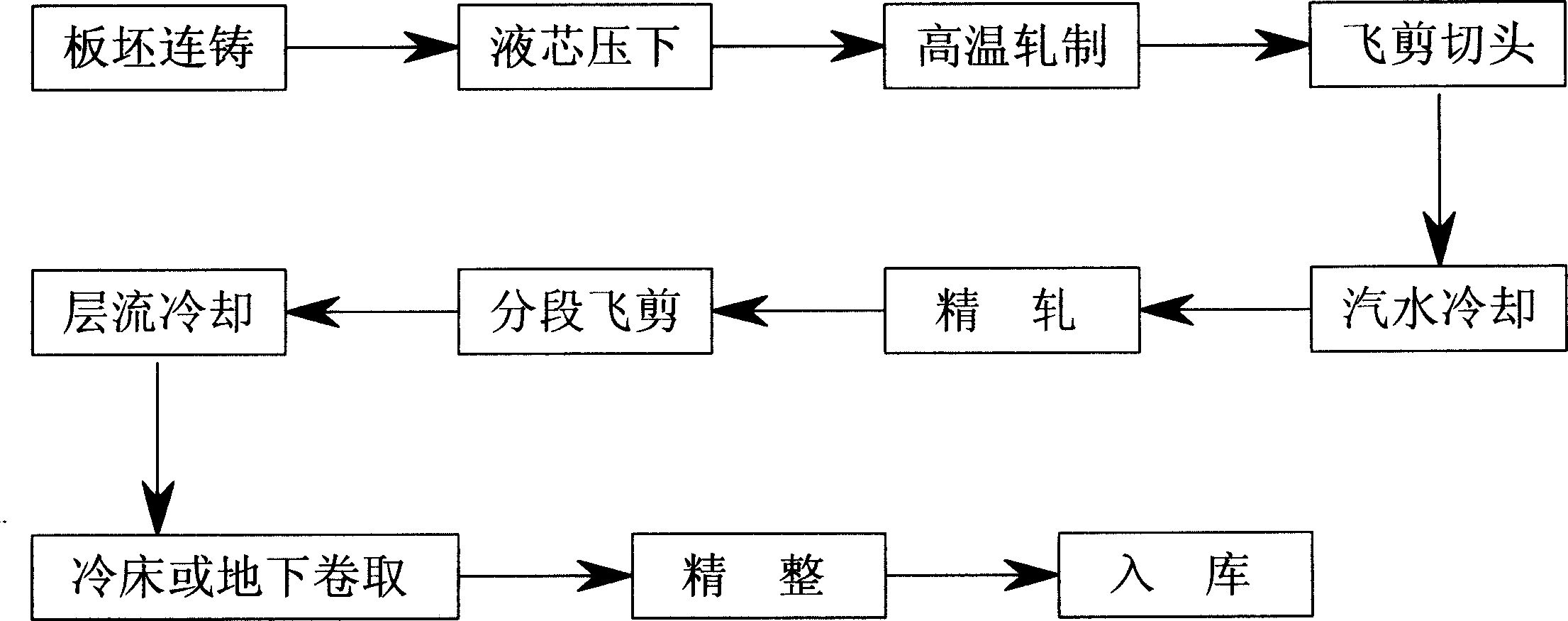

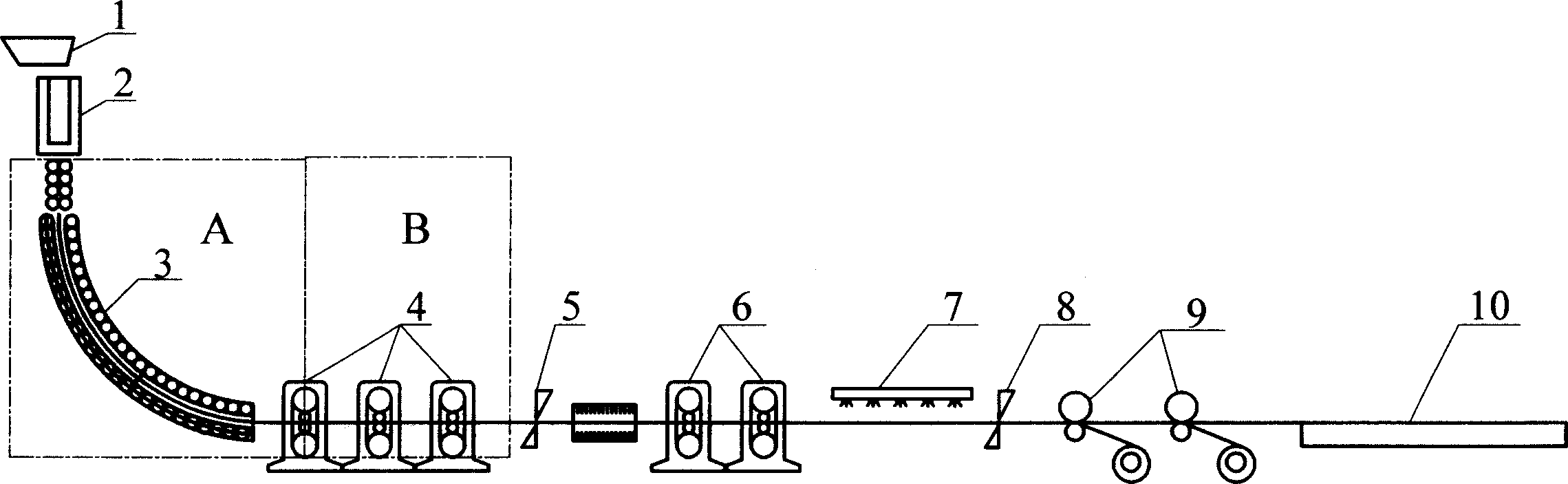

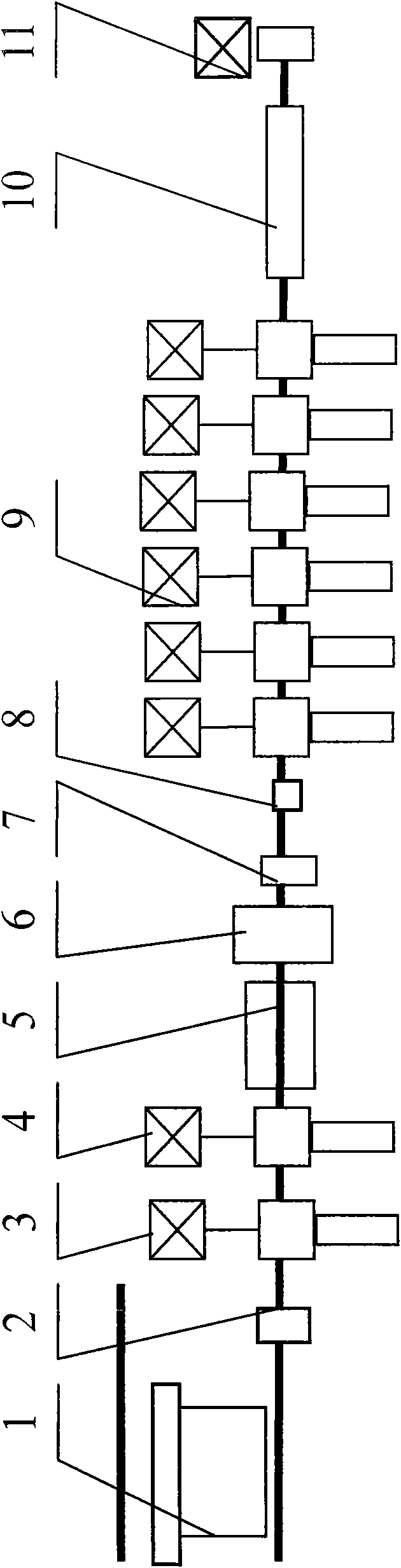

Medium thick plate continuously casting and head-less rolling process

The continuously casting and head-less rolling process for moderately thick plate includes the following steps: continuously casting plate blank, depressing liquid core, high temperature rolling, end cutting with flying shear, steam water cooling, finish rolling, sectional shearing, laminated cooling, cold bed or ground winding, finishing and warehousing. The present invention has raised metal yield, lowered fuel and power consumption, low end cutting rate, less rolling gates, and high output and finished product rate.

Owner:SHENYANG STEEL

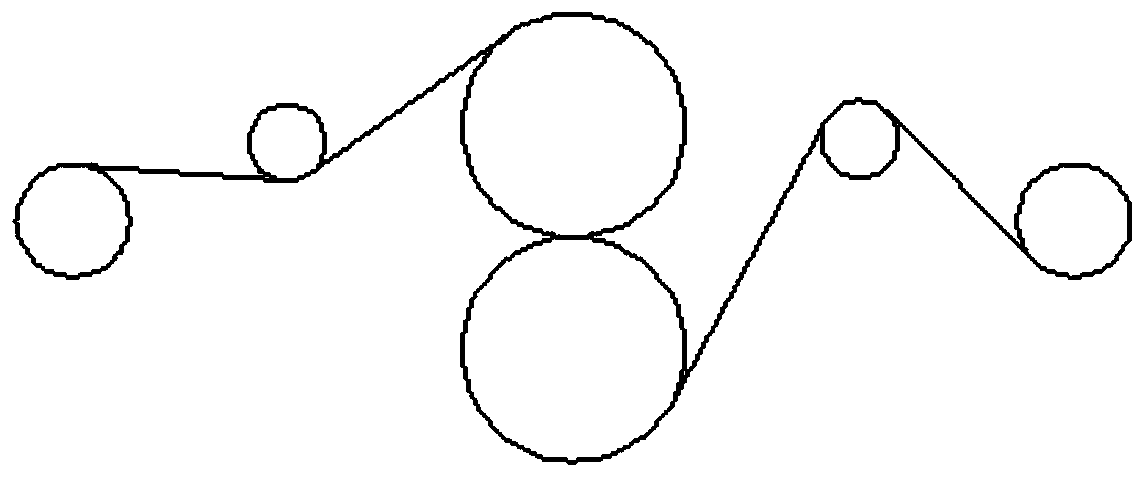

Two-roller reversible mill roller device and technology using continuous casting round billets for carrying out rolling production

ActiveCN103801560AIncrease the amount of steelImprove rolling yieldRollsMetal rolling arrangementsOne passMetallurgy

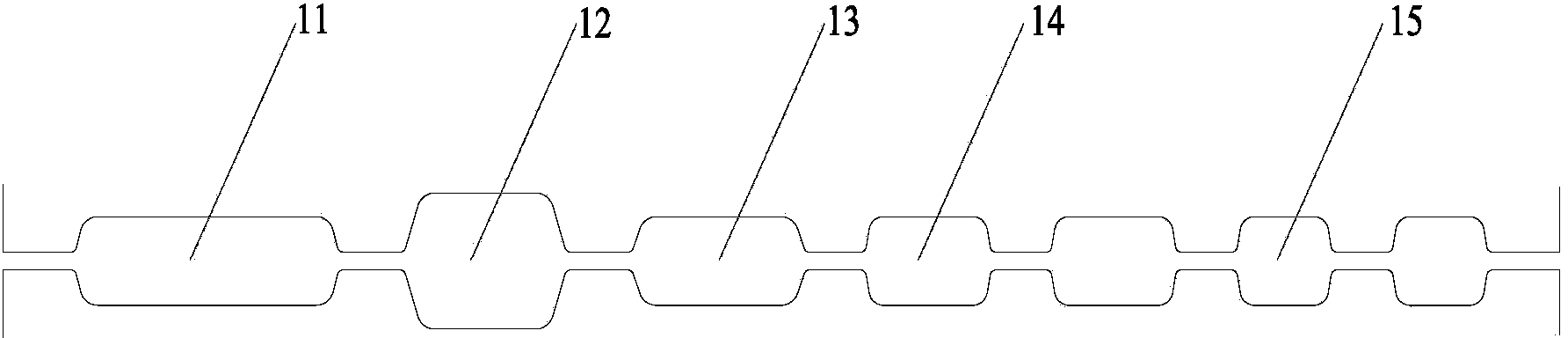

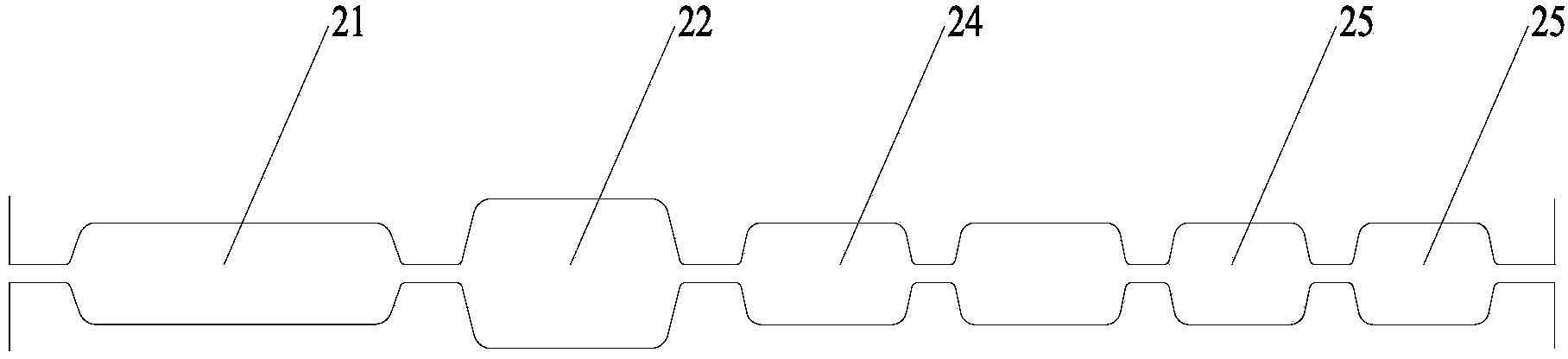

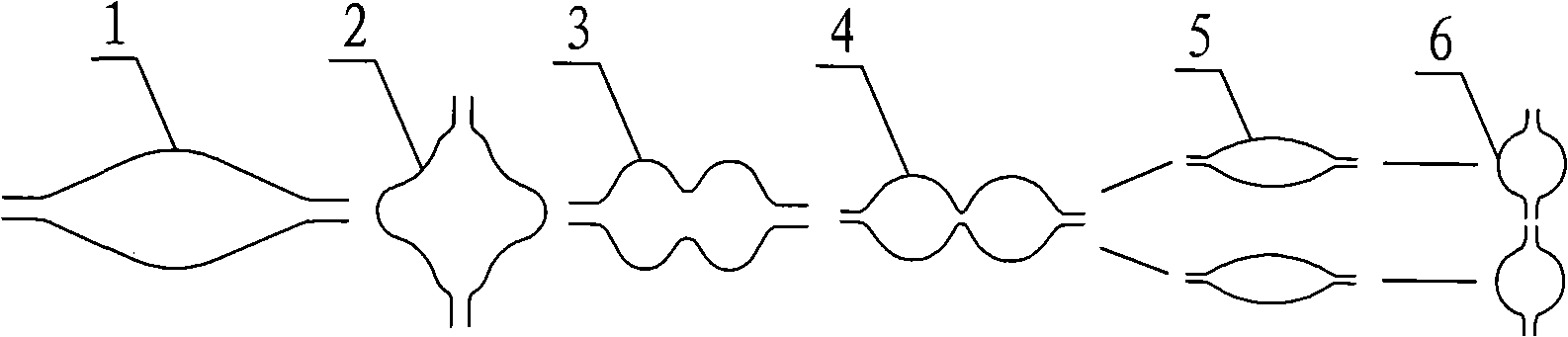

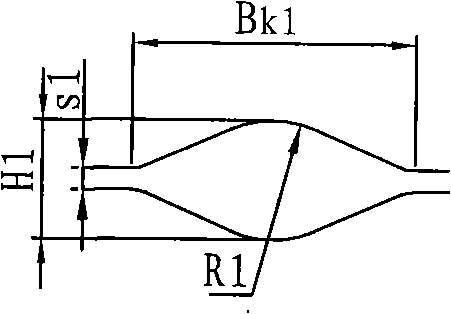

The invention discloses a two-roller reversible mill roller device and technology using continuous casting round billets for carrying out rolling production. Four types of hole patterns including a transition hole pattern, a supporting hole pattern, a before-finished-product hole pattern and a finished product hole pattern are designed on a pair of rollers. The rolling technology comprises the steps of using the transition hole pattern (1) for rolling the continuous casting round billets, and turning over steel after rolling is accomplished, wherein the rolling reduction ranges from 40 mm to 90 mm per pass; using the supporting hole pattern for continuously rolling the drum-shaped rolled pieces obtained in the previous step to obtain rectangular or square rolled pieces which have regular shapes, and turning over the steel after rolling is accomplished, wherein the rolling reduction ranges from 40 mm 90 mm per pass; using the before-finished-product hole pattern (3) for rolling the rolled pieces to obtain rectangular or oval rolled pieces with reserved rolling reduction and reserved broadening quantity, and turning over the steel billets after rolling is accomplished, wherein the rolling reduction ranges from 20 mm to 90 mm per pass; using the finished product hole pattern for rolling one pass to obtain rolled pieces which are high in dimensional accuracy and product quality, wherein the rolling reduction of square or rectangular steel finished products ranges from 40 mm to 60 mm per pass, and the nominal rolling reduction of round steel ranges from 10 mm to 40 mm per pass.

Owner:HUATIAN ENG & TECH CORP MCC

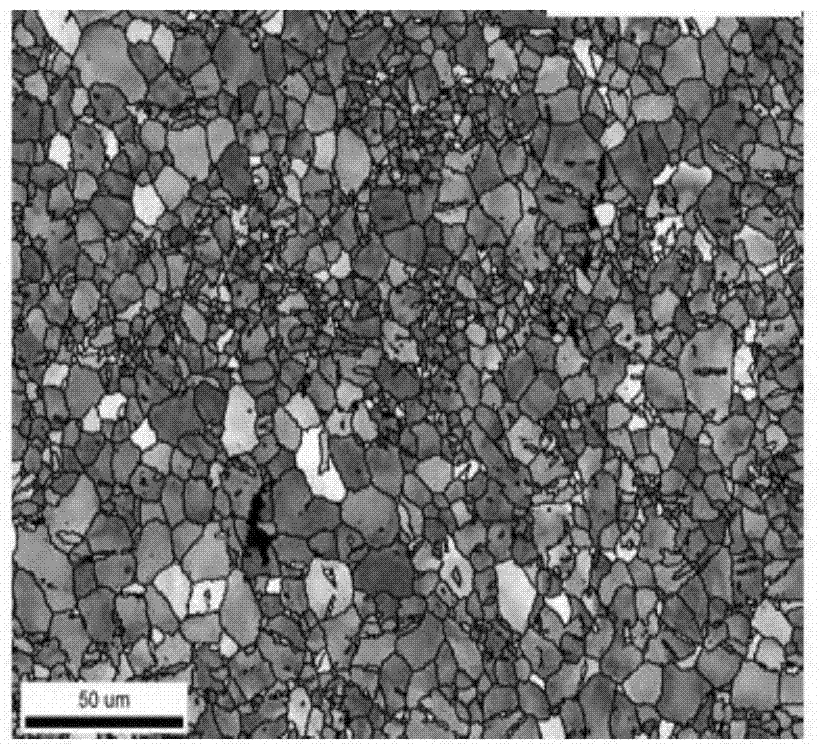

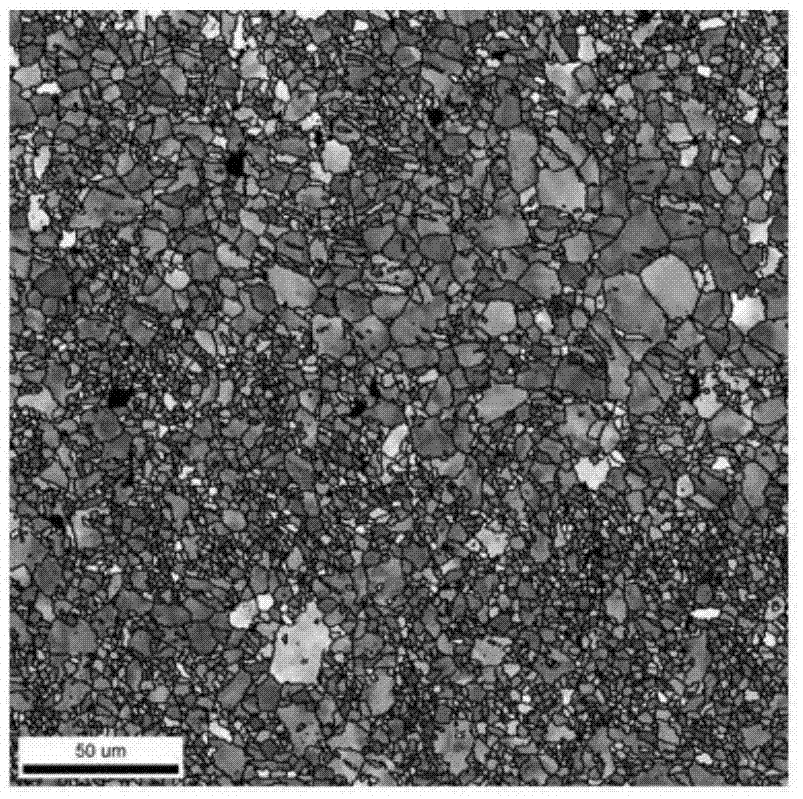

Large reduction rolling method for magnesium alloy

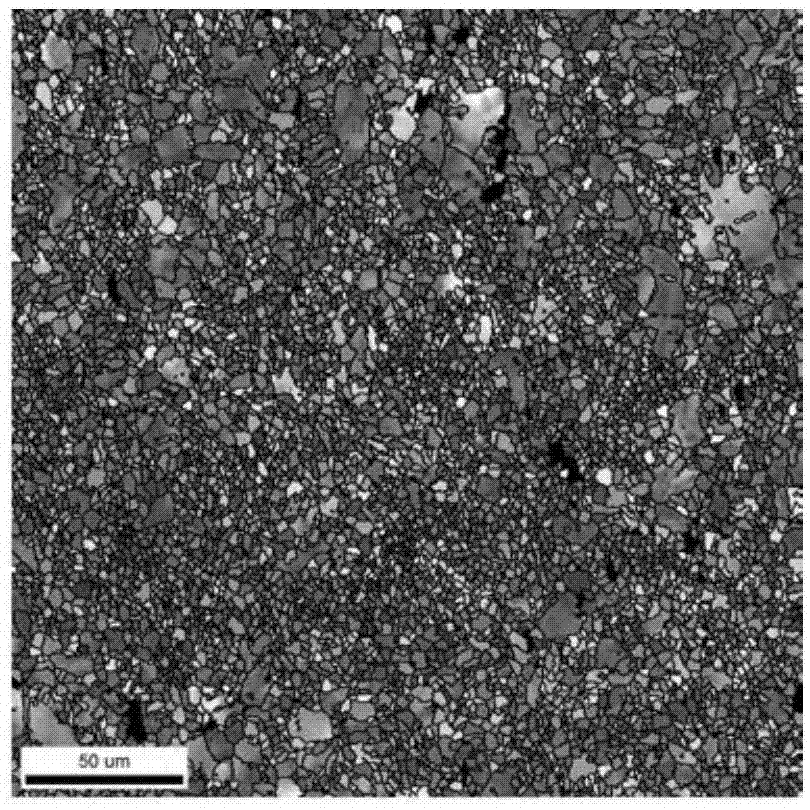

ActiveCN103962376AIncrease single pass reductionReduce rolling passesAuxillary arrangementsMetal rolling arrangementsThermal insulationManganese

The invention relates to a large reduction rolling method for magnesium alloy. According to the rolling method, a hard alloy lining plate is additionally arranged on the upper surface or the lower surface of the magnesium alloy, or two hard alloy lining plates are additionally arranged on the upper surface and the lower surface of the magnesium alloy at the same time, and the added hard alloy lining plates are rolled synchronously together with the magnesium alloy. The rolling method includes the steps that after a high temperature lubricating agent is evenly smeared on the surfaces of the lining plates and the surface of the magnesium alloy, the high temperature lubricating agent, the lining plates and the magnesium alloy are simultaneously placed into a heating box to be heated, after the temperature rises to a preset temperature, standing and thermal insulation are performed for a certain period of time, one hard alloy lining plate is placed on the upper surface or the lower surface of magnesium alloy blank, or the two hard alloy lining plates are placed on the upper surface and the lower surface of the magnesium alloy at the same time, and the hard alloy lining plates and the magnesium alloy are simultaneously fed into the position between rollers so that rolling can be completed. Through the method, the single pass reduction of the magnesium alloy can be greatly increased in the rolling process, the number of rolling passes is decreased, magnesium alloy crystalline grains are thinned, the texture is weakened, magnesium alloy plates with high strength and plasticity are prepared, and the large reduction rolling method for the magnesium alloy is also suitable for the large deformation rolling process of titanium, manganese and metal-matrix composite materials.

Owner:JILIN UNIV

Manufacturing method of thick-walled titanium tube

ActiveCN102240890AEasy to prepareReduce manufacturing costRoll force/gap control deviceIngotTitanium

The invention discloses a manufacturing method of a thick-walled titanium tube. The method comprises the following steps: firstly preparing a cast ingot; forging the cast ingot, processing, then extruding to form a tube blank, and further performing acid cleaning; rolling the tube blank after acid cleaning, and sequentially performing deoiling treatment and recrystallization annealing treatment on the rolled tube blank after rolling every time; after rolling, further rolling the rolled tube blank again to obtain a finished tube product; and finally performing annealing treatment on the finished tube product, and performing acid cleaning to remove oxide skins on the inner surface and the outer surface so as to obtain the Gr.3 thick-walled titanium tube. The Gr.3 thick-walled titanium tube manufactured by adopting the method is excellent in performance, the tensile strength is not less than 500MPa, the yield strength is 380-550MPa, the elongation rate is not less than 20%, the ratio of the outer diameter of the tube to the wall thickness is 5-10, and the inner surface and the outer surface are better in quality and can meet the requirements of ASTM (American society for testing and materials) B 338, thereby meeting the requirements of tubes for industrial fields such as pressure vessels, condensers, heat exchangers and the like.

Owner:WESTERN TITANIUM TECH

Technique for rolling figured steel for magnetic suspension train rail

ActiveCN101214494ALow costIncrease productivityRoll force/gap control deviceTemperature control deviceProduction lineThermal treatment

The invention belongs to the technology field of metal thermal treatment, which relates to the rolling technology of deformed steel used for a maglev train rail. The invention comprises the procedures in turn of rough rolling, finishing rolling, coolant-controlling and straightening, which is characterized in that two reversible mills rolling is adopted for rough rolling and the maximum rolling force of a two reversible mill is 8000 to 10000KN. And the rolling deformation should account for 60 to 90 per cent of total deformation. Three-stand universal continuous rolling line with high rolling force and high accuracy is adopted for finishing rolling to realize mixing roll under universal mode. The invention can merely use large H-shaped hot- rolling production line to produce finished products and does not require thermal treatment and machining process, with the result that the cost can be greatly reduced and the requirement of mass production can be fully satisfied.

Owner:LAIWU IRON & STEEL GRP

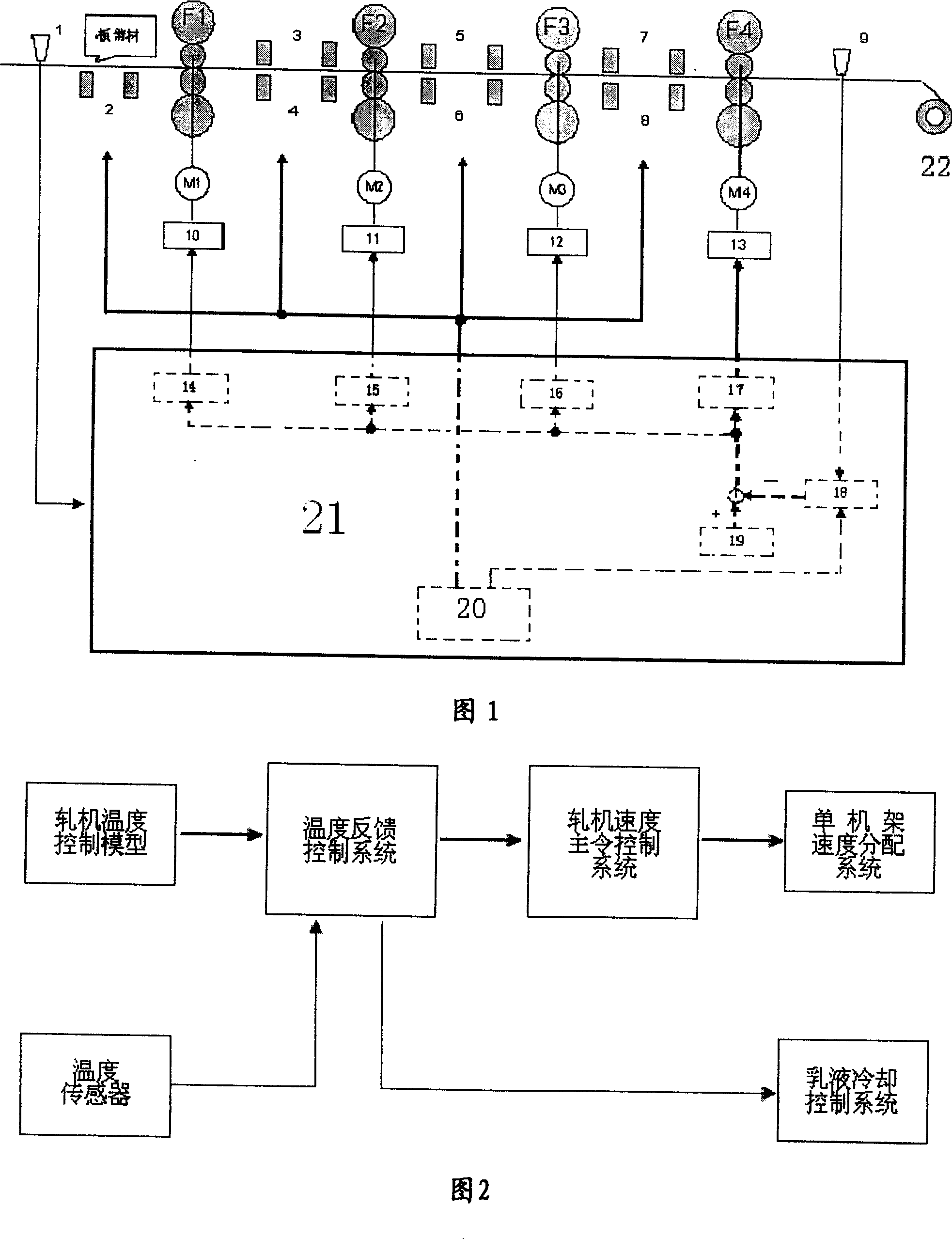

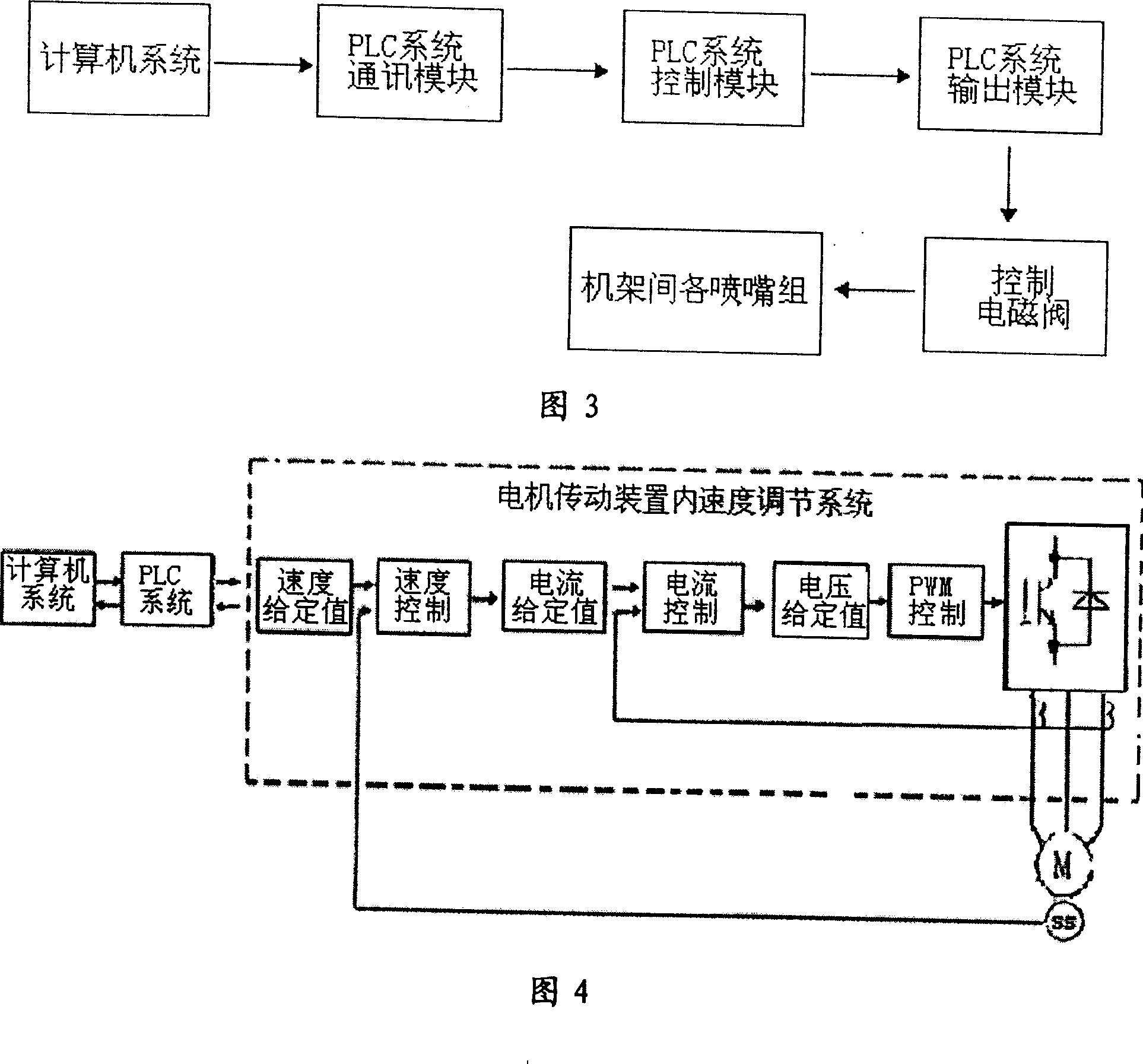

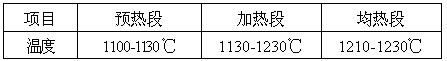

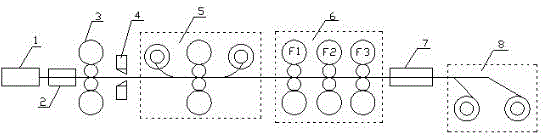

Temperature control system of milling uluminium/aluminium alloy coiled material and control method

InactiveCN100998995ARealize automatic controlIncrease and stabilize rolling temperatureTemperature control deviceAutomatic control5005 aluminium alloy

A temp control system for rolling the coiled Al / Al-alloy material is composed of the second-class computer system in a computer system, a tandem mill speed control system, and a temp feedback control system. It features that the front probe of front-end temp sensor is arranged in the front of the first rolling mill and connected to computer system, the rear probe of rear-end temp sensor is arranged behind the fourth rolling mill and connected to second-class computer system via temp feedback control system, the electromagnetic valves for controlling cooling liquid nozzles are connected to computer system, and the given speed values are provided by the speed distributing system.

Owner:中铝西南铝板带有限公司

Super duplex stainless steel S32750 medium plate rolling process

ActiveCN103286128AGuaranteed heating timeGuaranteed surface qualityTemperature control deviceMetal rolling arrangementsSheet steelHigh pressure water

The invention discloses a super duplex stainless steel S32750 medium plate rolling process which includes blank selection, heating, high-pressure water descaling, two-roll rough rolling, and four-roll finish rolling. By increasing heating temperature, reducing rolling pass, and increasing finish rolling temperature of steel plates, edge cracks and partial cracks on the surface of the steel plates are reduced, medium plate rejection rate is lowered, rolling yield is increased, and contract fulfillment rate is increased.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

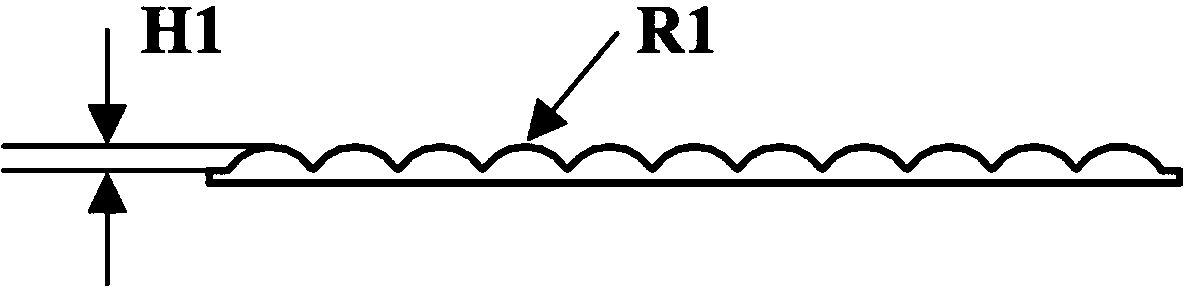

Non-groove rolling method for high speed wire bar intermediate rolling train

InactiveCN101152654AImprove work rateImprove productivityRoll force/gap control deviceTemperature control deviceReduction rateWire rod

The invention discloses a non-groove rolling method for high speed wire rod roughing mill group and mainly solves rolling technical problem of the high speed wire rod roughing mill group. The non-groove rolling method comprises two pass non-groove rolling, four pass non-groove rolling or six pass non-groove rolling; the ratio of height and width of the rolling component is 0.90 to 1.58, reduction rate of pass is 15 percent to 45 percent, rolling temperature is 1000 celsius degree to 1100 celsius degree, the adaptation range of blank is 120*120mm to 180*180mm, and the absolute spread coefficient range is 0.25 to 0.45. The invention adopts a pass-free flat roller to replace a rough rolling pass roller of the prior art and realizes non-groove rolling of the high speed wire rod roughing mill group. The invention aims to provide the non-groove rolling method for the high speed wire rod roughing mill group adopting the flat roller to replace the rough pass roller, meanwhile, decreasing production cost, improving product quality and productivity of the mill and expanding the adaptation range of blank.

Owner:BAOSHAN IRON & STEEL CO LTD +1

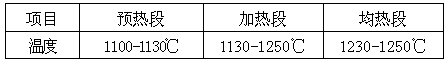

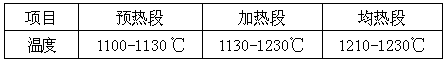

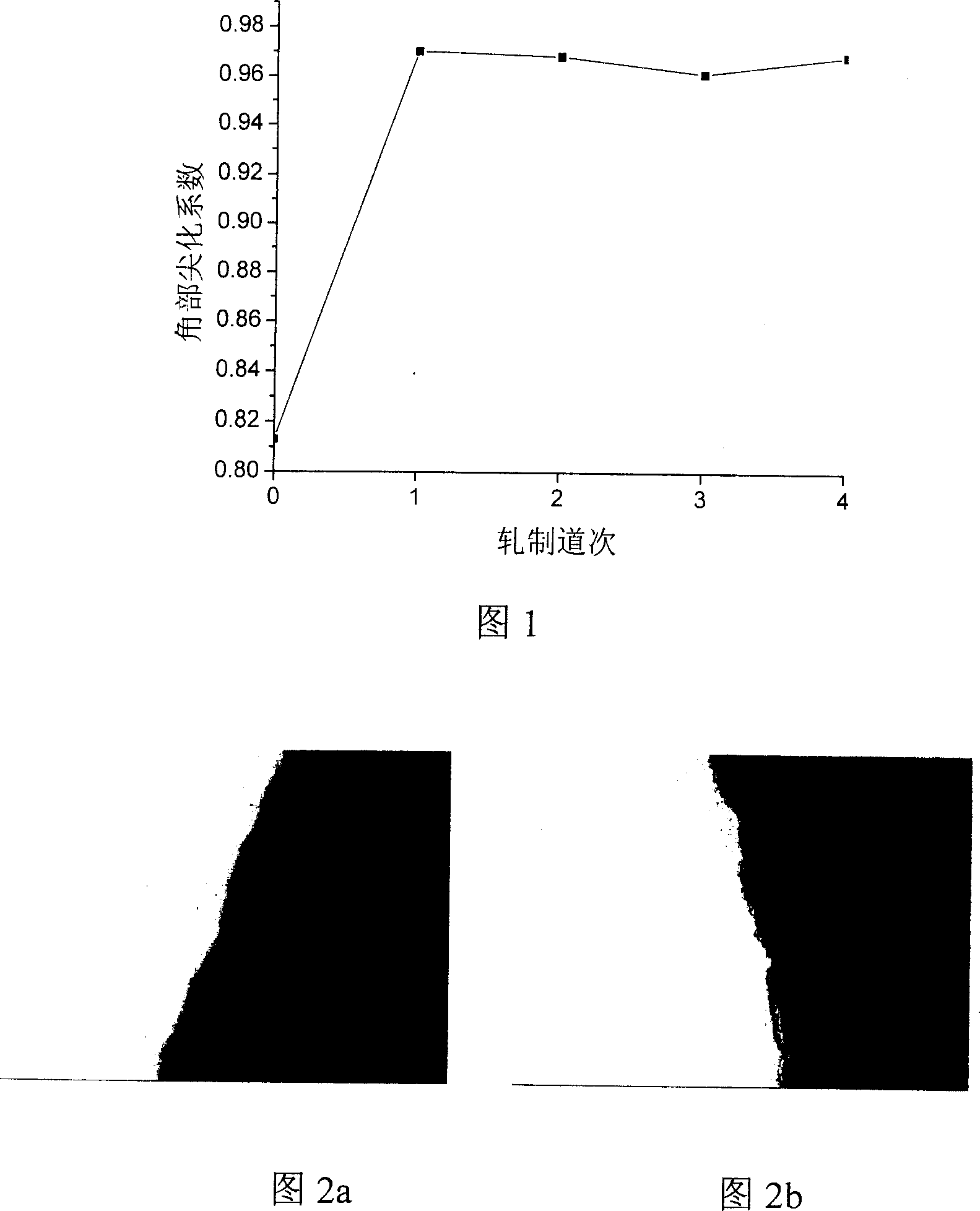

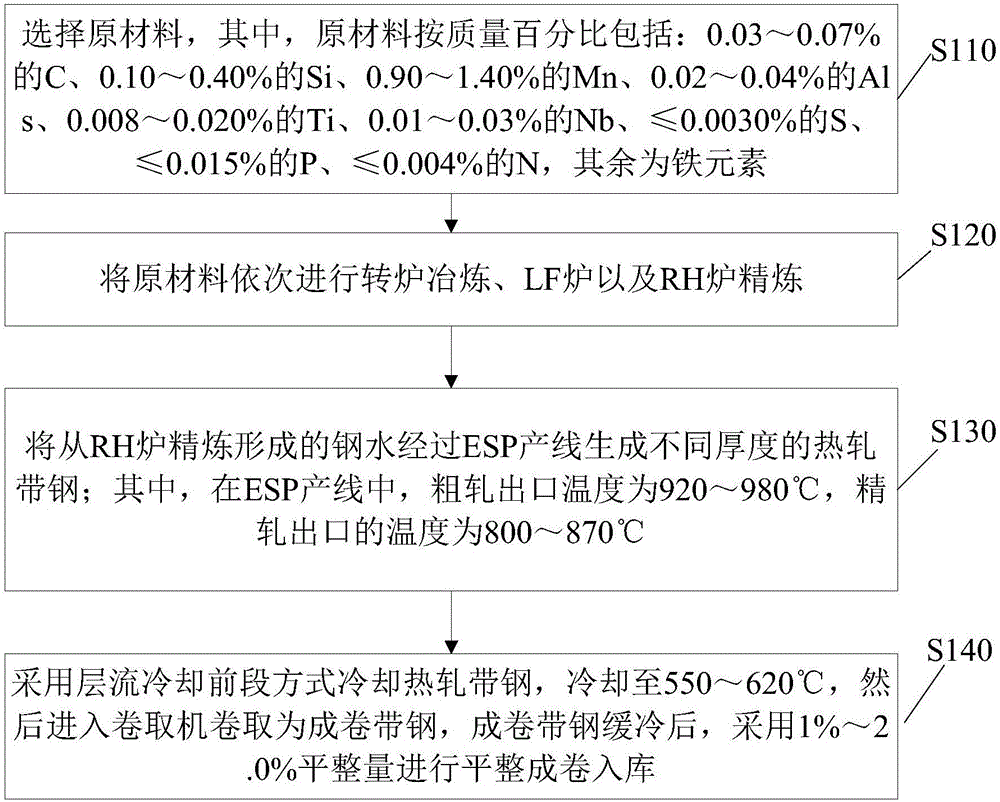

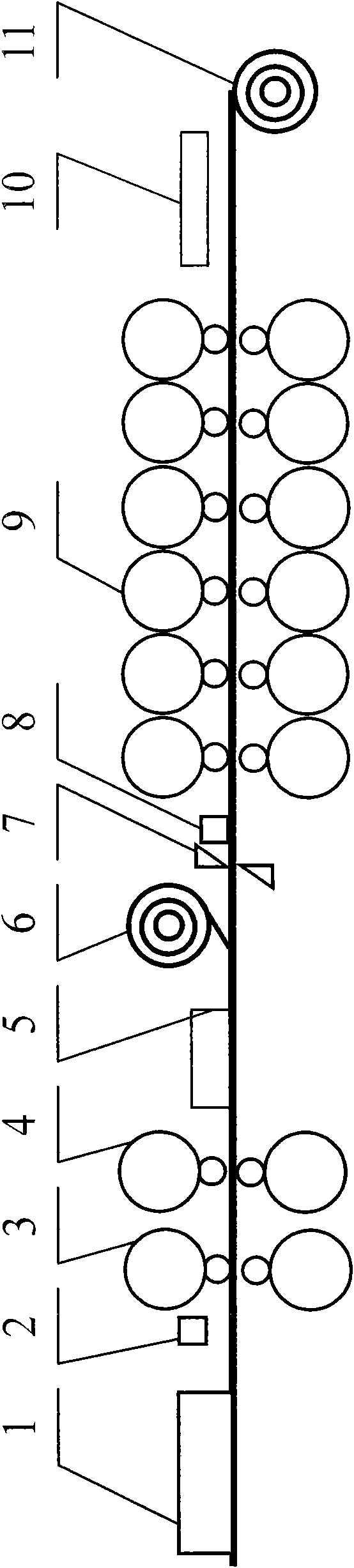

Method for producing RE510L steel of thin specification based on ESP sheet billet continuous coasting and rolling procedure

ActiveCN106834887ASolve the costSolve the problem of energy consumptionMetal rolling arrangementsProduction lineStrip steel

The invention provides a method for producing RE510L steel of a thin specification based on an ESP sheet billet continuous coasting and rolling procedure. The method includes the steps that raw materials are selected, and the raw materials comprise, in percentage by mass, 0.03-0.07% of C, 0.10-0.40% of Si, 0.90-1.40% of Mn, 0.02-0.04% of Als, 0.008-0.020% of Ti, 0.01-0.03% of Nb, less than or equal to 0.0030% of S, less than or equal to 0.015% of P, less than or equal to 0.004% of N and the balance Fe elements; the raw materials are subjected to converter smelting and LF furnace and RH furnace refining; molten steel formed through RH furnace refining generates hot rolling strip steel of different thicknesses through an ESP production line; in the ESP production line, the rough rolling outlet temperature is 920-980 DEG C, the finish rolling outlet temperature is 800-870 DEG C; the hot rolling strip steel is cooled in a front segment laminar flow cooling manner, and the hot rolling strip steel is cooled to 550-620 DEG C and then enters a recoiling machine to be coiled into coiled strip steel; and after the coiled strip steel is cooled, leveling, coiling and entering warehouse are performed by adopting the leveling quantity of 1-2.0%. By means of the method, problems that traditional hot rolling is high in cost, energy consumption is large and the like are solved.

Owner:RIZHAO STEEL HLDG GROUP

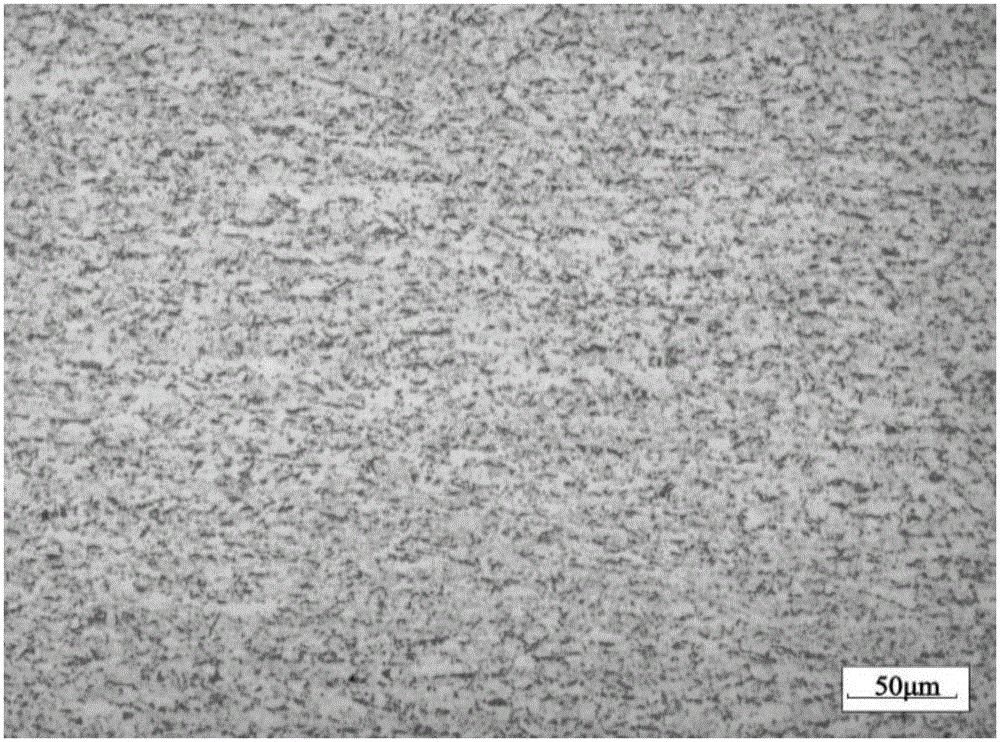

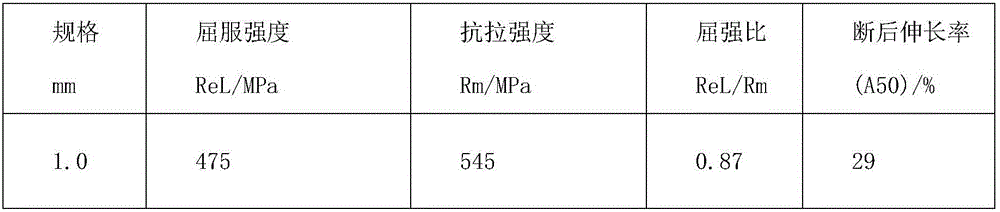

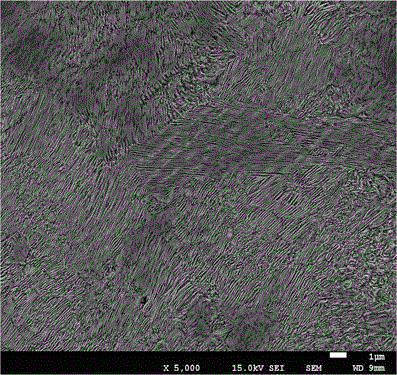

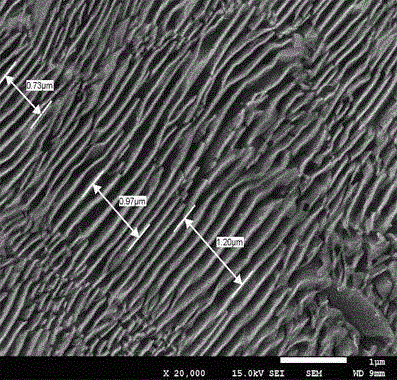

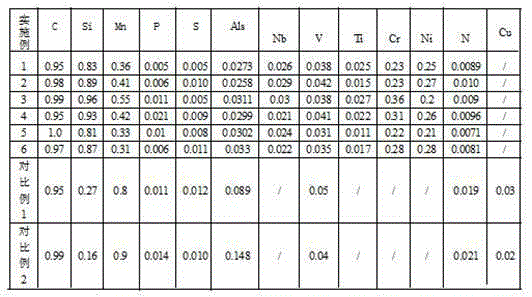

High-strength bridge cable steel with pearlite inter-lamellar spacing smaller than 150nm and production method

The invention relates to a high-strength bridge cable steel with pearlite inter-lamellar spacing smaller than 150nm. The high-strength bridge cable steel with pearlite inter-lamellar spacing smaller than 150nm is prepared from the following chemical components by weight percentage: 0.95 to 1.0 percent of C, 0.8 to 1.0 percent of Si, 0.3 to 0.6 percent of Mn, less than or equal to 0.025 percent of P, , less than or equal to 0.025 percent of S, 0.030 to 0.045 percent of V, 0.025 to 0.035 percent of Als, 0.010 to 0.03 percent of Ti, 0.2 to 0.4 percent of Cr, 0.2 to 0.3 percent of Ni, 0.02 to 0.03 percent of Nb and 0.007 to 0.010 percent of N. Production processes comprise molten iron desulphurization and converter smelting; argon blowing at argon blowing station; LF refining; RH treatment; steel taping and continuous casting; cogging; heating; rolling; air cooling to room temperature; secondary heating; high-speed rolling; reducing-sizing rolling; spinning; cooling, air cooling to room temperature. The pearlite inter-lamellar spacing of the high-strength bridge cable steel is smaller than 150nm, the alloy recovery rate is high, the steel purity is high, the tensile strength is greater than or equal to 2000MPa, and the tensile strength can be finally improved by 15 percent under the situation of not influencing elongation.

Owner:武汉钢铁有限公司

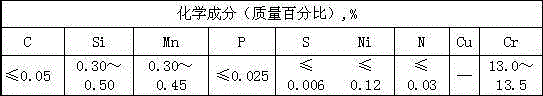

Method and system for rolling 410S ferrite stainless steel

InactiveCN104785521AFulfil requirementsGood effectMetal rolling arrangementsReduction rateSS - Stainless steel

The invention discloses a method for rolling 410S ferrite stainless steel. The method includes the steps of 1, carrying out heating, wherein 410S ferrite stainless steel plate slabs are heated through multi-walking-beam type heating furnaces, the furnace staying time ranges from 180 minutes to 240 minutes, the tapping temperature ranges from 1140 DEG C to 1160 DEG C, and the amount of residual oxygen in the furnaces ranges from 3.0% to 5.0%; 2, carrying coarse rolling, wherein the heated plate slabs are descaled through a plate slab descaling machine to enter a four-roller coarse rolling machine to be rolled seven times to form intermediate slabs, and the reduction rate of each time of coarse rolling ranges from 18% to 30%; 3, rolling intermediate products, wherein after the heads and the tails of the intermediate slabs are cut off through a flying shear cutter, the intermediate slabs enter a steekle mill to be rolled three times to form the intermediate products, the each-time reduction rate of the steekle mill ranges from 32% to 49%, and the temperature of a reeling furnace ranges from 1110 DEG C to 1140 DEG C; 4, carrying out fine rolling, wherein the intermediate products sequentially enter a fine rolling unit to be continuously rolled to be at the finished-product thickness, and the reduction rate of each time of fine rolling ranges from 12% to 28%; 5, cooling finished products. The invention further discloses a system for rolling the 410S ferrite stainless steel. By means of the technological method, the production efficiency is high, the product quality is stable, and the difference between the heads and the tails of steel tape is small.

Owner:SHANDONG TAISHAN STEEL GROUP

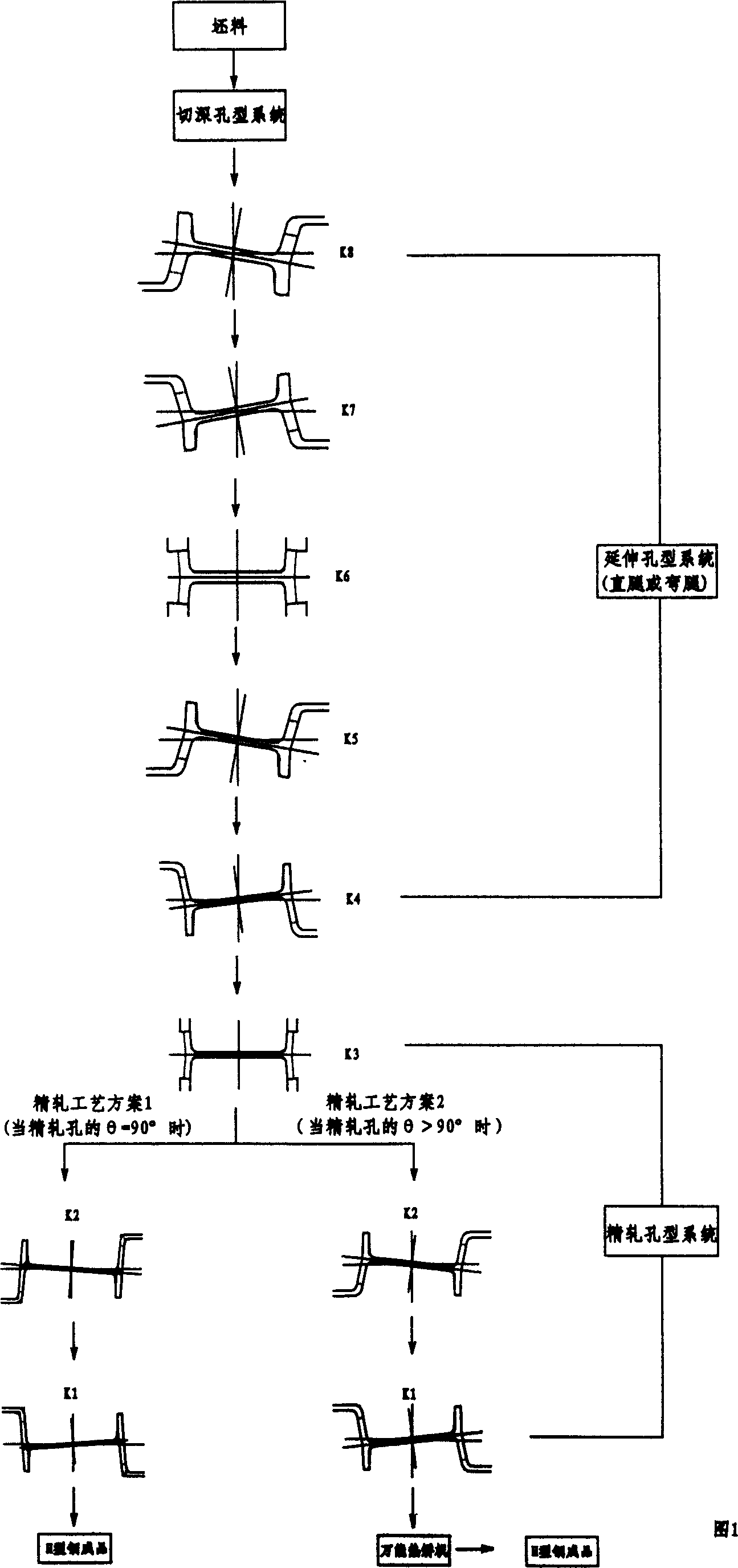

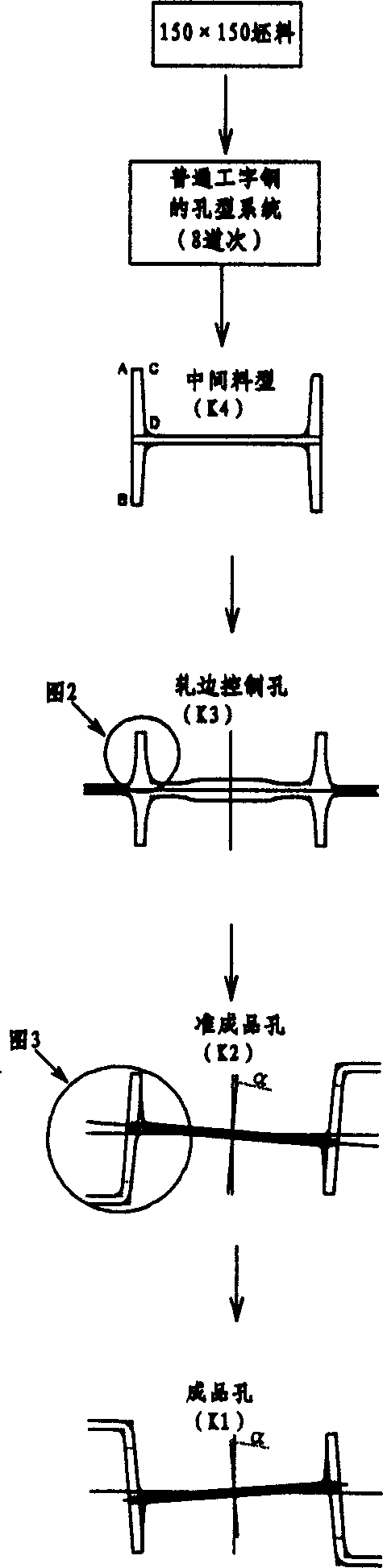

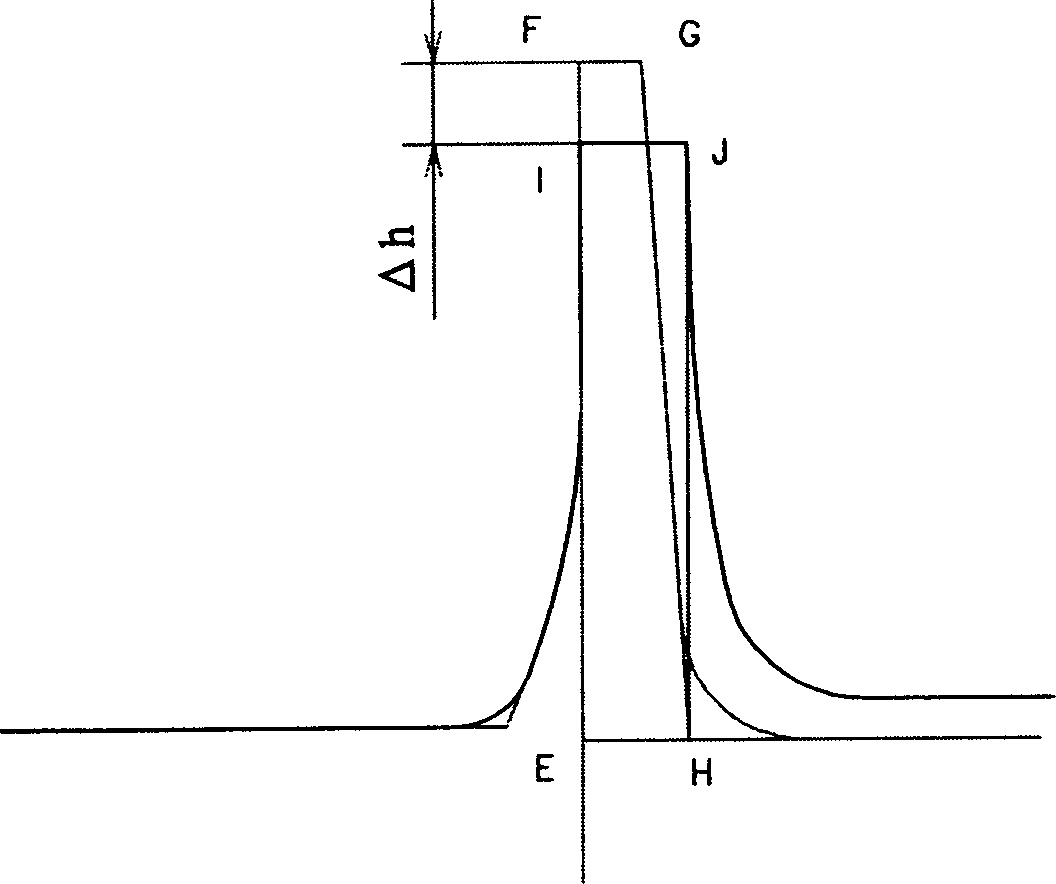

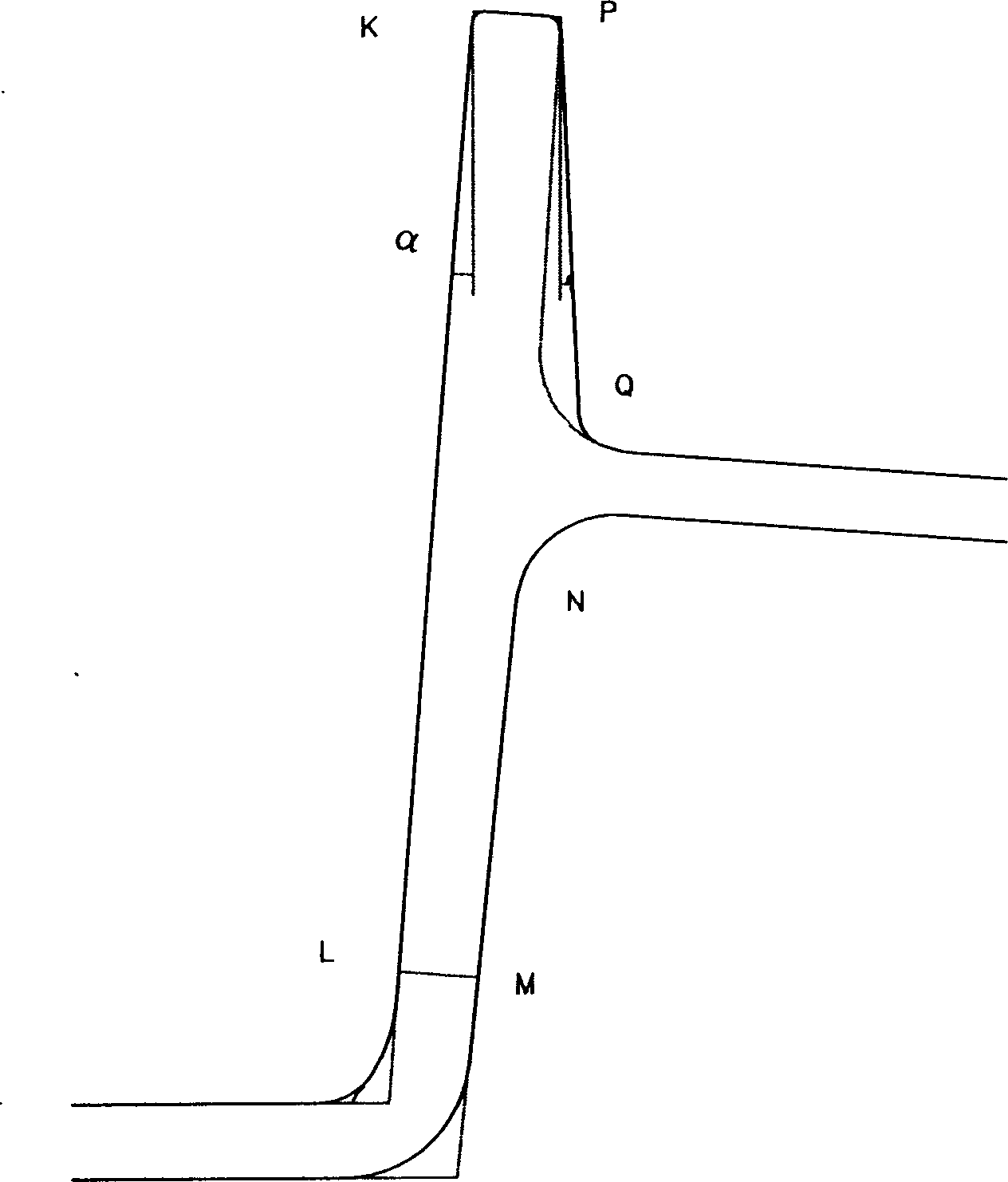

Process for rolling H steel using trio mill and heat rectification machine

InactiveCN1504277ALower the thresholdIncrease profitMetal rolling arrangementsEngineeringRoller mill

The invention relates to a process for rolling I-section steel using the three-high or two-high mills, wherein after heating square bloom, rectangular bloom etc., knifing is performed on the three-high mill, then entering the extrusion hole type system and fine rolling hole system of the common three-high or two-high roller mill for rolling, and one or two rolling lateral openings are added between the elongation pass system and fine rolling hole system, both of the elongation pass system and fine rolling hole system comprises parallel wing rim inclined rolling hole moulds.

Owner:李宝安

Short-process production method for high-strength and high-conductivity copper alloy strips

ActiveCN107716885AThe overall thickness is thinFlat surfaceMetal rolling arrangementsIngot castingHigh conductivity

The invention discloses a short-process production method for high-strength and high-conductivity copper alloy strips, and belongs to the technical field of metal materials. In order to solve the problem that large hot rolling equipment is needed when a traditional 'semi-continuous ingot casting-hot rolling-face milling-cold rolling-solid dissolving-cold rolling-aging' process is adopted for producing high-strength and high-conductivity copper alloy strips, meanwhile, the yield is low, energy consumption is large and the cost is high, hot-cold combined casting type horizontal continues castingis adopted for preparing copper alloy plate blanks, then the cold-rolling-solid dissolving-cold rolling-aging process is carried out, the high-strength and high-conductivity copper alloy strips are produced, blank reheating, hot rolling and face milling treatment can be omitted, and the method has the advantages that equipment investment is low, the technological process is short, the yield is high, energy consumption is low, and the production cost is low. The horizontal continuous casting plate blanks are 200-800 mm wide and 5-50 mm thick, the rolling pass deformation is 20-50%, the rollingspeed is 60-600 m / min, and the processed product is 200-800 mm wide and 0.05-2 mm thick.

Owner:UNIV OF SCI & TECH BEIJING

High-efficiency rolling technology for high-strength and high-ductility magnesium alloy sheet and preparation method

ActiveCN106862272AHigh strengthImprove plasticityTemperature control deviceMetal rolling arrangementsHigh intensityParameter control

The invention discloses a high-efficiency rolling technology for a high-strength and high-ductility magnesium alloy sheet. The high-efficiency rolling technology is a technology used for rolling a rolled blank. According to the parameter control of the rolling technology, the rolling speed of each rolling pass is 10-50m / min, the rolling reduction of each rolling pass is controlled to be 40%-90%, and the preheating temperature and rolling temperature in each rolling pass before rolling are both 250-450 DEG C. The invention further discloses a preparation method of the high-strength and high-ductility magnesium alloy sheet. The method includes the steps that (1) the rolled blank is prepared; (2) high-efficiency hot rolling is carried out, the rolling speed of each rolling pass is controlled to be 10-50m / min, the rolling reduction of each rolling pass is 40%-90%, and the preheating temperature and rolling temperature in each rolling pass before rolling are both 250-450 DEG C; and (3) annealing is performed. By the adoption of the high-efficiency rolling technology for the high-strength and high-ductility magnesium alloy sheet, the mechanical property level of the sheet can be effectively improved, and the strength and ductility of the sheet can be greatly improved particularly.

Owner:BAOSHAN IRON & STEEL CO LTD

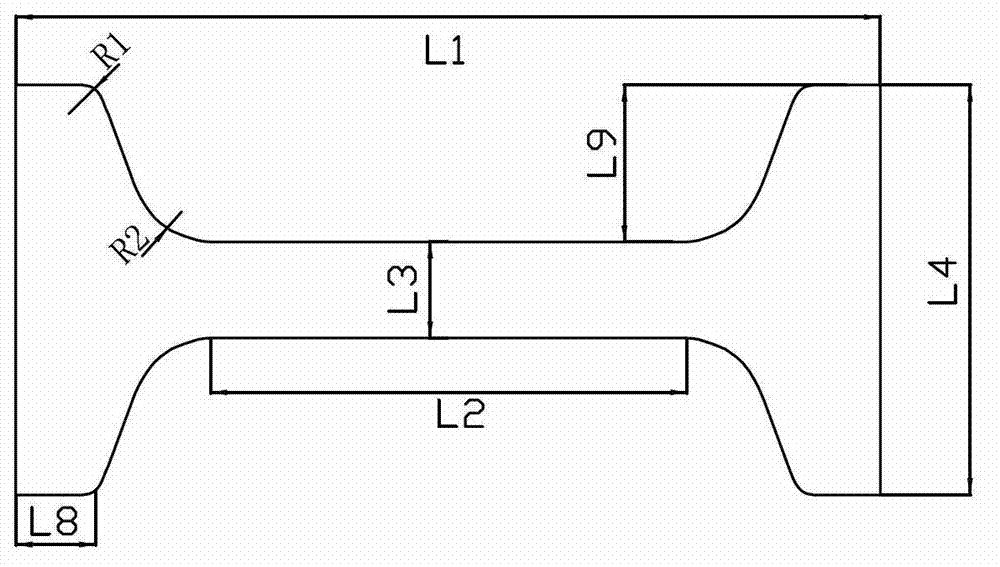

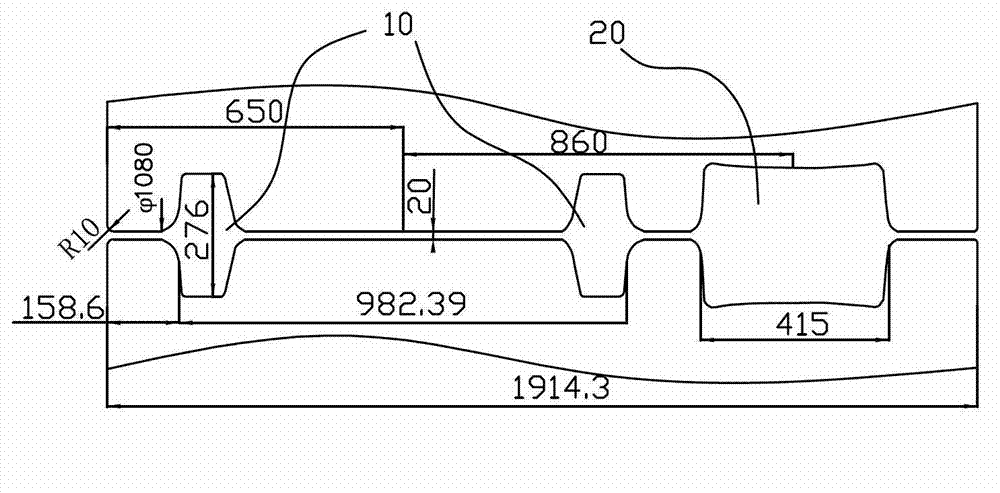

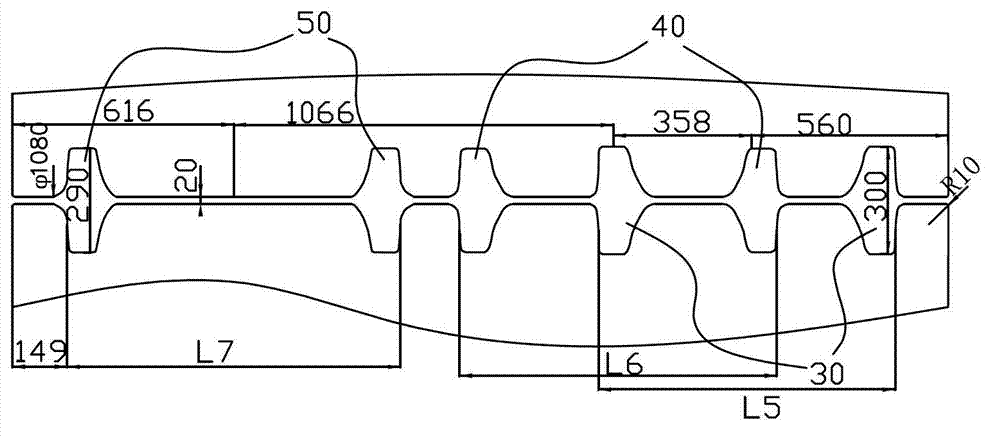

Special-shaped blank design method for high-temperature alloy F-type section ring

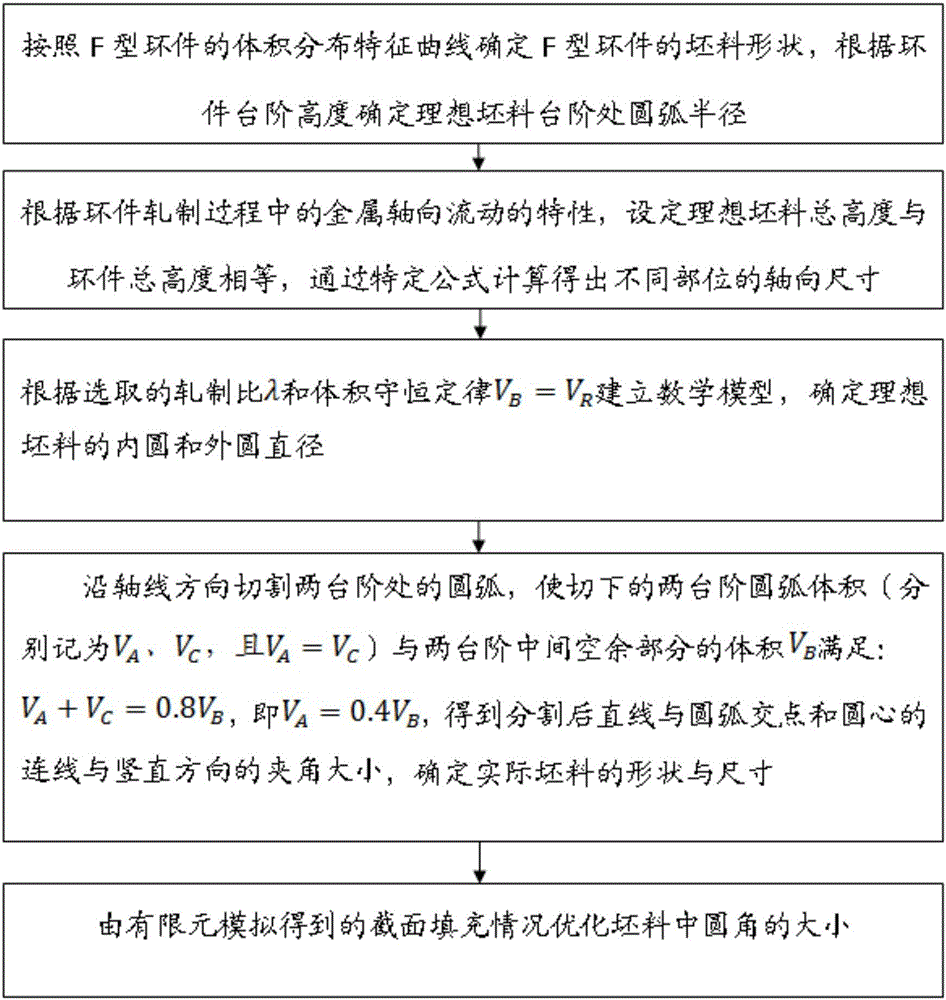

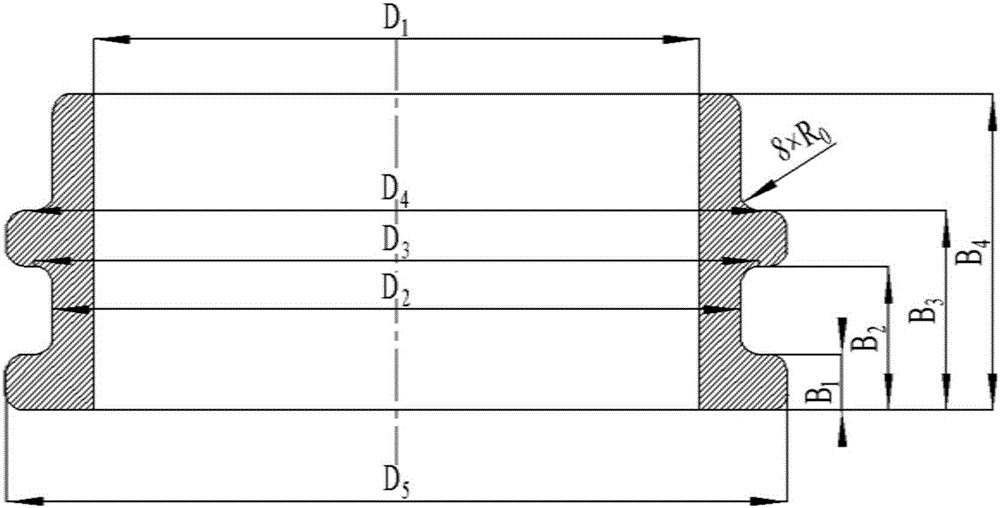

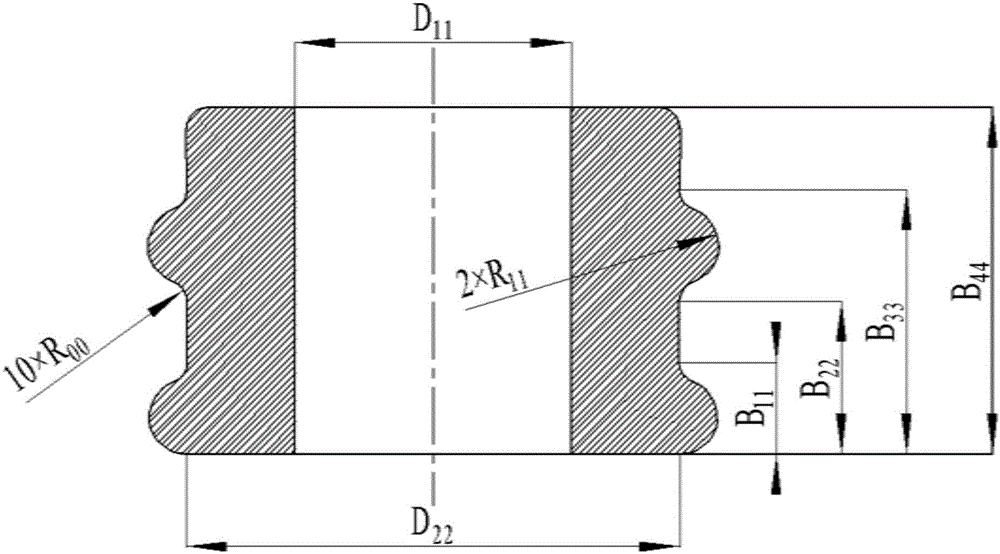

ActiveCN106825339ASolve the defect of filling dissatisfactionComplete outlineGeometric CADSpecial data processing applicationsMathematical modelDistribution characteristic

The invention discloses a special-shaped blank design method for a high-temperature alloy F-type section ring. The special-shaped blank design method includes the steps: designing a blank according to an F-type ring volume distribution characteristic curve; setting equal overall heights of an ideal blank and the ring according to metal axial flow characteristics in the rolling process of the ring; determining the height between two steps according to the height of the corresponding step of the ring. A mathematical model is built according to selected rolling ratio and space conservation laws, and the radial size of the ideal blank is determined. The size of the ideal blank is simplified according to the volume splitting complementary principle. The size of a fillet in the blank is optimized according to section filling conditions obtained by finite element simulation, and the shape and the size of an actual blank are finally determined. By the method, the shortcoming of filling incompleteness in the rolling process of the F-type ring can be effectively overcome, production cost is saved while material utilization rate is increased, and damage of machining to the internal streamline of a forging is avoided.

Owner:安徽汉正轴承科技有限公司

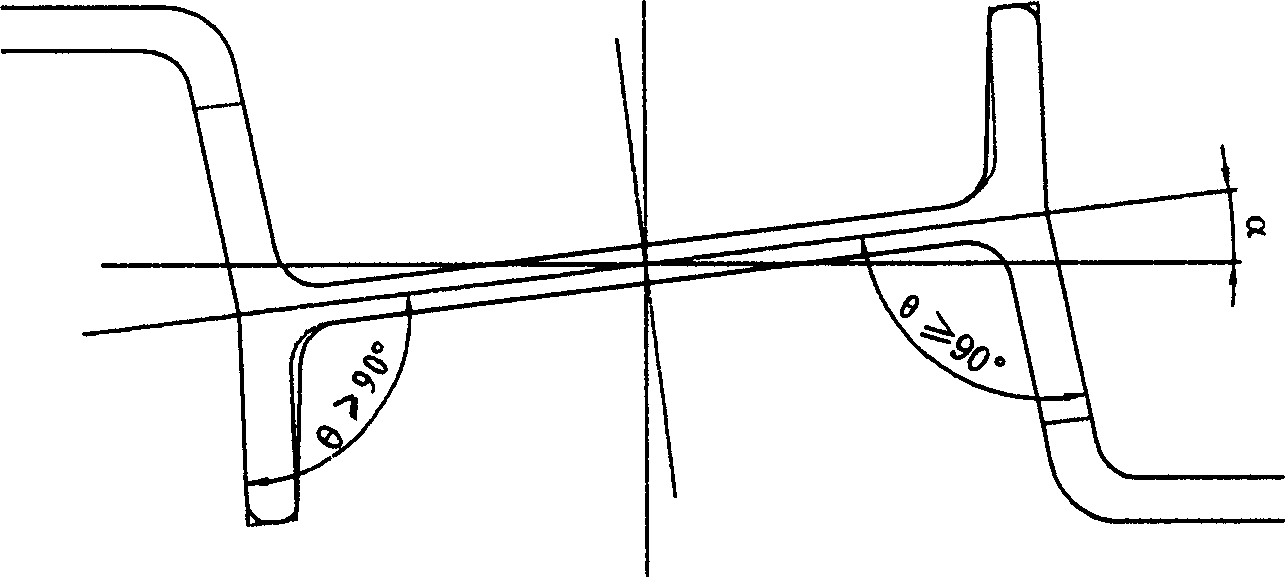

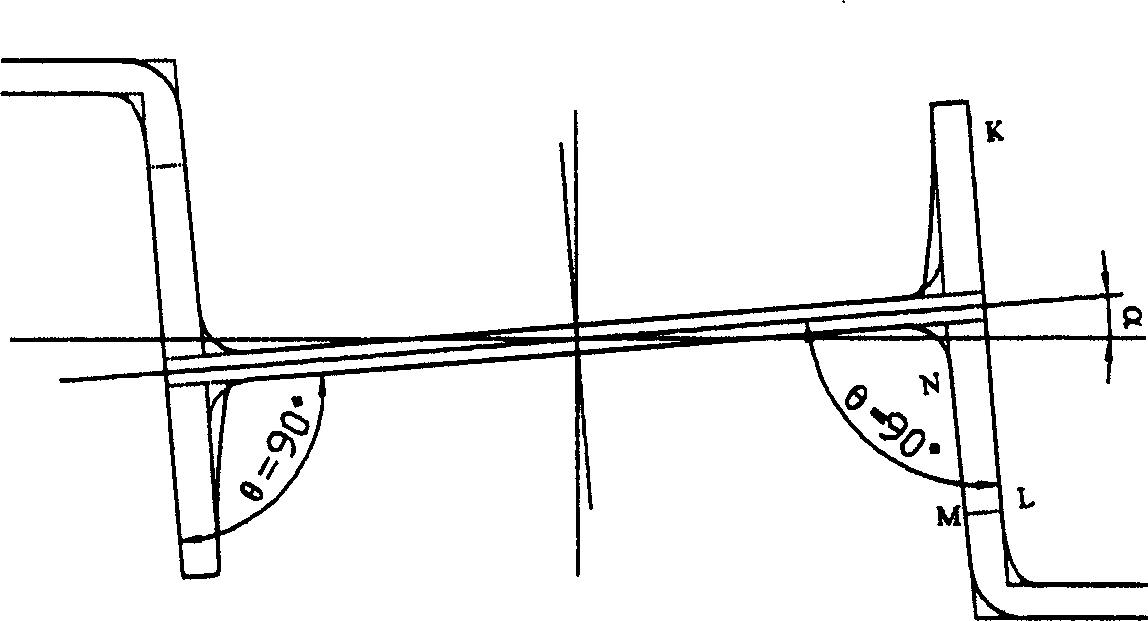

Round steel splitting rolling technique

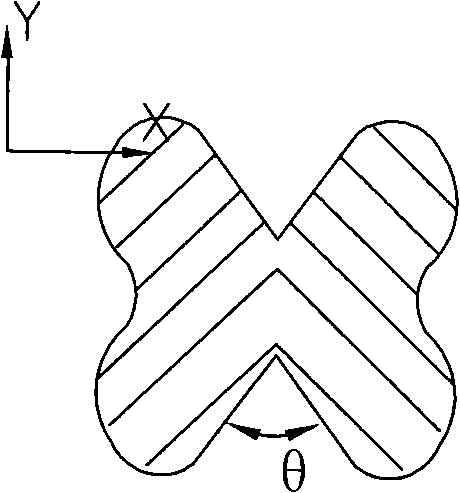

InactiveCN101306432AHigh speedImprove machine-hour throughputRollsMetal rolling arrangementsProduction rateEllipse

The invention discloses a slit rolling technique of round steel, which comprises the following steps: a blank is rolled into parallel rolled pieces after undergoing the stages of rough rolling, medium rolling and precision rolling; the rolled pieces are slit by a slitting wheel for obtaining the round steel rolled pieces, wherein the roll passes with specific structures and sizes including the rhomboid pass, the cinquefoil square pass, the dumbbell-shaped pre-slit pass, the double-circle slitting pass, the ellipse pass and the round pass are sequentially adopted in the medium rolling and the precision rolling stages, the square rolled pieces rolled by the cinquefoil square pass require further slitting and positioning by a slitting wedge, and the point angle Theta of the slitting wedge is 60 DEG- 65 DEG; finally each thin and narrow connecting band of the rolled pieces is slit by the slitting wheel on a slitting foreplate, wherein the point angle of the slitting wheel is 90 DEG- 95 DEG. The round steel produced by adopting the slit rolling technique of the invention has good surface quality and high production rate, and the slit rolling process can effectively improve the machine-hour yield of the round steel and increase the production efficiency in a factory.

Owner:XINJIANG BAYI IRON & STEEL

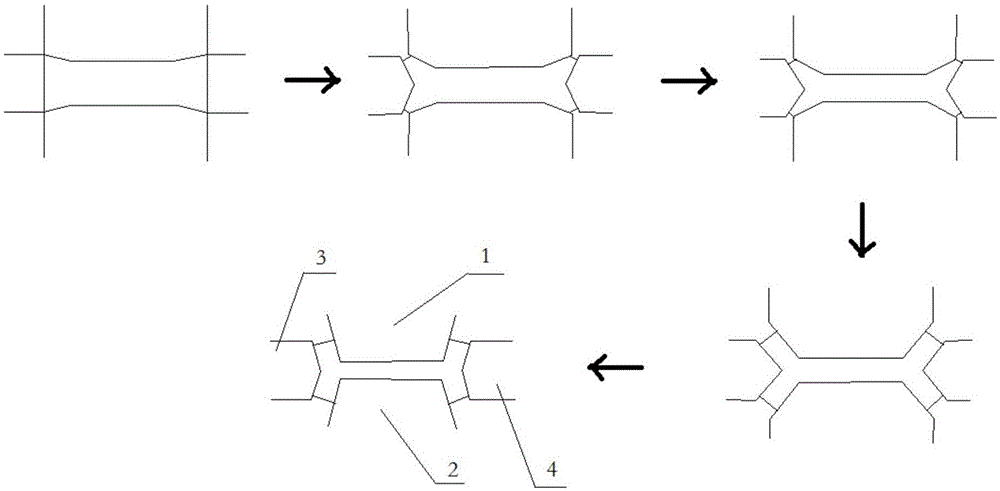

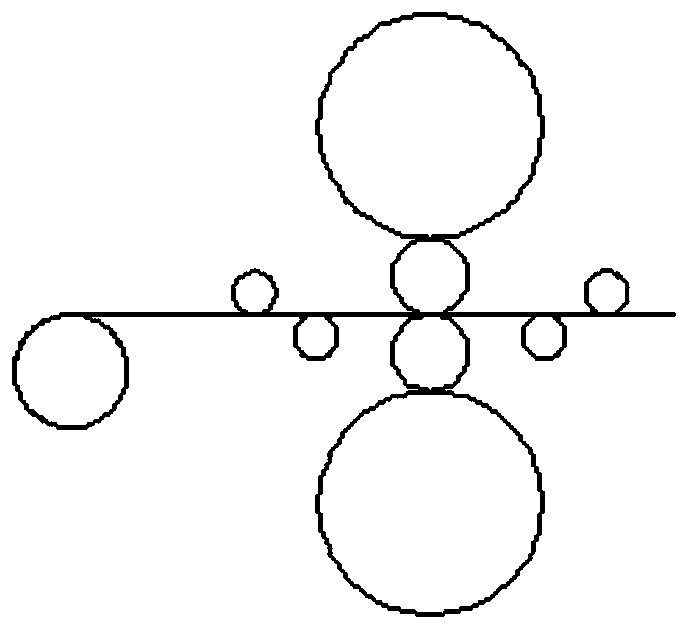

Method for producing H-steel by chopping and rolling slabs with universal mills

ActiveCN105057345AImproved surface quality of rolled piecesThere is no problem of chopping instabilityMetal rolling arrangementsStrip millInstability

The invention provides a method for producing H-steel by chopping and rolling slabs with universal mills. The method comprises the following steps: firstly, a suitable slab is selected; then the slab is heated, is conveyed in front of a universal mill group through a roller bed, and is fed into the universal mills; each universal mill is of a hole-type structure formed by up-down horizontal rolls and left-right vertical rolls, wherein the up-down horizontal rolls are driving rolls, and the left-right vertical rolls are driven rolls; the up-down horizontal rolls first grab the slab and then drive the slab to pass through the powerless left-right vertical rolls; the left-right vertical rolls are provided with convex roll rings for cutting the slab; the slab is subjected to multiple steps of rolling of the multiple universal mills; and the angles of the roll rings of the vertical rolls of each universal mill are changed sequentially, so that the slab is milled into an intermediate blank of H-steel. The slab is clamped by the up-down horizontal rolls, so that the problem of cutting instability does not exist; blanks with small thickness can be cut; in a chopping and cutting process of the vertical rolls, along with the pressing of the horizontal rolls, the thickness at the waist part of the rolled slab is reduced at the same time; the extension coefficients of the whole rolled slab tend to be uniform; the internal stress is small; and the quality of products is high.

Owner:中重科技(天津)股份有限公司

Process for rolling H steel using trio mill

The invention relates to a process for rolling I-section steel using the common three-high mill, wherein after heating square bloom, rectangular bloom or special-shaped bloom, an intermediate blank similar to I-beam steel is rolled using the common three-high mill, and entering parallel wing ring hole system for rolling, then entering in turn two parallel inclined rolling hole mould with opposite opening directions, the inner and outer walls are fabricated in the open slot to make them parallel, the leg sides are processed into qualified shape in the closed end until the final I-section steel product is achieved.

Owner:李宝安

Method for producing steel board with thickness of 5-8mm by utilization of heavy and medium plate mill

InactiveCN103586280ASave billetReduce billet thicknessTemperature control deviceMetal rolling arrangementsSheet steelUltimate tensile strength

A method for producing a steel board with the thickness of 5-8mm by the utilization of a heavy and medium plate mill comprises the steps that a casting blank with the thickness of 120-250mm is heated for the first time, rolled for the first time and split according to user requirements; the casting blank is heated and rolled for the second time, wherein the thickness is controlled to be 25-40mm; the casting blank is rolled in a fine mode; the steel board is meshed under the condition of 30-40 turns per minute and is rolled under the condition of 60-80 turns per minute, steel casting is carried out under the condition of 30-40 turns per minute, air blowing and cooling are carried out in the rolling process, and the steel board is straightened to be used. The method effectively overcomes the defects of edge waves, middle waves, deflection, steel overlapping and waste rolling occurring when the steel board with the thickness standard of 5-8mm is produced by the heavy and medium plate mill. The differences of the strength indexes of the head, the middle and the tail of the produced steel board are within the range of 5-20MPa; the degree of convexity of the steel board is low, the intra-plate difference is small, namely the degree of convexity of the steel board is smaller than or equal to 0.1mm, the intra-plate difference is smaller than or equal to 0.2mm, the intra-plate temperature uniformity is good, the unevenness degree of the steel board is small than three per thousand, no buckling phenomenon exists, the shape of the steel board is good, cost is low and the production process is simple.

Owner:武汉钢铁有限公司

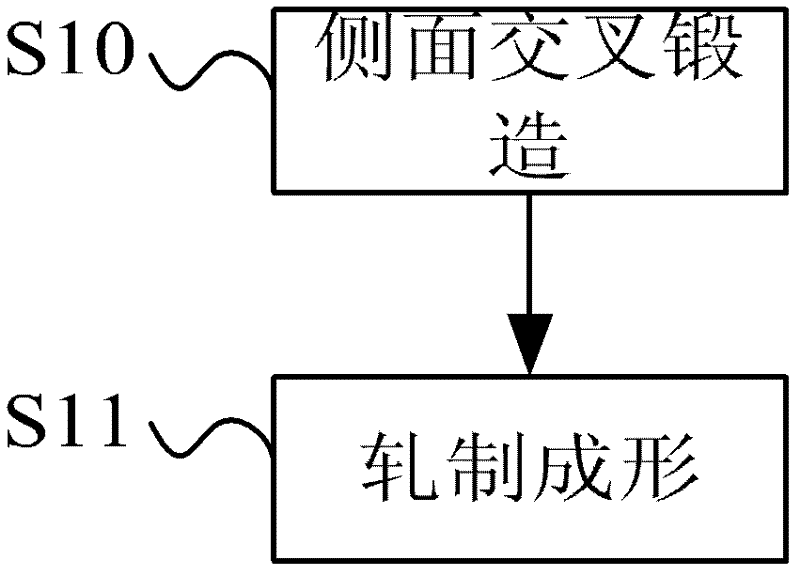

Method for forging and cogging magnesium alloy sheet

InactiveCN102513484AQuality improvementReduce processing costsMetal-working apparatusSingle processProcessing cost

The invention discloses a method for forging and cogging a magnesium alloy sheet, comprising the following steps: forging the side with a low temperature and a small stress in a cross way, namely, carrying out multi-process forging to the sheet from the side in a cross way along horizontal direction and vertical direction of the sheet, and forging with a relatively low process stress. By adopting the forging and cogging, the material undergoes large cold deformation at a low temperature, and twin refined crystal grains are effectively excited, so as to form a structure type that is helpful for consequent rolling shaping by refining the crystal grain size of the cast sheet and by effectively utilizing the twin divided crystal grains. Therefore, the single-process maximum pressing amount and continuous deforming property are greatly improved in the consequent rolling process, the rolling times and the intermediate annealing times are decreased, so that the processing cost of the magnesium alloy sheet is reduced. At the same time, the magnesium alloy sheet prepared by the method has more even and thinner crystal grain tissue and excellent mechanical property; the break tendency of the side of the sheet is greatly improved, so that the quality of the magnesium alloy sheet is improved.

Owner:CHONGQING UNIV

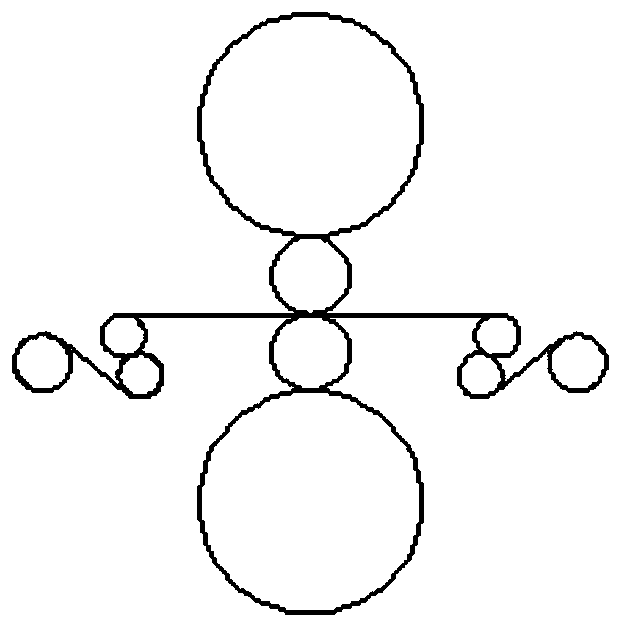

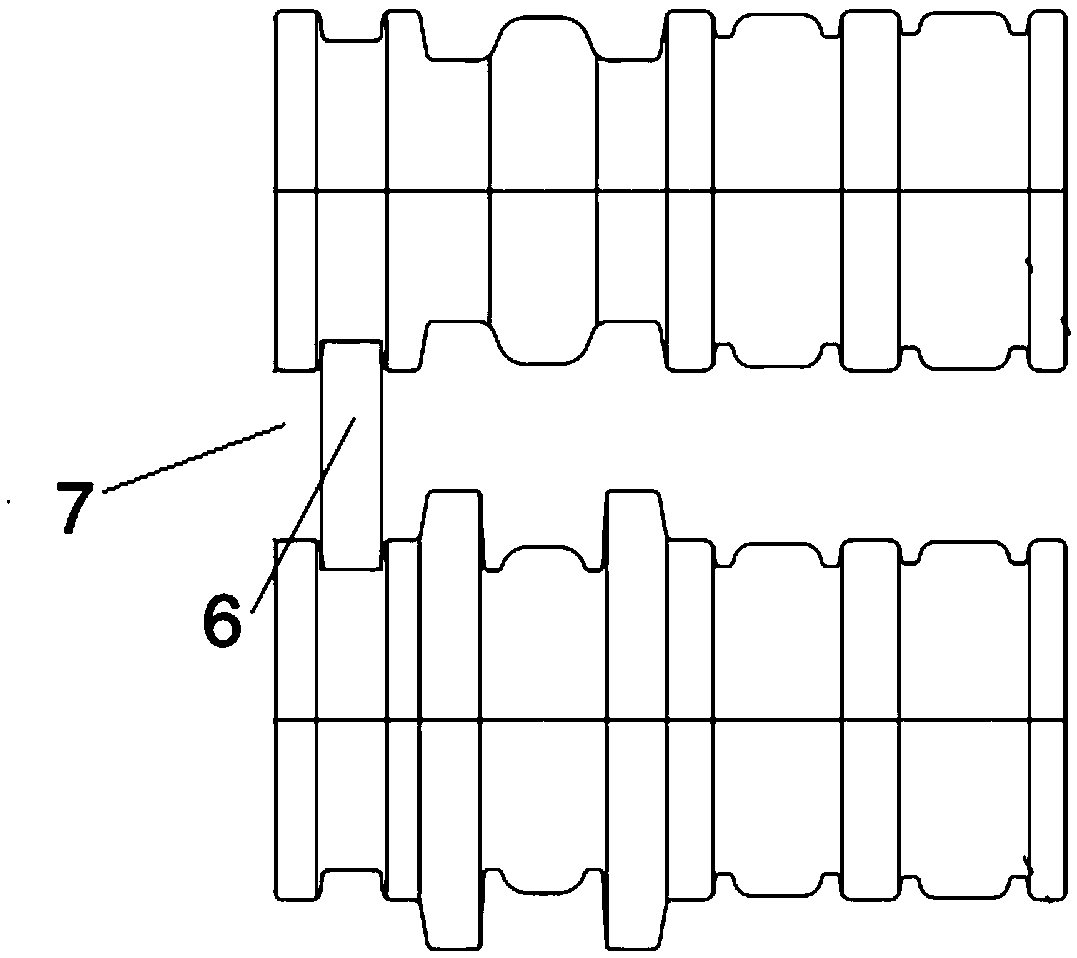

H-shaped steel rolling equipment and method

ActiveCN102921722AReduce billet rolling passesReduce rolling passesMetal rolling arrangementsMetallurgyH shaped

Owner:LAIWU IRON & STEEL GRP

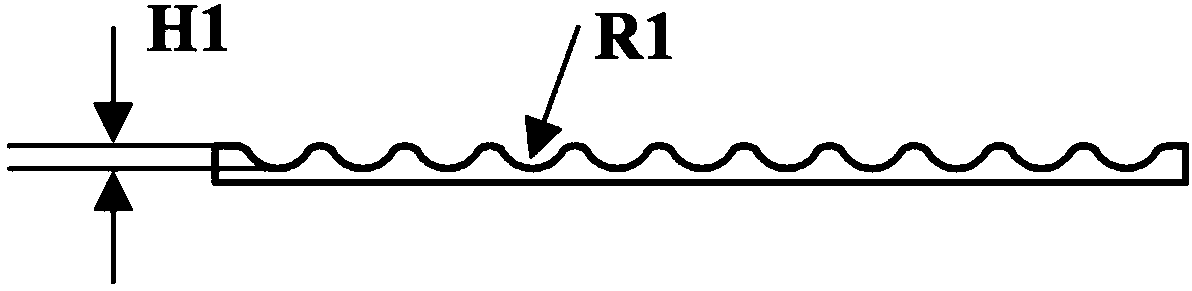

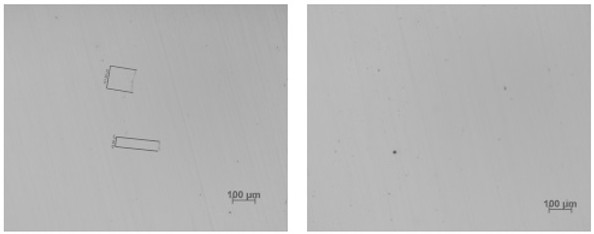

Single-stander furnace rolling mill rolling plate shot-blasting pitted surface control method

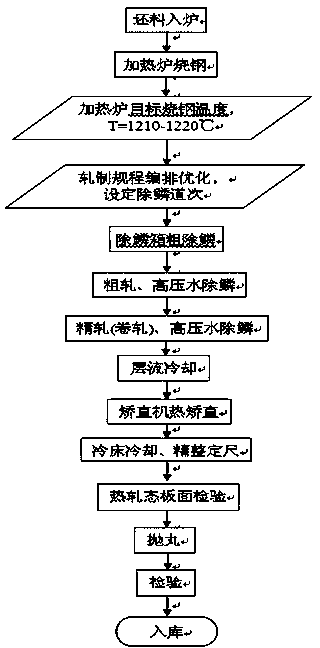

ActiveCN103978042AImprove surface qualityReduce rolling passesTemperature control deviceMetal rolling arrangementsHeating furnaceHot rolled

The invention discloses a single-stander furnace rolling mill rolling plate shot-blasting pitted surface control method. The method is characterized in that stability for controlling the ending of the high-temperature phosphorus removal of a single-stander furnace rolling mill rolled piece is realized by optimizing a steel sintering process of a heating furnace, optimizing the rolling process and optimizing the phosphorus removal process, so that a hot-rolled panel is uniform and blue, an overcooled zone caused by the phosphorus removal overlap ratio can be eliminated, the shot-blasted panel is uniform, smooth and free from water grains, the defects such as shot-blasting pitted surfaces can be controlled, and the hot-rolling state of the single-stander furnace rolling mill rolled piece and the quality of a shot-blasted surface can be improved.

Owner:NANJING IRON & STEEL CO LTD

Asynchronous cold rolling forming process of aluminum alloy stainless steel composite plate

ActiveCN110883093AIncrease rolling capacityImprove rolling precisionTemperature control deviceWork cooling devicesComposite plateLine heating

The invention discloses an asynchronous cold rolling forming process of an aluminum alloy stainless steel composite plate. The process comprises the following process steps: 1, rolling and compoundinga stainless steel plate and an aluminum alloy plate in an asynchronous rolling mode, and 2, after asynchronous rolling, diffusing and annealing the composite plate, specifically, in the step 1, online heating is carried out on the opposite surface of the composite plate surface of the stainless steel plate, online cooling is carried out on the opposite surface of the composite plate surface of the aluminum alloy plate online, and the heating temperature is 350 DEG C-850 DEG C; the temperature of the composite plate surface of the stainless steel plate from which the composite plate is rolledis lower than 650 DEG C, and the temperature of the composite plate surface of the aluminum alloy plate from which the composite plate is rolled is lower than 300 DEG C; the rolling reduction rate is20%-90%; the different speed ratio of a roller for asynchronous cold rolling is 1.05-1.50; the thickness ratio of the aluminum alloy plate to the stainless steel plate is 1.5-4.0; and in the step 2, the annealing temperature is 250 DEG C-500 DEG C and the annealing time is 15-120 min. The single-side online heating process for rolling the composite plate is creatively provided so as to improve theinterface bonding strength of the composite plate and realize rolling compounding in an interface semi-melting state.

Owner:JIANGYIN KANGRUI MOLDING TECH CO LTD

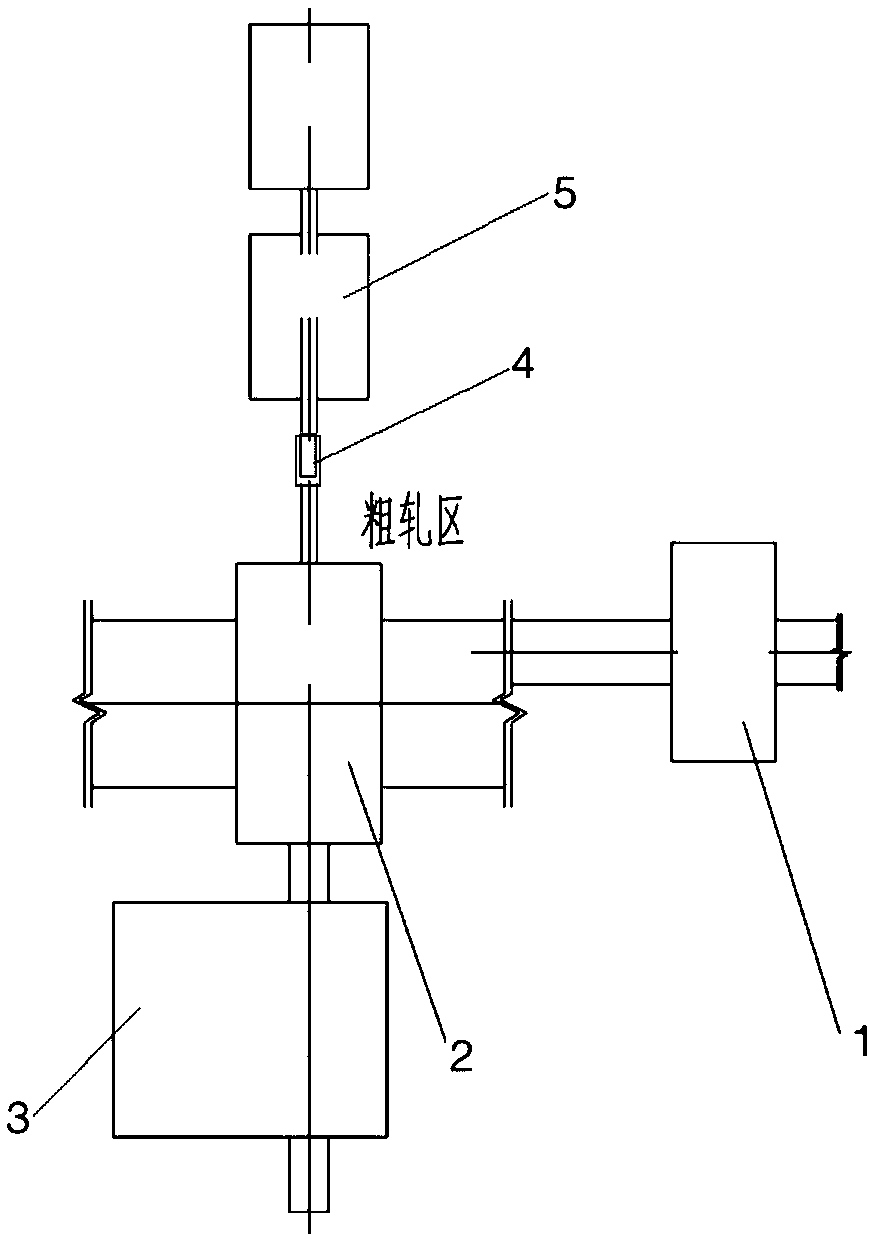

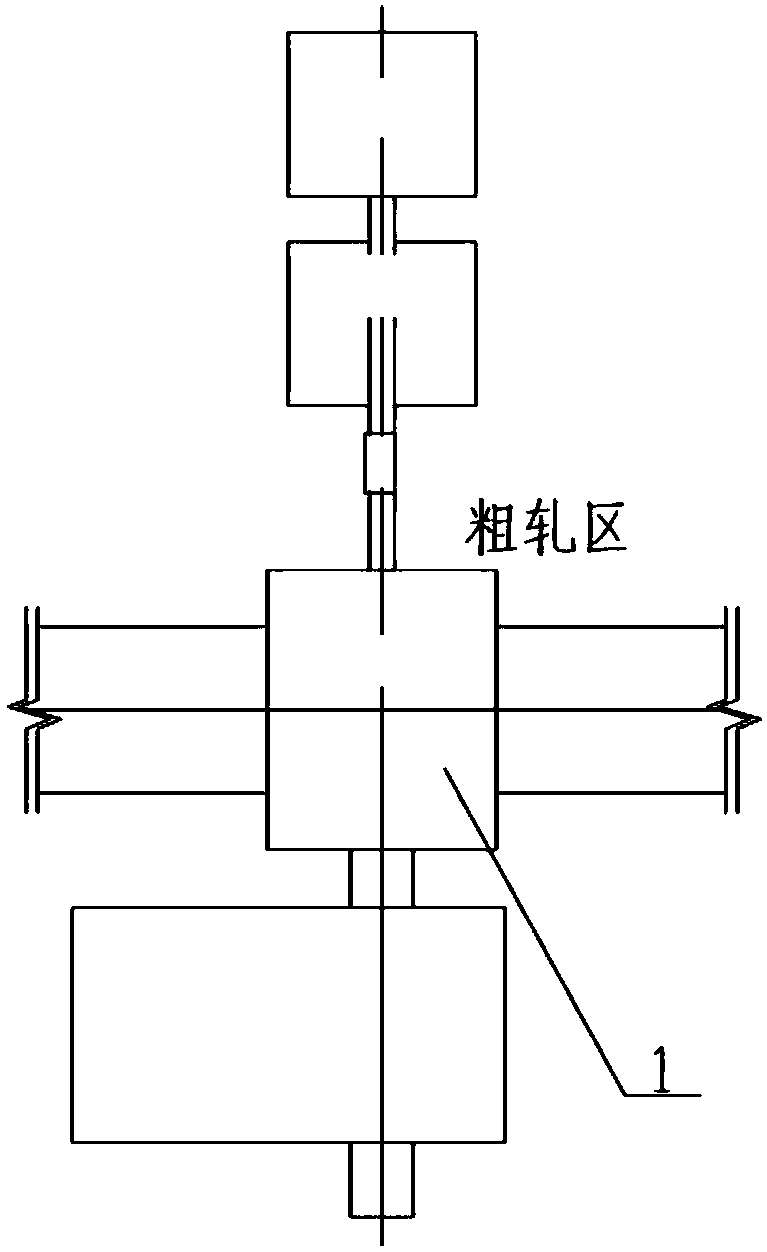

Rolling technology for large-scale and super-large steel in rough rolling zone

InactiveCN109290368AShorten the timeReduce rolling passesMetal rolling arrangementsHeating furnaceManufacturing line

The invention provides a rolling technology for large-scale and super-large steel in a rough rolling zone. The rolling technology comprises the following steps that after a steel billet is heated by aheating furnace, the steel billet is transported to a reversible edging mill for reversible rolling; then the rolled piece after vertical rolling is transported to a roughing mill for reversible rolling, rolling of a next rolled piece can be performed at the reversible edging mill immediately, when the steel billet is transported to the roughing mill, no turning is required, and the roughing milland the reversible edging mill simultaneously perform rolling; and then the steel billet is transported to a finish rolling zone for finish rolling. According to the rolling technology for the large-scale and super-large steel in the rough rolling zone, the time of adjusting a roll gap of the roughing mill and the rolling pass of the roughing mill are reduced by transferring a vertical rolling hole pattern of the billet to the rolling by the separate edging mill, the time of vertical rolling and turning of the steel by the roughing mill is completely eliminated, the production rhythm and efficiency are effectively improved, and the production line yield is greatly improved.

Owner:中重科技(天津)股份有限公司

Rolling technical skill of hot strip rough rolling process

ActiveCN101590488ACompact processShort processWork treatment devicesMetal rolling arrangementsHot strip rollingLine length

The invention belongs to the forming technical field, in particular relates to the novel rolling technical skill of the rough rolling process of a conventional hot strip rolling process (conventional hot strip rolling process). The rolling technical skill comprises the steps that after a continuous casting sheet billet is heated by a heating furnace to a prescribed tapping temperature, the iron scale of the casting sheet billet is removed, the casting sheet billet then enters a rough rolling mill set which is serially arranged by two reversing rolling mills for reverse rolling, an interim billet with certain thickness is rolled and is made into a hot strip with the thickness of a finished product after heat preservation, head and tail cutting and regenerated iron scale removing, and the finished hot strip enters a recoiler to be recoiled after the finished hot strip is cooled. The invention has the advantages of high production possibility of the rough rolling mill set, short rolling line length of a rough rolling area, little temperature fall of the sheet billet in the rough rolling area, and the like. The rolling technical skill of the hot strip rough rolling process can be used for the construction of a new or reformed hot strip rolling mill.

Owner:CISDI ENG CO LTD

Method of manufacturing oriented silicon steel strip in razor-thin

InactiveCN1295035CSolve difficult-to-manufacture problemsMagnetically stableLiquid surface applicatorsWork treatment devicesAcid washingSilicon

Owner:NORTHEASTERN UNIV LIAONING

Cold charging production process of high-compactness and high-purity fine-grain grinding ball steel

ActiveCN112281061AImprove the ability to adsorb inclusionsImprove purityManufacturing convertersProcess efficiency improvementTemperature controlAustenite grain

The invention discloses a cold charging production process of high-compactness and high-purity fine-grain grinding ball steel. The cold charging production process comprises the following processes ofpre-desulfurizing molten iron, smelting in a converter, refining in an LF furnace, carrying out RH vacuum treatment, continuously casting, slowly cooling a large round billet casting blank, heating,rolling, cooling, high-temperature pit entering slow cooling, pit exiting finishing, packaging and warehousing. According to the production process, a grinding ball steel round billet cold charging temperature control system is adopted for heating, and a mode of combining differential temperature rolling and single-pass high-pressure rolling is adopted, so that the deformation of the center of thebillet is increased, and the internal compactness and the grain size of the steel are improved. The grinding ball steel produced by the production process has the advantages of excellent macrostructure (central porosity is less than or equal to 1.0 grade and general porosity is less than or equal to 0.5 grade), high purity (A-type inclusions are less than or equal to 1.0 grade, B-type inclusionsare less than or equal to 0.5 grade, C-type inclusions are less than or equal to 0.5 grade and D-type inclusions are less than or equal to 1.0 grade) and fine austenite grains (austenite grain size isgreater than or equal to 6.5 grade). The grinding ball obtained by carrying out a conventional rolling process on the produced grinding ball steel is good in impact toughness and long in fatigue life.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

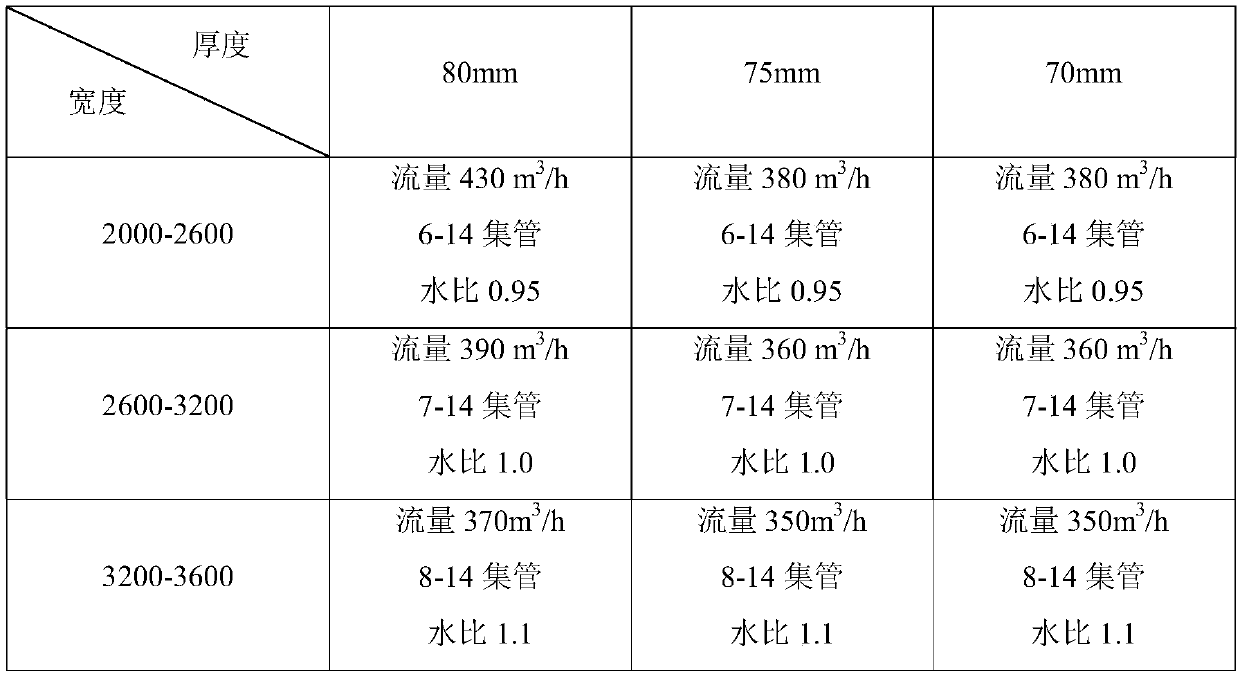

Production method of crack arresting steel for container ship

ActiveCN110076196ALarge amount of depressionAccurate and effective production processTemperature control deviceWork cooling devicesSheet steelUltra fast

The invention discloses a production method of crack arresting steel for a container ship. Billets having different cross sections are selected for rolling according to different finished product widths, the rolling pass is reduced, and the reduction in pass is increased; as for planning arrangement, according to the characteristics that the rolling mode is special and the rolling frequency is slow, the time in a furnace is shortened through blank positions in a heating furnace, execution of a heating technology is ensured, and the surface quality is ensured; the heating process ensures the uniformity of a plate slab in the thickness direction; a rolling technology uses a full longitudinal rolling or full horizontal rolling manner as many as possible, and the effective compression ratio isincreased; and in order to refine grains, the intermediate billet is subjected to ultra-fast cooling, different cooling technologies are set according to specifications, and a finished steel sheet cooling technology is determined. A stable production technology for accurately and effectively producing the crack arresting steel can be realized, the stability of the production technology of the crack arresting steel meets the batch industrial production, the mechanical properties, the product quality stability and various indexes meet the standard requirement, and the production process is easyto control.

Owner:NANJING IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com