Temperature control system of milling uluminium/aluminium alloy coiled material and control method

A temperature control system, aluminum alloy technology, applied in the direction of temperature control, etc., can solve problems such as no control of rolling temperature, simple control method, and influence on coil performance, so as to reduce energy consumption, reduce rolling passes, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

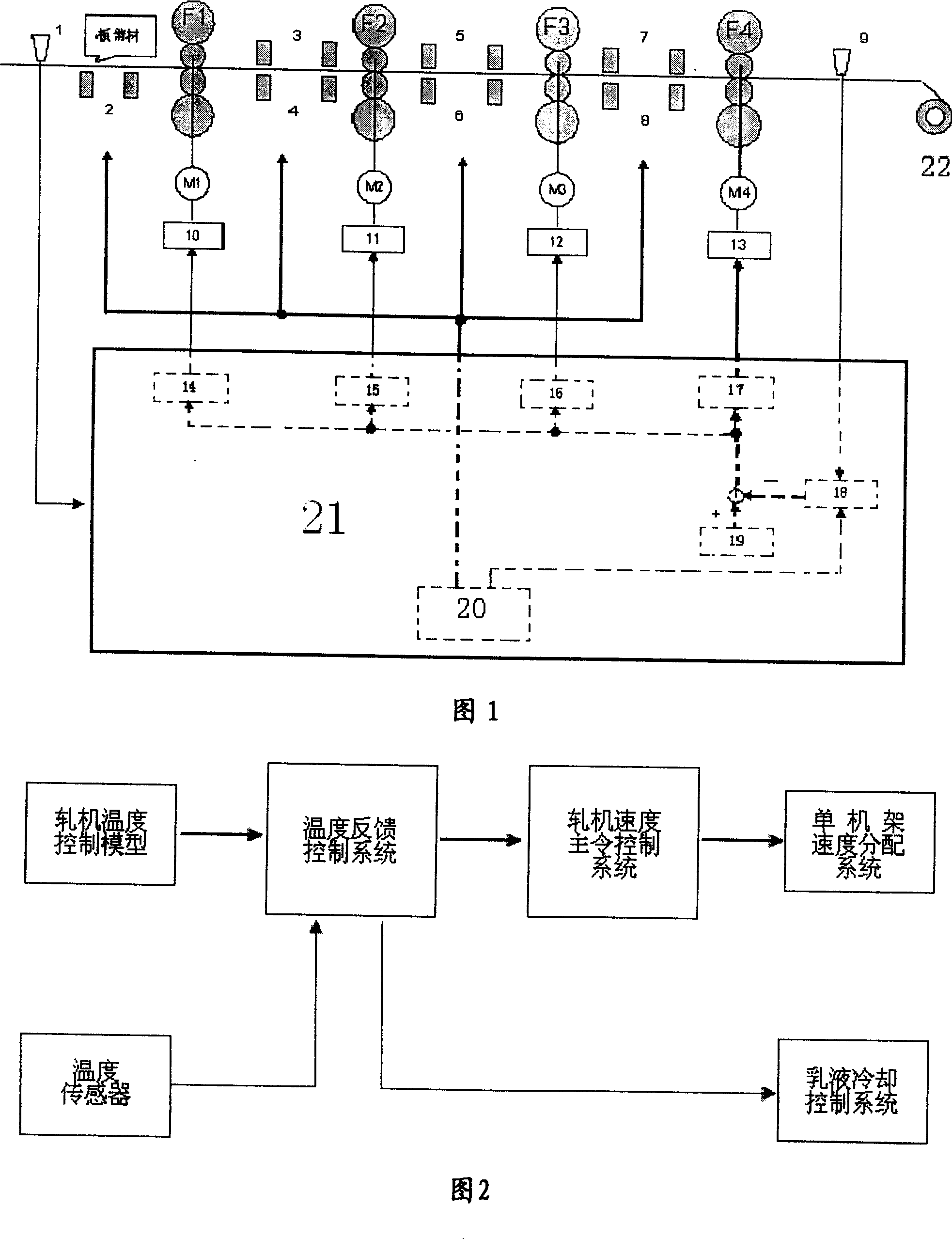

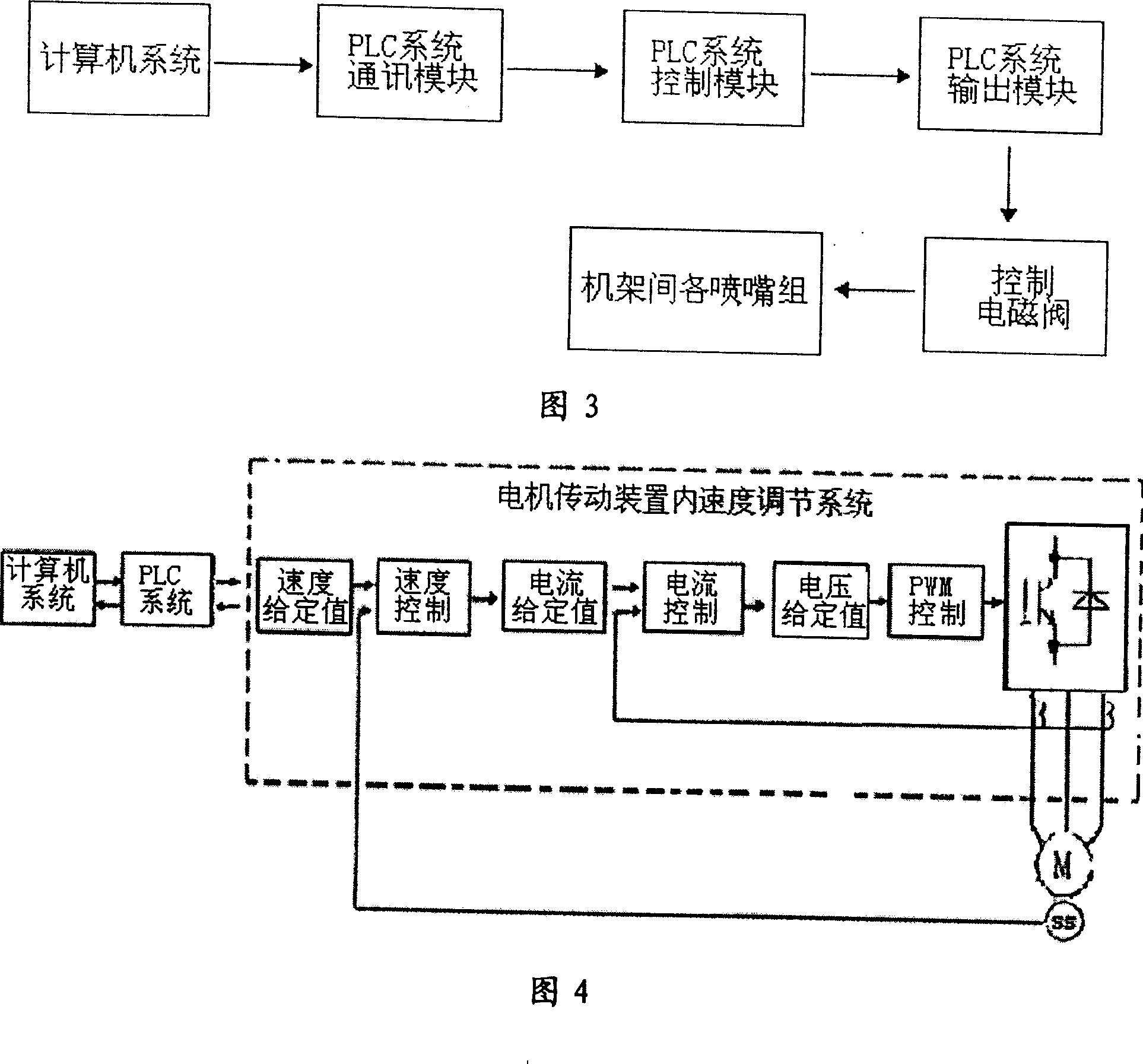

[0024] Referring to Fig. 1 and Fig. 2, the control software including rolling temperature control model, temperature feedback control module (FB-FDTC), rolling mill master command speed control module, stand-alone speed distribution control module and cooling emulsion control module is loaded into the computer system; The front measuring head 1 of the front-end temperature sensing device is installed in front of the first rolling mill F1, and the front-end temperature sensing device is connected with the computer system 21; the rear measuring head 9 of the rear-end temperature sensing device is installed behind the fourth rolling mill F4, The back-end temperature sensing device is also connected with the computer system 21;

[0025] Referring to Figure 1 and Figure 3, the first group of emulsion cooling nozzles 2 is installed at the entrance of the first rolling mill F1 and located below the rolling line, the second group of emulsion cooling nozzles 3 and the third group of emu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com