High-strength bridge cable steel with pearlite inter-lamellar spacing smaller than 150nm and production method

A technology of lamellar spacing and production method, which is applied in the field of high-strength bridge cable steel and production, can solve the problems of insufficient nitrogen-fixing elements, large deviation of lamellar spacing, and unsatisfactory elongation, and achieve the reduction of spinning temperature and rolling start temperature. Reduced, good overall performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

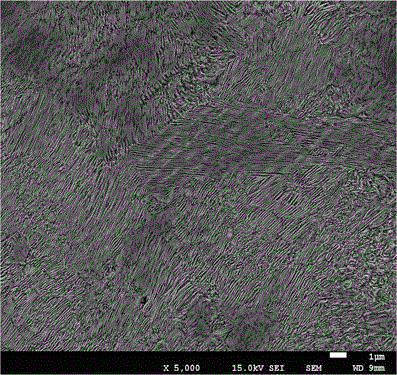

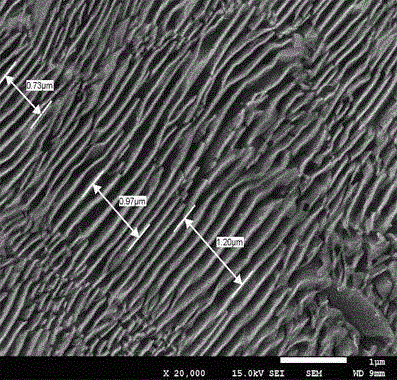

Image

Examples

Embodiment Construction

[0028] The present invention is described in detail below:

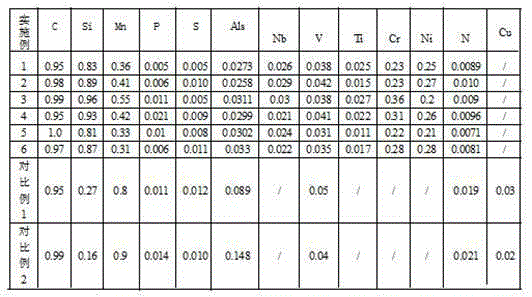

[0029] Table 1 is the chemical components and value list of each embodiment of the present invention and comparative examples;

[0030] Table 2 is the value list of the main process parameters of each embodiment of the present invention and comparative example;

[0031] Table 3 is a list of performance and results of each embodiment of the present invention and comparative examples.

[0032] Each embodiment of the present invention is produced according to the following steps:

[0033] 1) Desulfurization of molten iron and blowing at the top and bottom of the converter, wherein the end point C of the converter is controlled at 0.09-0.15%; the tapping temperature is 1650-1670 ° C; the tapping time is 3-9 minutes, and the slag is blocked; the alloy is added conventionally with the steel flow , C, Si, Mn, V, Nb, Cr, Ti and Ni components are controlled according to the lower limit of the internal control range;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com