Cold charging production process of high-compactness and high-purity fine-grain grinding ball steel

A technology of production process and compactness, which is applied in the cold-packing production process of high-purity fine-grained ball steel, and in the field of high-density, which can solve the problem that only cold-packing process can be selected for hot slabs, casting slabs cannot be diffused in time, and casting It can reduce the energy consumption of refining, improve the effect of argon sealing, and achieve the effect of excellent structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

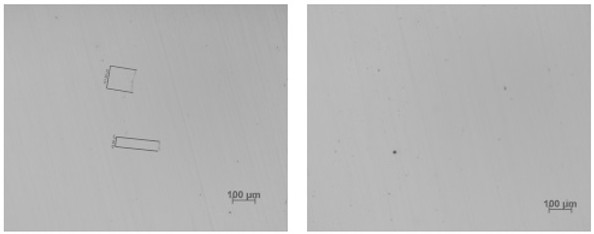

Image

Examples

Embodiment 1-2

[0041] Process of hot metal pre-desulfurization-100t converter-100tLF furnace refining-100tRH vacuum treatment-continuous casting-bloom billet slow cooling-heating-rolling-cooling-high temperature slow cooling into pit-exit pit finishing-packing and storage route. The chemical composition requirements of the steel types applicable to the process method of the present invention are shown in Table 1. The steel materials prepared in Example 1 and Example 2 are two specifications of Ф90 and Ф130, respectively.

[0042] Table 1 The chemical composition / % of the grinding ball steel applicable to the process of the present invention

[0043]

[0044] Specific process

[0045] (1) Hot metal pre-desulfurization

[0046] The sulfur content of molten iron is required to be ≤0.070%, the temperature of molten iron is ≥1250°C, and the KR mechanical stirring method is used for pre-desulfurization. Before desulfurization, the molten iron slag is cleaned up, and then desulfurization is pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com