Patents

Literature

56results about How to "Increase the amount of steel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

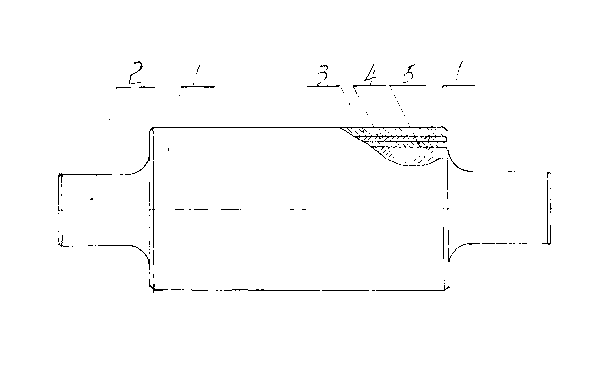

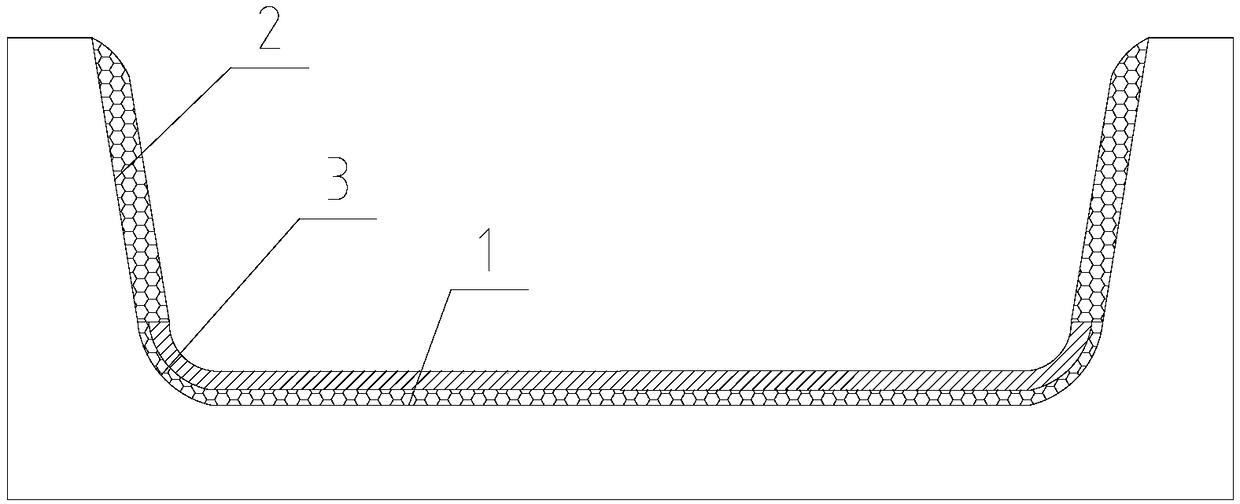

Method for manufacturing double metal composite wear-resistant metallurgical rollers

ActiveCN103009015AIncrease the amount of steelAvoid Roll Breaking AccidentsArc welding apparatusWear resistantHardness

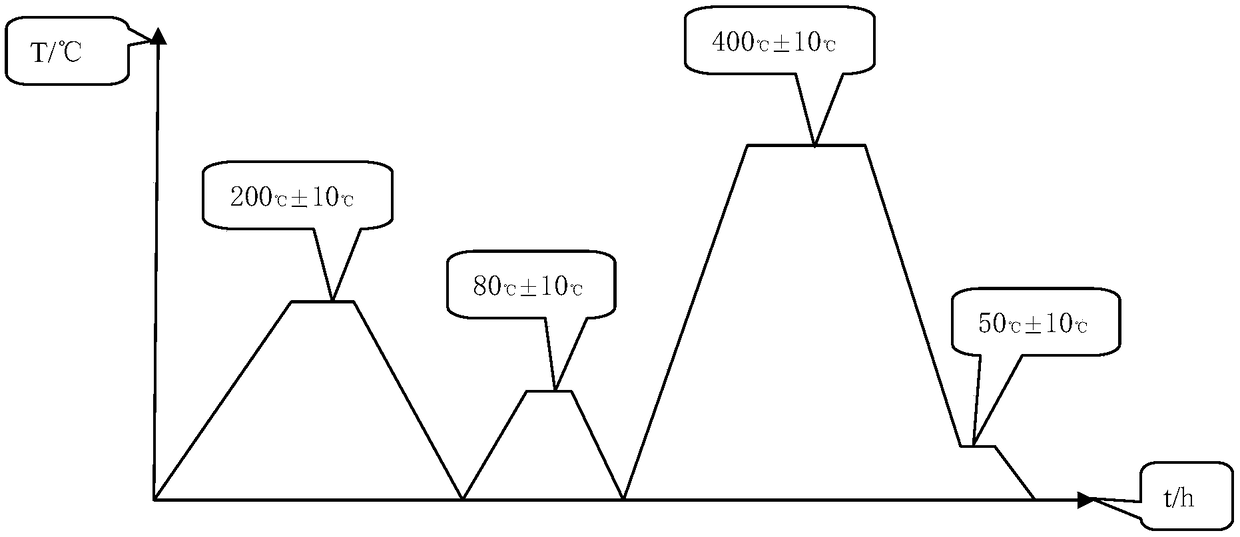

A method for manufacturing double metal composite wear-resistant metallurgical rollers includes steps of roller core processing, preheating, surfacing of a composite layer, finish machining and thermal treatment. The roller core processing step includes subjecting steel good in tensile strength, yield strength and impact resistance to forging, pressing and tempering, manufacturing roller core blanks, subjecting the roller core blanks to rough machining to reserve size for a surfaced composite layer. The preheating step includes preheating the roller cores to the optimum surfacing temperature of 380 DEG C + / - 5 DEG C. The surfacing step of the composite layer includes surfacing and filling the reserved surfaced composite layer by flux-cored wires on the surface of the preheated roller cores by means of submerged-arc welding process. The finish machining step includes processing the surfaced double metal composite wear-resistant metallurgical roller blanks into design size. The thermal treatment step includes quenching and tempering the double metal composite wear-resistant metallurgical rollers subjected to finish machining, so that the surfaces of the double metal composite wear-resistant metallurgical rollers can meet the requirements for good anti-sticking abrasion, grain abrading resistance, red hardness, resistance to cold and hot fatigue, and peeling resistance.

Owner:邯郸市永固冶金备件有限公司

Slag adjusting and furnace protecting method for controlling rising of converter bottom and furnace wall slag deposition

InactiveCN102127612AIncrease the content of MgOImprove furnace protection effectManufacturing convertersSteelmakingSludge

The invention belongs to the technical field of steelmaking and provides a slag adjusting and slag splashing furnace protecting method for controlling rising of a converter bottom and furnace wall slag deposition, solving the problems that the effective volume is reduced and the center of gravity of a furnace body shifts as slag stacked at the converter bottom rises and slag deposits at the lining of the furnace wall when the traditional slag splashing furnace protecting process is adopted. The method provided by the invention is characterized by adopting a two-step slag adjusting method, primary slag adjusting is carried out before molten steel is tapped, a boric sludge-magnesia slag adjusting agent is added into a furnace to reduce the viscosity of the slag, slag deposition at the lining of the unilateral furnace wall and slagging at the converter bottom in the tapping process can be prevented, the slag remaining and no steel remaining operation is adopted in the follow-up tapping process; and secondary slag adjusting is carried out after tapping, namely a magnesia carbon slag adjusting agent (coke powder and material containing magnesium oxide) is added into the slag remained in the furnace, and then the slag splashing slag protecting process is carried out. By adopting the method provided by the invention, the rising of the converter bottom and thickening of slag depositedon the furnace wall can be controlled, the thickness uniformity of the furnace wall can be guaranteed, and the slag splashing furnace protecting effect is obviously improved, thus the service life ofthe lining of a converter can be greatly prolonged.

Owner:JIANGSU UNIV

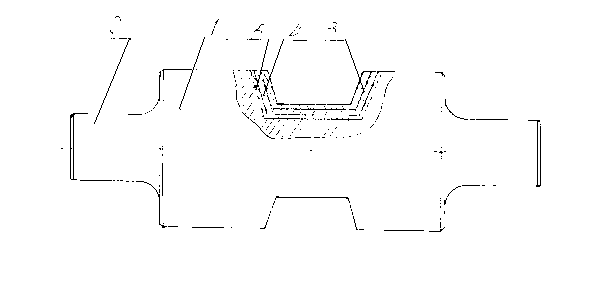

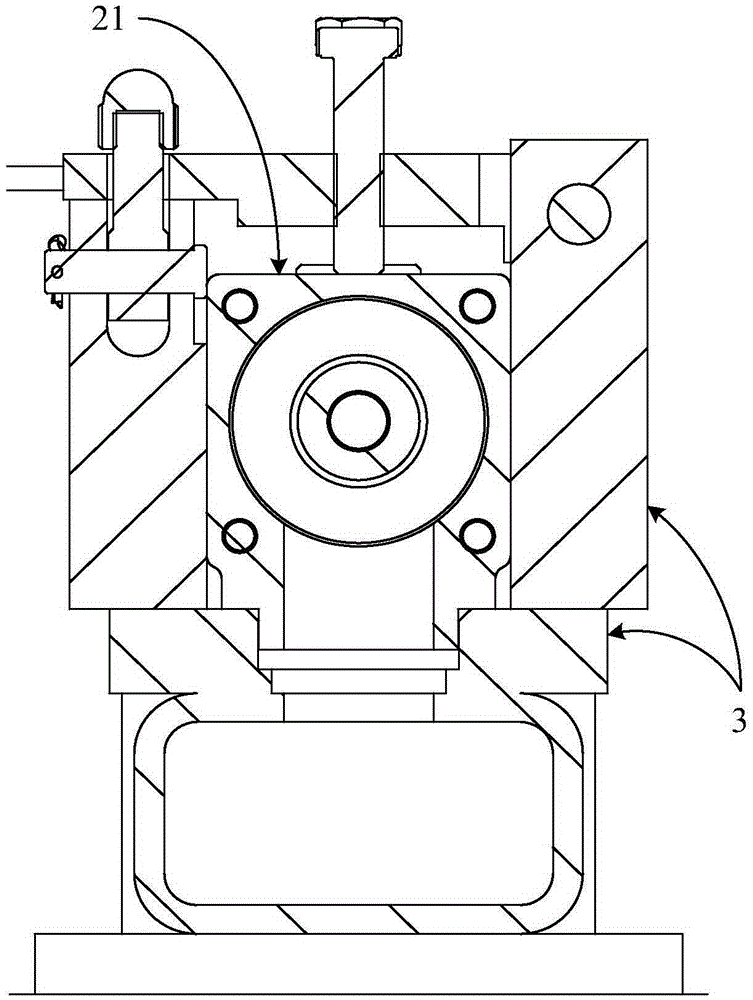

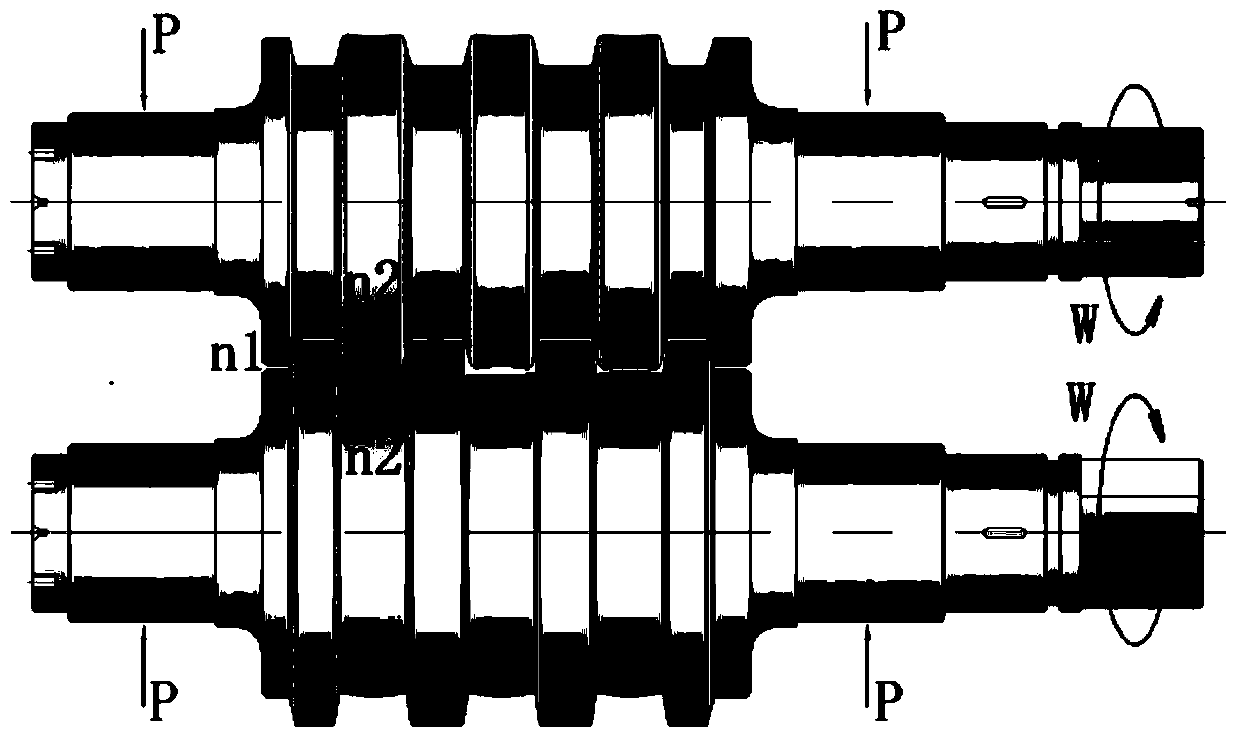

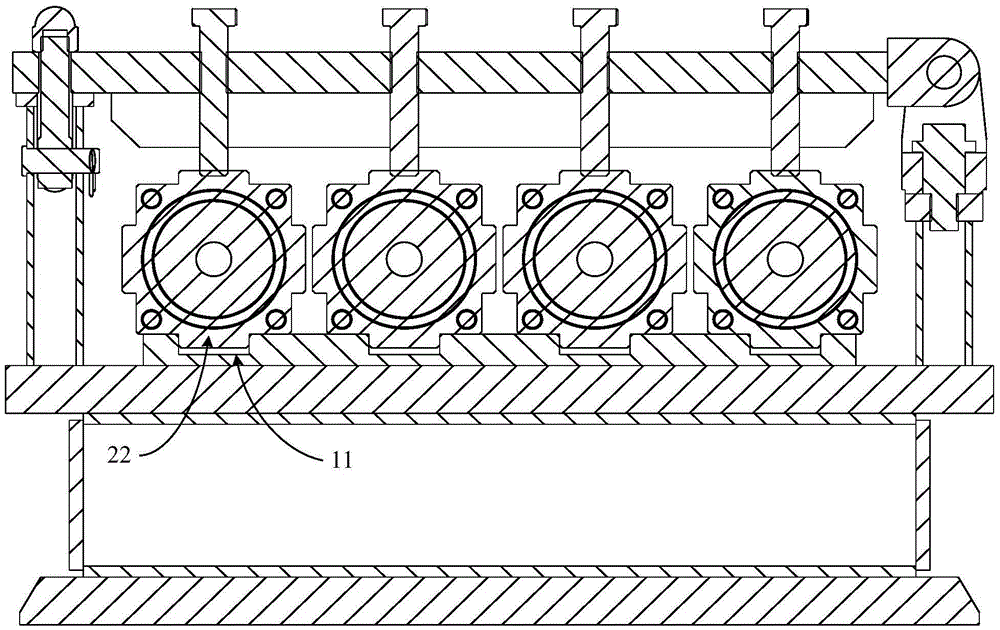

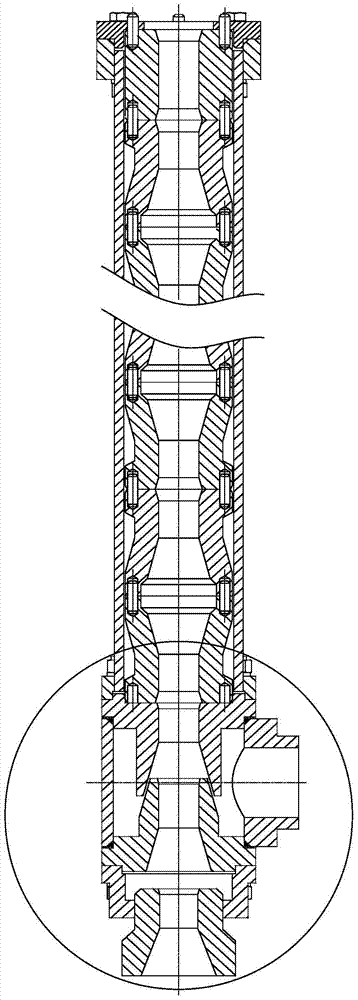

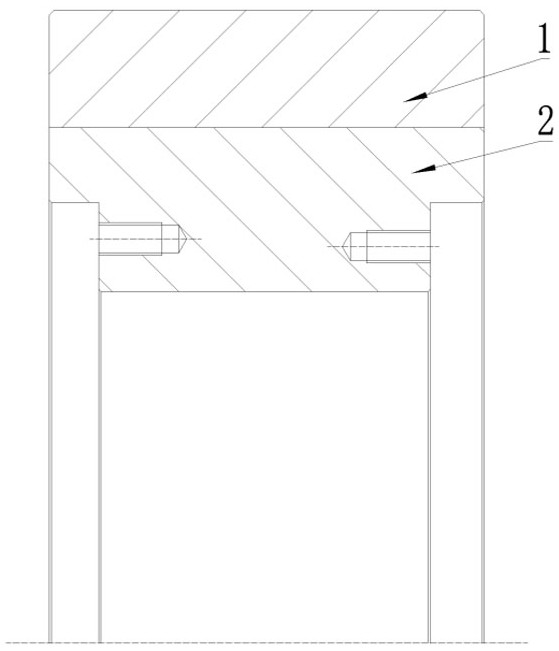

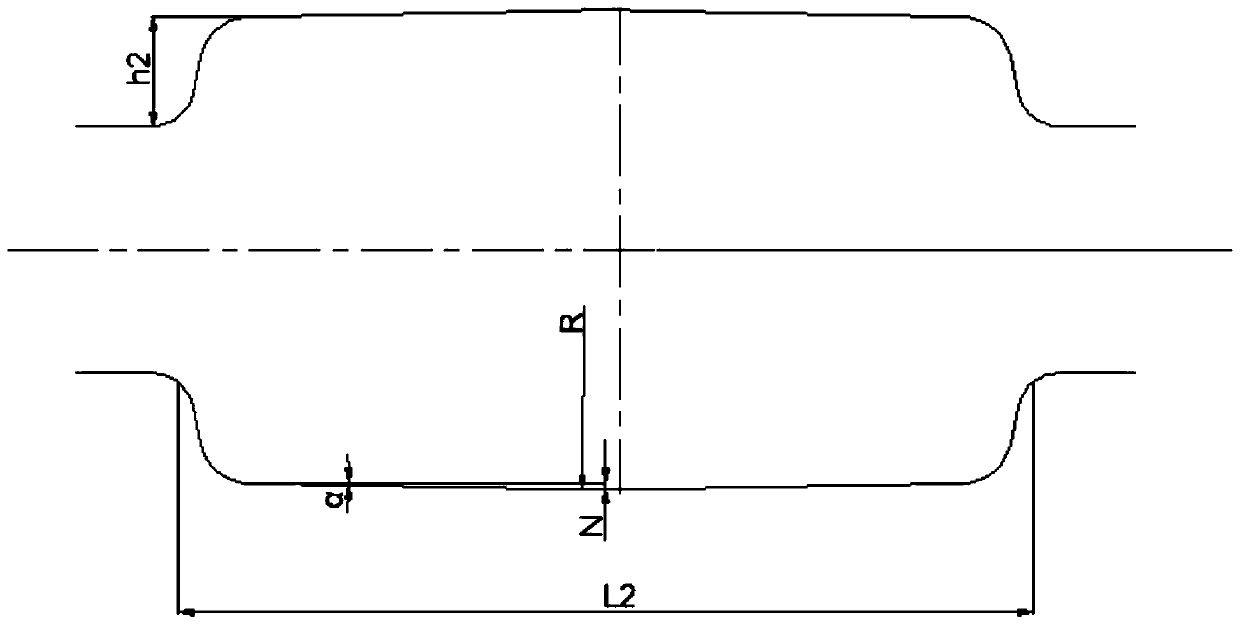

Two-roller reversible mill roller device and technology using continuous casting round billets for carrying out rolling production

ActiveCN103801560AIncrease the amount of steelImprove rolling yieldRollsMetal rolling arrangementsOne passMetallurgy

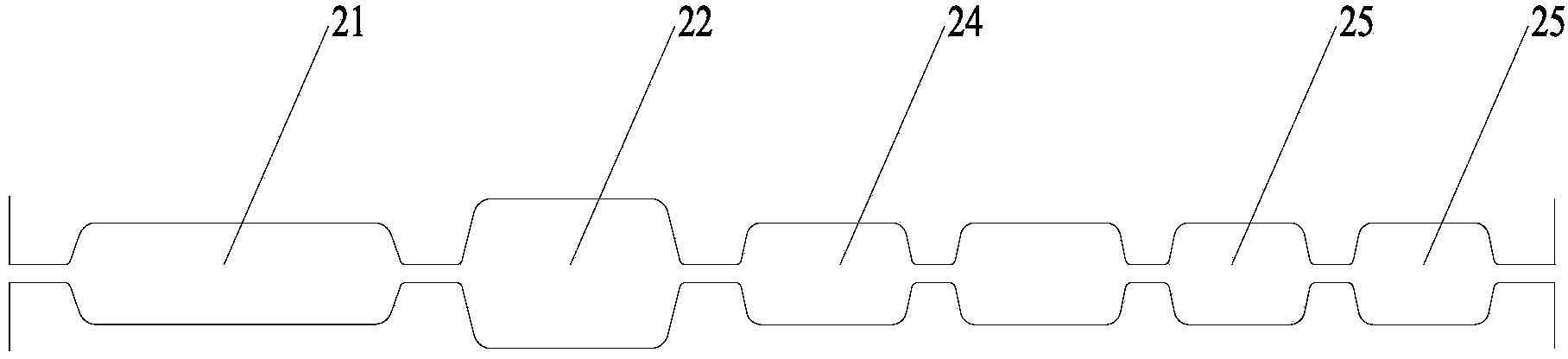

The invention discloses a two-roller reversible mill roller device and technology using continuous casting round billets for carrying out rolling production. Four types of hole patterns including a transition hole pattern, a supporting hole pattern, a before-finished-product hole pattern and a finished product hole pattern are designed on a pair of rollers. The rolling technology comprises the steps of using the transition hole pattern (1) for rolling the continuous casting round billets, and turning over steel after rolling is accomplished, wherein the rolling reduction ranges from 40 mm to 90 mm per pass; using the supporting hole pattern for continuously rolling the drum-shaped rolled pieces obtained in the previous step to obtain rectangular or square rolled pieces which have regular shapes, and turning over the steel after rolling is accomplished, wherein the rolling reduction ranges from 40 mm 90 mm per pass; using the before-finished-product hole pattern (3) for rolling the rolled pieces to obtain rectangular or oval rolled pieces with reserved rolling reduction and reserved broadening quantity, and turning over the steel billets after rolling is accomplished, wherein the rolling reduction ranges from 20 mm to 90 mm per pass; using the finished product hole pattern for rolling one pass to obtain rolled pieces which are high in dimensional accuracy and product quality, wherein the rolling reduction of square or rectangular steel finished products ranges from 40 mm to 60 mm per pass, and the nominal rolling reduction of round steel ranges from 10 mm to 40 mm per pass.

Owner:HUATIAN ENG & TECH CORP MCC

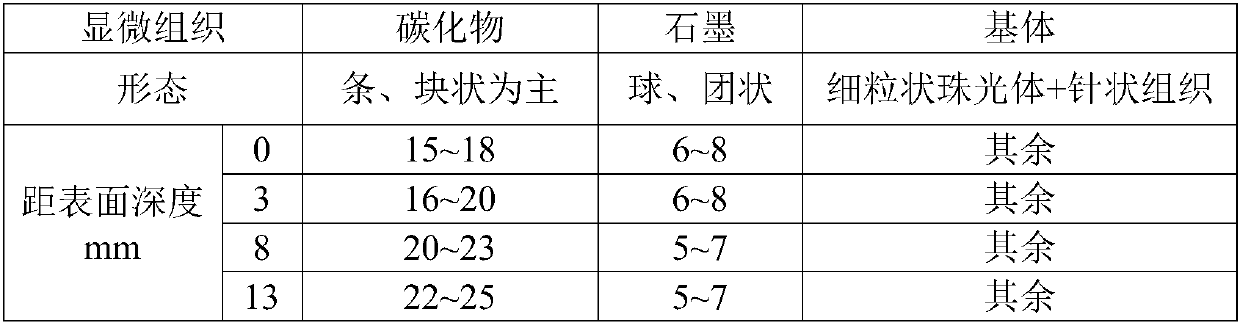

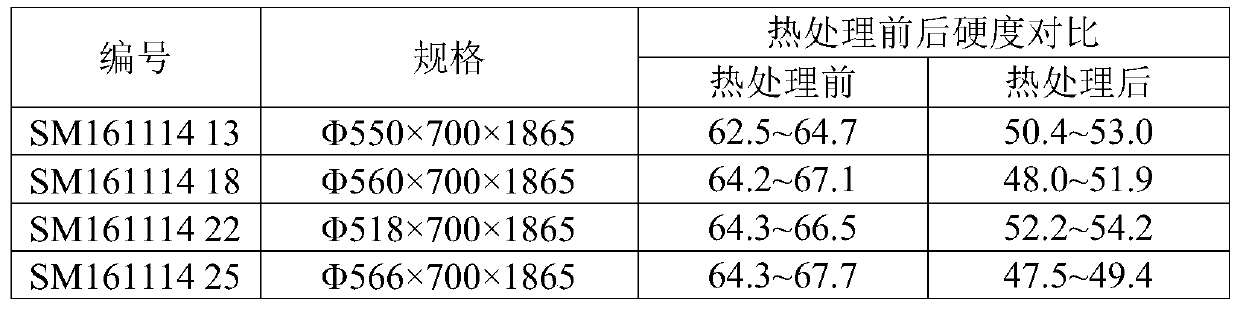

High-strength alloy nodular cast iron coarse roller and production process thereof

InactiveCN111349843AIncrease the amount of formationHigh hardnessFoundry mouldsFurnace typesCarbideDuctile iron

The invention discloses a high-strength alloy nodular cast iron coarse roller and a production process thereof. The high-strength alloy nodular cast iron coarse roller comprises the following chemicalcomponents of, in percentage by mass, 3.0-3.5 of C, 1.2-1.8 of Si, 0.7-1.0 of Mn, less than or equal to 0.03 of P, less than or equal to 0.015 of S, 1.2-2.2 of Ni, 0.3-0.8 of Mo, 0.1-0.5 of V, 0.2-1.0 of Cr, 0.045-0.075 of Mg, 0.01-0.016 of Re, and the balance Fe and unavoidable impurities. According to the coarse roller and the production process thereof, the forming quantities of different types of carbides in a material are increased through the reasonable addition of alloy elements such as Cr, Mo and V, so that the wear resistance of the material is improved; proper quantities of the elements are dissolved in a substrate, so that the strength of the material is improved; and the combined action of Mg and Re reduces the cutting action, on the substrate, by graphite, so that the strength and toughness of the material are further improved.

Owner:江苏凯达重工股份有限公司

Nano ceramic alloy material for strengthening surface of ductile iron roller with laser and preparation method thereof

InactiveCN103060651AWith ultrafineAntioxidantMetallic material coating processesChemical compositionAlloy

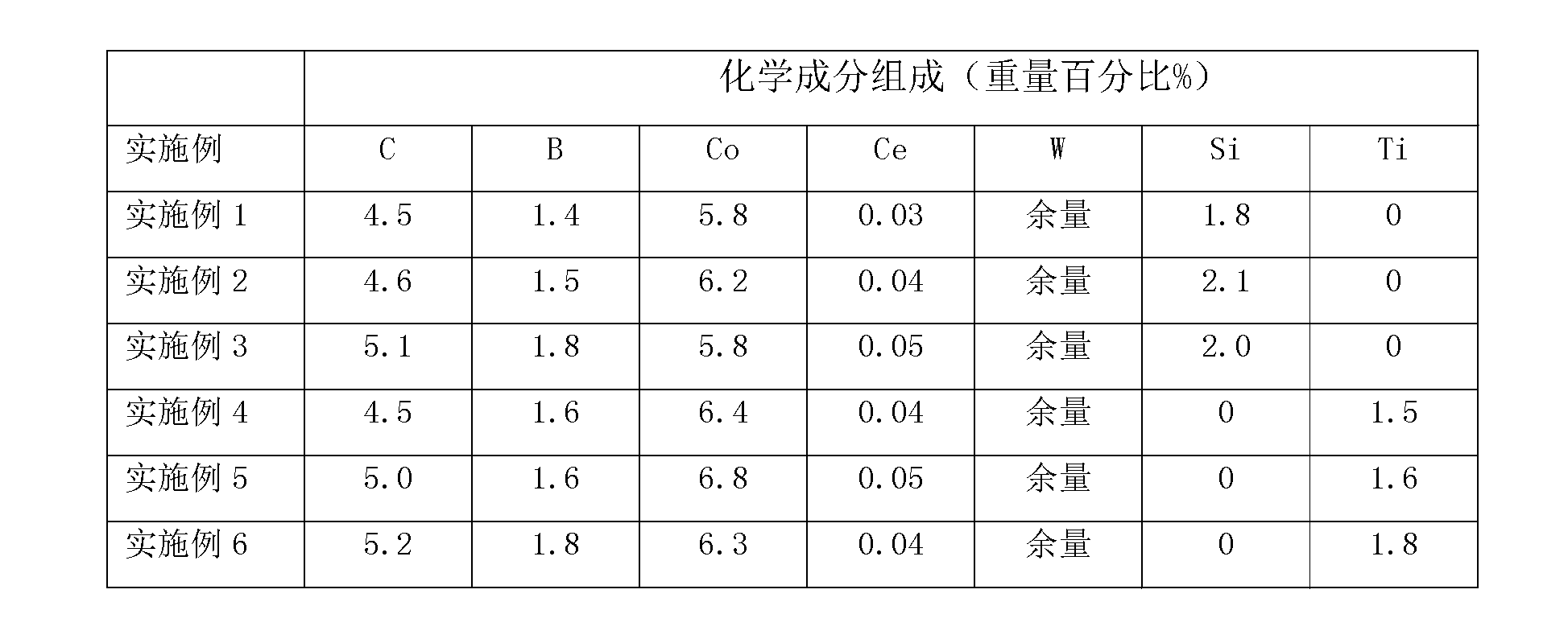

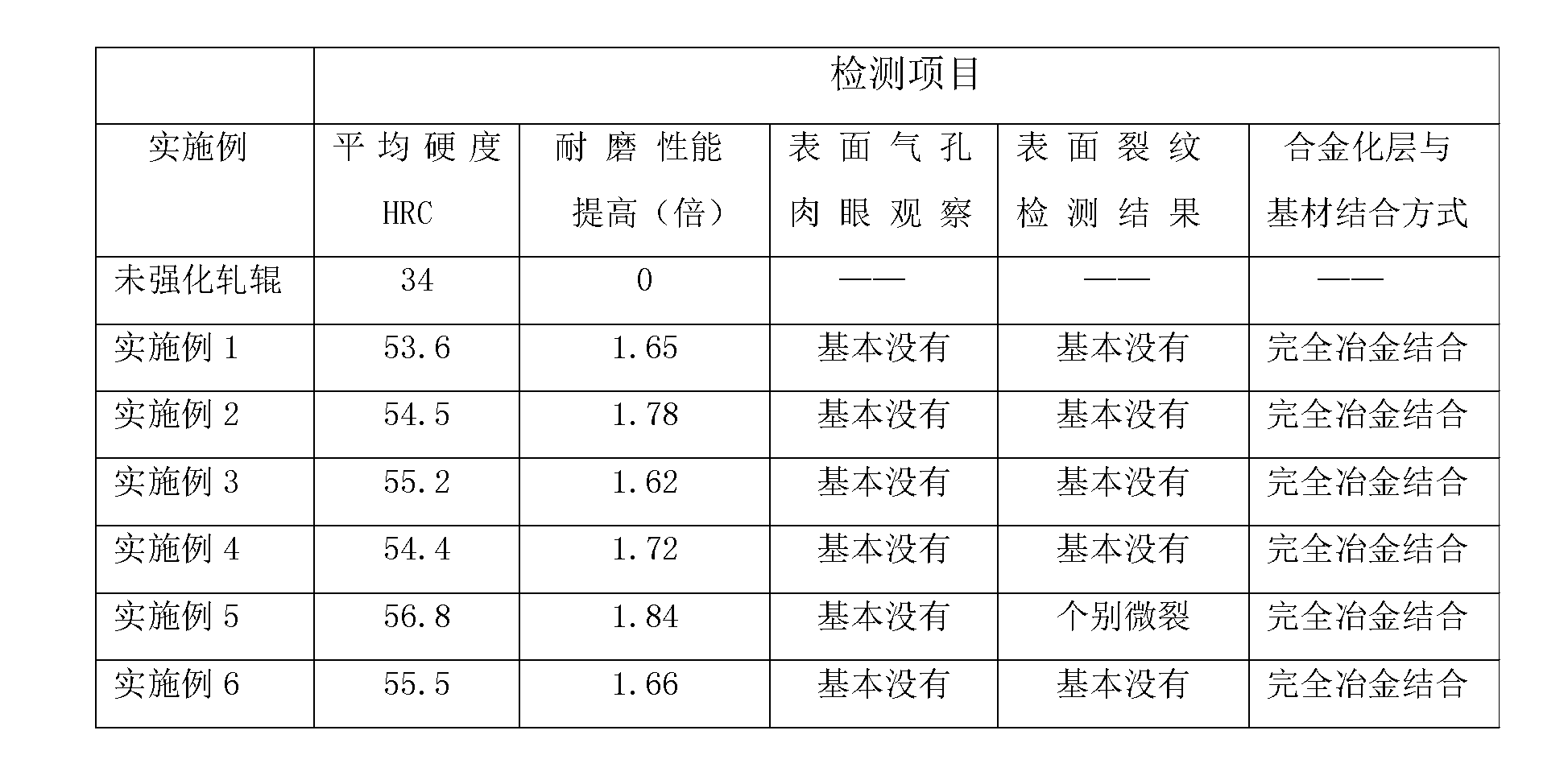

The invention relates to the field of laser fusion covering alloy materials, in particular to a nano ceramic alloy material for strengthening the surface of a ductile iron roller with laser and a preparation method thereof. The method is characterized by taking WC ceramic alloy as the base and comprising the following chemical components in weight percentage: 4.0 to 5.5 percent of C, 1.2 to 2.0 percent of B, 1.5 to 2.5 percent of Si, 4.0 to 14.0 percent of Co, 0.02 to 0.06 percent of Ce, and the balance of W. The laser fusion covering nano ceramic alloy material of the surface of the ductile iron roller is characterized by taking WC ceramic alloy as the base and comprising the following chemical components in weight percentage: 4.0 to 5.5 percent of C, 1.2 to 2.0 percent of B, 1.2 to 2.0 percent of Ti, 4.0 to 14.0 percent of Co, 0.02 to 0.06 percent of Ce, and the balance of W. Compared with the prior art, the nano ceramic alloy material has the advantages that the nano ceramic alloy material provides a convenient and rapid method for repairing disabled ductile iron rollers for steel rolling industry, with remarkable efficiency.

Owner:鞍山煜宸科技有限公司

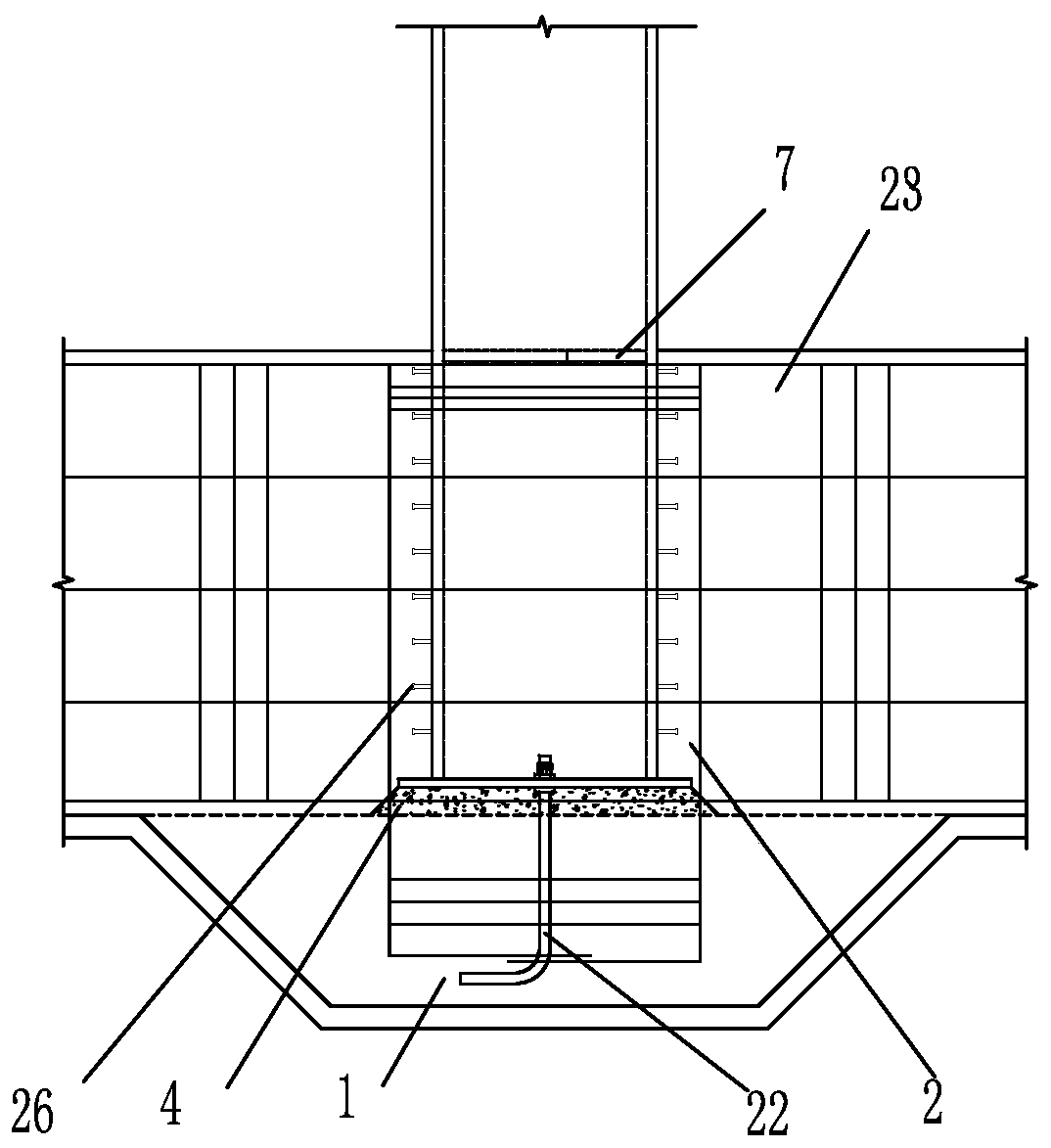

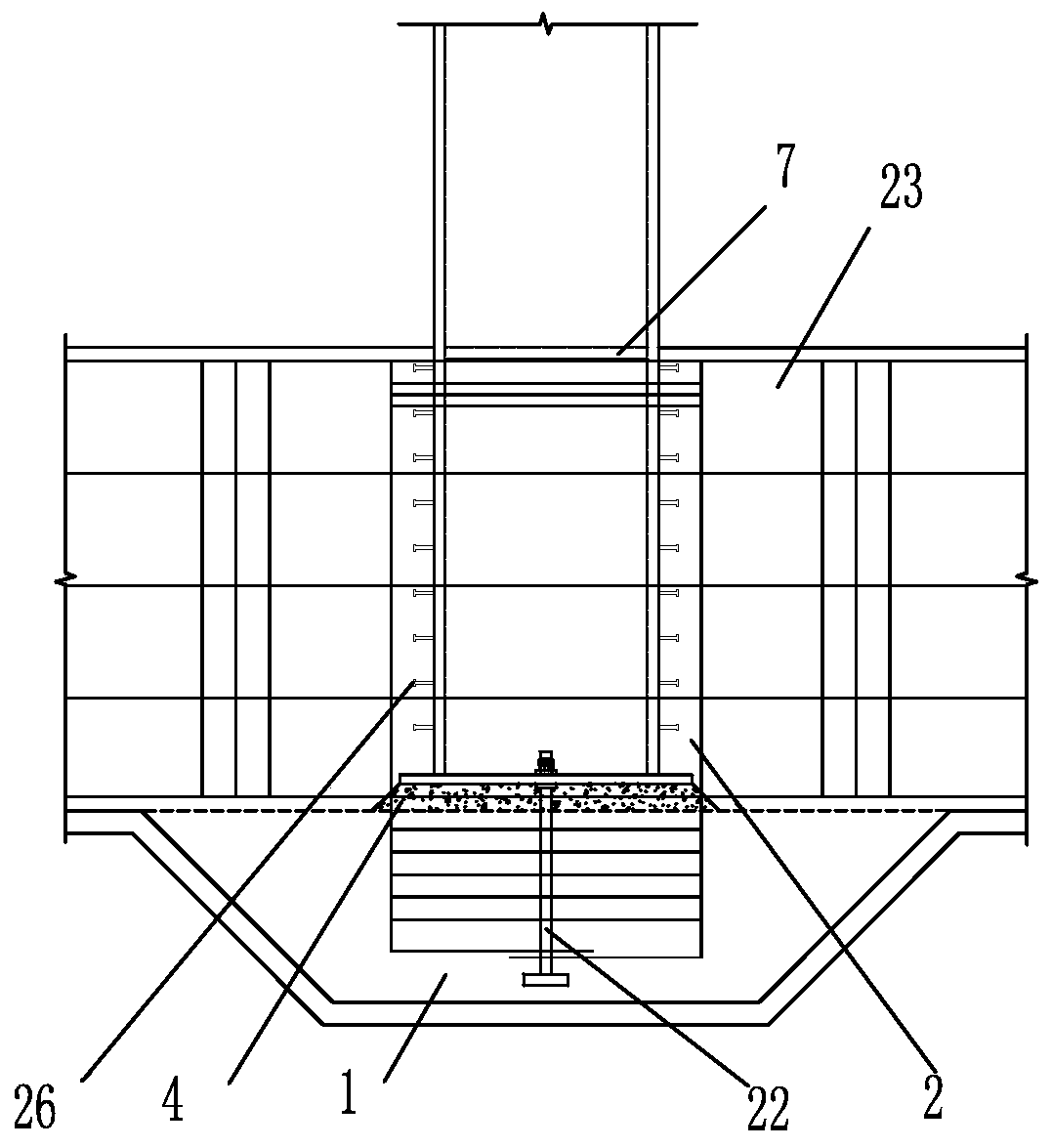

External-stretching-beam buried column base construction for reducing height of bearing table and construction method

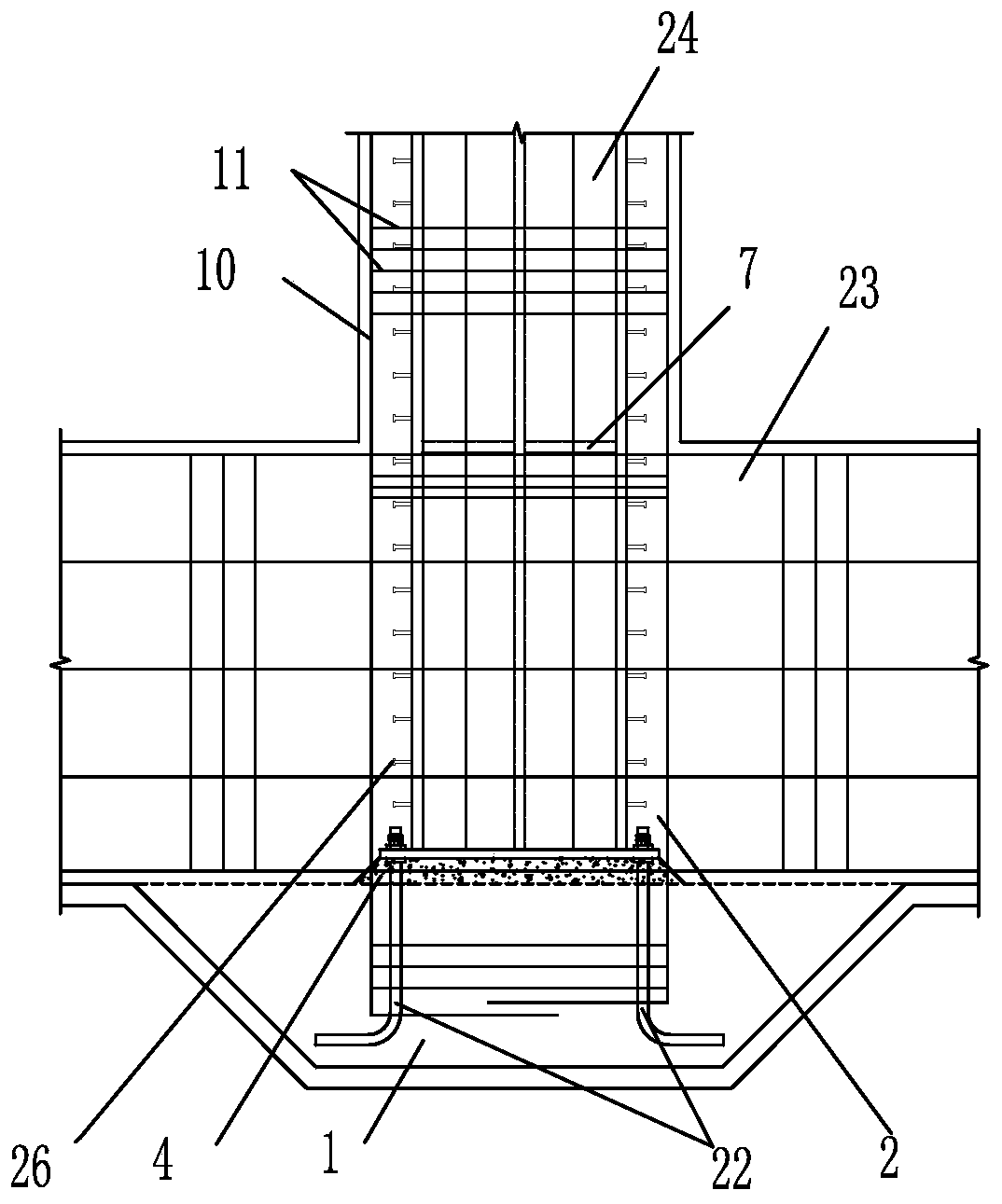

PendingCN110644526ASolve the problem of large heightNodes are safe and reliableStrutsFoundation engineeringSteel framePipe

The invention discloses an external-stretching-beam buried column base construction for reducing the height of a bearing table and a construction method. The construction includes the bearing table, aframe column, and base piles, the frame column comprises section steel, the section steel at the root of the frame column is inserted into the bearing table, the base piles are symmetrically arrangedat the lower portion of the bearing table in a dispersed mode with the frame column as the center, the pile top of each base pile penetrates through a cushion layer and is embedded into the bottom ofthe bearing table, an external-stretching steel beam is arranged on the part, buried in the bearing table, of the section steel with the axis of the section steel as the center towards each base column at the periphery, and the cross section of the external-stretching steel beam is in an H or a square-pipe shape; and one end of each external-stretching steel beam is fixedly connected with the section steel on the frame column to form a whole steel component with the section steel, the other end of each external-stretching steel beam extends above the pile head of the corresponding base columnand makes the end of each external-stretching steel beam stretch out of the center of the corresponding base column, and the section steel at the root of the frame column and the external-stretchingsteel beams are supported on the cushion layer at the lower portion through a supporting steel frame at the bottom of the section steel and poured into the bearing table in an overall mode with concrete. The external-stretching-beam buried column base construction can solve the problems of unnecessary waste and inconvenient construction due to the too-large height of a bearing table in the prior art.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST +2

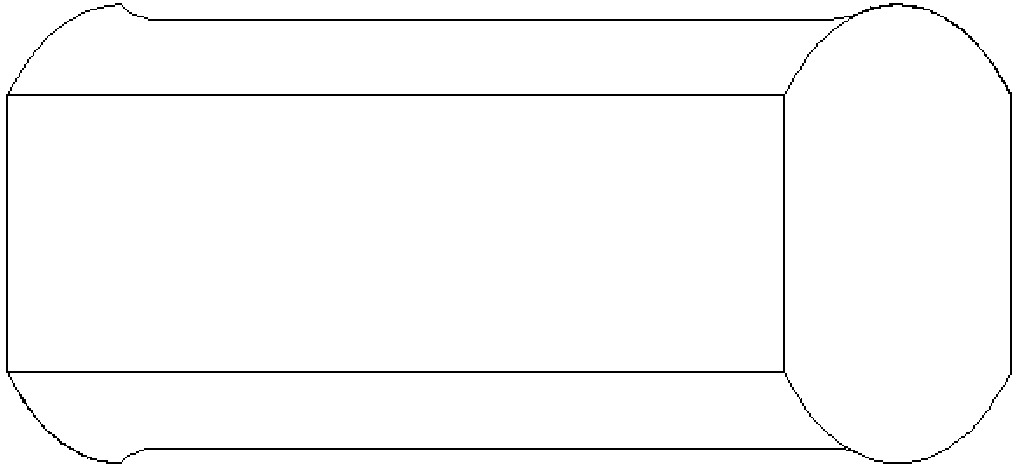

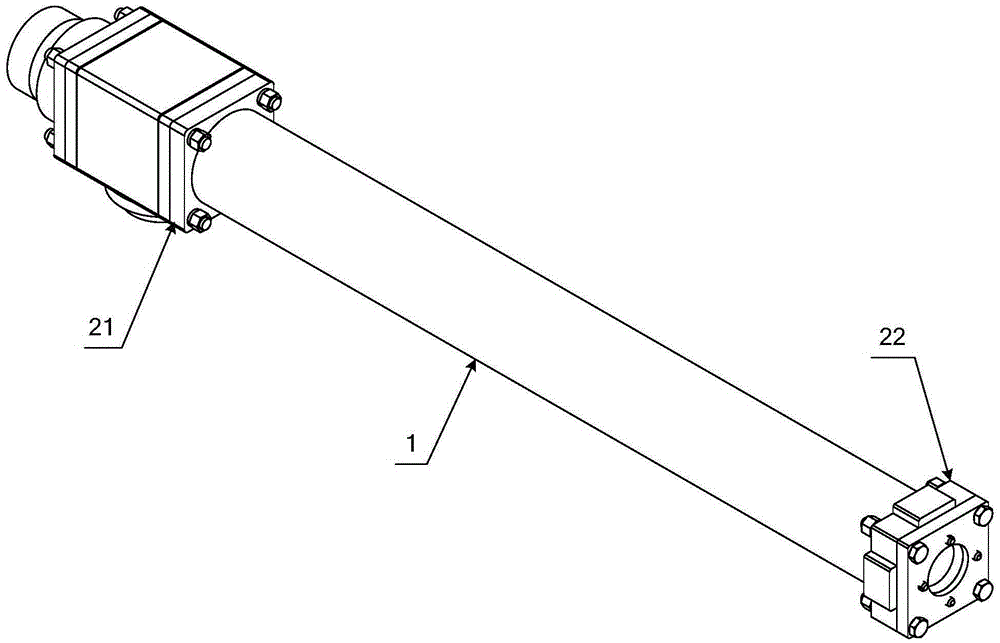

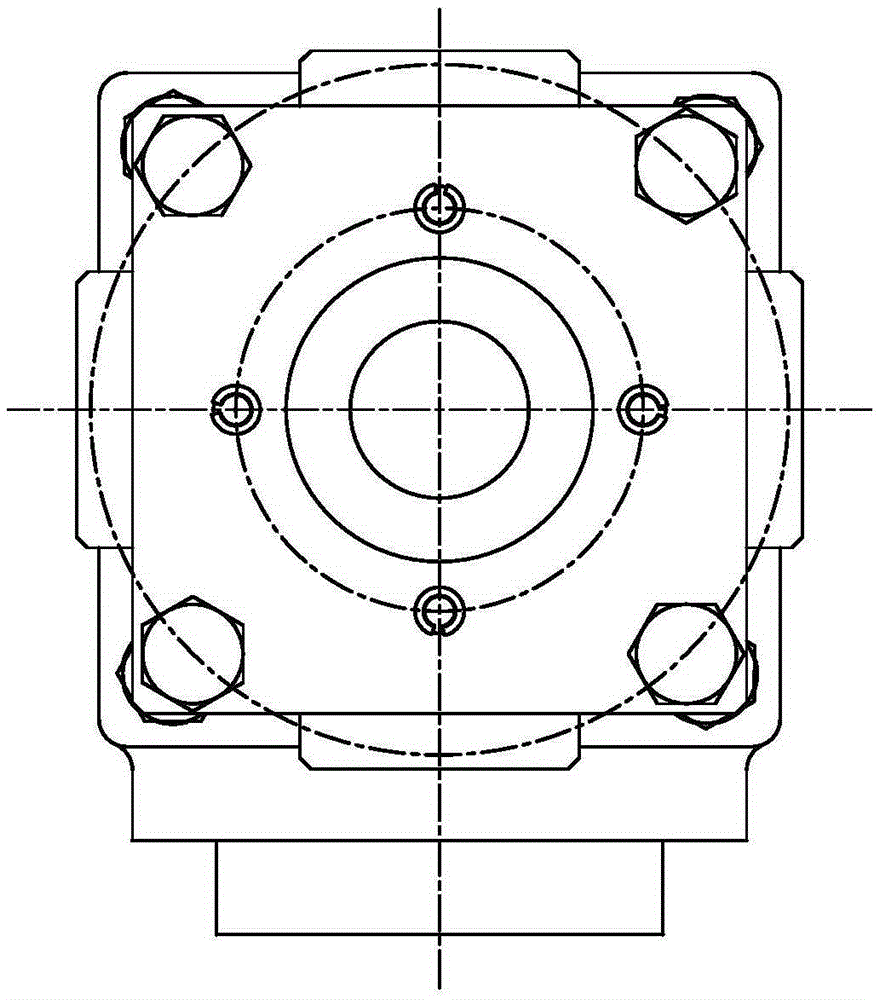

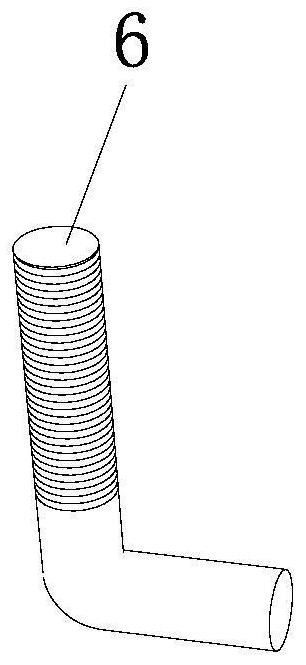

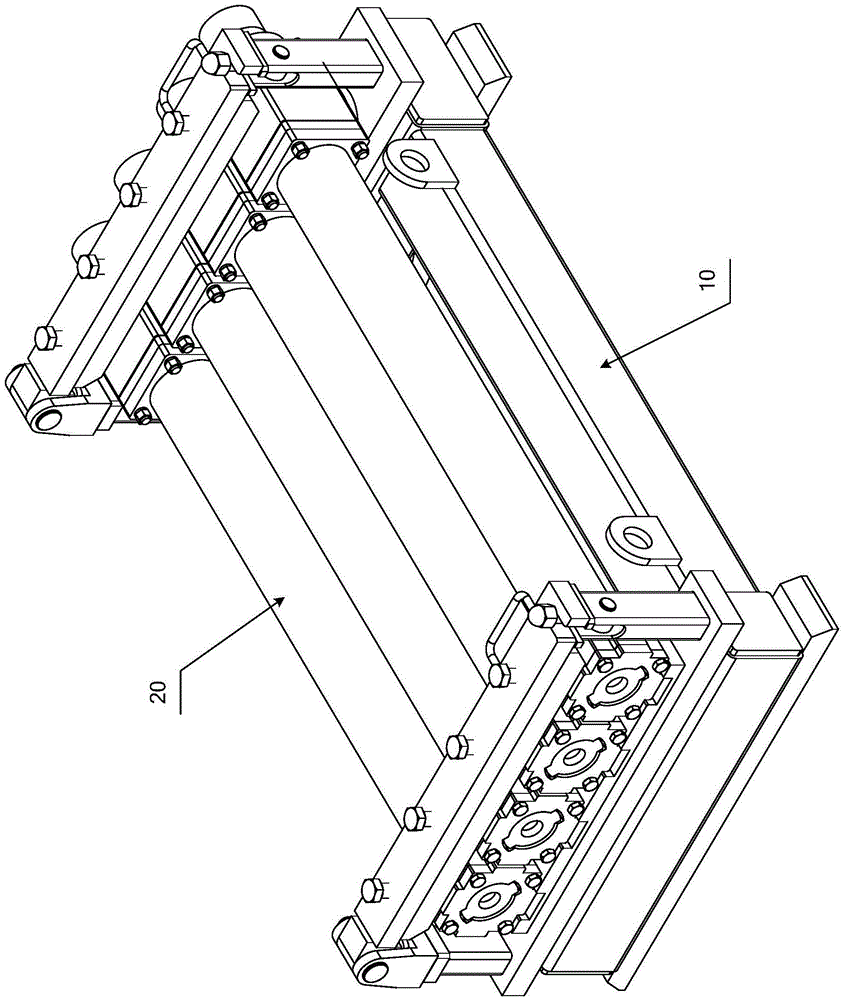

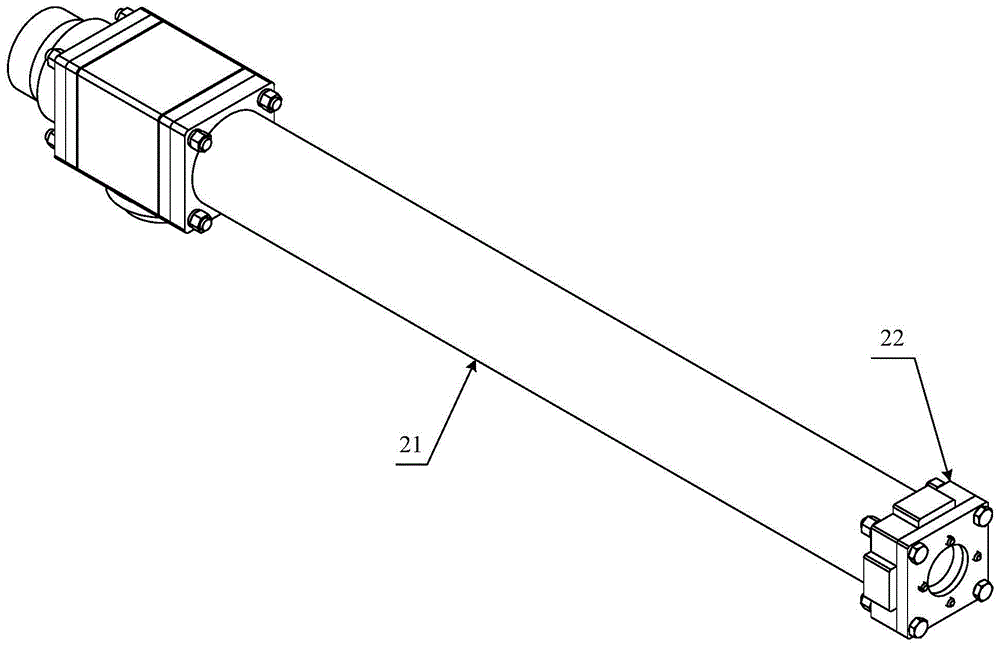

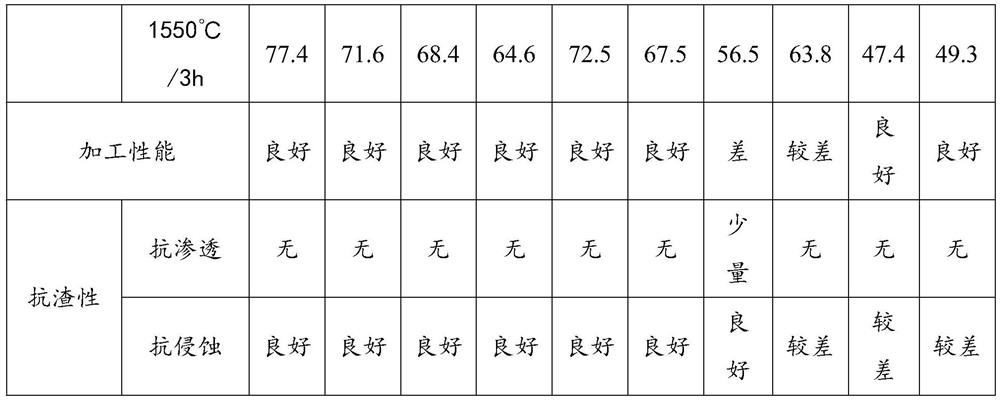

Through water cooling tube

ActiveCN105382042AIncrease the amount of steelExtended service lifeWork cooling devicesMetal rolling arrangementsEngineeringWater cool

The invention discloses a through water cooling tube. A mounting mechanism of the through water cooling tube is positioned on the same axial position of a tube body, and is staggered in a circumferential direction of the tube body, so that after the inner bottom surface of the tube body is worn by through steel, the tube body is turned over by certain angle around the central axis, and is fixed to a base of a cooling device by adopting another mounting mechanism while the inner worn part of the tube body is turned over to the side surface or the top surface, and can be continuously used, so that total amount of steel of single tube can be improved, and therefore, the service life of the single tube is prolonged, and the production cost is reduced.

Owner:安徽诺泰工程技术有限公司

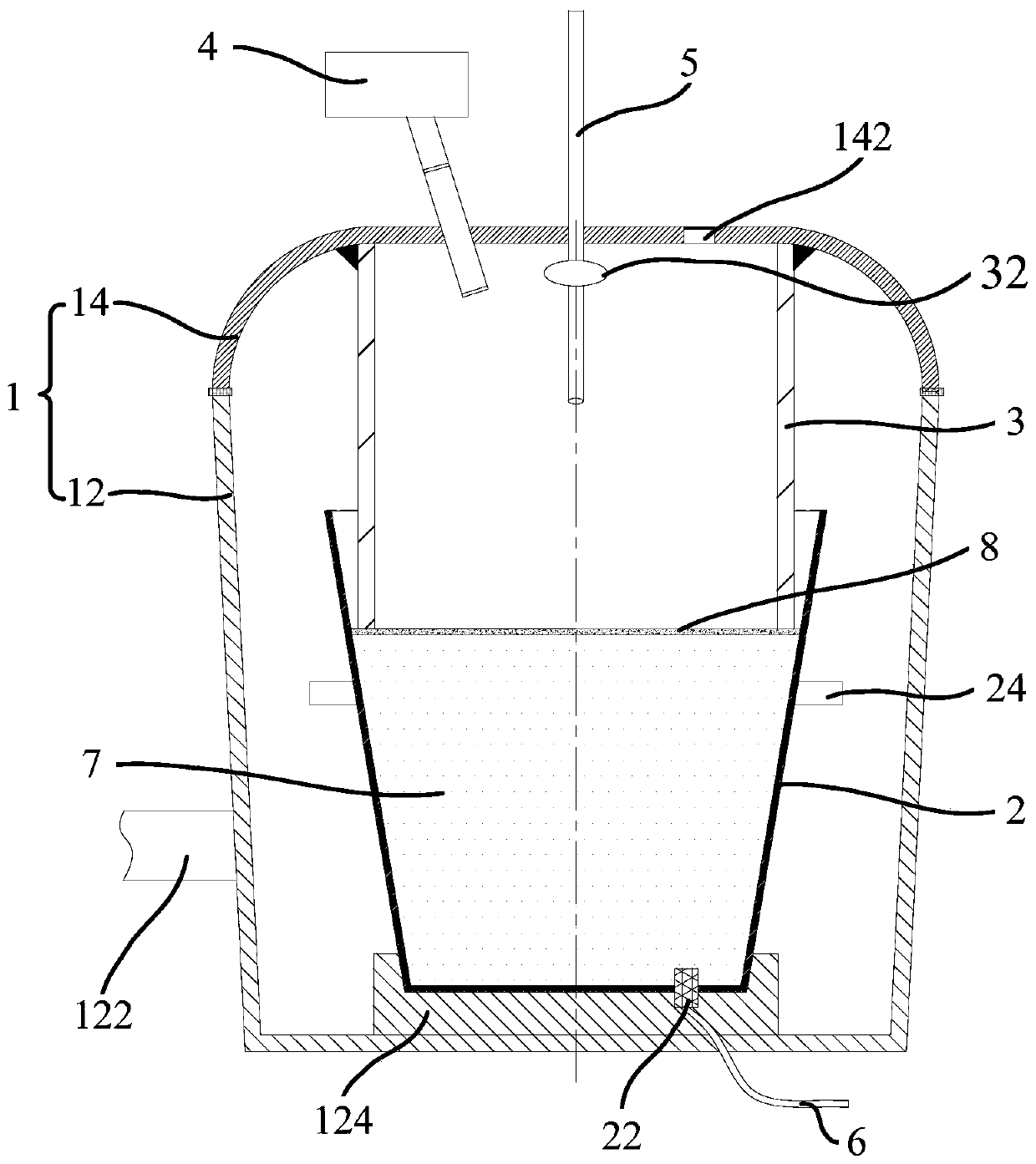

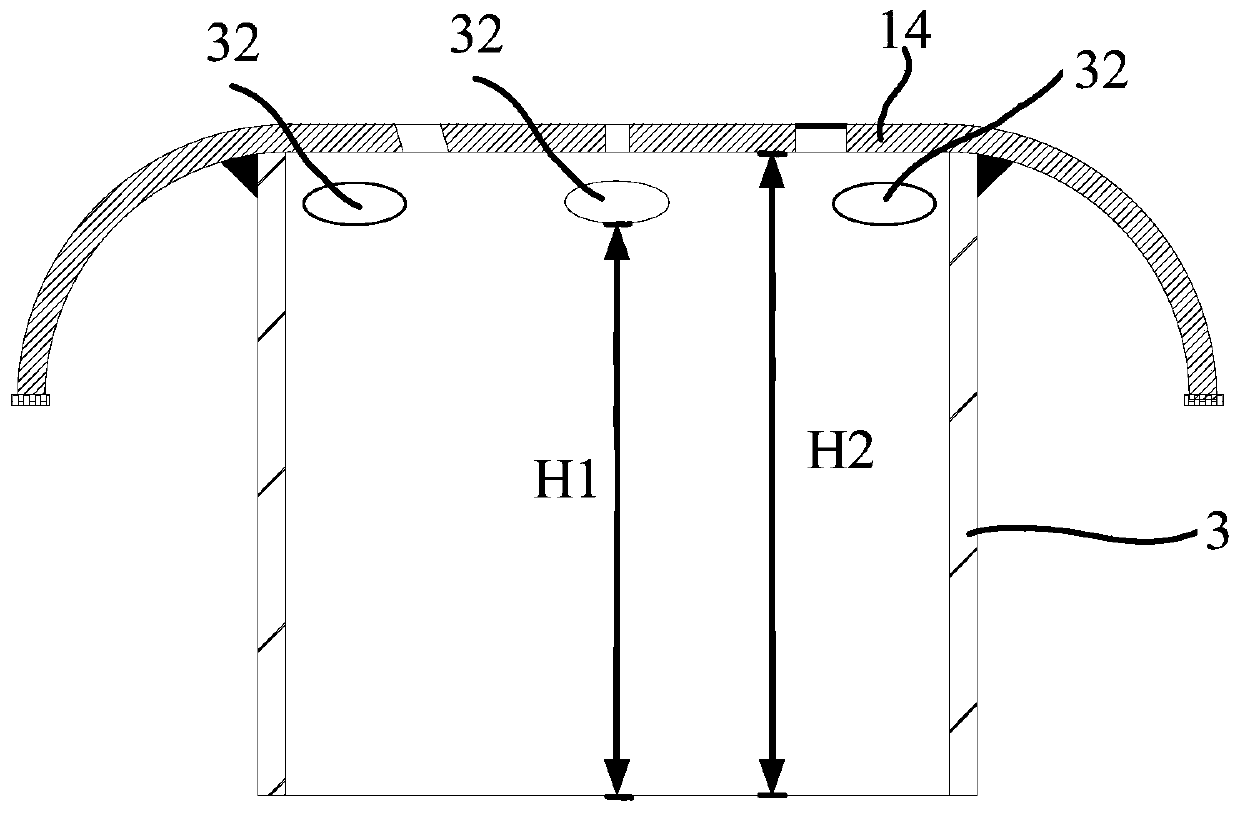

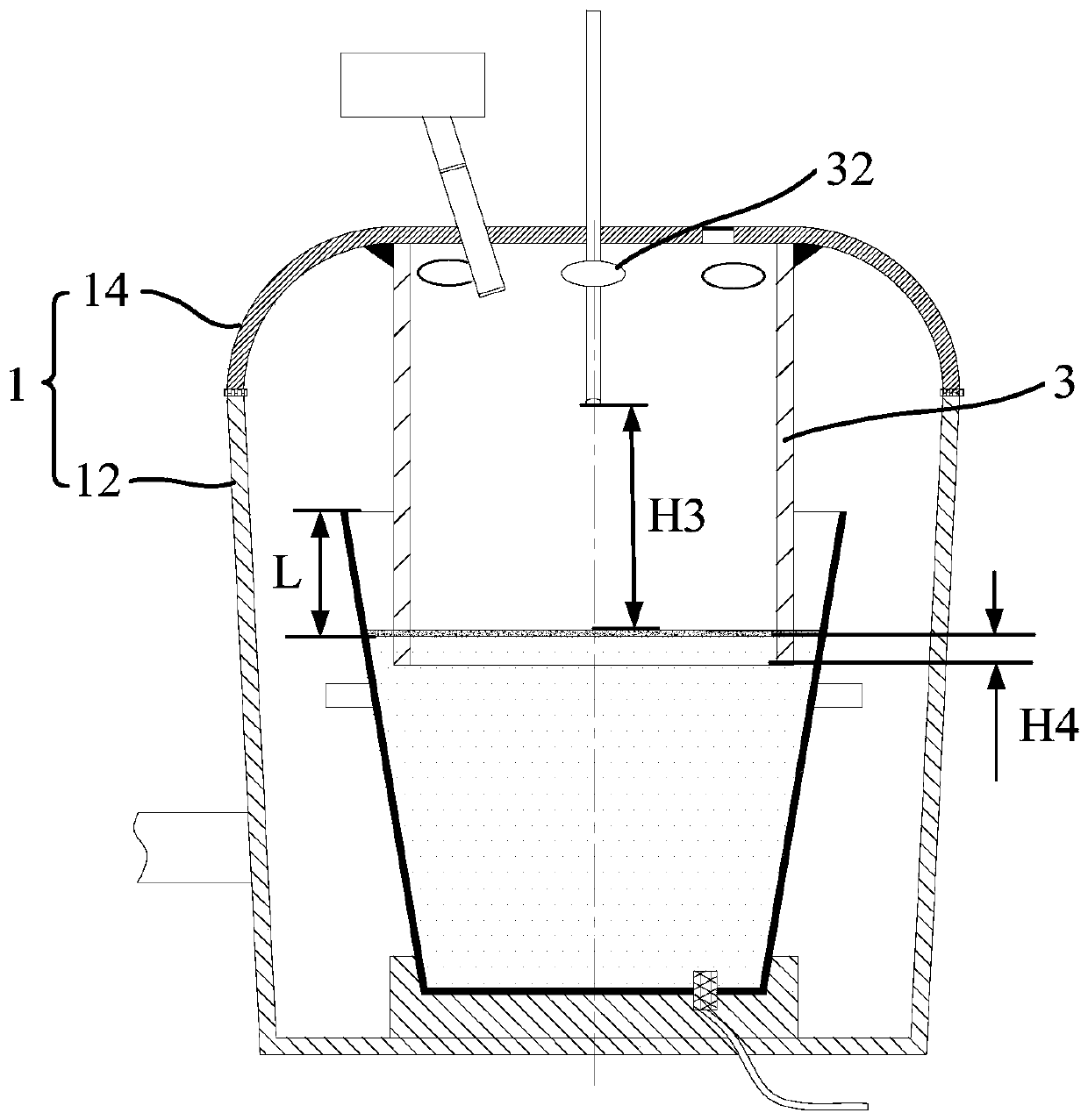

Tank type single-nozzle refining furnace and vacuum refining method

The invention provides a tank type single-nozzle refining furnace and a vacuum refining method. The tank type single-nozzle refining furnace comprises a vacuum tank and a single-nozzle dipping pipe, wherein the vacuum tank consists of a vacuum tank body and a vacuum tank cover; a vacuum air extracting pipeline is arranged on the vacuum tank body; a steel ladle containing molten steel to be treatedcan be placed in the vacuum tank; one end of the single-nozzle dipping pipe is integrated with the vacuum tank cover; after the steel ladle is hung in the vacuum tank, the lower end of the single-nozzle dipping pipe can extend into the steel ladle when the vacuum tank cover is lowered; and a vent hole for communicating the dipping pipe with the vacuum tank is formed in the upper end of the single-nozzle dipping pipe. In the scheme, the dipping pipe covers above the molten steel or is inserted into the molten steel, so that when slag overflow or molten steel splashing occurs in the dipping pipe, the slag overflow or the molten steel is prevented from being separated from the steel ladle to enter the vacuum tank body, the pollution to the vacuum tank body can be reduced, the steel tapping amount of a primary steel-making furnace can be increased, and the steel yield is further increased; and meanwhile, the argon blowing amount can be increased, the refining effect is enhanced, the refining efficiency is improved, the tank type single-nozzle refining furnace is better linked with the primary steel-making furnace and a subsequent continuous casting process, and the smoothness and continuity of each process are guaranteed.

Owner:赵元庆 +1

Laser alloying method of shaped roll

InactiveCN104250809AExtended service lifeTough enoughMetallic material coating processesSurface layerCarbonization

The invention relates to a laser alloying method of a shaped roll, which comprises the following steps: A)pre-treating the surface of the roll; B)coating a layer of light absorption paint containing 35-45% of carbonization particles on the pretreated roll surface, and drying in air; C)scanning the coating surface of the roll by layer, wherein the laser power is 2.0-2.5KW, the scanning speed is 200-300mm / min, spot size is 15*2mm; and D)detecting the product. The unique performance of rapid heating and cooling of the layer can be used, the carbide material alloy particles are added on a surface fusion layer of the work surface of the shaped roll by laser beam, and then a layer of alloying layer is formed, the carbide particles are existed on a work surface layer of the roll by a coating mode, the carbide particles with high hardness and high wear resistance are used for increasing the service life of the work surface, so that the roll has enough toughness, production efficiency of the roll is greatly increased, and roll loss can be reduced.

Owner:DANYANG HONGTU LASER TECH

Hot-rolled section steel roll and preparation method thereof

ActiveCN110508785AImproved wear and thermal crack resistanceGood plastic deformation abilityFurnace typesHeat treatment furnacesPearliteHot rolled

A hot-rolled section steel roll takes a SGA 1 material as an outer layer and a QT 500-5 material as a core material; after heat treatment, the composition of a god phase structure at the outer layer changes, such as that at the position 0 mm deep from the surface, 30-35% of carbide, 5-7% of graphite and a matrix with lamellar pearlite are converted into 15-18% of carbide, 6-8% of graphite and a matrix with a fine grained pearlite and an acicular structure. The hot-rolled section steel roll is prepared by adopting a centrifugal composite bimetal casting method, so that the wear resistance and the thermal cracking resistance of the product are further improved while the alloy content of the outer layer of the roll is greatly improved. Through actual rolling, the steel passing amount is improved by more than 30 percent, and the phenomena of ring breakage and roll breakage are not generated; and the direct cost of roller consumption is decreased by more than 30 percent for iron and steel enterprises.

Owner:思诺冶金设备(上海)有限公司

Novel roller surfacing process

InactiveCN109108516AImprove wear resistance and impact resistanceIncrease the amount of steel passing through a single grooveWelding apparatusEngineeringImpact resistance

The invention provides a novel roller surfacing process. Layered surfacing is carried out on a roller by using welding sticks made of various materials, bottom-layer surfacing facilitates welding fusion with a base body, upper-layer surfacing is a working layer, the wear resistance and impact resistance of the roller can be effectively improved, the service life of a roller hole model is effectively prolonged, hole model processing is facilitated, the single-slot steel passing quantity is improved, the production efficiency is effectively improved, and the surface quality of products is improved.

Owner:ZENITH STEEL GROUP CORP +1

Method for increasing tapping quantity of converter

PendingCN114381568AImprove utilization efficiencyEmission reductionManufacturing convertersSmelting processProcess engineering

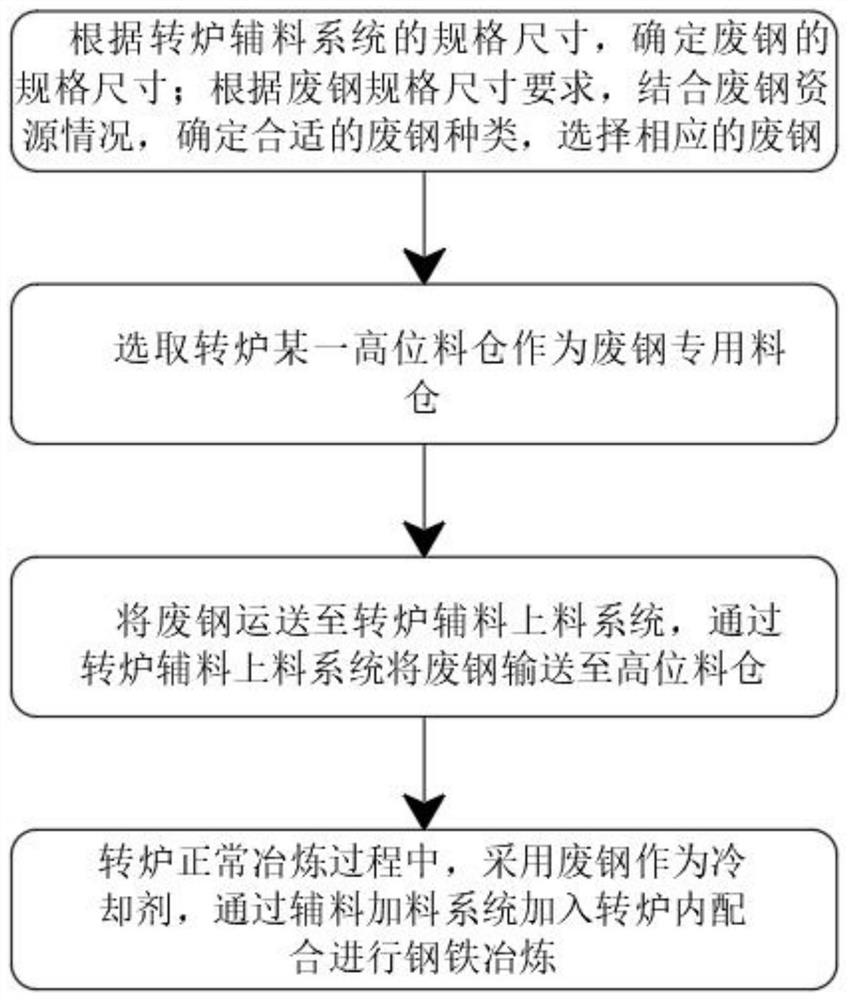

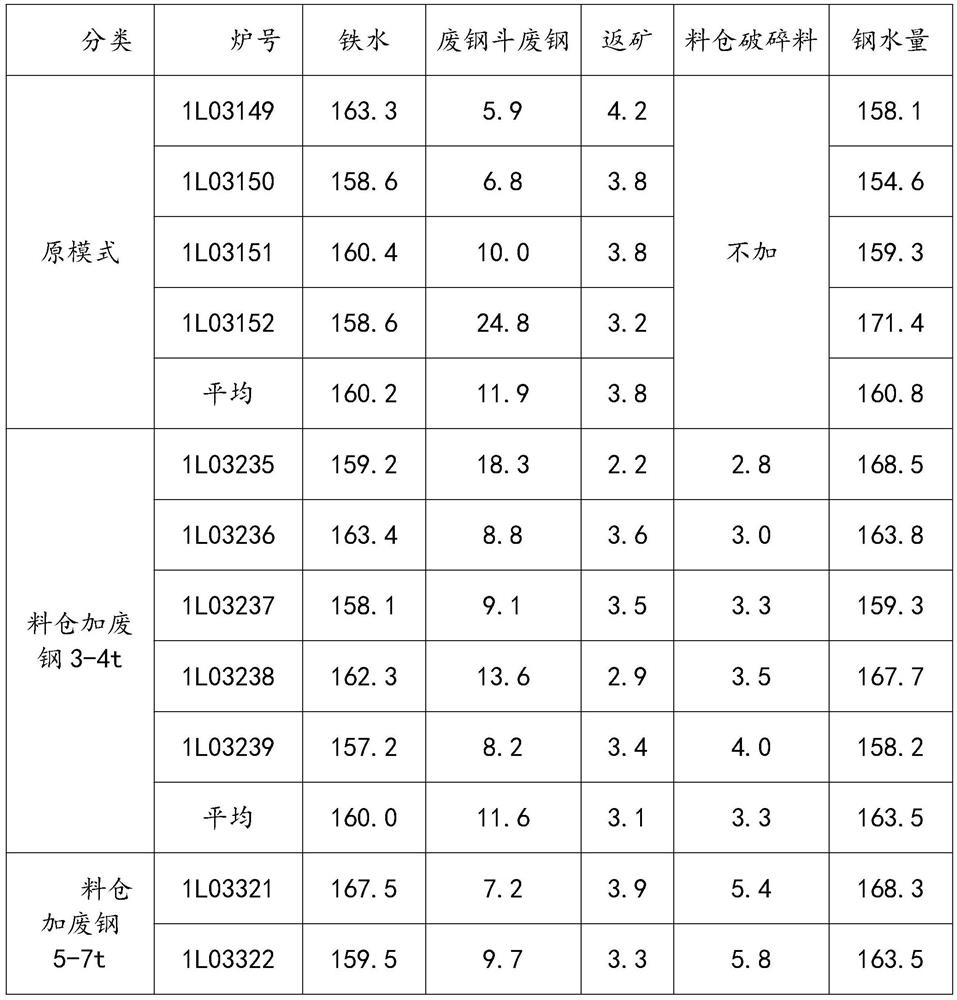

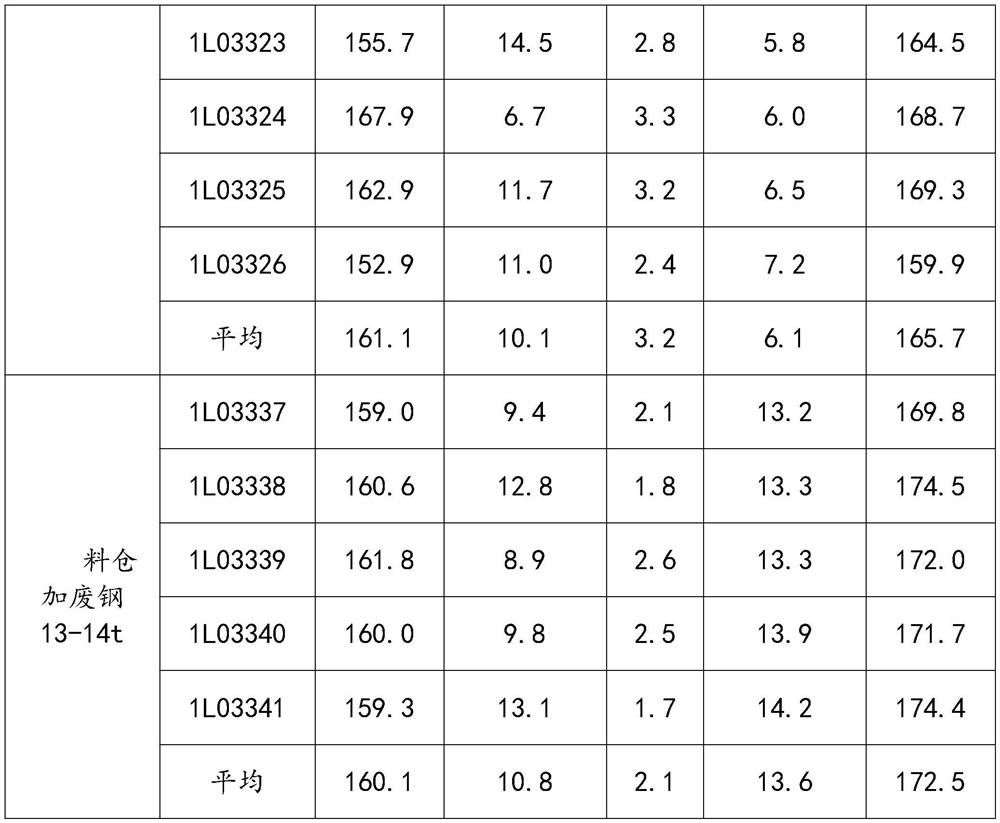

The invention discloses a method for increasing the tapping quantity of a converter, which comprises the following specific steps: selecting waste steel: determining the specification and size of the waste steel according to the specification and size of an auxiliary material system of the converter; according to the specification and dimension requirements of the scrap steel, the appropriate scrap steel type is determined in combination with the scrap steel resource condition, and the corresponding scrap steel is selected; selecting a stock bin: selecting a certain overhead stock bin of the converter as a special stock bin for scrap steel; waste steel is conveyed, specifically, the waste steel is conveyed to a converter auxiliary material feeding system, and the waste steel is conveyed to an overhead bunker through the converter auxiliary material feeding system; in the normal smelting process of the converter, the waste steel is adopted as a cooling agent and added into the converter through an auxiliary material feeding system to be matched for steel smelting, the method is suitable for steel smelting, the waste steel with the high yield is adopted as a temperature adjusting agent in the smelting process of the converter, and the addition amount of the waste steel is secondarily adjusted according to the heat balance change of the converter; physical heat and chemical heat of molten iron are fully utilized, waste steel is added as much as possible, and the tapping amount of the converter is increased.

Owner:ANYANG IRON & STEEL +1

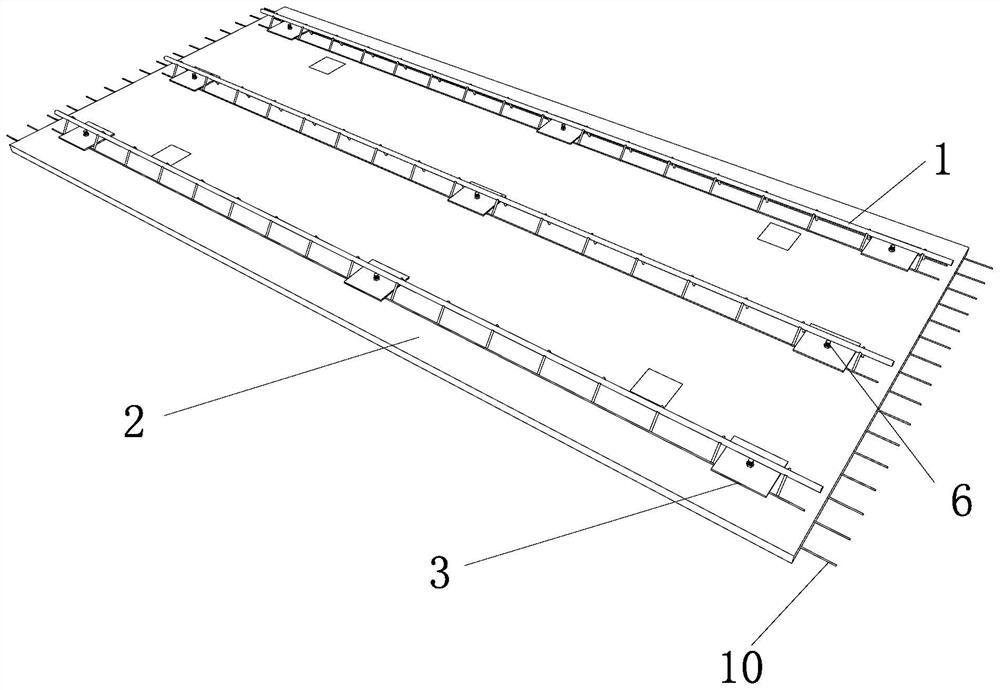

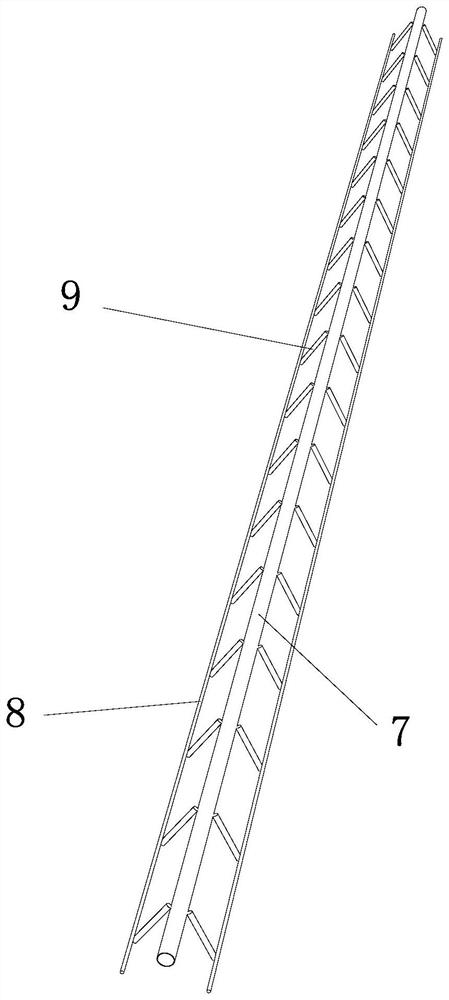

Construction method of prestressed thin plate and laminated plate with detachable ribs

PendingCN113931364AIncreased compressive strength and stiffnessGood integrity and rigidityFloorsCeramic shaping apparatusThin slabRebar

The invention relates to a construction method of a prestressed thin plate and a laminated plate with detachable ribs. The prestressed thin plate comprises a prestressed bottom plate, the detachable ribs and connecting assemblies, the detachable ribs comprise upper chords, lower steel bars and web members, and the two lower steel bars and one upper steel bar are fixed through the plurality of web members; the connecting assembly comprises a fixing plate, a fixing piece and a connecting piece, the first end of the connecting piece is anchored in the prestressed bottom plate, and the second end of the fixing piece is exposed out of the prestressed bottom plate and fixed to the fixing plate through the connecting piece; the lower steel bars are placed on the surface of the prestress bottom plate, the fixing plate stretches across the two lower steel bars, and the connecting piece is arranged between the two lower steel bars. The laminated slab comprises the prestressed thin slab and a cast-in-place layer, concrete of the cast-in-place layer is poured on the surface, away from the detachable ribs, of the prestressed bottom plate, the construction method comprises the steps that S1, the prestressed thin plate is produced; S2, the cast-in-place layer is poured; and S3, dismantling is conducted. The prestressed thin plate is large in span, small in thickness, not prone to cracking and high in transportation efficiency.

Owner:筑友智造建设科技集团有限公司

Casting emulsifier of continuous casting crystallizer copperplate and production method thereof

The invention discloses a casting emulsifier of a continuous casting crystallizer copperplate and a production method thereof. The casting emulsifier of the continuous casting crystallizer copperplate comprises the following components in weight percentage: 86.00-99.00% of C solid, 0.10-5.58% of CaO, 0.23-3.31% of Al2O3 and 0.11-6.68% of MgO. The lubrication effect of molten steel on the crystallizer copperplate in a casting process is realized by adding large quantities of nanographites into a liquid resin; the dispersity of the nanographites is particularly prominent by effect of a proper solvent, such as a liquid resin or a chelating agent; and the casting emulsifier of the continuous casting crystallizer copperplate can be densely and firmly adhered to the prewashed continuous casting crystallizer copperplate by brushing or spraying, and a coating-like protection film is formed on the surface of the copperplate, so that the sufficient lubrication of casting blanks is realized, the friction of the casting blanks on the crystallizer copperplate is reduced, and the copperplate is protected.

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

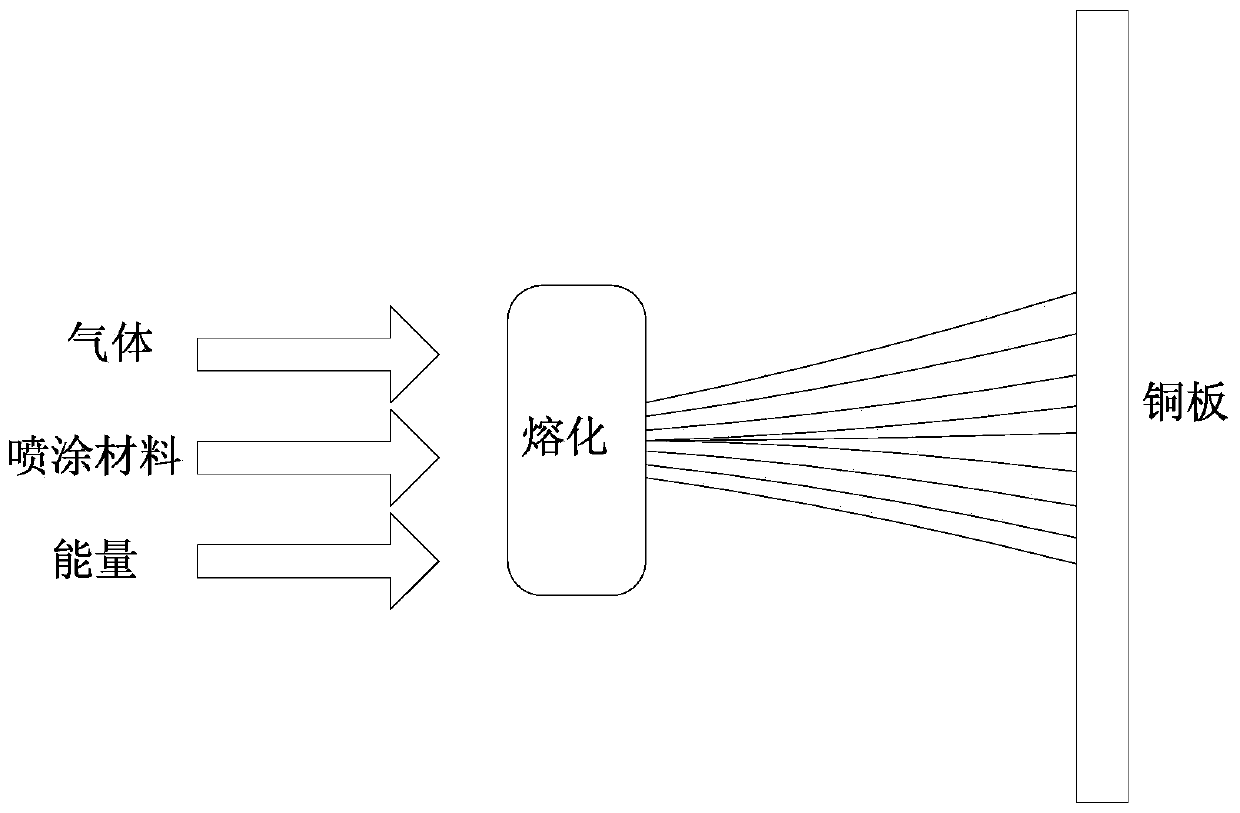

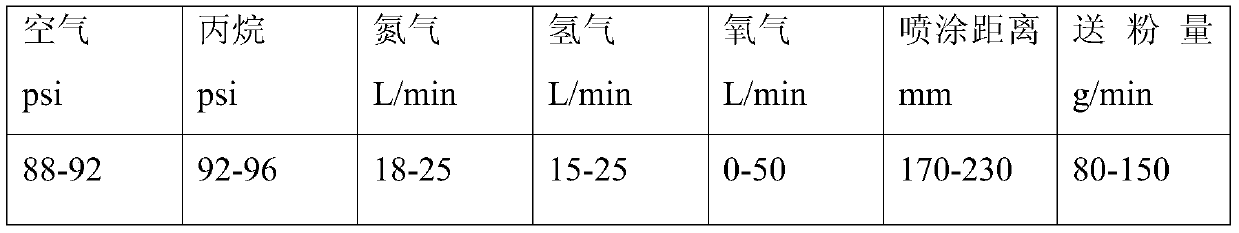

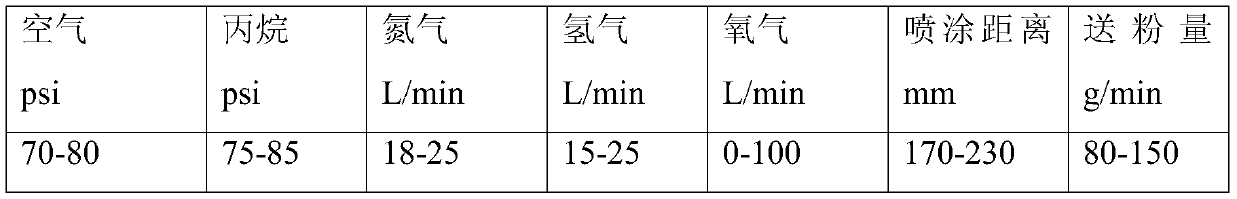

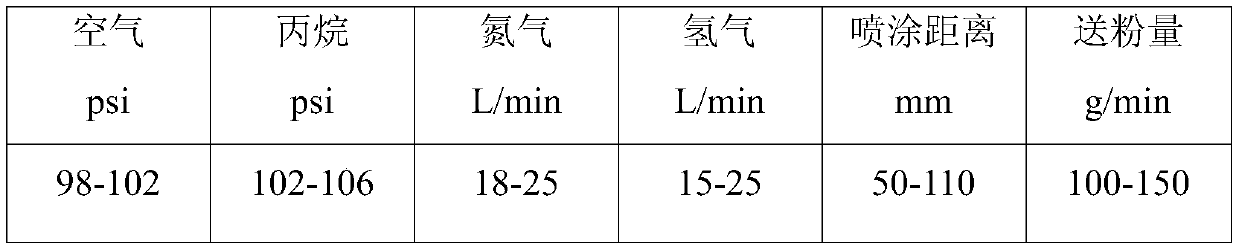

Supersonic Spraying Technology of Roll Passes Made of Semi-steel

ActiveCN103173713BImprove performanceImprove heat resistanceMolten spray coatingCoated surfaceHeat resistance

The invention discloses a supersonic spray process for a shaped roll pass made of semisteel, which comprises the following steps: 1) carrying out pretreatment on the working surface of the roll pass; 2) carrying out shot blasting on the working surface of the roll pass; 3) carrying out supersonic spray on the working surface of the roll pass; and 4) carrying out hole sealing treatment on a coating. The supersonic spray process disclosed by the invention has the advantages that 1, by using a JP5000-type supersound flame spraying system, the flying speed of melting powder is greater than 720 m / s, the property of the coating is excellent, and the surface of the coating is dense, so that the surface quality of products is greatly improved; 2, the tungsten carbide metal composite powder coating is good in wear resistance and heat resistance, so that for insufficiently cooled shaped lower rolls, the steel bonding caused by frictional wear and the roll marks caused by adhesive wear are avoided, thereby reducing the accident loss due to poor quality; and 3, the wear resistance of the roll pass is increased, the steel passing quantity of the roll pass is increased, the roll loss is reduced, and the service life of a semi-steel shaped roll is prolonged.

Owner:ANHUI HENGYI HARD FACE ENG CO LTD

Reinforced alloy cast steel roller and preparation method thereof

ActiveCN112011743AHigh strengthImprove impact toughnessFoundry mouldsFurnace typesSteel castingPlasticity

The invention discloses a reinforced alloy cast steel roller. The reinforced alloy cast steel roller is prepared from the alloy elements in percentage by weight: 0.7%-0.9% of C, 0.3%-0.8% of Si, 0.5%-1.0% of Mn, 1.0%-1.5% of Cr, 0.5%-1.0% of Ni, 0.3%-0.8% of Mo, 0.1%-0.3% of Nb, 0.1%-0.3% of V, less than or equal to 0.03% of P, less than or equal to 0.025% of S, and the balance of Fe and inevitable impurities. A matrix structure of a roller is improved by adding the elements Nb and V, roll usability performance is improved, and Nb can achieve the effects of grain refinement and solid solutionstrengthening. The trace Nb can improve the strength and impact toughness of steel under the condition of not influencing the plasticity and toughness of the steel, V can refine grains, improve high-temperature strength and yield ratio of the roller after normalizing and improve crack tendency, so that tensile strength of the roller surface of the roller is improved, the defects of groove chipping, stripping and the like of the roller are avoided, meanwhile, a steel passing amount is increased, and production efficiency is improved.

Owner:江苏凯达重工股份有限公司

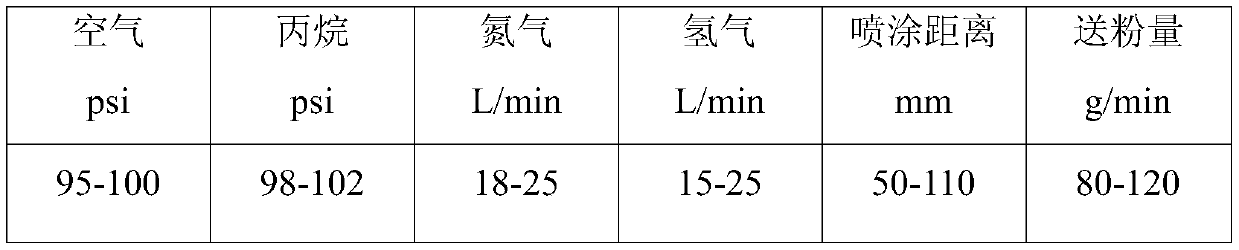

A kind of metal ceramic coating continuous casting mold copper plate and preparation method thereof

ActiveCN108842125BReduce pollutionHigh melting pointMolten spray coatingCeramic coatingSand blasting

The invention discloses a metal ceramic coating continuous casting crystallizer copper plate and a preparation method thereof, and belongs to the technical field of continuous casting crystallizer surface treatment. The preparation method comprises the following steps that a copper plate is straightened to undergo oil removal; an HVAF spraying system taking air as a combustion improver is started,sand blasting preheating is carried out, then a spraying process program is started, ignition is achieved, a spraying material of WC-17Co powder is supplied, and a metal ceramic layer is sprayed on the preheated copper plate to obtain a copper plate with the metal ceramic coating; and a three-layer hole sealing process is adopted for carrying out hole sealing on the surface of the copper plate, and then surface layer curing is carried out on the copper plate, wherein the hardness of the obtained metal ceramic coating is HV1250-HV1400, the porosity is less than or equal to 1%, and the bindingforce of the metal ceramic coating and the continuous casting crystallizer copper plate is greater than or equal to 70 MPa. Therefore, the prepared metal ceramic coating continuous casting crystallizer copper plate is high in coating hardness, small in brittleness, low in porosity and high in binding force.

Owner:东创博实(沈阳)科技有限公司

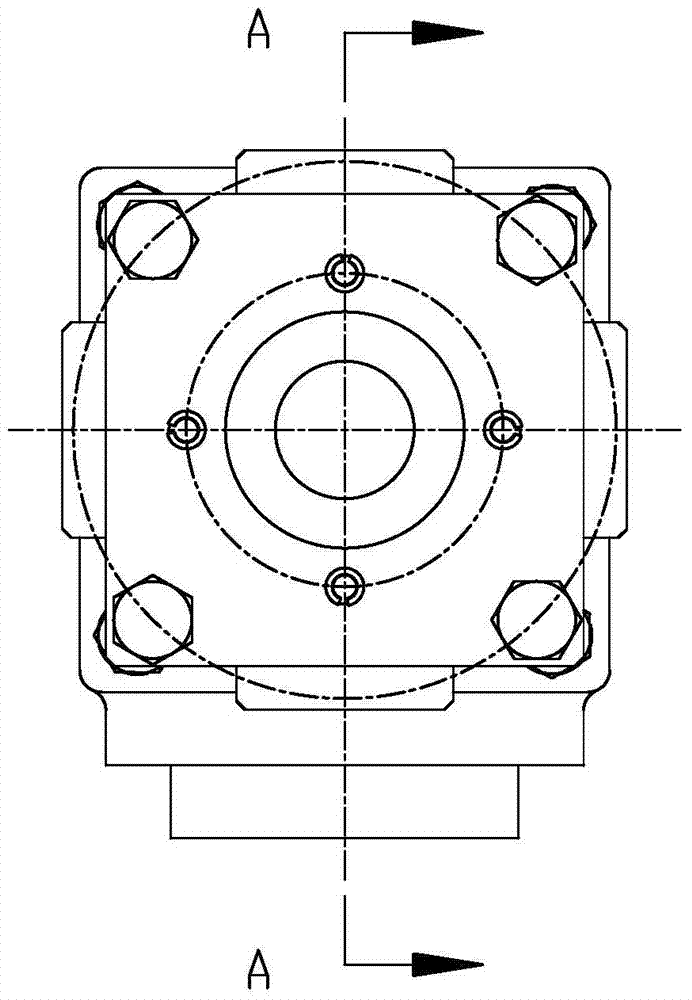

Water cooling device

ActiveCN105414213AIncrease the amount of steelExtended service lifeWork cooling devicesMetal rolling arrangementsWater pipeCivil engineering

The invention discloses a water cooling device. Second installation mechanisms of water passing pipes are located at the same axial positions as pipe bodies and are staggered in the circumferential direction of the pipe bodies, and therefore after the interior bottom surfaces of the pipe bodies are worn out due to steel penetration, the pipe bodies can be overturned around the central axes of the pipe bodies by a certain angle and then fixed to first installation mechanisms of a base through other second installation mechanisms, then the worn parts inside the pipe bodies are overturned to the side surfaces or the top surfaces from the bottom surfaces, the pipe bodies can be continuously used, the amount of steel penetration can be increased for one pipe, the service life of the pipes can be prolonged, and the production cost can be lowered. Furthermore, the multiple water passing pipes are installed on the base in parallel, steel can penetrate into water synchronously, and therefore the yield can be increased.

Owner:安徽诺泰工程技术有限公司

Alloy powder and alloying treatment process for laser surface alloying of low-nickel-chromium infinitely chilled cast iron rolls

InactiveCN103589932BSmall tissueInhibit expansionMetallic material coating processesSurface layerOrganic solvent

The invention provides an alloy powder for low-nickel / chromium infinite chilled cast iron roll laser surface alloying and an alloying technique thereof. The alloy powder comprises WC, TiC, Ni, Cr, Co, Si, Mo and Y2O3 powders. The invention also provides an alloy powdering technique which comprises the following steps: removing rust by sanding a roll surface to be treated, removing oil stains on the surface with an organic solvent, mixing the alloy powder and a varnish ethanol solution, uniformly spraying the mixed solution on the working surface of the roll to be treated, airing, scanning the roll surface with a laser so as to melt and mix the alloy powder and roll surface layer, thereby forming a laser alloyed layer, and the like. When the alloy powder and alloying technique are utilized to perform laser alloying on the low-nickel / chromium infinite chilled cast iron roll, a superfine-structure alloy layer is formed on the working surface of the roll, thereby improving the microhardness and enhancing the steel throughput of the roll.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

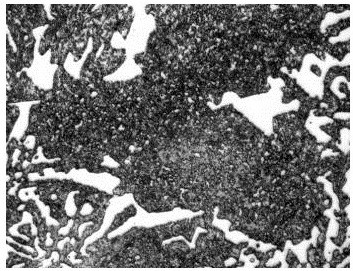

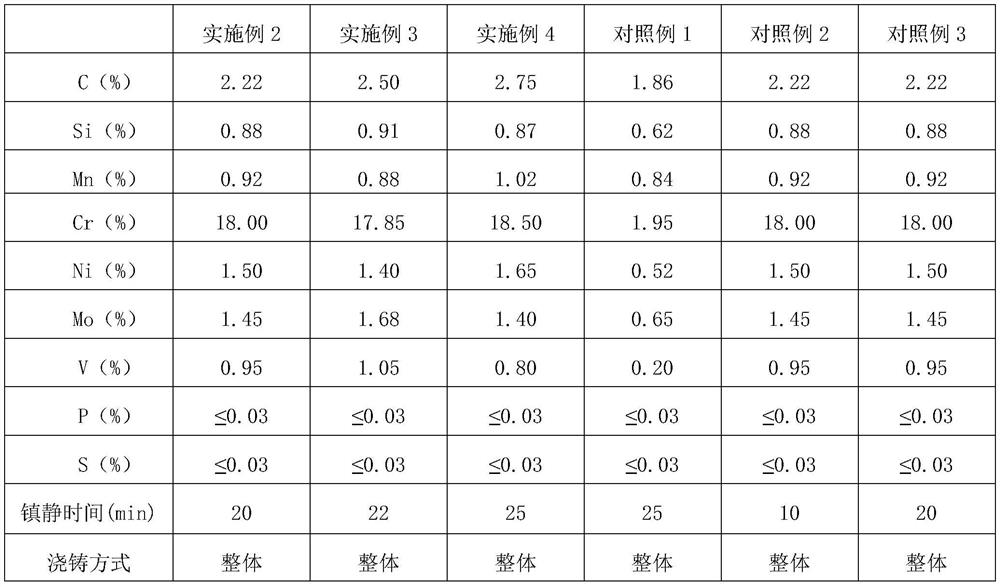

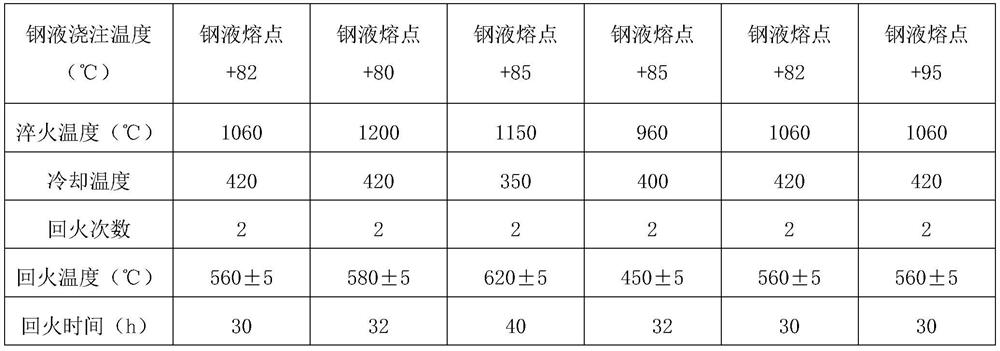

High-wear-resistance high-chromium cast iron universal roll collar and preparation method thereof

ActiveCN113549812AMeet the requirements of horizontal roll ringIncrease the amount of steelFoundry mouldsFurnace typesMachiningRolling mill

The invention relates to a high-wear-resistance high-chromium cast iron universal roll collar and a preparation method thereof, and belongs to the technical field of machining. The high-wear-resistance high-chromium cast iron universal roll collar comprises the following alloy element components of, in percentage by weight, 2.00%-3.00% of C, 0.30%-1.20% of Si, 0.50%-1.50% of Mn, less than or equal to 0.03% of P, less than or equal to 0.03% of S, 12.0%-22.0% of Cr, 0.50%-3.00% of Ni, 0.60%-2.00% of Mo, 0.10%-2.00% of V and the balance Fe and inevitable impurities. The prepared alloy raw materials are put into an intermediate frequency furnace to be smelted and then are poured in an integral mode. The comprehensive performance of the universal roll collar prepared by the method can meet the requirements of a horizontal roll collar of a section steel rolling line universal rolling mill, the on-machine period is prolonged, the steel passing amount of a rolled material is improved, the surface quality of the rolled material is improved, the integral pouring mode improves the compactness of the roll collar structure and improves the integral use effect of the product.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Method for restoring and improving service life of hot roller and cold rolling subsidiary roller

InactiveCN101225463BExtended service lifeIncrease productionFurnace typesHeat treatment furnacesStress concentrationEngineering

The present invention relates to a method to resume and improve the service life of hot rollers and cold auxiliary rollers, which comprises the following steps: (1) test the stress of working roller body of invalid or scrapped rollers, and then test the damage degree of cracks and peeling layers on stress concentration parts; evaluate the residue life and analyze the strength based on the tested damage degree; evaluate remanufacturing craftwork and economical efficiency, forecast the service life and design the service life period on the basis; (2) use laser quick shape deposition manufacture to quickly form the original shape of the roller with designed service life; (3) after the roller is quickly formed through laser quick shape deposition manufacture, conduct the process treating of strengthening and toughening for the material of the deposition layer. The method to resume and improve the service life of hot rollers and cold auxiliary rollers has the advantages that: the steel rolling throughput during the rolling process can be improved by 30% to 50%; the service cycle can be prolonged; and the service life of the backup roller can be improved by more than 30%.

Owner:天津大族烨峤激光技术有限公司

A kind of metal-ceramic coating continuous casting crystallizer copper tube and preparation method thereof

The invention discloses a metal ceramic coating continuous casting crystallizer copper pipe and a preparing method thereof, and belongs to the technical field of continuous casting crystallizer surface treatment. The method comprises the steps that the copper pipe is straightened and subjected to oil removal; an HVAF inner hole spray gun is used, an HVAF spraying system with a combustion improverbeing air is started, sand blasting and preheating are conducted, the spraying technology procedure is started, ignition is conducted, spraying material WC-10Co-4Cr powder is conveyed, a metal ceramiclayer is sprayed to the preheated copper pipe, and the copper pipe with a metal ceramic coating is obtained; and the three-layer hole sealing technology is adopted for conducting copper pipe surfacehole sealing, then, copper pipe surface layer curing is conducted, the hardness of the metal ceramic coating ranges from HV1200 to HV1350, the porosity is smaller than or equal to 1%, and the bondingforce of the metal ceramic coating and the continuous casting crystallizer copper pipe is larger than or equal to 70 MPa. The prepared metal ceramic coating continuous casting crystallizer copper pipeis high in coating hardness, low in brittleness and porosity and high in bonding force.

Owner:东创博实(沈阳)科技有限公司

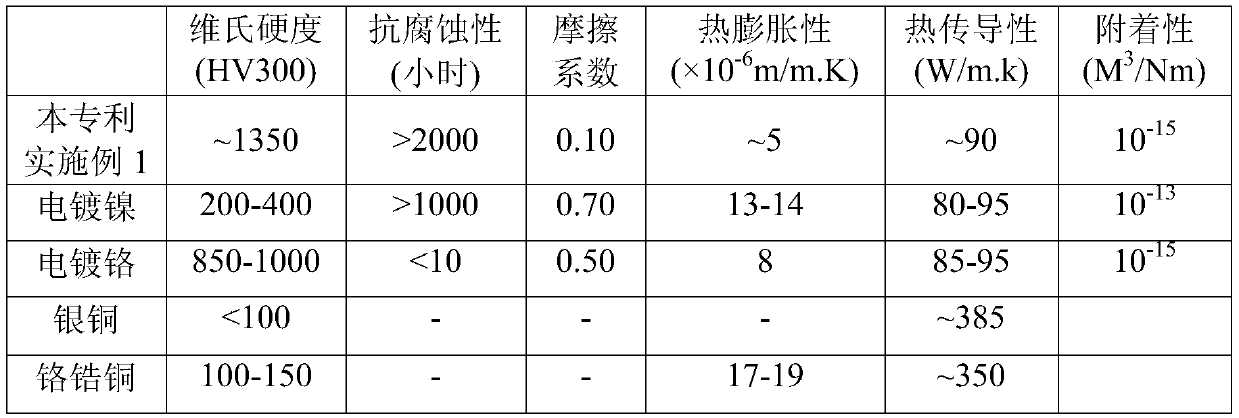

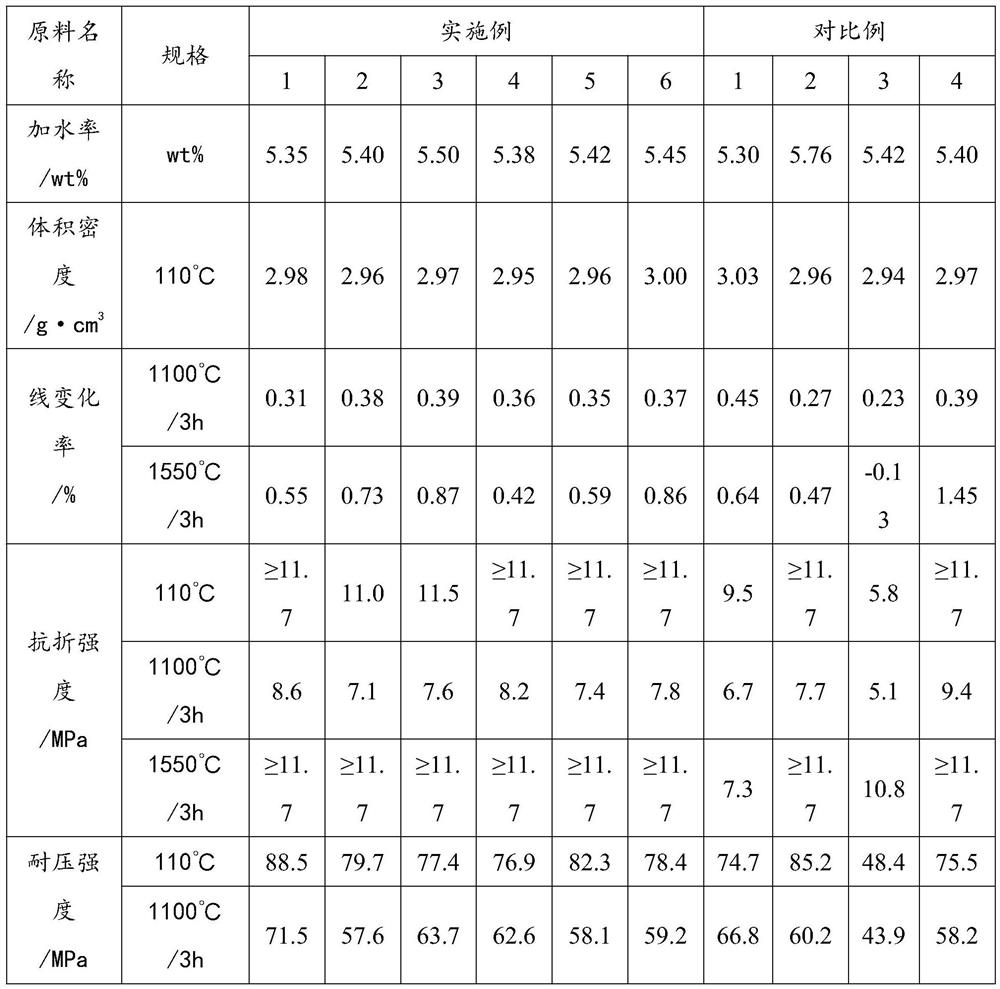

Low-expansion high-fracture-resistance tundish retaining wall castable

PendingCN114873995AImprove high temperature strengthImprove corrosion resistanceProcess efficiency improvementBreaking strengthUltimate tensile strength

The invention relates to the technical field of tundish working layer refractory materials, in particular to a low-expansion high-fracture-resistance tundish retaining wall castable. The raw material components comprise, by mass, 13 to 16% of 85 alumina with a particle size of 15 to 8 mm, 13 to 16% of 85 alumina with a particle size of 8 to 5 mm, 6 to 8% of 85 alumina with a particle size of 5 to 3 mm, 6 to 10% of 85 alumina with a particle size of 3 to 1 mm, 5 to 10% of 85 alumina with a particle size of 1 to 0 mm, 6 to 10% of 91 magnesia with a particle size of 5 to 3 mm, 6 to 10% of 91 magnesia with a particle size of 3 to 1 mm, 4 to 9% of 95 magnesia with a particle size of 1 to 0 mm, 3 to 5% of 95 magnesia with a particle size of 200 meshes, 10 to 13% of white corundum dedusting powder and 2 to 5% of chrome corundum waste. The invention relates to a low-expansion-coefficient refractory castable which comprises the following components in percentage by weight: 2% of silica powder, 1-2% of aluminum oxide, 0.2-0.5% of 71 cement, 0.2-0.3% of sodium dihydrogen phosphate, 0.05-0.1% of sodium tripolyphosphate, 0.1-0.3% of organic fibers and 1-1.5% of steel fibers. Compared with the prior art through design, the low-expansion-coefficient refractory castable has the advantages of low expansion coefficient, high breaking strength, moderate cost and molten steel purification function.

Owner:SHANGHAI LIER REFRACTORY MATERIAL +1

a water cooler

ActiveCN105363809BGuaranteed flow rateGuarantee product qualityWork cooling devicesMetal rolling arrangementsCooling effectWater flow

The invention discloses a passing water cooler. An existing straight cooling tube is improved into a Venturi tube (a reducing tube fitting provided with an expansible portion and a contractible portion), the water flowing speed can be changed to form speed difference, stable water film forming on the surface of a rolled piece is avoided through kinetic energy and impulse produced through the speed difference, and sufficient heat exchange is ensured. The passing water cooler is better than a traditional water tube in cooling effect, the total amount of steel is remarkably increased, and the using cost is reduced. In addition, a water inlet is designed to be an annular water spraying port circumferentially surrounding the Venturi tube, the flowing speed of cooling water can be effectively ensured, it is ensured that water is evenly fed, accordingly the rolled piece is evenly cooled, and product quality is ensured.

Owner:安徽诺泰工程技术有限公司

Wear-resistant guide disc coil for seamless steel pipe mill

InactiveCN102828102AHigh strengthImprove antioxidant capacityGuiding/positioning/aligning arrangementsDuctile ironPipe

The invention discloses a wear-resistant guide disc coil for a seamless steel pipe mill. The wear-resistant guide disc coil comprises the following elements of: by weight, 3.0-3.90% of C, 0.20-0.60% of Si, 0.35-0.85% of Mn, 0.20-0.60% of Mo, 0-0.03% of P, 0-0.03% of S, 0.30-0.75% of Cu, 0.20-0.50% of V, 0.02-0.03% of RE, and the balance being Fe. According to the invention, based on the adoption of a wear-resistant alloy nodular cast iron material, a proper amount of microalloying elements of V and Cu is added so as to refine steel's grain size and improve cast structures. Therefore, high-temperature creep strength and antioxidation capacity of the product are raised, and production requirements of a pipe mill are satisfied. The product provided by the invention is widely applied in various pipe mill guiding equipment.

Owner:蔡宏

High-speed steel vertical roll ring and its preparation method

ActiveCN113249658BImprove wear resistanceIncrease the amount of steelFoundry mouldsFurnace typesChemical compositionDuctile iron

The invention discloses a high-speed steel vertical roll ring and a preparation method thereof, comprising: a rolling roll ring and a transmission roll ring, the rolling roll ring is sleeved on the outside of the transmission roll ring, the chemical composition and weight of the rolling roll ring The percentage content is: C is 1.2‑1.6%, Si is 1.0‑1.5%, Mn is 0.3‑0.8%, Cr is 3.5‑4.0%, Mo is 4.5‑5.0%, V is 1.5‑2.0%, W is 4.5‑ 5.0%, Co is 1.5-2.0%, the rest is Fe and unavoidable impurities, the rolling ring is high-speed steel; the chemical composition and weight percentage content of the transmission roll ring are: C is 2.7-3.0%, Si is 2.5- 3.0%, Mn is 0.3‑0.8%, Mg is 0.04‑0.1%, the rest is Fe and unavoidable impurities, and the driving roller ring is high toughness ferritic nodular cast iron. In the present invention, by designing the reasonable components of the rolling roll ring and the driving roll ring, the surface hardness of the roll can reach 80-90HSD, which has high impact toughness, improves the service life, and avoids the occurrence of blocky shedding on the surface of the roll. The amount of steel passing through a single slot is more than 3 times higher than that of ordinary rolls.

Owner:江苏凯达重工股份有限公司

A method for strengthening cast iron rolls

Owner:合肥九州龙腾科技成果转化有限公司

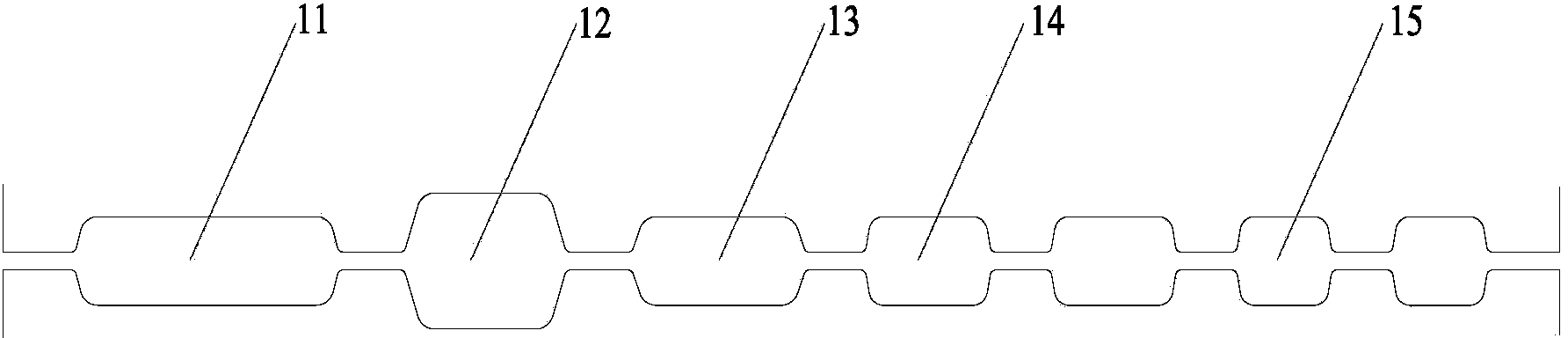

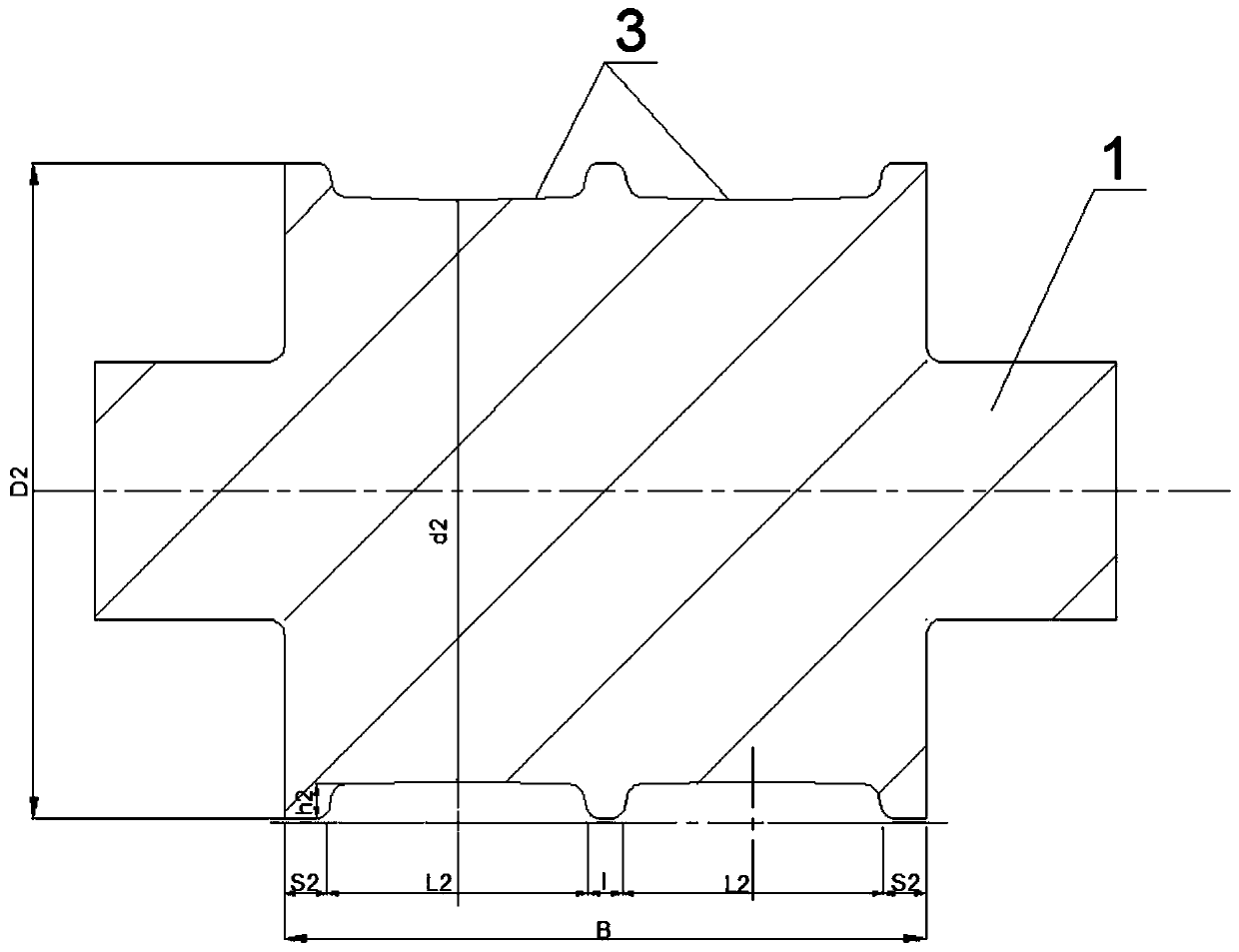

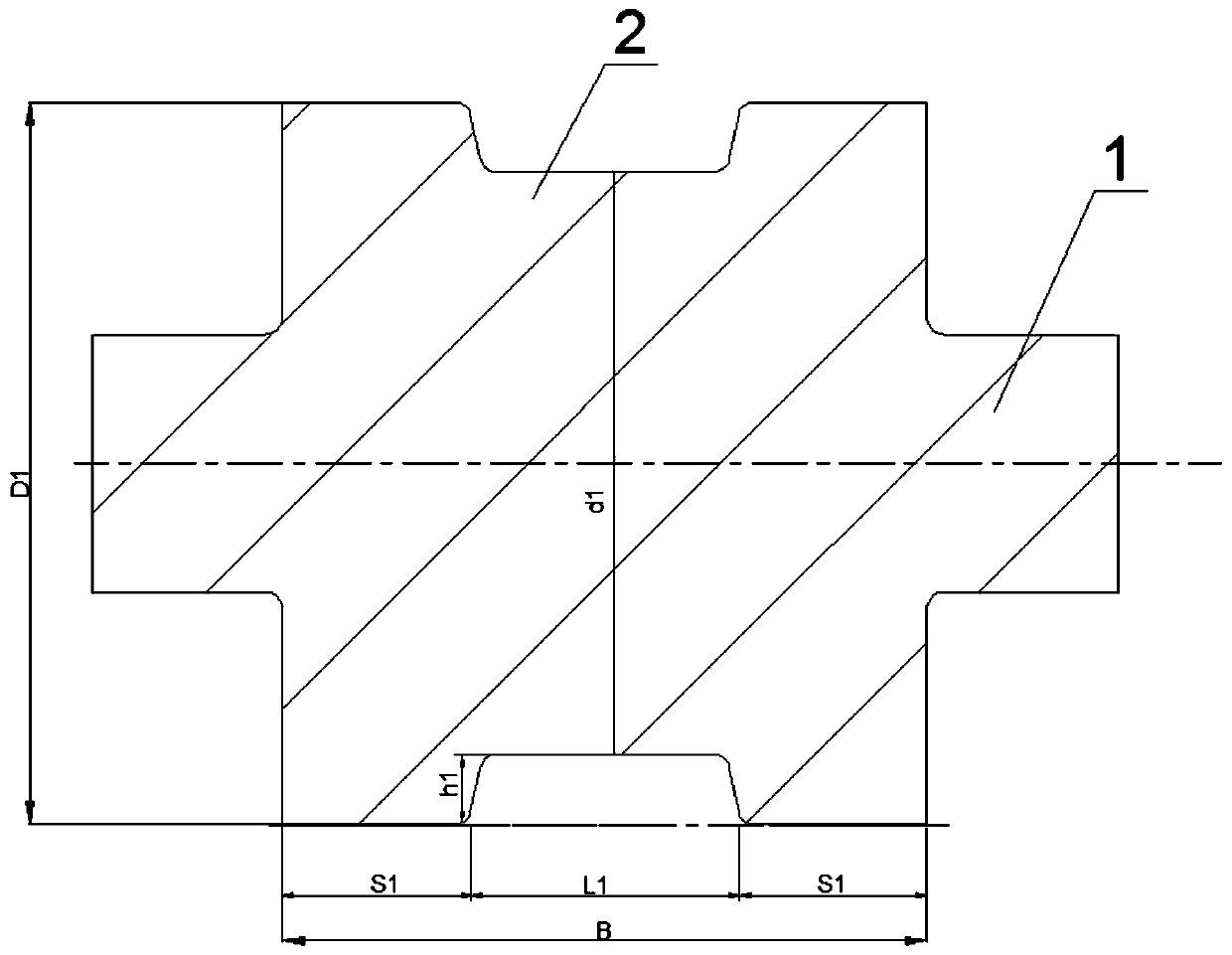

Blooming down-the-hole pattern design method used on continuous rolling mill

ActiveCN111581751AGuaranteed over-steel requirementsReduce use costGeometric CADRollsStructural engineeringMechanical engineering

The invention discloses a blooming down-the-hole pattern design method used on a continuous rolling mill, belongs to the technical field of steel rolling, and aims at the current situation that the utilization rate of an existing roller body is low, and the blooming down-the-hole pattern design method comprises the specific steps that under the condition that the inclination of the side wall of anexisting hole pattern is not changed, the grooving depth of the existing hole pattern is reduced; according to the grooving depth of the down-the-hole patterns and the number of the down-the-hole patterns, the roll collar width of the edge of the roll is obtained; the number of the down-the-hole patterns distributed on the roller needs to meet the requirement that S is larger than or equal to h;and under the condition that the working diameters of the rollers are the same, the diameters of the rollers are determined according to the grooving depth of the down-the-hole pattern. On the premisethat the rolling quality of special steel products is guaranteed, an existing hole pattern is designed into a down-the-hole pattern, the grooving depth of the hole pattern on the roller is reduced byhalf, then the groove bottom of the hole pattern is located at the position with a high hardness layer, the requirement for the steel passing amount of the roller is met, and the use cost of the roller is reduced.

Owner:建龙北满特殊钢有限责任公司

Reinforced chilled roll and preparation method thereof

InactiveCN103056164BImprove the situation of unstable combinationGood shape of graphiteRollsMetal rolling arrangementsSlagInstability

The invention discloses a reinforced chilled roll. The reinforced chilled roll comprises an outer alloy layer and a core portion, and a medium layer is arranged between the outer alloy layer and the core portion. By the aid of the medium layer arranged between the outer alloy layer and the core portion, combination instability of an original outer alloy layer and the core portion is improved. In addition, graphite form and number of the alloy outer layer can be obtained and improved in the ideal form by means of adding a preliminary inoculation processing procedure and a microalloying processing procedure to a casting process and controlling nodulizer explosion time. Besides, the performance of the reinforced chilled roll is improved by means of refined crystalline strengthening and strain strengthening of microalloy beneficial elements, quality problems of slag dropping and small spalling are avoided, and steel passing quantity is increased obviously.

Owner:JIANGSU GANGBAO ROLLER

Reinforcing method of cast iron milling roller

ActiveCN110129788ATo overcome the shortcomings of cracking and the inability to realize the strengthening of new angle steel rollsIncrease the amount of steelMetallic material coating processesAlloyMetal

The invention provides a reinforcing method of a cast iron milling roller and belongs to the technical field of metal surface treatment. The reinforcing method comprises the following steps that firstalloy powder is adopted for carrying out first laser cladding on the roller face of the cast iron milling roller, and a first alloy layer is formed on the roller face; and second alloy powder is adopted for carrying out second laser cladding on the first alloy layer, a second alloy layer is formed on the surface of the first alloy layer, and the reinforced cast iron milling roller is obtained. Bythe adoption of the method, by controlling the composition of the first alloy powder and the second alloy powder, the surface quality of the cast iron milling roller can be improved remarkably, the steel passing amount of the milling roller is increased, and the service life is prolonged.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com