Construction method of prestressed thin plate and laminated plate with detachable ribs

A prestressed bottom plate, prestressed technology, applied in the direction of floor slabs, manufacturing tools, building components, etc., to achieve the effect of reducing production costs, optimizing costs, and improving compressive strength and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

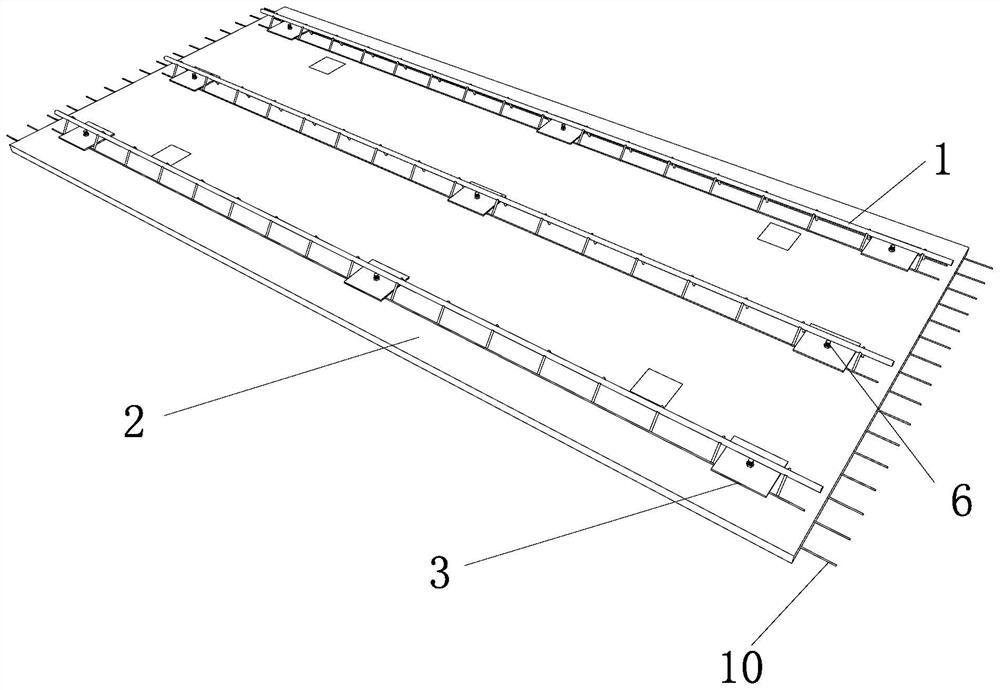

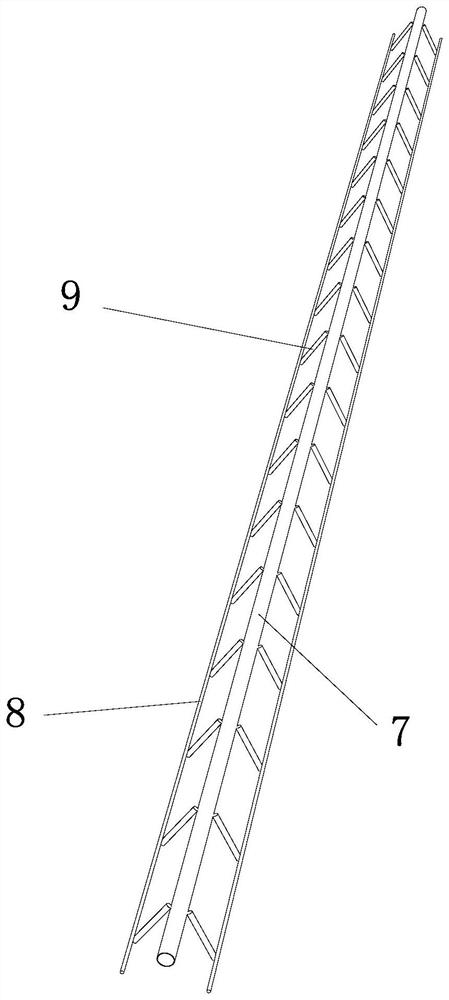

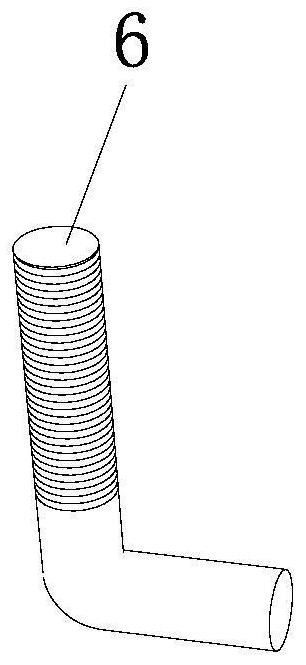

[0039] See attached figure 1 to attach Figure 4 The present embodiment is a prestressed thin plate with a detachable rib 1, including a prestressed bottom plate 2, at least two detachable ribs 1 and a plurality of connecting components, and the detachable rib 1 includes an upper chord 7 and a lower steel bar 8 And the web 9, two lower steel bars 8 and an upper chord 7 are fixedly connected through the web 9; the connecting assembly includes a fixing plate 3, a fixing piece and a connecting piece, the connecting piece includes a first end and a second end, and the connecting The first end of the piece is anchored in the prestressed bottom plate 2, the second end of the fixed piece exposes the prestressed bottom plate 2, passes through the fixed plate 3 and is fixed on the fixed plate 3 through the connecting piece; the lower steel bar 8 is placed on the prestressed bottom plate 2 The surface of the fixed plate 3 spans the two lower steel bars 8, and the connecting piece is ar...

Embodiment 2

[0050] See attached figure 1 to attach Image 6 The present embodiment is a construction method of a laminated slab, the laminated slab includes the prestressed thin slab and the cast-in-place layer in Embodiment 1, and the concrete of the cast-in-place layer is poured on the surface of the prestressed floor 2 away from the detachable rib 1 , specifically include the following steps:

[0051] S1 production of prestressed thin plates: place prestressed steel bars 10 and ordinary steel bars in the production mold, connect and fix the first end of the connector with prestressed steel bars 10 or ordinary steel bars, place the embedded parts and connectors, and the first end of the connectors The height of the two ends is higher than the thickness of the prestressed base plate 2, the detachable rib 1 is placed, the fixed plate 3 is clamped between the two lower steel bars 8, and the second end of the connector is located between the two lower steel bars 8, passing through the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com