Patents

Literature

45results about How to "Improved mechanical property" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

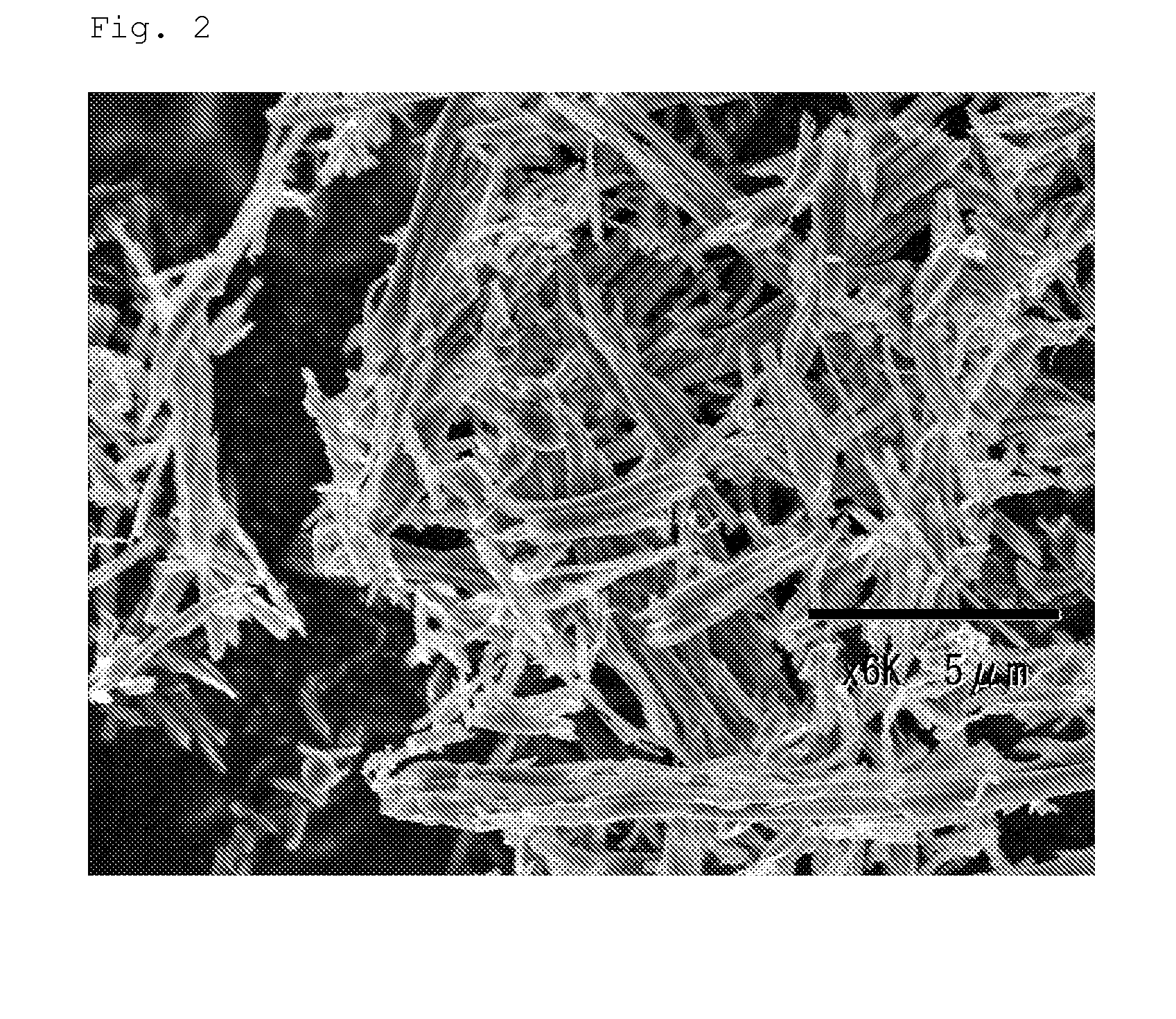

Carbon fiber and method for producing the same

ActiveUS20110033705A1Improved mechanical propertyExcellent propertyMaterial nanotechnologyMonocomponent synthetic polymer artificial filamentCrystalliteMaterials science

A carbon fiber having a lattice spacing (d002) of 0.336 nm to 0.338 nm and a crystallite size (Lc002) of 50 nm to 150 nm as measured and evaluated by X-ray diffraction and a fiber diameter of 10 nm to 500 nm, the carbon fiber having no branched structure.

Owner:TEIJIN LTD +1

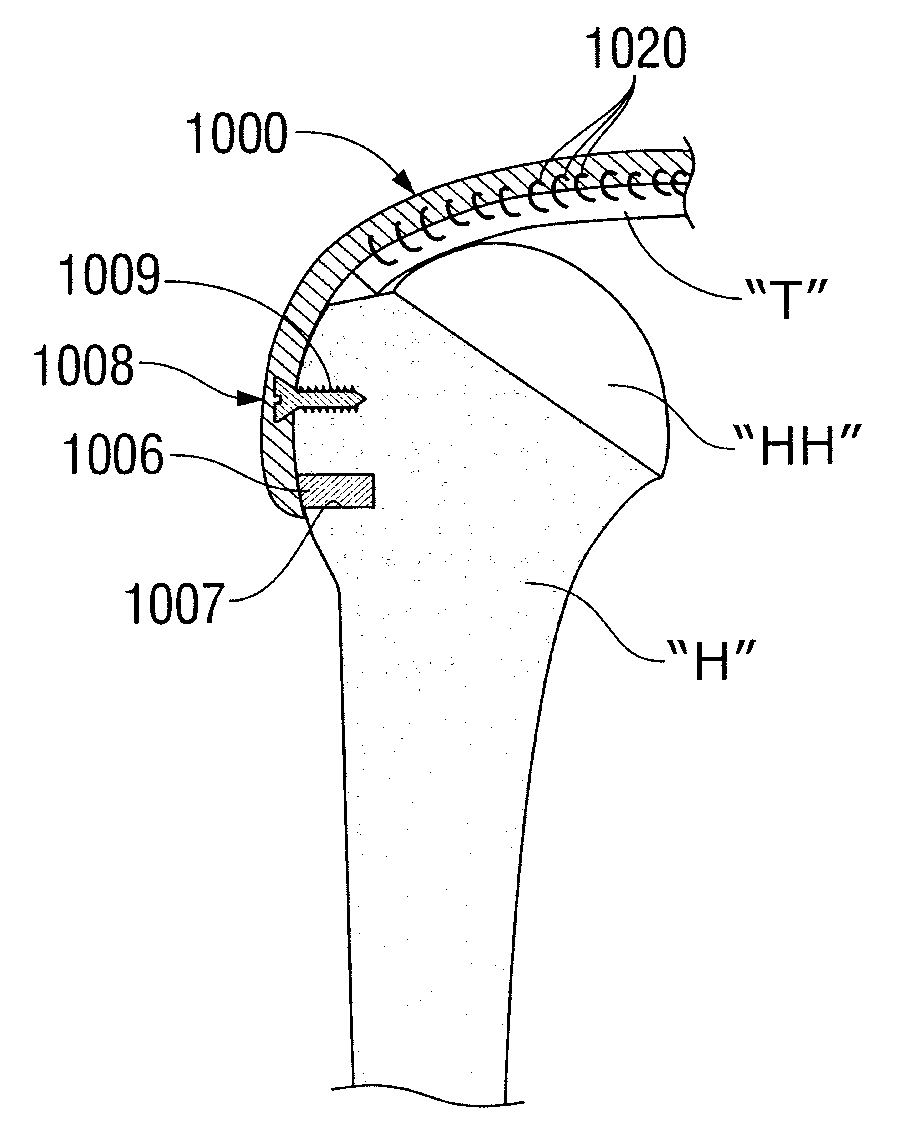

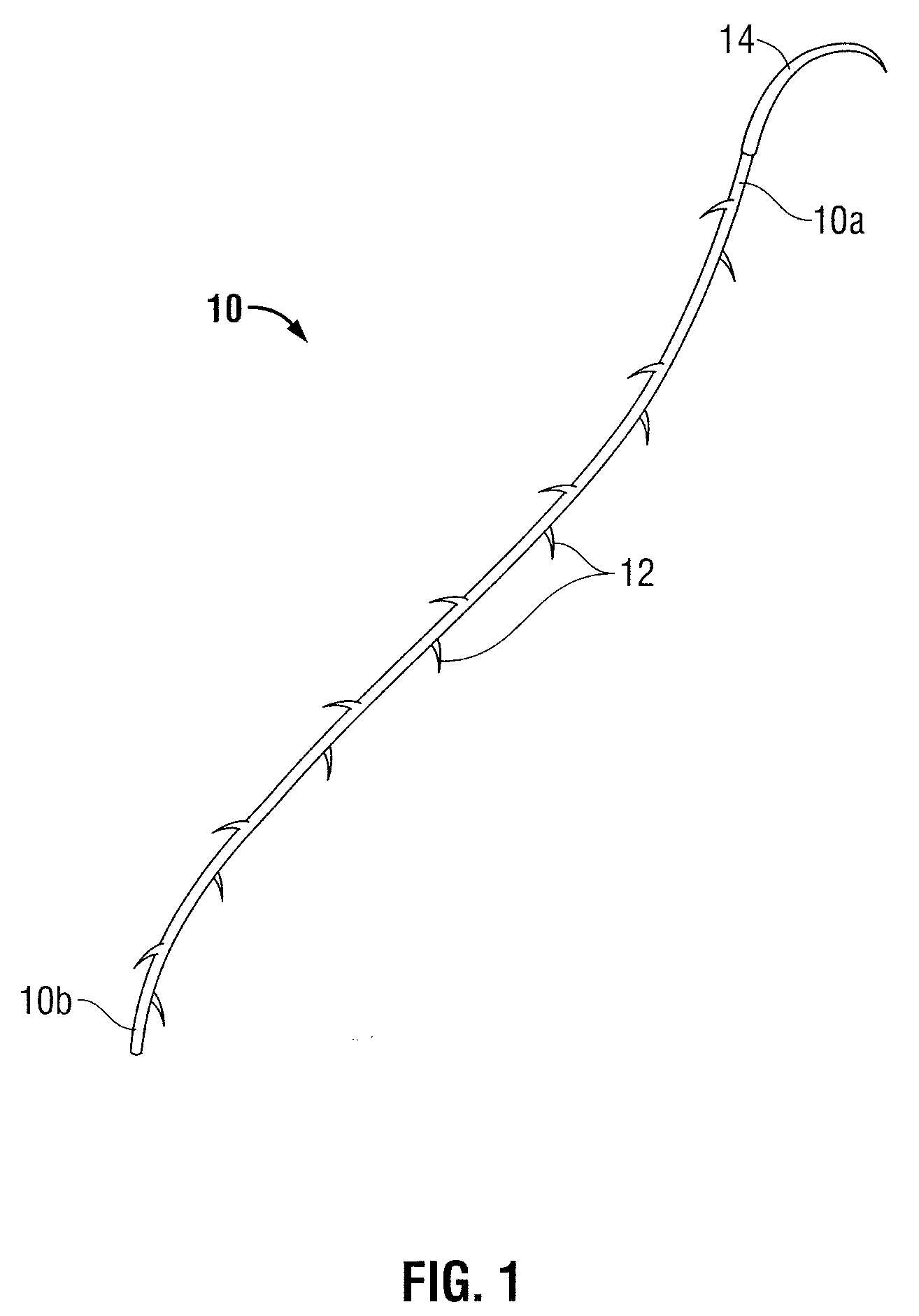

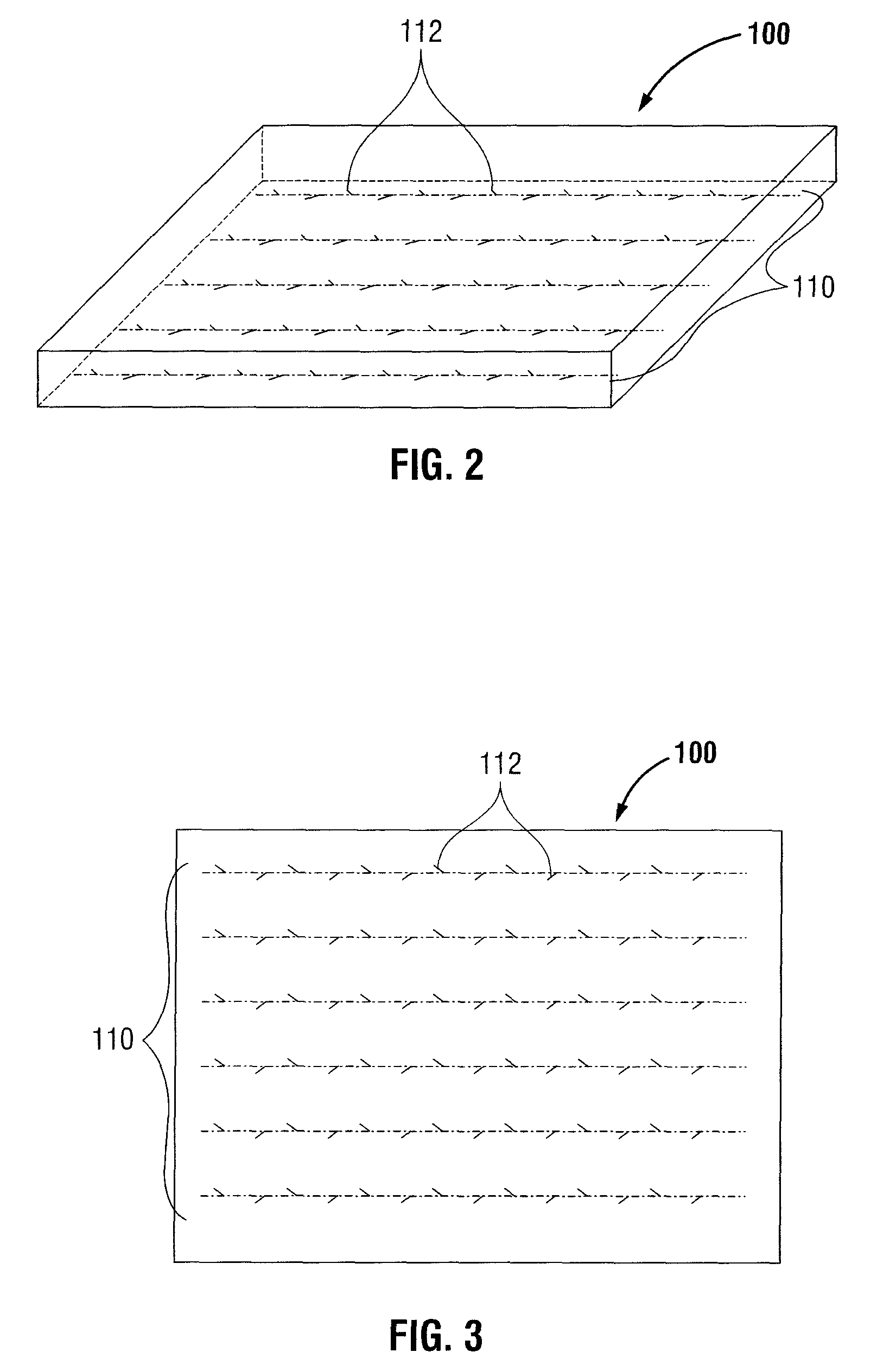

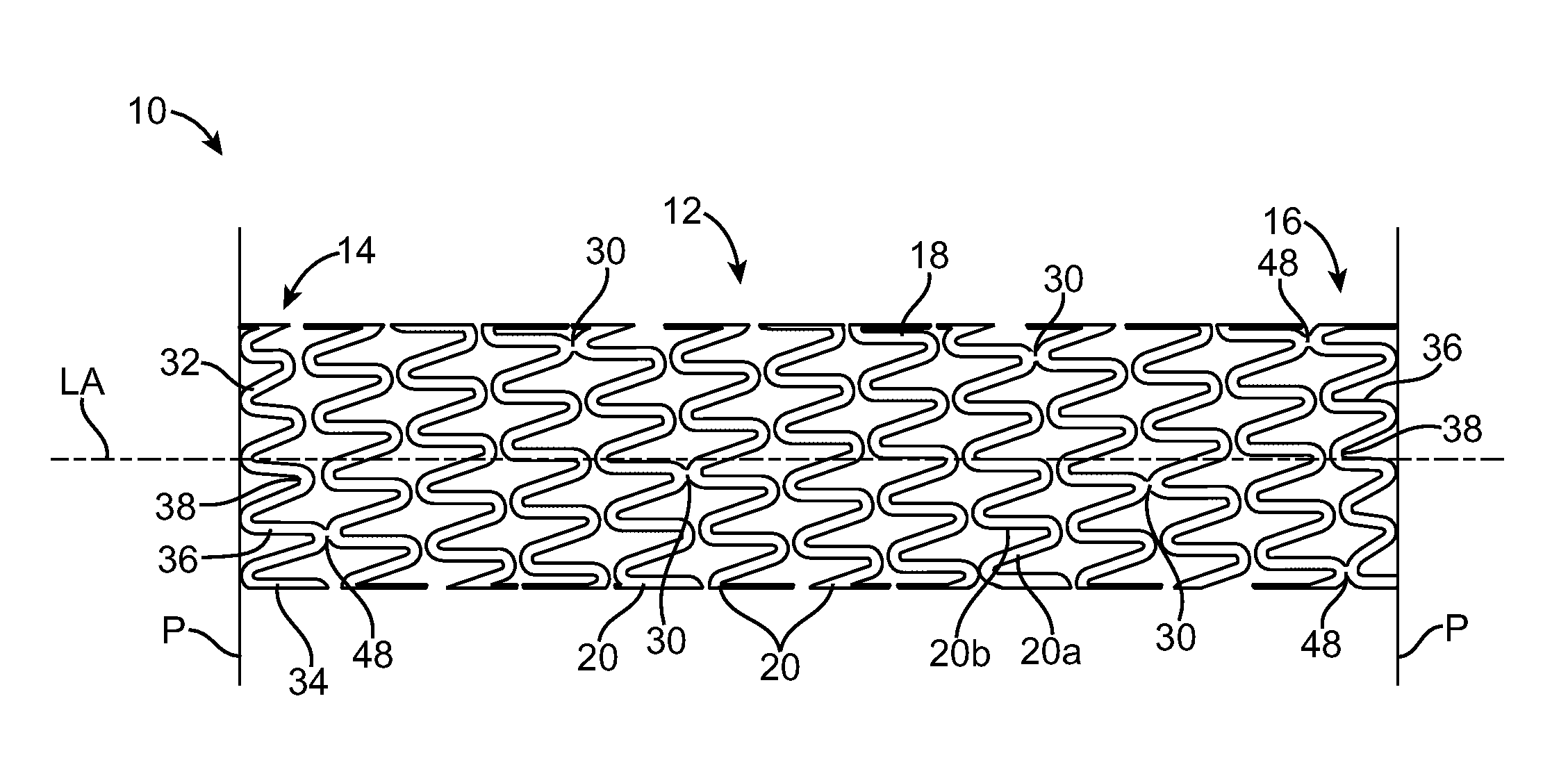

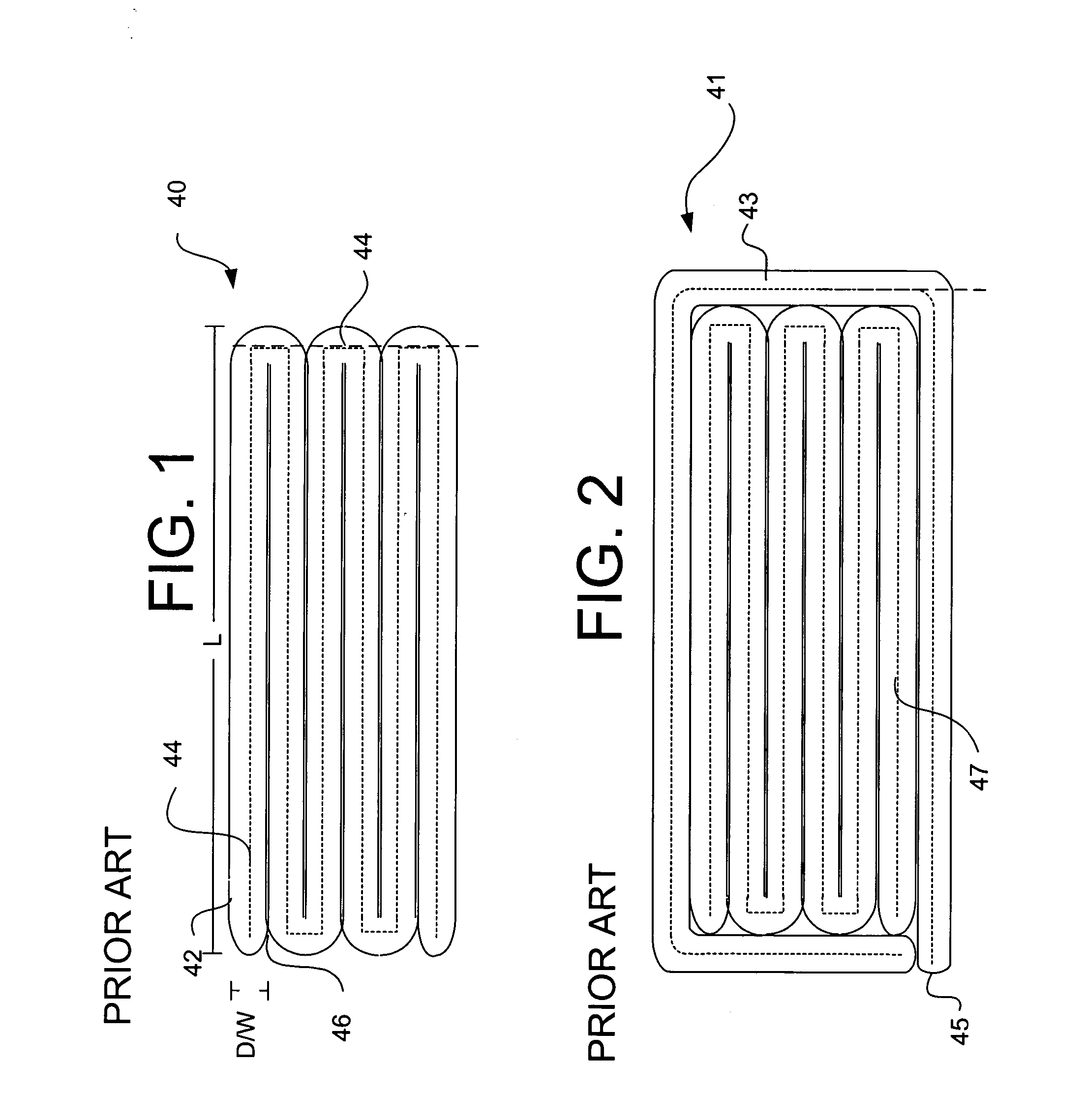

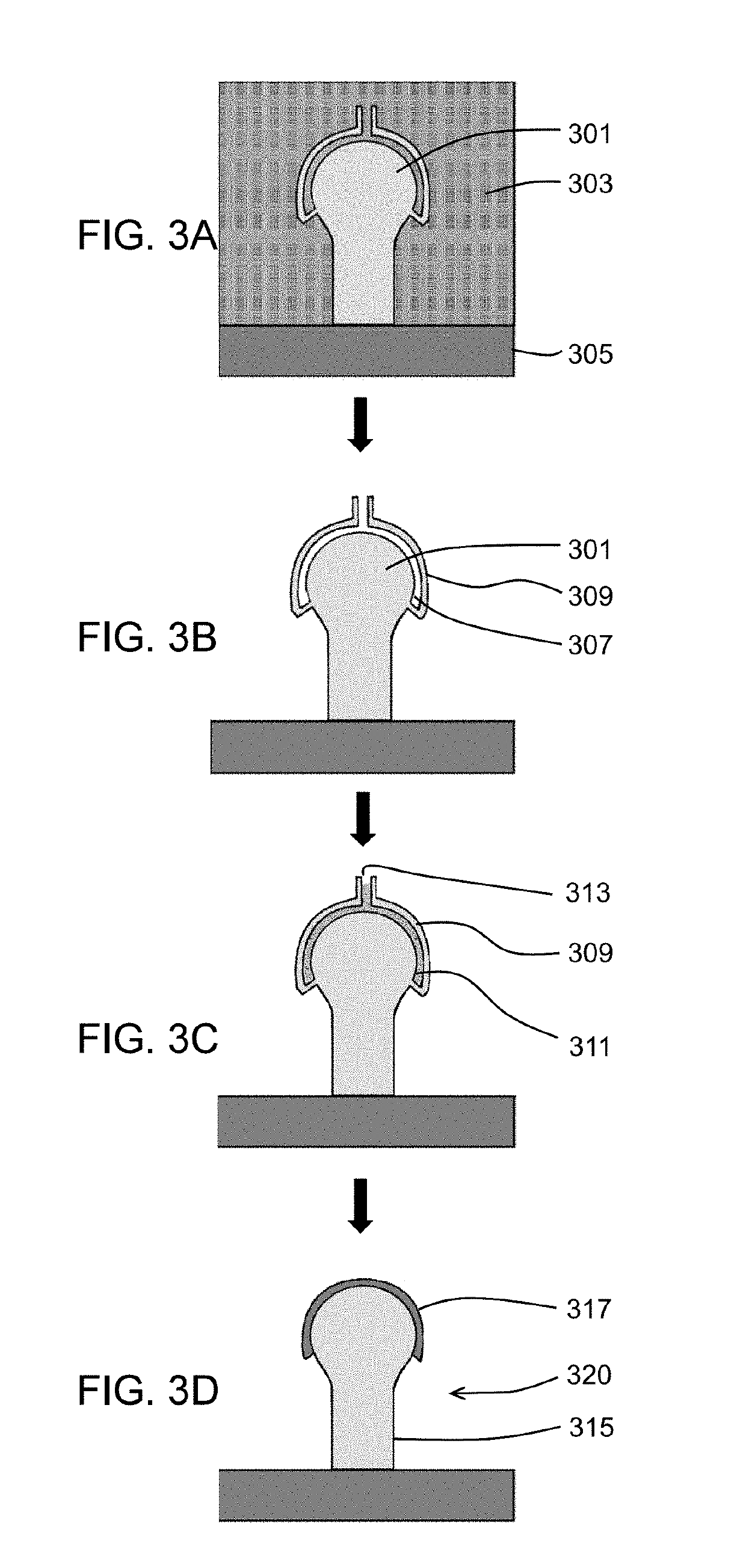

Reinforced Tissue Patch

ActiveUS20110125287A1Improved mechanical propertyImprove mechanical propertiesSuture equipmentsDiagnosticsBarbed sutureBiomedical engineering

A method of improving the mechanical properties of a tissue patch is provided. The method includes the steps of providing a tissue patch and placing at least one barbed suture along at least a portion of the tissue patch. The method may further include the step of placing one or more additional barbed sutures in a laterally spaced relation to the barbed suture. The barbed suture may be biodegradable or non-biodegradable.

Owner:TYCO HEALTHCARE GRP LP

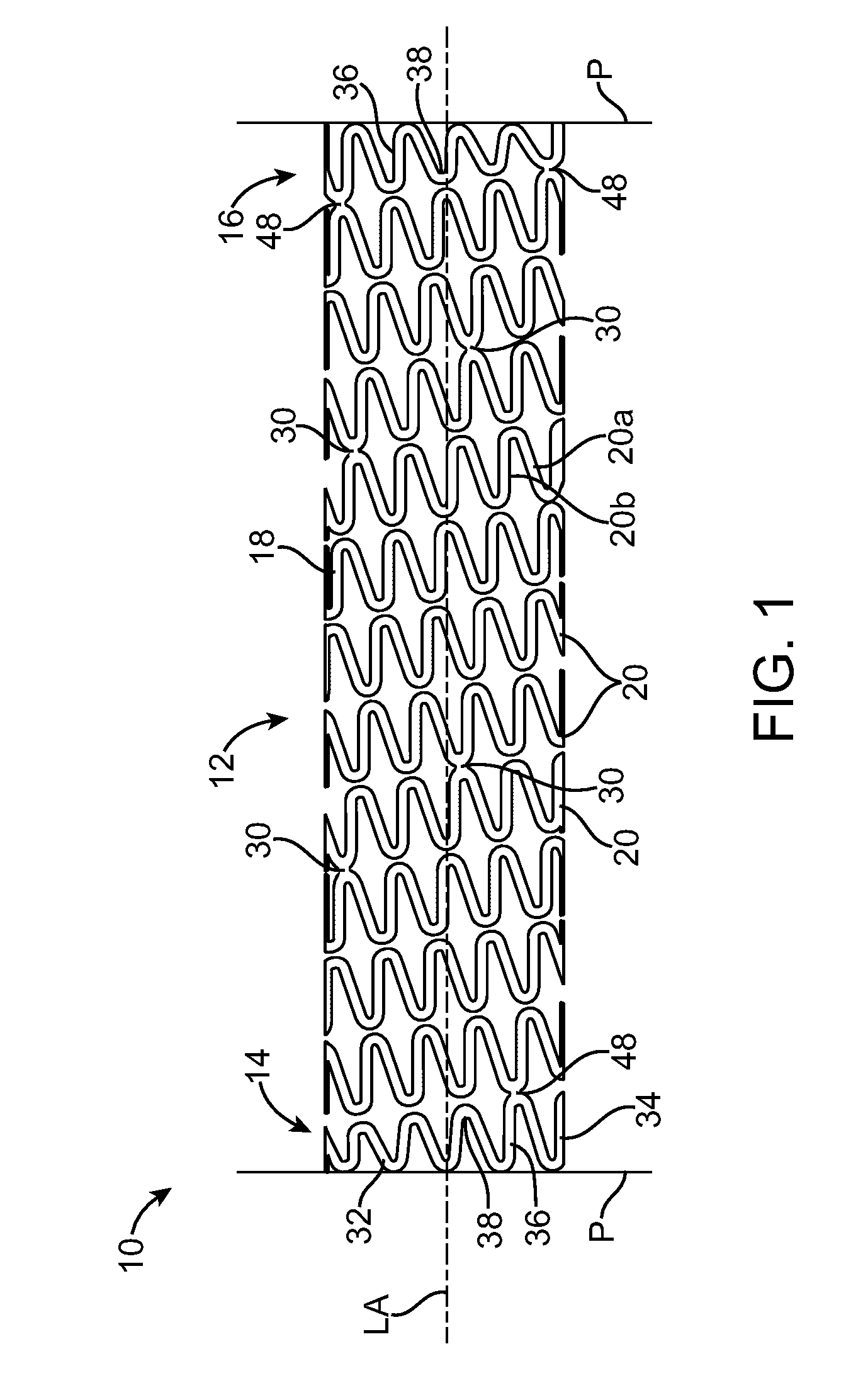

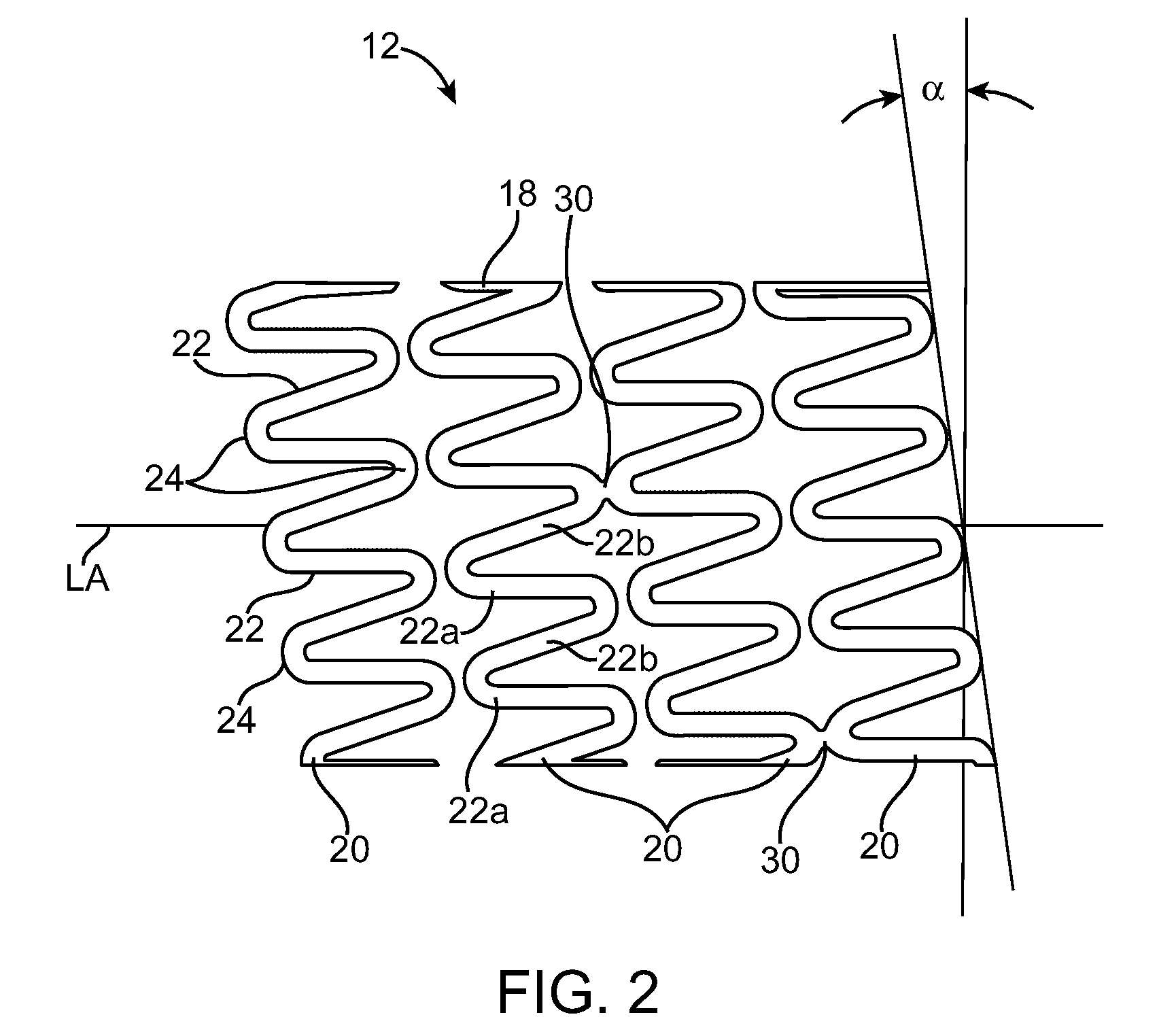

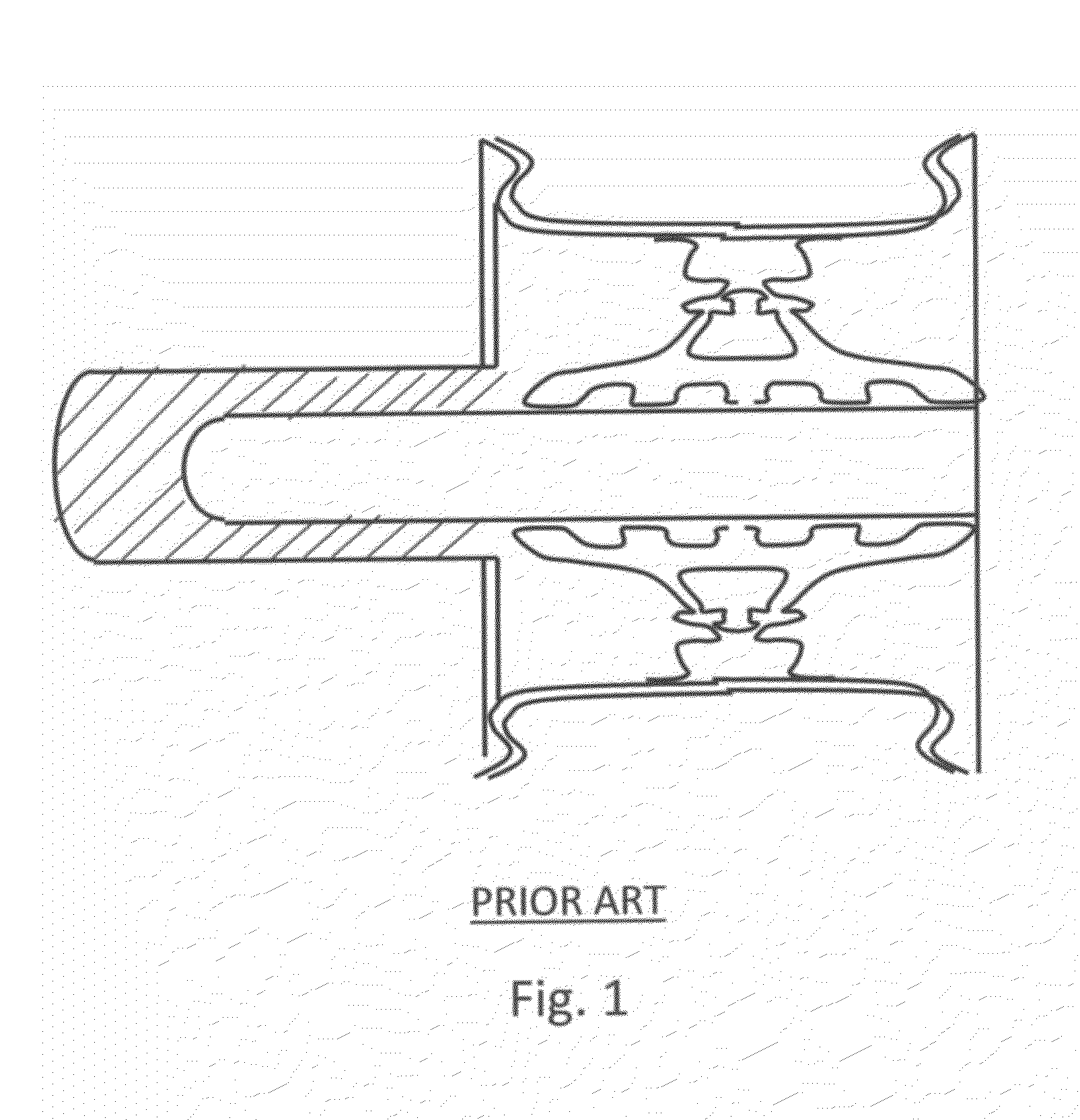

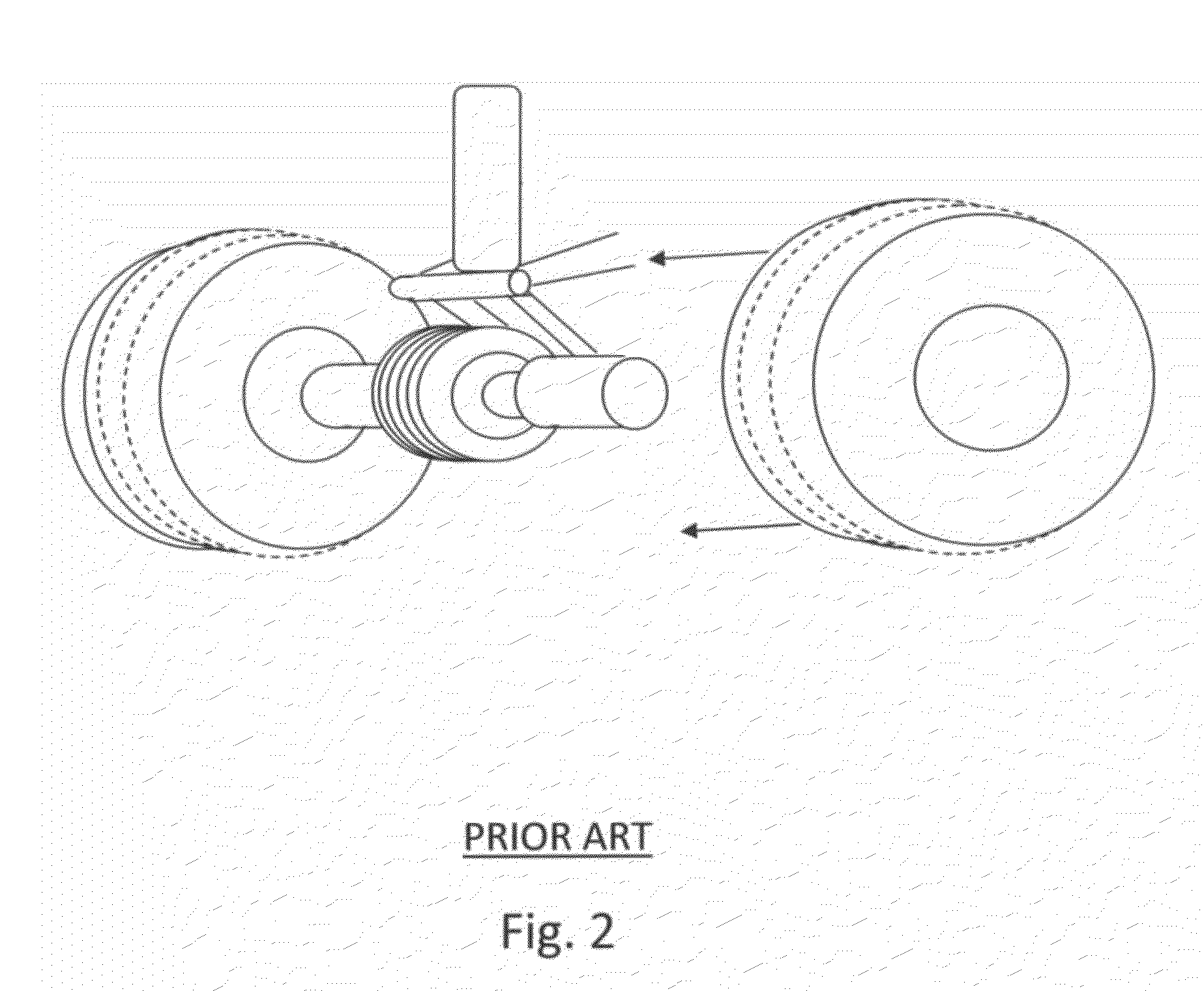

Stent With Improved Mechanical Properties

InactiveUS20080319529A1Improved mechanical propertyImprove mechanical propertiesStentsBlood vesselsWrap aroundMechanical property

A stent includes a central portion having a first waveform. The first waveform is wrapped around a longitudinal axis of the stent at a pitch to define a plurality of helical turns. The stent also includes an end segment connected to one end of the central portion. The end segment has a second waveform that includes a plurality of struts and a plurality of crowns. Each of the plurality of struts has a different length so that peaks of the crowns that define an end of the stent lie within a plane that is substantially perpendicular to the longitudinal axis. Cross-sectional areas of the struts having different lengths vary so that the struts move substantially uniformly during radial contraction and / or radial expansion of the stent.

Owner:MEDTRONIC VASCULAR INC

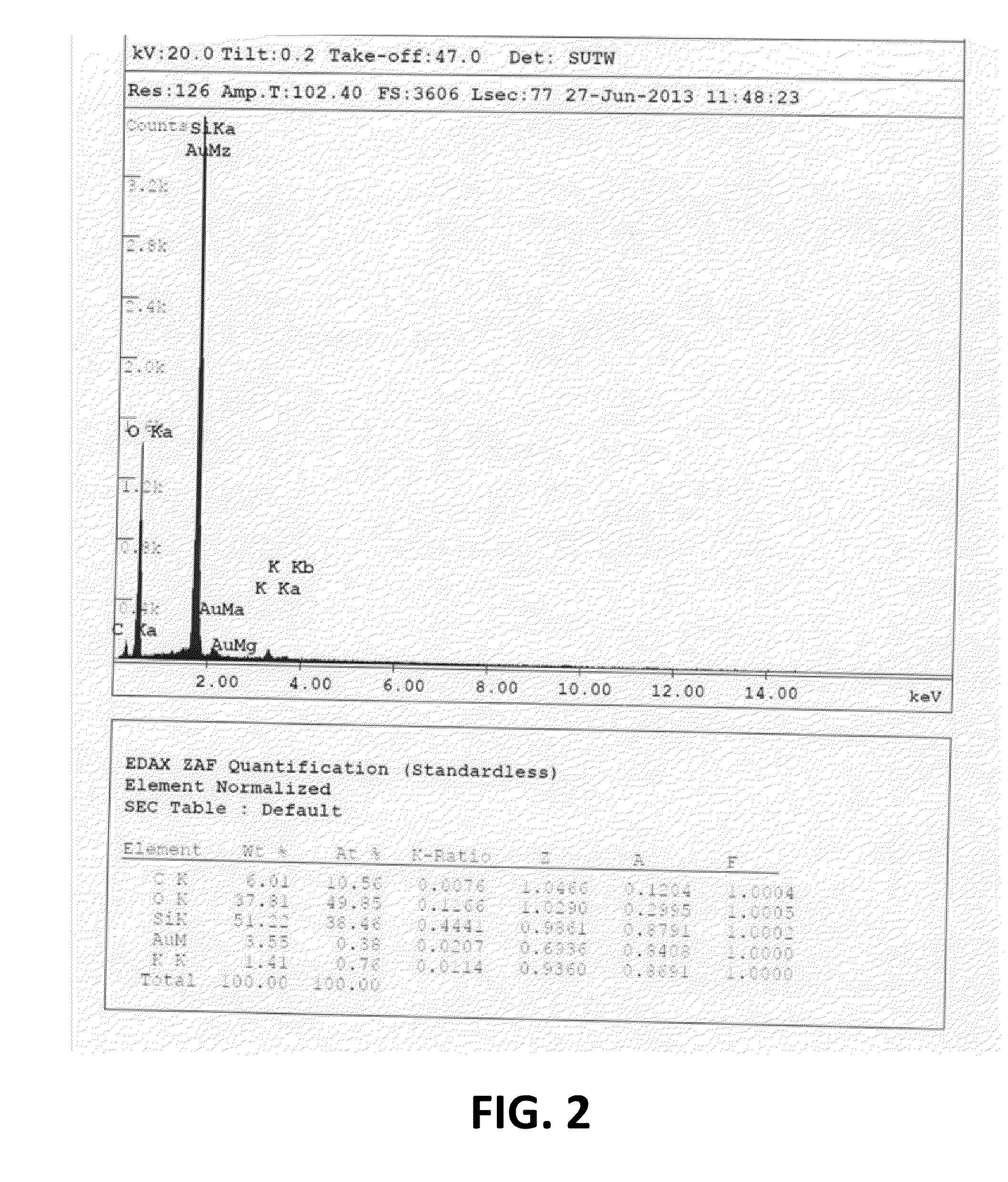

Methods for modifying oxygen content of atomized intermetallic aluminide powders and for forming articles from the modified powders

ActiveUS6863862B2Improved mechanical propertyImprove characteristicCoatingsPowder metallurgyAluminide

Methods of producing atomized intermetallic aluminide powders with a controlled oxygen content, and articles made from the powders by powder metallurgical techniques are disclosed. Gas atomized intermetallic aluminide powders can be oxidized to increase their oxygen content. Water atomized intermetallic aluminide powders can be milled to change their size, shape and / or oxygen content. Blends or mixtures of modified gas and water atomized intermetallic aluminide powders can be processed into articles by powder metallurgical techniques.

Owner:PHILIP MORRIS USA INC

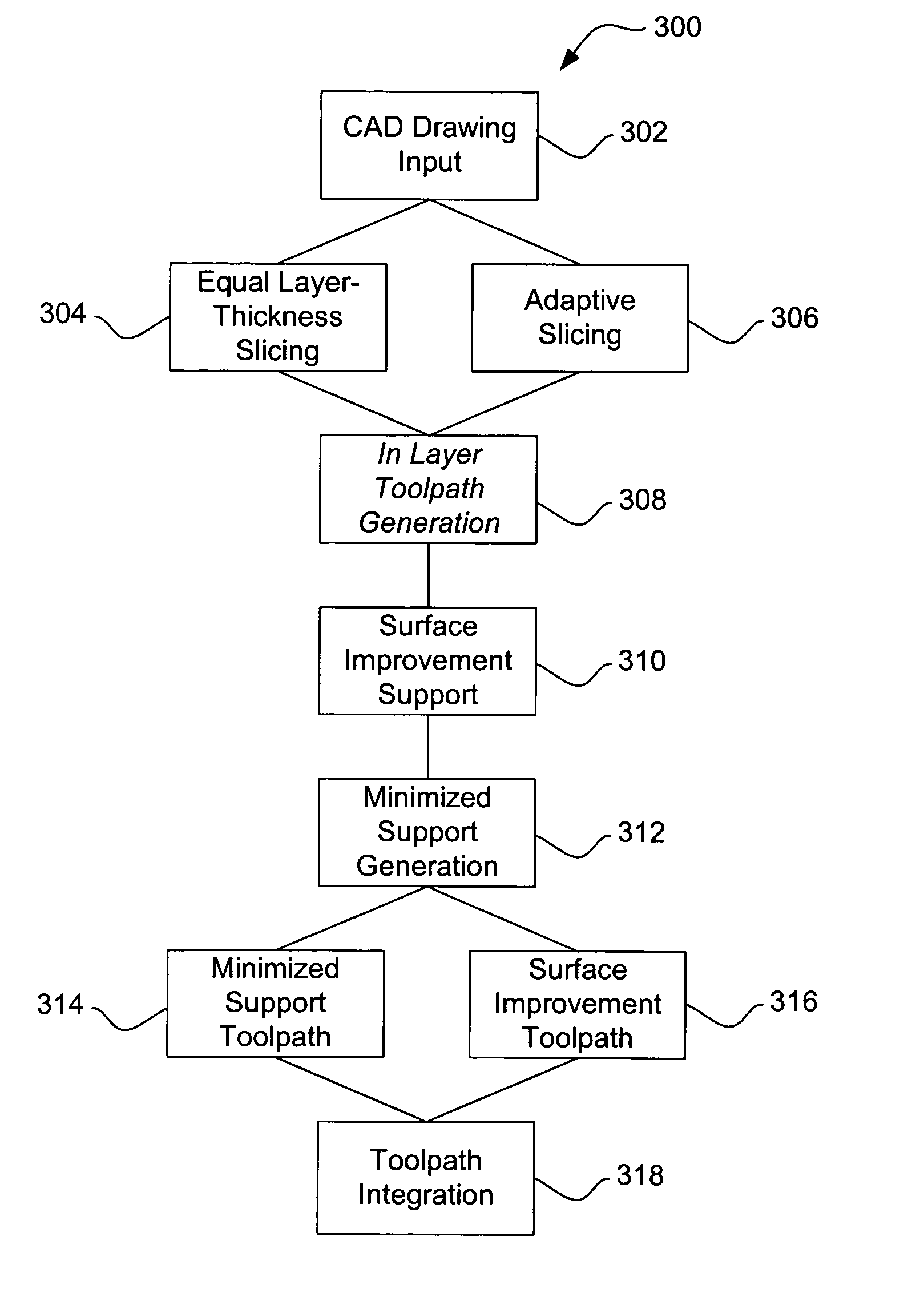

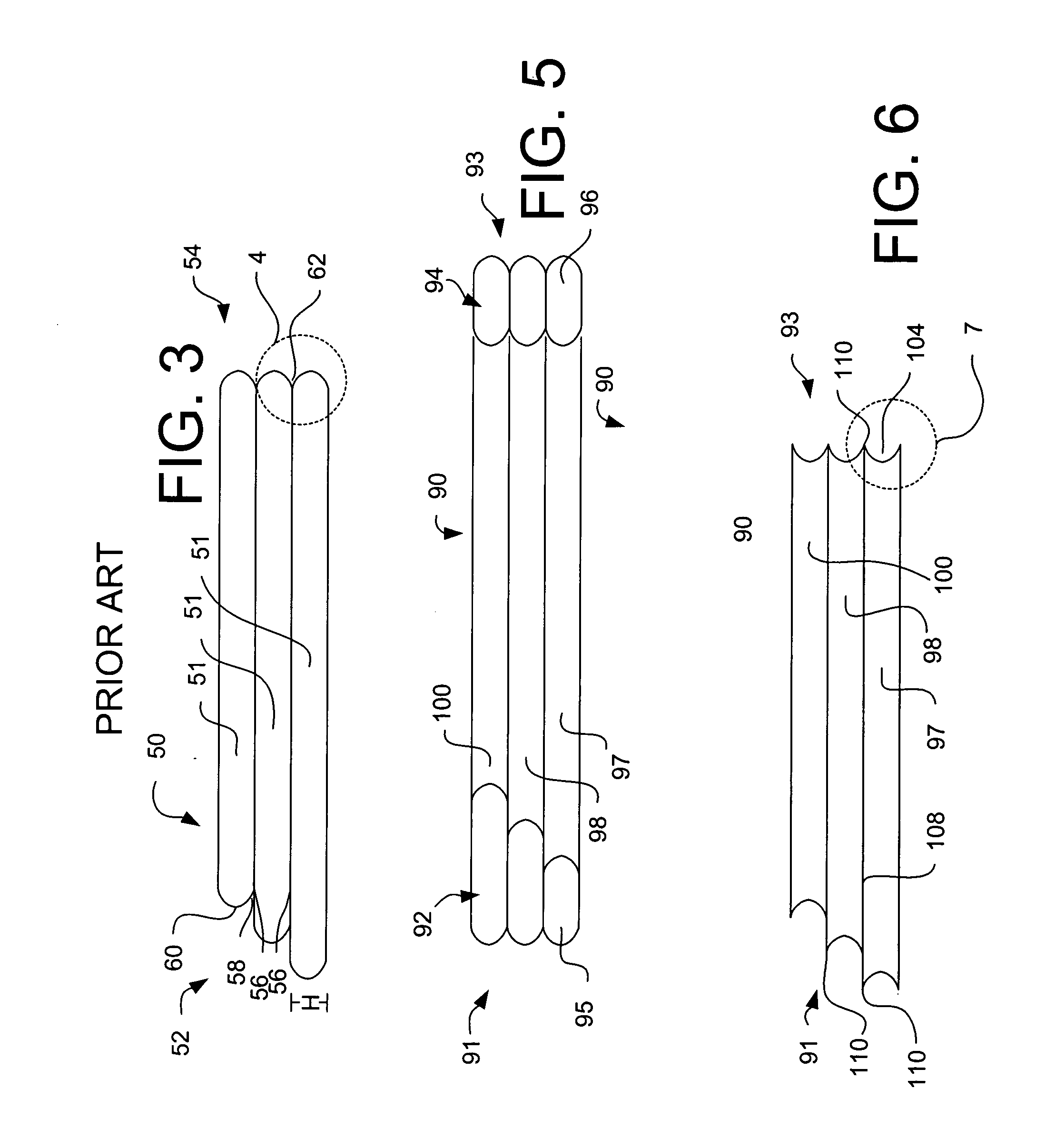

Procedures for rapid build and improved surface characteristics in layered manufacture

InactiveUS20050131570A1Improved mechanical propertyHigh mechanical strengthCeramic shaping apparatusAdditive manufacturing with liquidsCavity wallStructure support

Methods for improving layered manufacturing techniques to improve an objects' surface properties and shorten manufacturing time for support structures. One aspect of the invention forms surfaces having reduced or no concavities between layers having improved crack resistance. One method deposits alternate, surface improvement material on each layer near the future location of the main material surface, followed by deposition of the main material, the edges of which conform to the previously deposited and solidified alternate material. In this method, the center of the main material layers can be concave rather than the interlayer regions. Another aspect of the invention provides removable structures to support the deposition of main material. The support structures provide support over main material cavities for depositing the material to form the cavity ceilings, while minimizing the time and material required to build the support structures. Minimized support structures include structures formed as columns supported by the cavity floor and angle braces to supported by the cavity walls. Some supports are supported by the side wall but not the floor, and other by the floor and not the side walls.

Owner:JAMALABAD VIKRAM +2

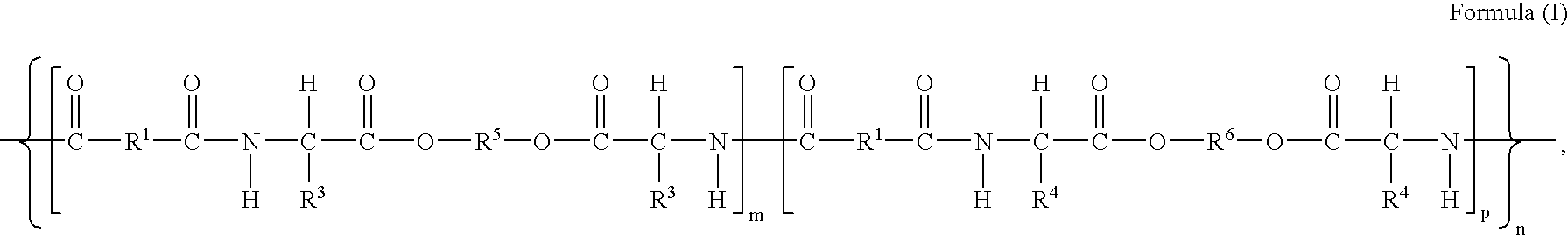

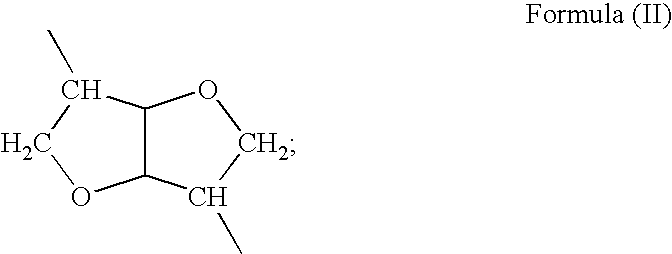

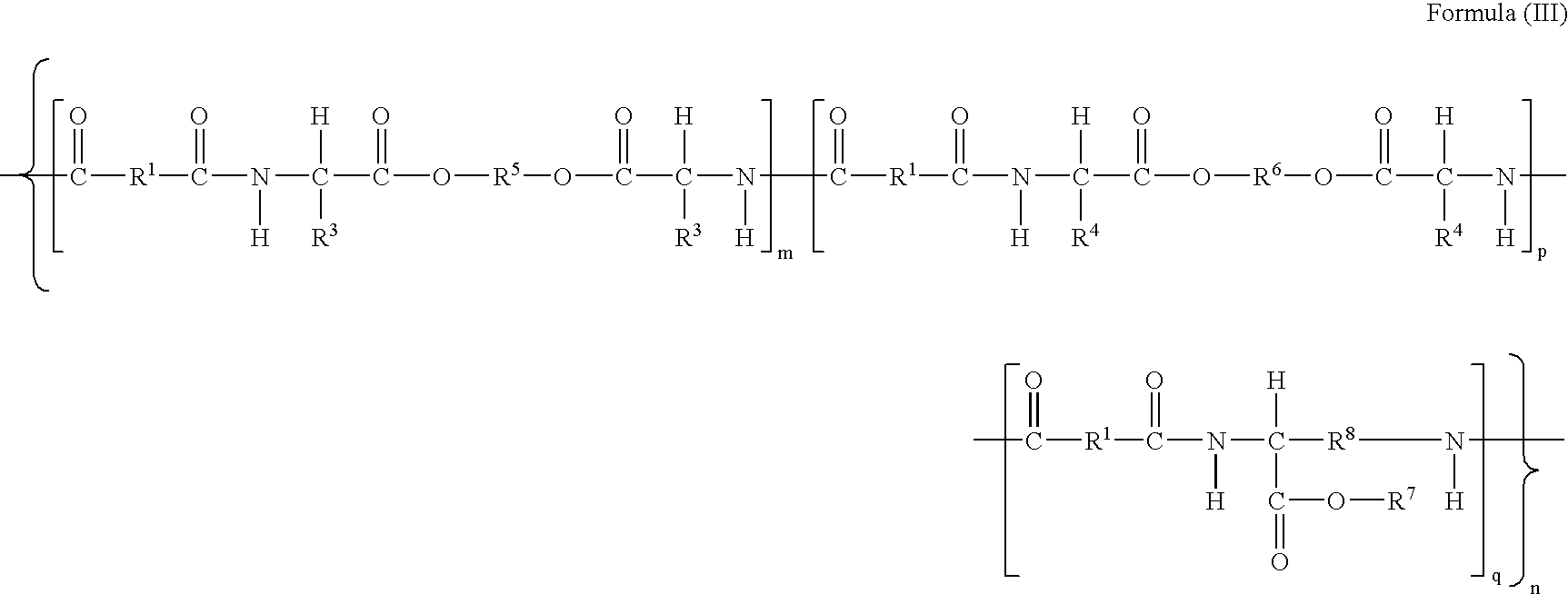

Bis-(Alpha-Amino)-Diol-Diester-Containing Poly (Ester Amide) and Poly (Ester Urethane) Compositions and Methods of Use

ActiveUS20080299174A1Improved mechanical propertyHigh glass transition temperatureStentsBiocideActive agentInternal Fixation Devices

The present invention provides biodegradable, biocompatible bis-(α-amino acyl)-diol-diester-containing poly(ester amide) (PEA) and poly(ester urethane) (PEUR) co-polymer compositions with mechanical properties that can be readily tailored by selection of various combinations and proportions of the building blocks of the co-polymers. The compositions are suitable for use in production of drug-releasing biodegradable particles and implantable surgical devices, such as stents and internal fixation devices. The co-polymer compositions, particles and surgical devices biodegrade in vivo by enzymatic action to release bioactive agents in a controlled manner over time as well as biocompatible breakdown products, including one to multiple different amino acids.

Owner:MEDIVAS LLC

Lignin Enhanced Wood-Plastic Material and Preparation Method thereof

It discloses a lignin enhanced wood-plastic composite, belonging to the field of polymer based composites. The wood-plastic composite is composed of one or more of plant fiber, lignin, a recycled thermoplastic plastic, mineral powder and a processing aid, and is processed by a screw granulating extrusion process. Compared with the prior art, the mechanical properties, heat stability and aging resistance of a wood-plastic material are improved by adding lignin into the wood-plastic material according to the present invention.

Owner:NANJING UNIV OF TECH

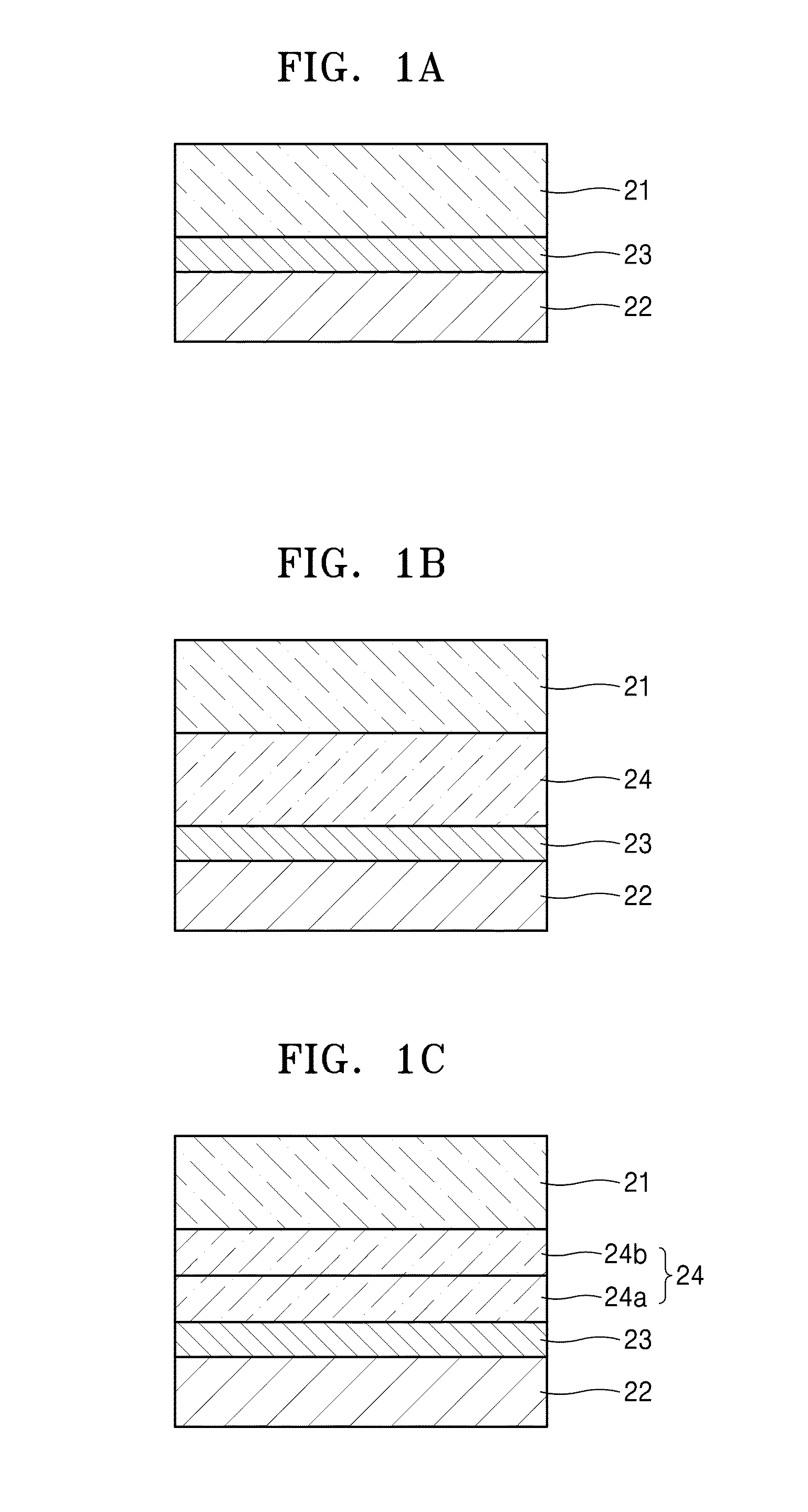

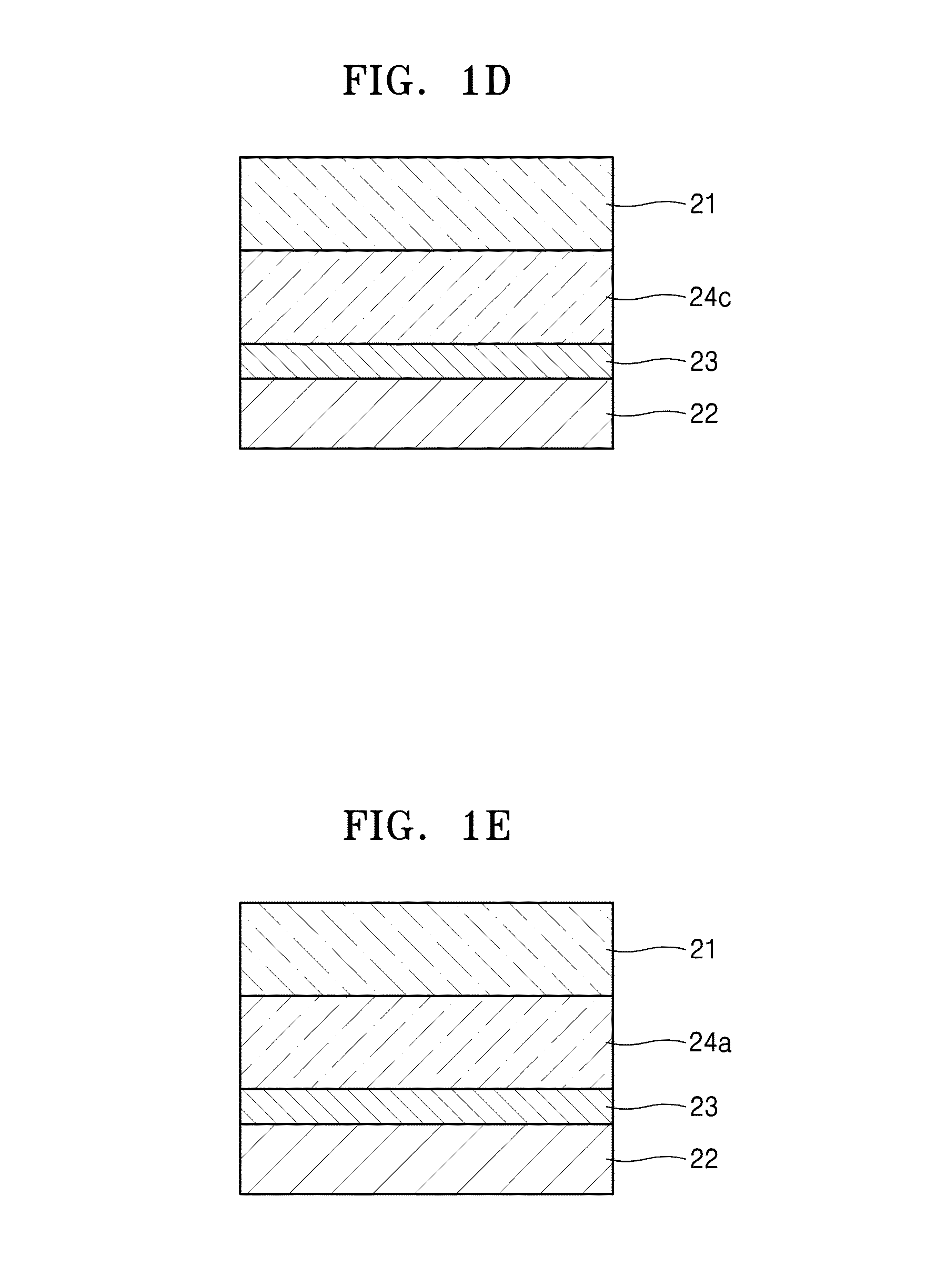

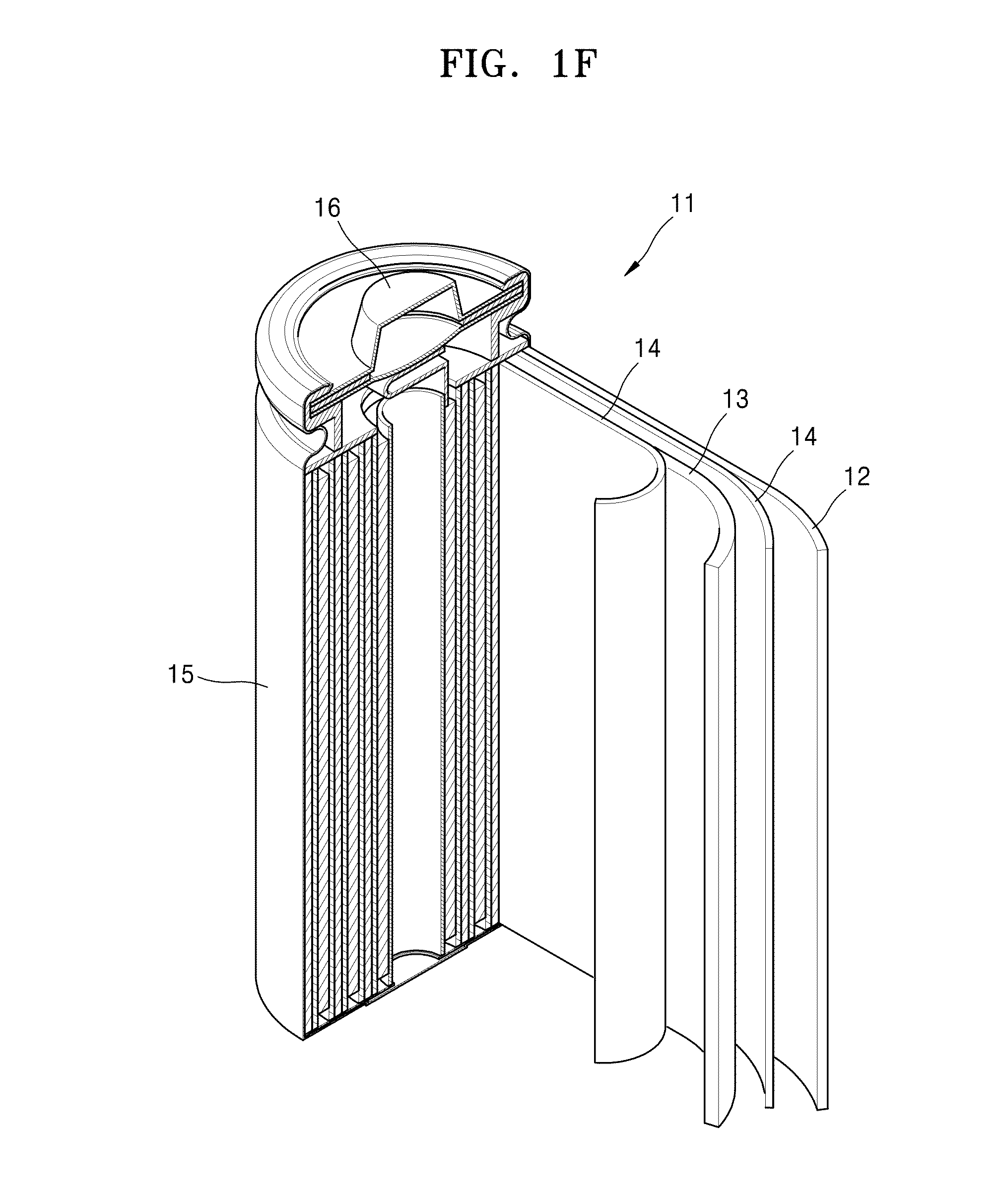

Electrolyte, method of preparing the electrolyte, and secondary battery including the electrolyte

ActiveUS20160093916A1Improved mechanical propertyImprove efficiencySolid electrolytesSolid electrolyte cellsIonPolymer chemistry

An electrolyte including a block copolymer containing a co-continuous domain including an ion conductive phase and a structural phase, wherein the structural phase includes a polymer segment having a glass transition temperature that is equal to or lower than room temperature.

Owner:SAMSUNG ELECTRONICS CO LTD

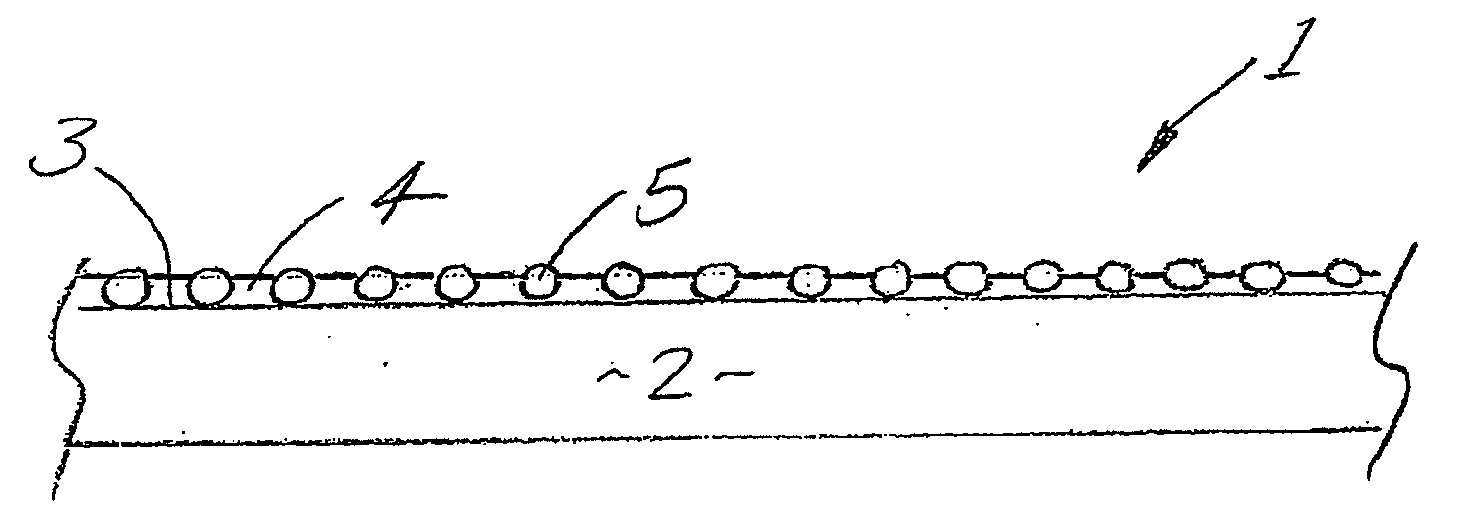

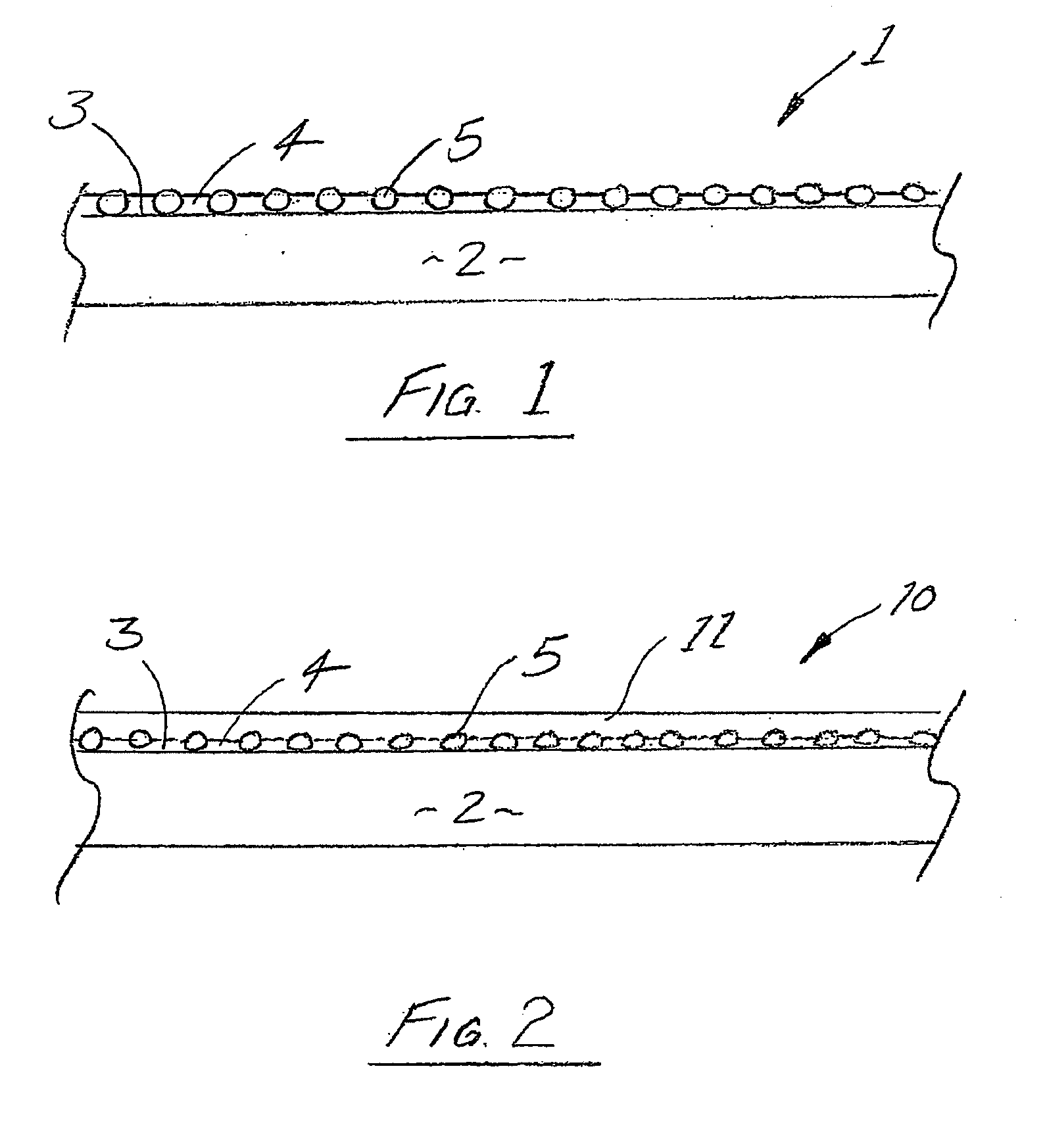

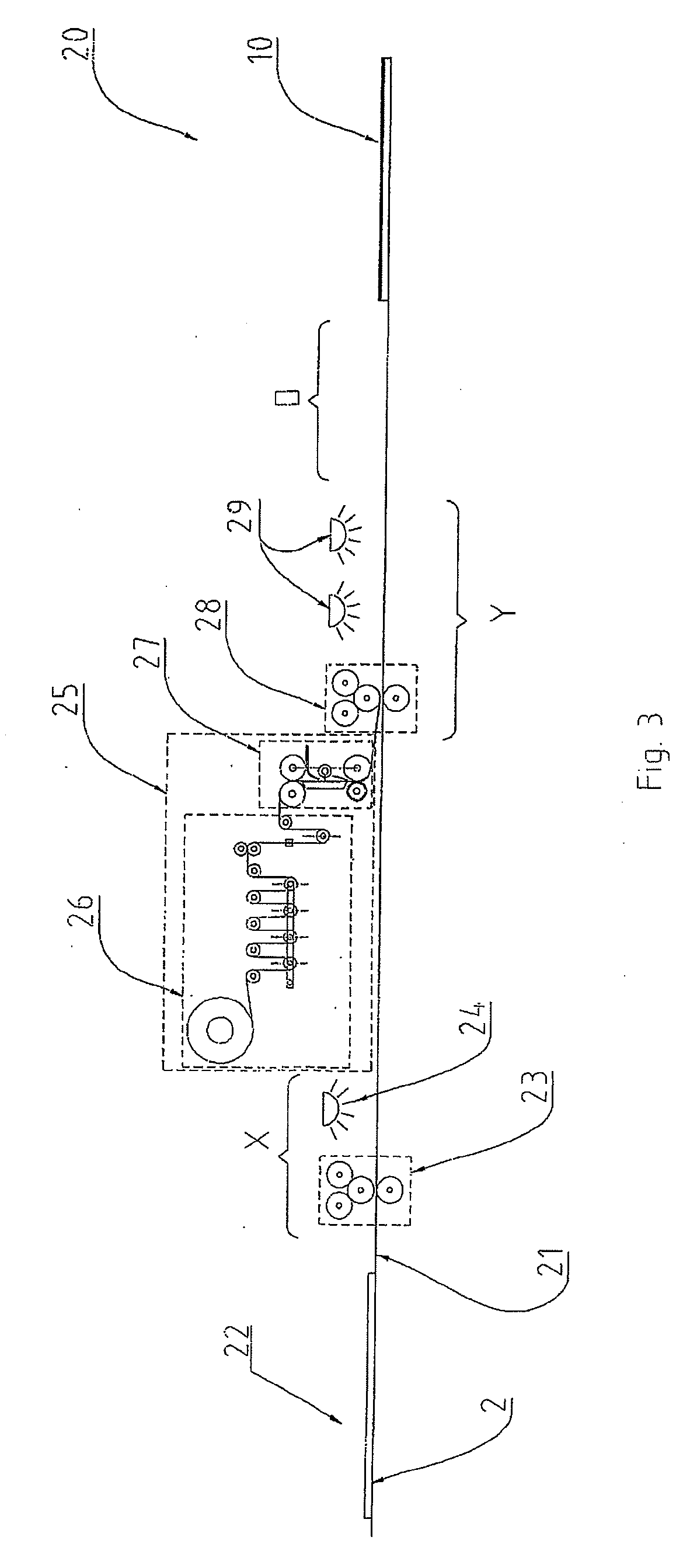

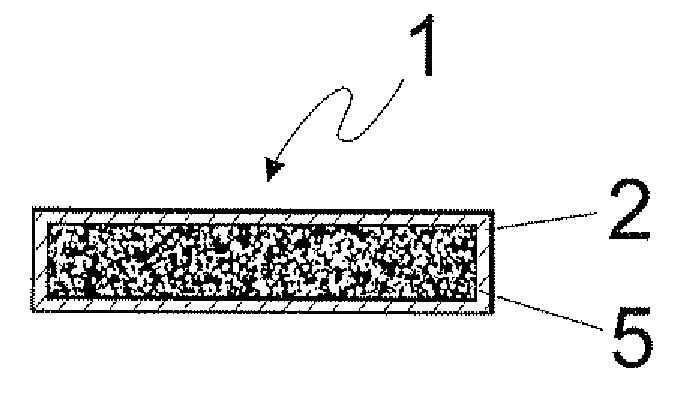

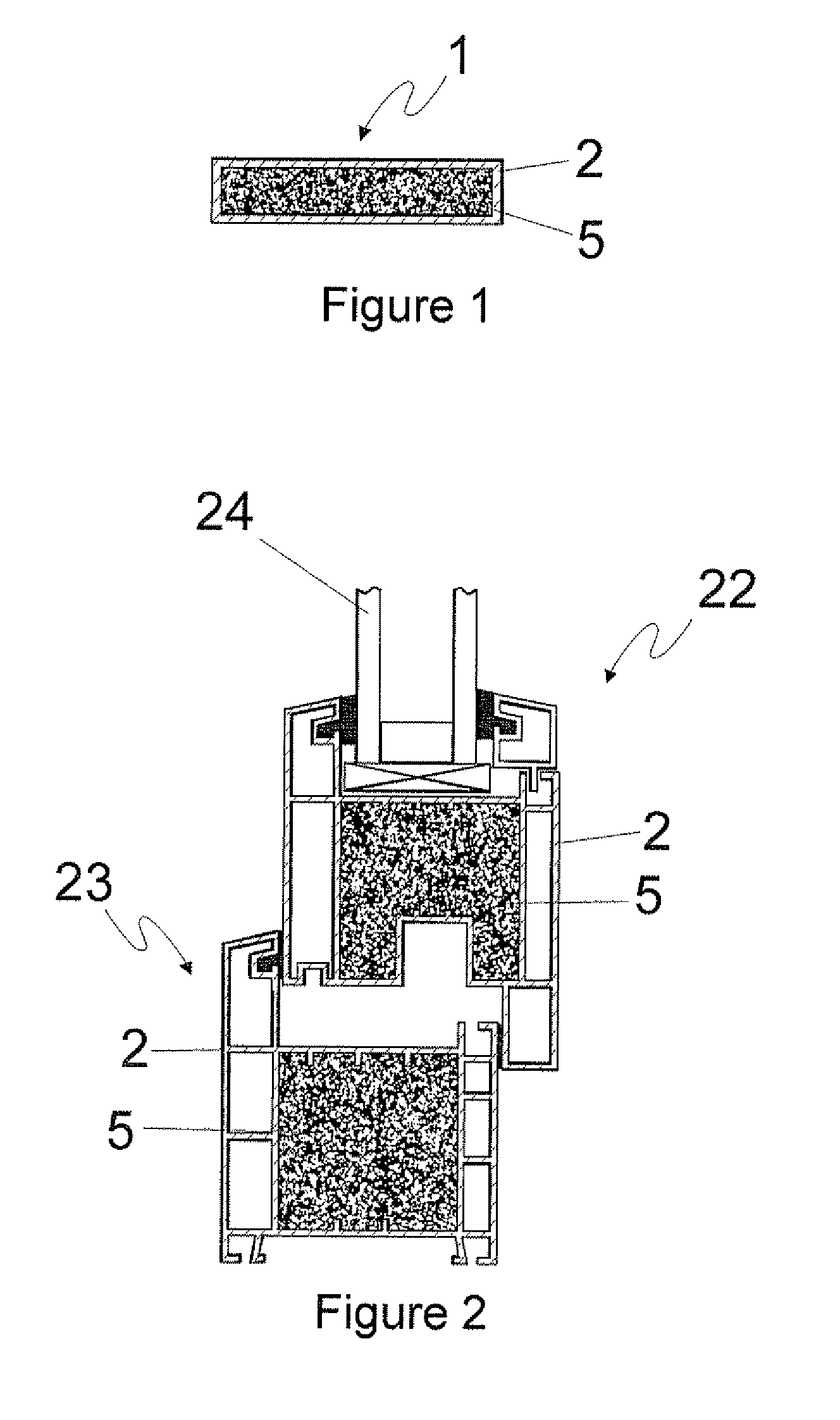

Surface Sealed Reinforced Building Element

ActiveUS20090272058A1Improved mechanical propertyLow quantityConstruction materialLamination ancillary operationsStructural elementBiomedical engineering

A building element (1) that is suitable for use as a structural element in wet areas or external docking. The building element (1) comprises a rigid substrate (2) having an upper face (3). Over the first face (3) lies a radiation curable resin (4) into which a layer of reinforcing material (5) is at least partially embedded. The reinforcing material (5) and resin (3) can be applied separately or together onto the first face (3) of the rigid substrate (2) or in some cases can be applied to both faces. An apparatus and method for producing the building sheet are also disclosed.

Owner:JAMES HARDIE TECH

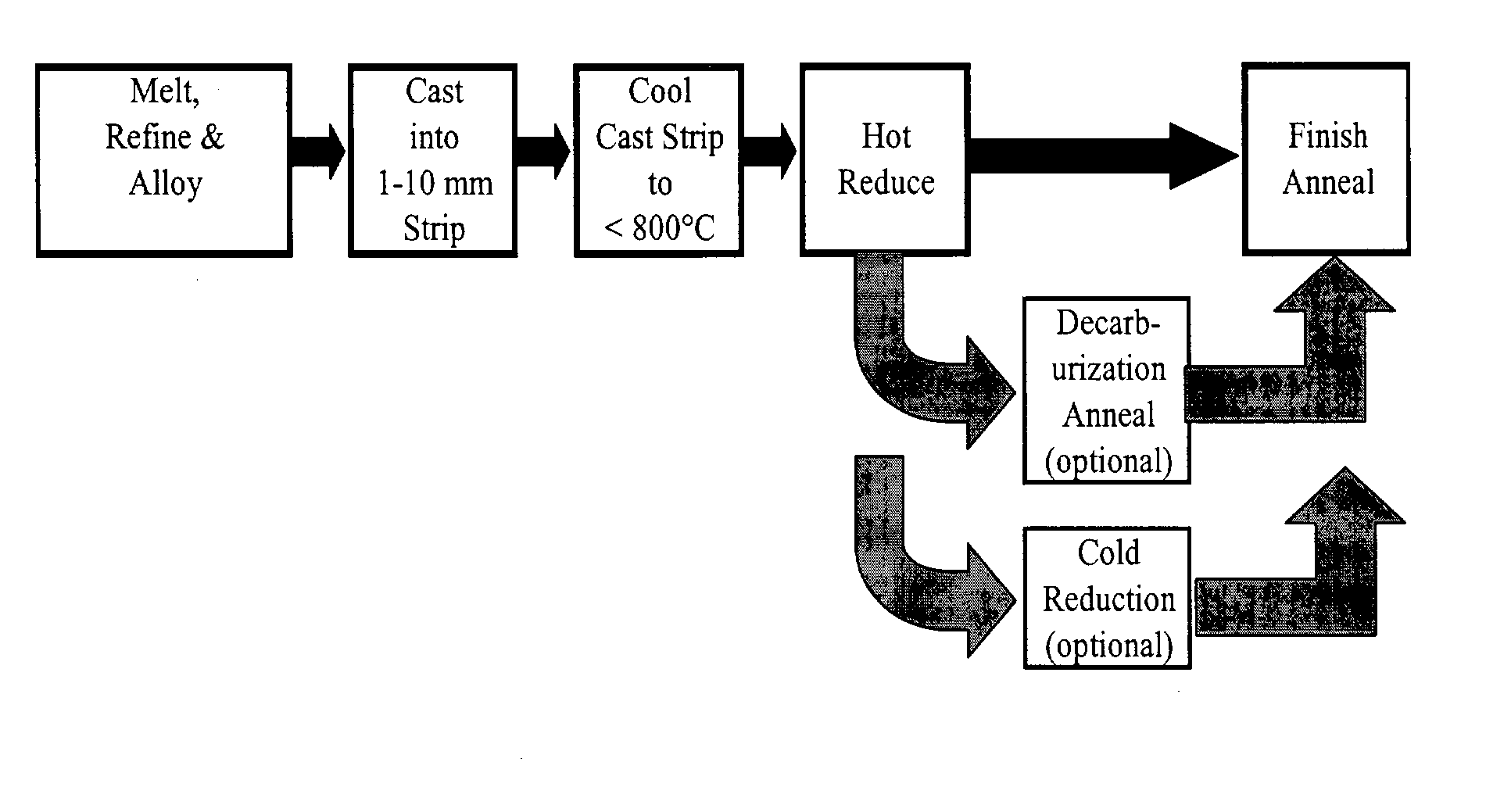

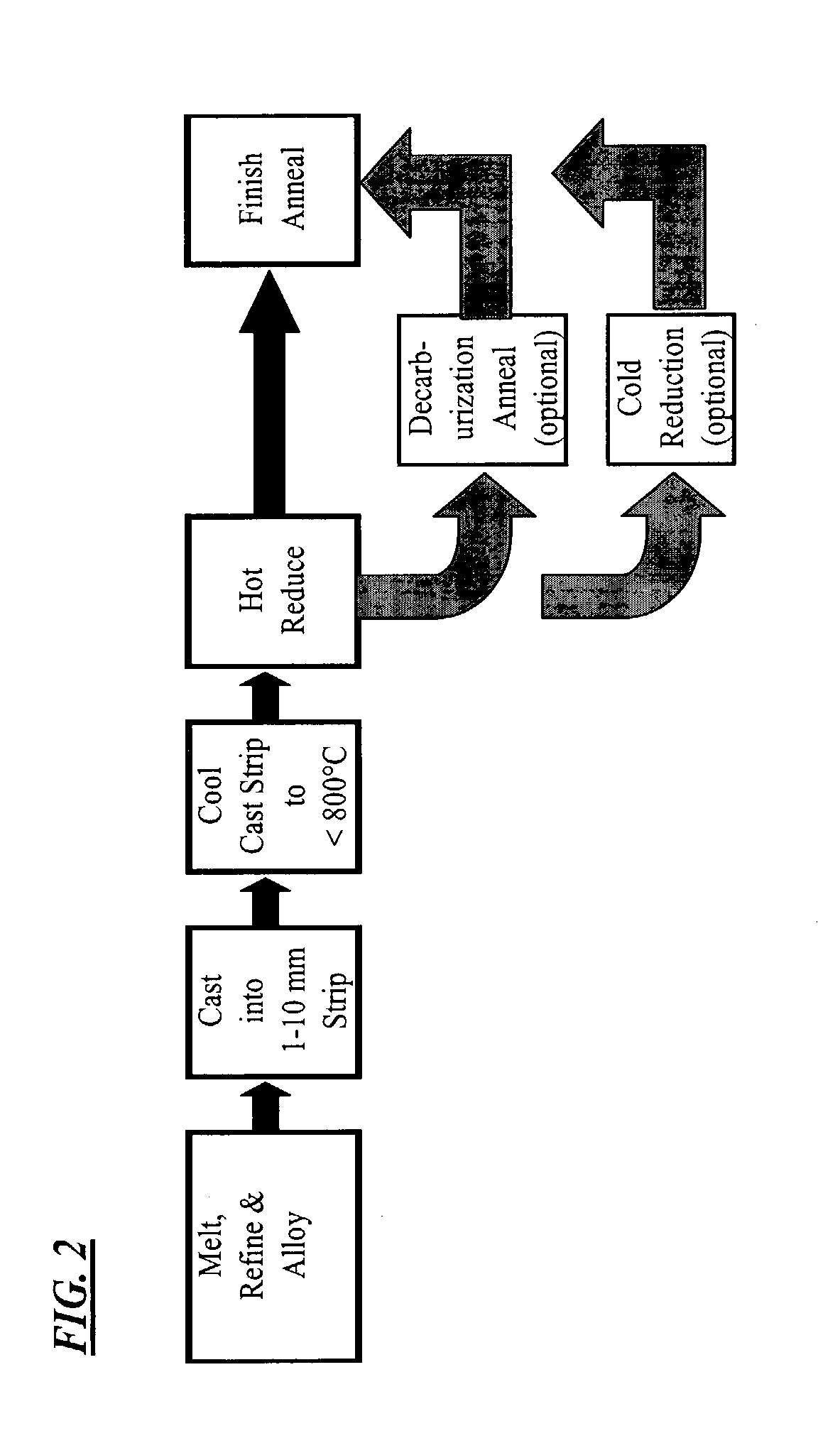

Method of continuous casting non-oriented electrical steel strip

InactiveUS20040016530A1Great resistanceImproved mechanical propertyMagnetic materialsElectric machineryMagnetic core

Non-oriented electrical steels are widely used as the magnetic core material in a variety of electrical machinery and devices, particularly in motors where low core loss and high magnetic permeability in all directions of the strip are desired. The present invention relates to a method for producing a non-oriented electrical steel with low core loss and high magnetic permeability whereby the steel is produced from a steel melt which is cast as a thin strip or sheet, cooled, hot rolled and / or cold rolled into a finished strip. The finished strip is further subjected to at least one annealing treatment wherein the magnetic properties are developed, making the steel strip of the present invention suitable for use in electrical machinery such as motors or transformers.

Owner:CLEVELAND CLIFFS STEEL PROPERTIES INC

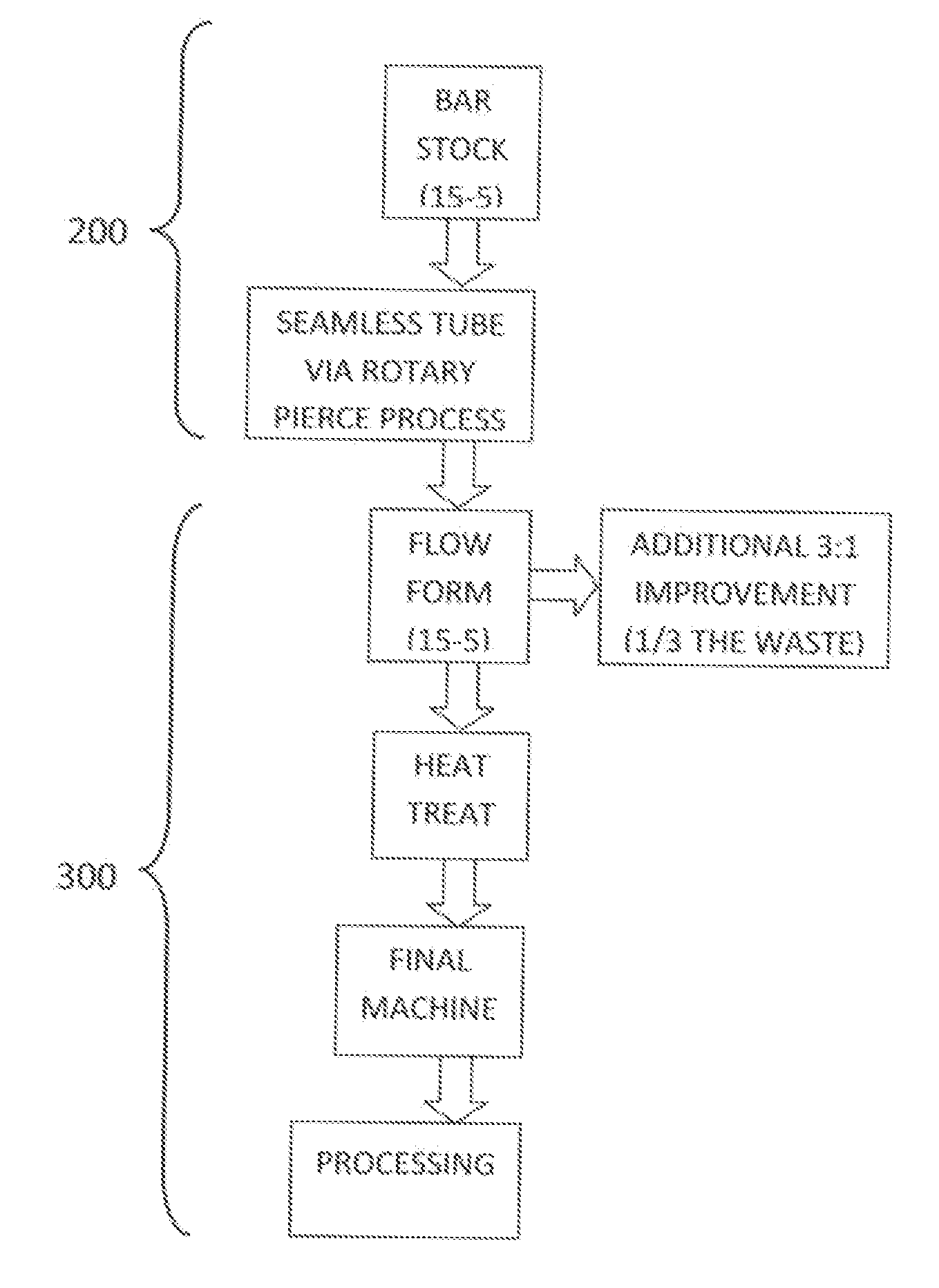

Axle Sleeve Manufacturing Process

InactiveUS20120031516A1Improved mechanical propertyLight weightTurning machine accessoriesHubsAirplaneForming processes

A system and method for the manufacture of aircraft landing gear axle equipment is provided of two primary steps: hot pierce and tube solid billet stock; and flow form process. The hot pierce and tube process converts a standard solid round billet by heating it well beyond its annealing temperature. The billet is then pierced with a lance and hot rolled into a seamless tube. The tube is then precision flow formed as an incremental metal forming technique in which a tube of metal is formed over a mandrel by a multiple rollers using tremendous pressure. The rollers deform the work piece, forcing it against the mandrel, simultaneously lengthening the part axially and radially thinning the cross-sectional wall of the workpiece.

Owner:THE NAT MASCH CO

Method for producing reinforced plastic profiles having improved thermal insulation for window construction

InactiveUS20100281811A1Improved mechanical propertyImprove thermal insulationDoor/window applicationsDomestic articlesThermal insulationSolid-state

Owner:SIKA TECH AG

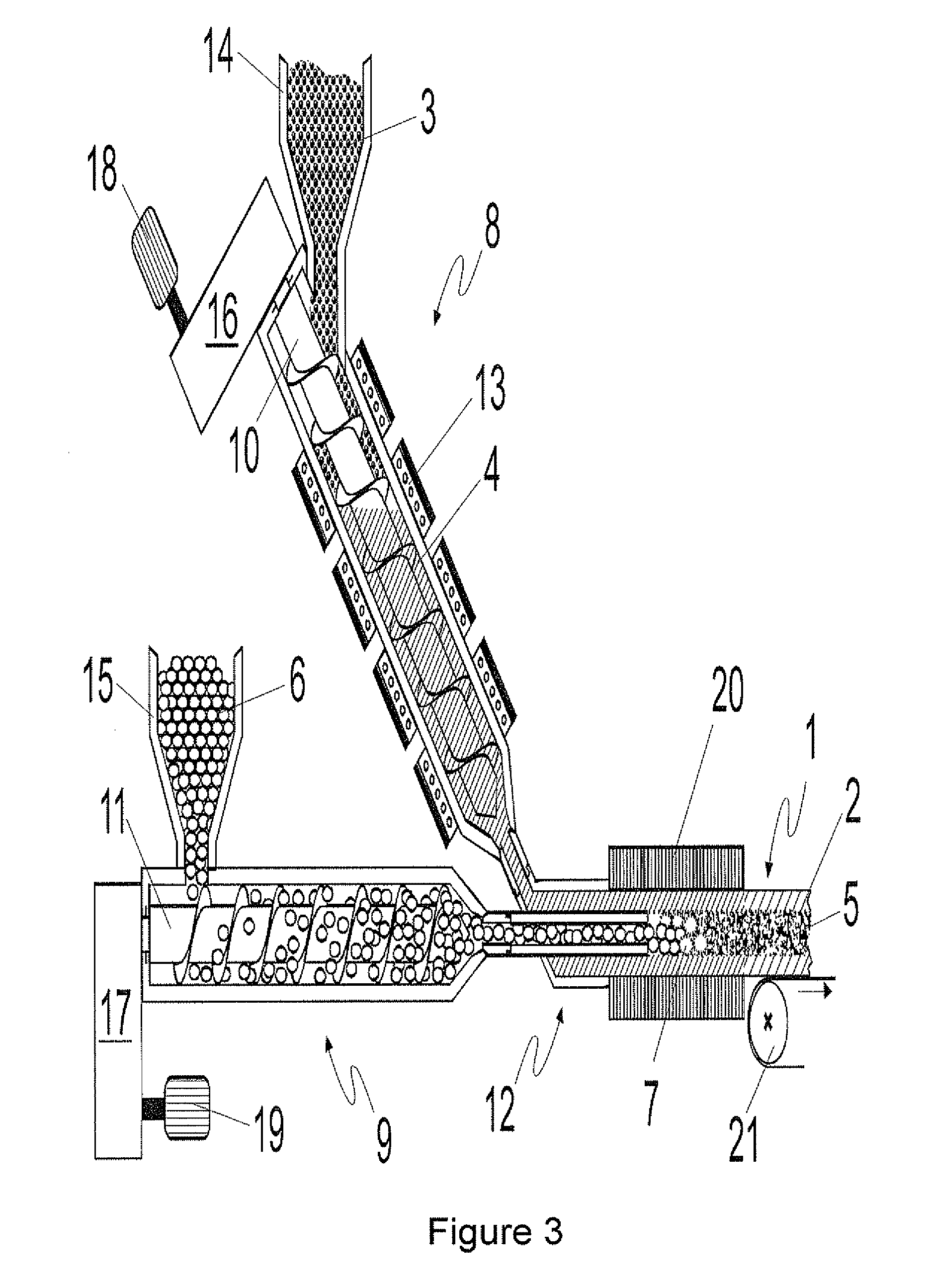

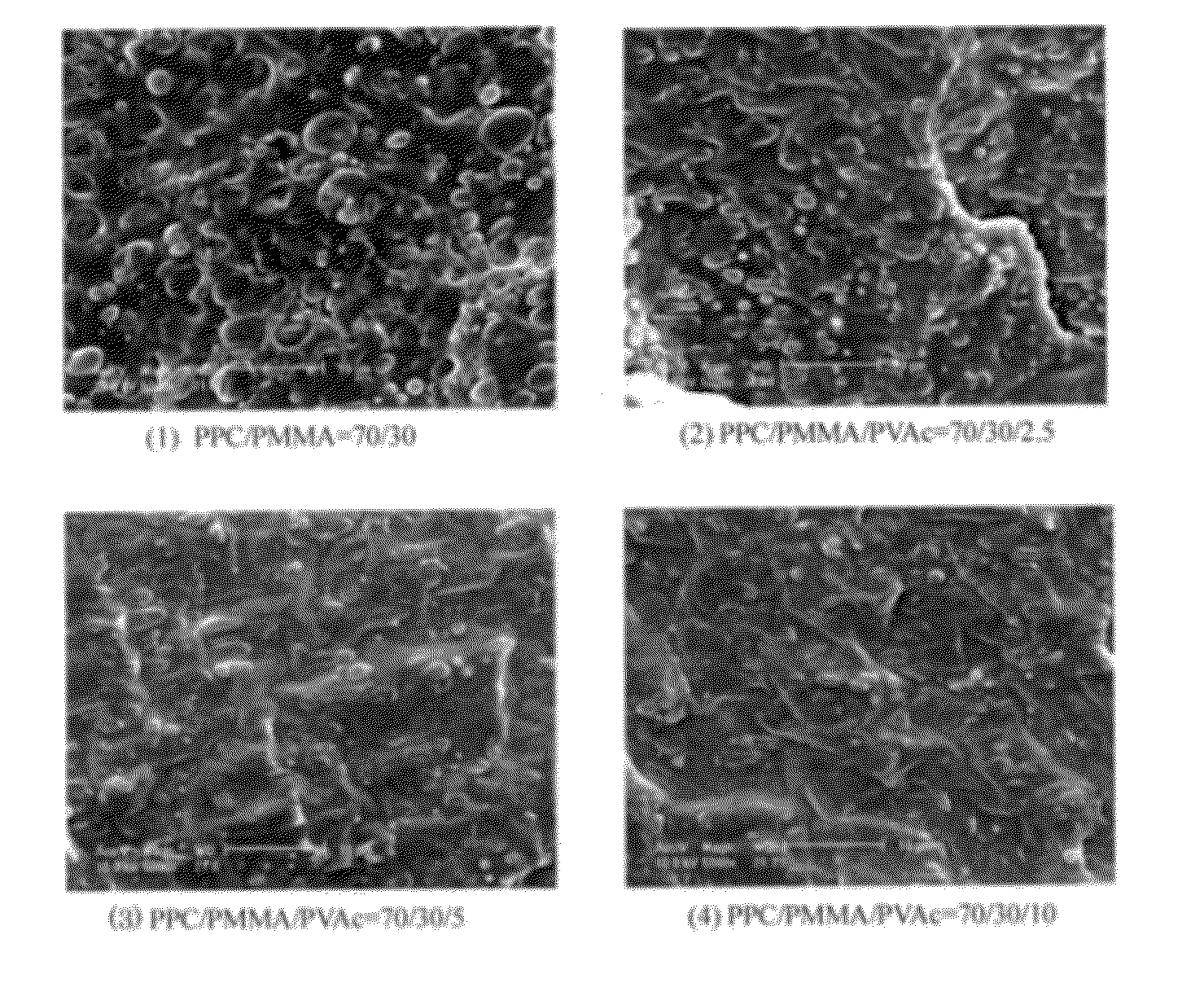

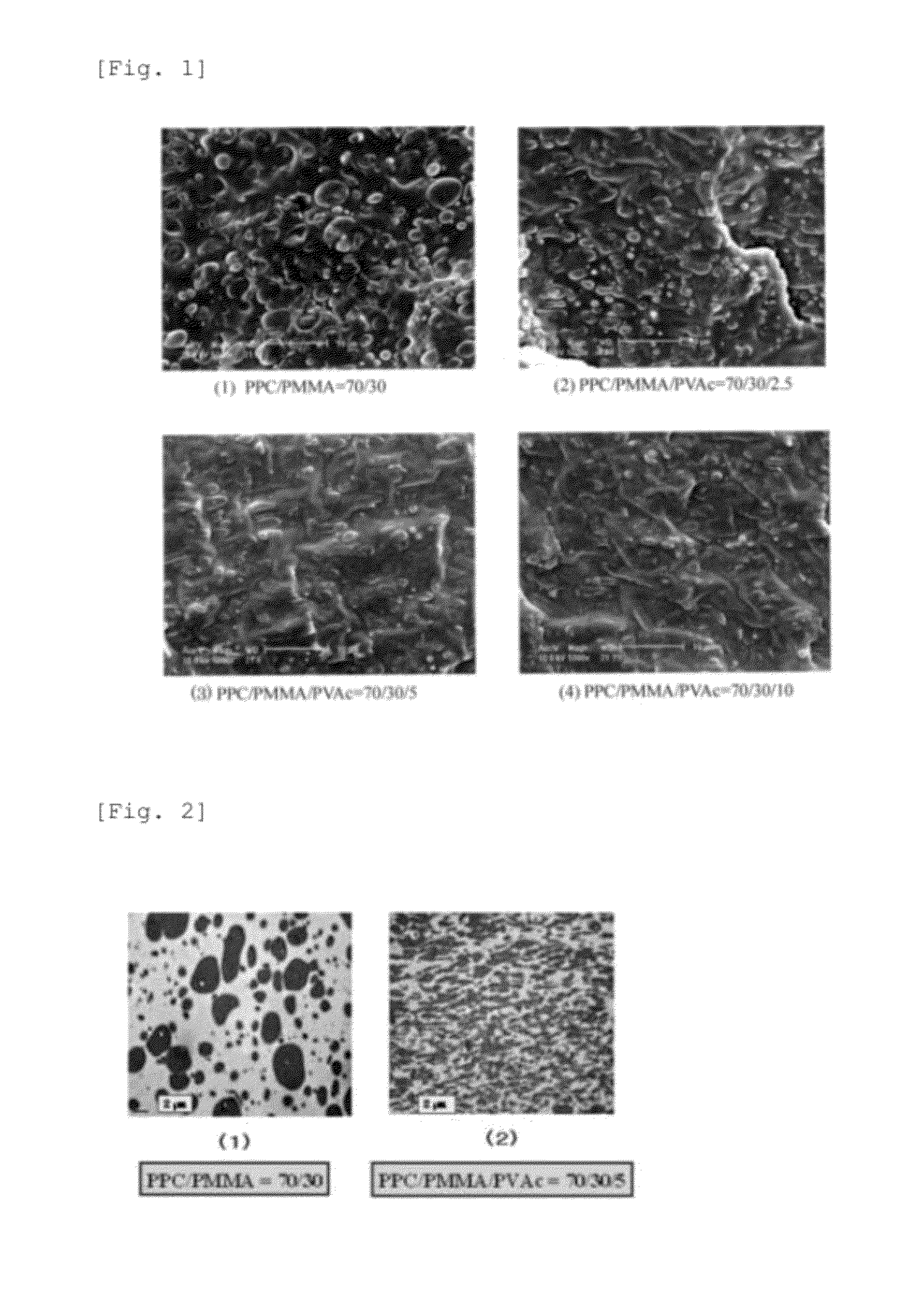

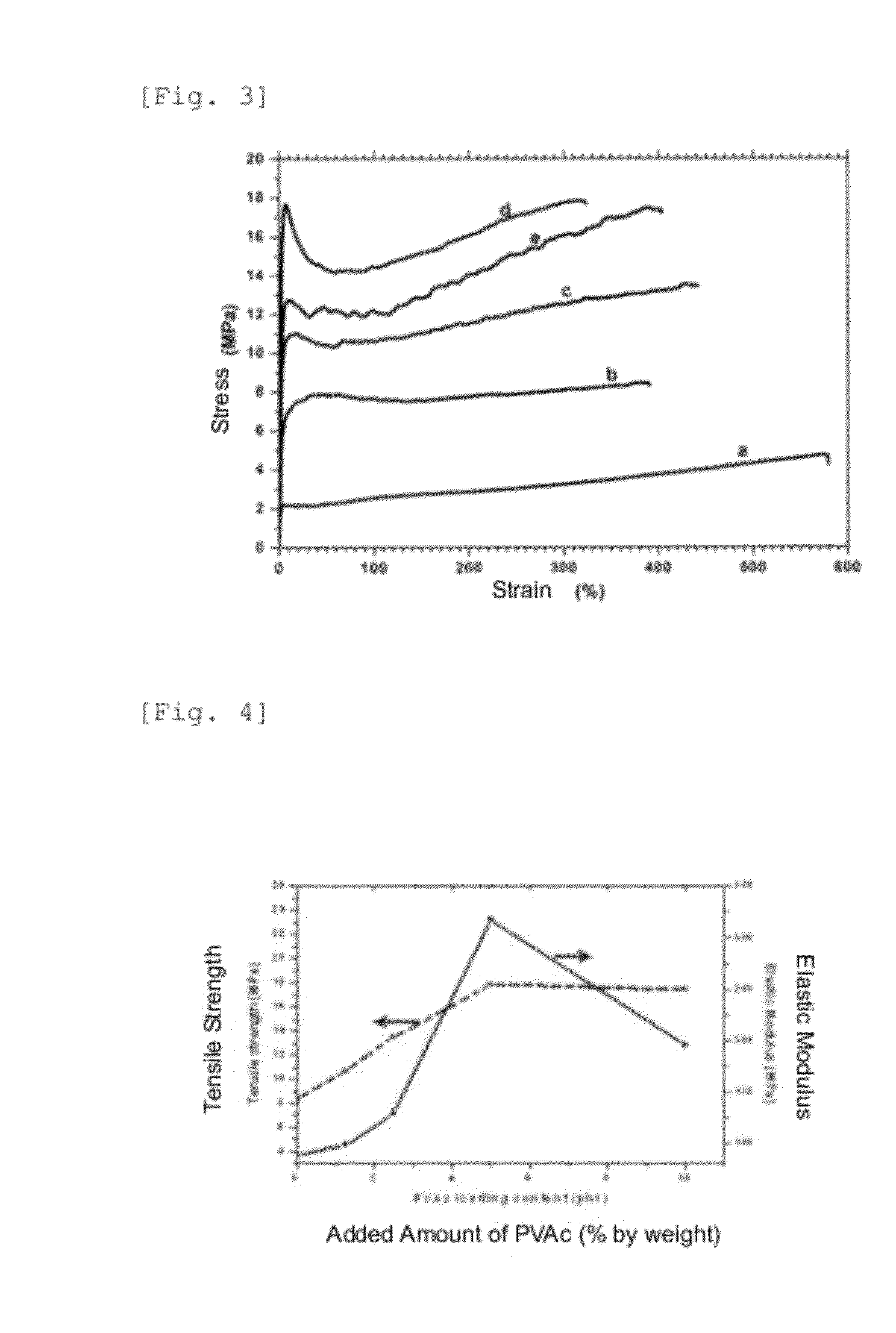

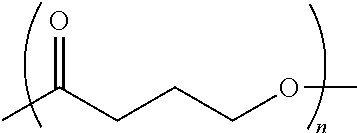

Ternary blends of aliphatic polycarbonate derived from carbon dioxide, and process for producing same

InactiveUS20120053282A1Improved mechanical propertyExcellent mechanical propertyPaper coatingMicaPolycarbonatePolyester

Disclosed is a novel ternary aliphatic polycarbonate blend derived from carbon dioxide, which is mainly composed of an aliphatic polycarbonate. Also disclosed is a process for producing the ternary aliphatic polycarbonate blend.A methacrylic resin or an aliphatic polyester is incorporated, as a second component, into an aliphatic polycarbonate to produce a blend, and a vinyl resin is added, as a third component, to the blend at a specified ratio, thereby producing a novel ternary aliphatic polycarbonate blend derived from carbon dioxide and having excellent mechanical properties that cannot be achieved by binary blends.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Composite material having a very low content of carbon-based nanofillers, process for the preparation thereof and uses thereof

InactiveUS20150147506A1Improved mechanical propertyImprove propertiesLayered productsCeramic shaping apparatusCarbon nanotubePolymer chemistry

A composite material containing a polymer composition and a very low concentration of carbon nanofillers, in particular carbon nanotubes, having improved mechanical properties. The method for producing said composite material and to the different uses thereof. The use of carbon nanofillers at a concentration of between 0.1 ppm and 99 ppm in order to improve mechanical properties, in particular the tensile properties of a polymer matrix encasing at least one polymer selected from a thermoplastic polymer alone or mixed with an elastomer resin base, while facilitating the shaping thereof into composite parts using any suitable technique, in particular injection, extrusion, compression or moulding, and while improving the electrostatic dissipation capability thereof.

Owner:ARKEMA FRANCE SA

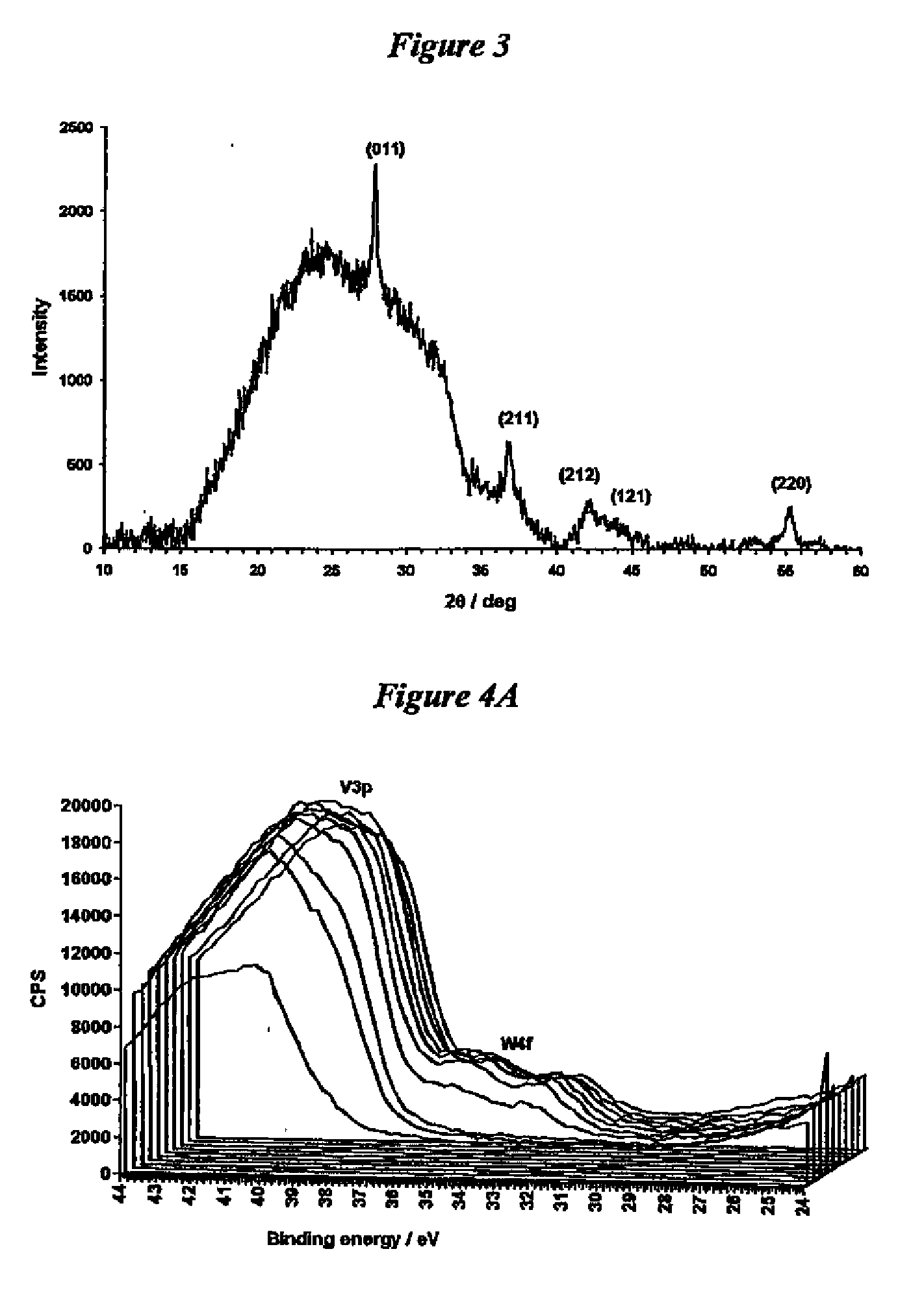

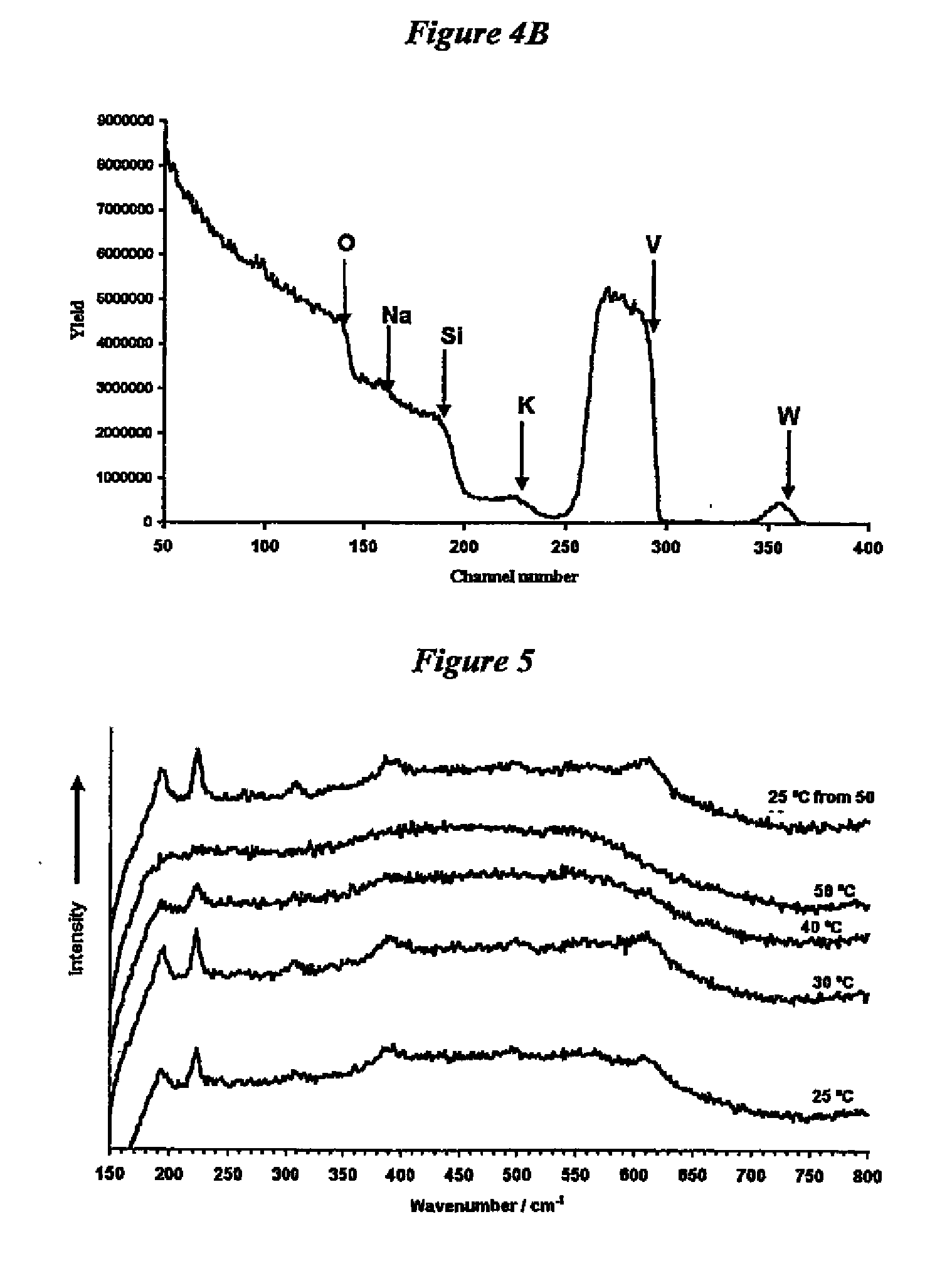

Thermochromic coatings

InactiveUS20070048438A1Improved mechanical propertyImprove adhesionVacuum evaporation coatingSputtering coatingCompound (substance)Oxide

The present invention provides the use of atmospheric pressure chemical vapour deposition (APCVD) for producing a film of thermochmmic transition metal-doped vanadium (iN) oxide on a substrate. Specifically, the invention prevides a method of producing a film of thermochromic transition metal-doped vanadium (IV) oxide on a substrate by atmospheric pressure chemical vapour deposition comprising the steps of: (i) reacting together (a) a vanadium precursor, (b) a transition metal dopant precursor, and (c) an oxygen precursor in an atmospheric pressure chemical vapour deposition reactor to form thermochromic transition metal-doped vanadium (IV) oxide, and (ii) depositing the thermochromic transition metal-doped vanadium (IV) oxide onto the substrate. A preferred transition metal dopant is tungsten. The invention also provides transition metal-doped vanadium (TV) oxide, films thereof and substrates (e.g., glass substrates) coated with a film of transition metal-doped vanadium (IV) oxide. Intelligent window systems, infrared modulators and data storage devices comprising such substrates are also provided.

Owner:UNIV COLLEGE OF LONDON

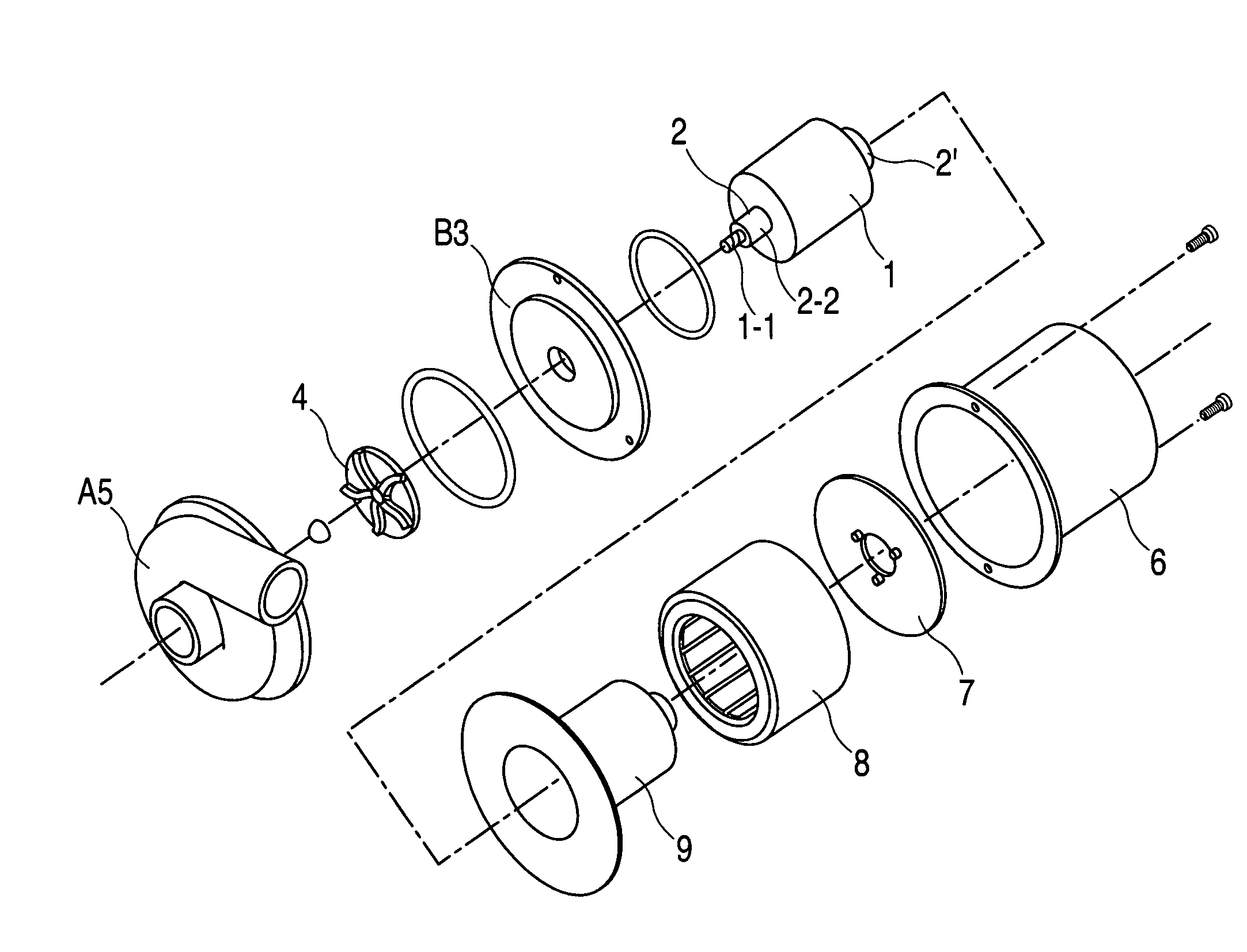

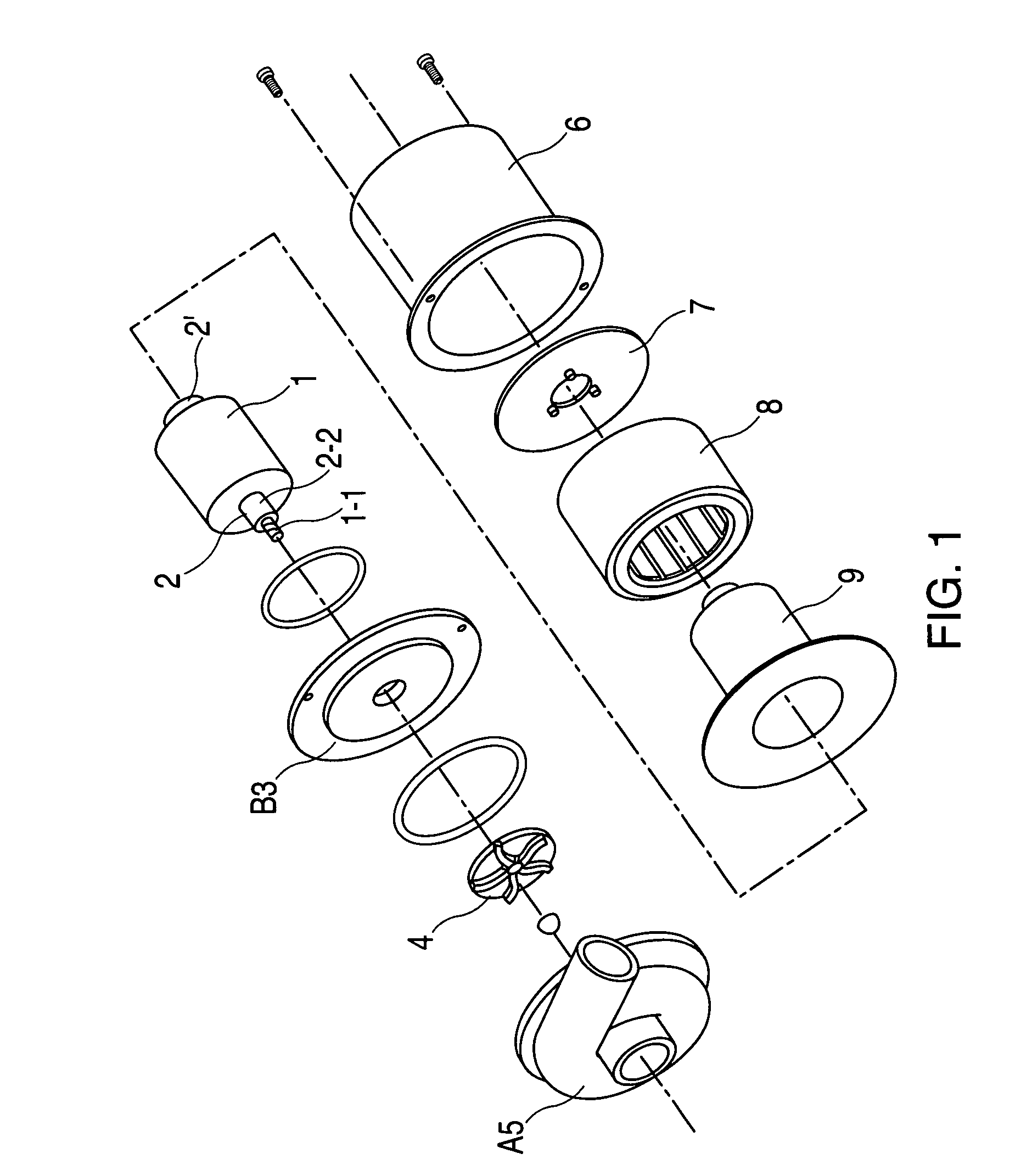

Electrically motorized pump having a submersible sleeve bearing

InactiveUS7008196B2Improved mechanical propertyImprove frictional characteristicPump componentsBearing componentsEnergy lossPolymer chemistry

The electrically motorized pump has a low energy loss because it uses of the shaft and the sleeve made from synthetic resin composition obtained by uniformly dispersing fine powder of RBC or CRBC in a resin. The typical process for the production of a synthetic resin composition for making the sleeve bearing for the pump for use in water includes kneading with a resin the fine powder of RBC or CRBC at a temperature in the neighborhood of the melting point of the resin, and thereby uniformly dispersing the fine powder of RBC or CRBC in the resin. Fibers, such as glass fibers, may be blended with the fine powder of RBC or CRBC and the resin.

Owner:MINEBEA CO LTD

Mixtures for producing biodegradable aliphatic polyester-based molded bodies and for producing polymer powders that can be re-dispersed in water

ActiveUS20110207858A1Improved mechanical propertyExcellent miscibilityImpression capsPaper coatingPolyesterPolymer chemistry

The object of the invention is mixtures for producing biodegradable molded bodies based on one or more aliphatic polyesters, characterized in that the mixtures also comprise one or more polymer powders that can be re-dispersed in water.

Owner:WACKER CHEM GMBH

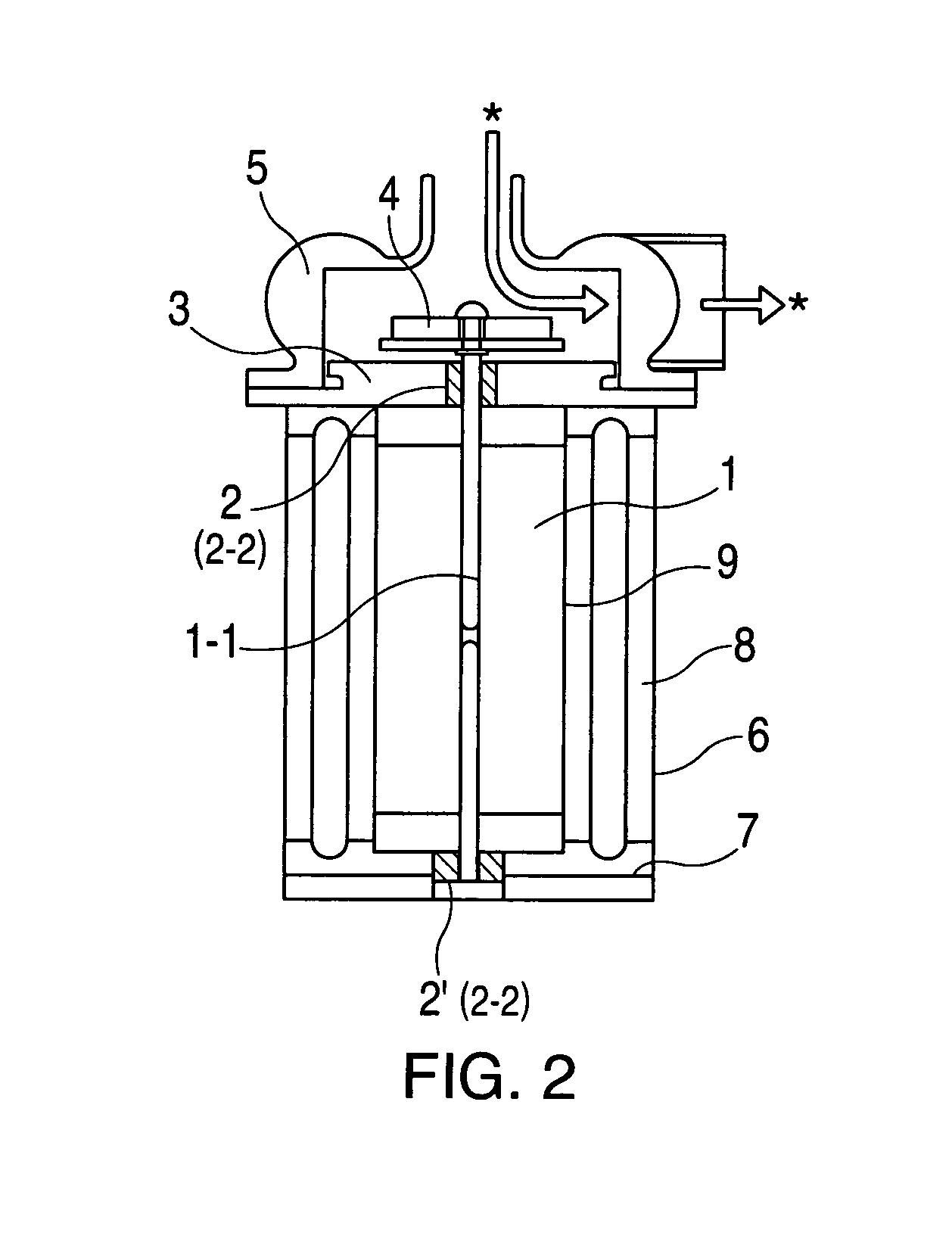

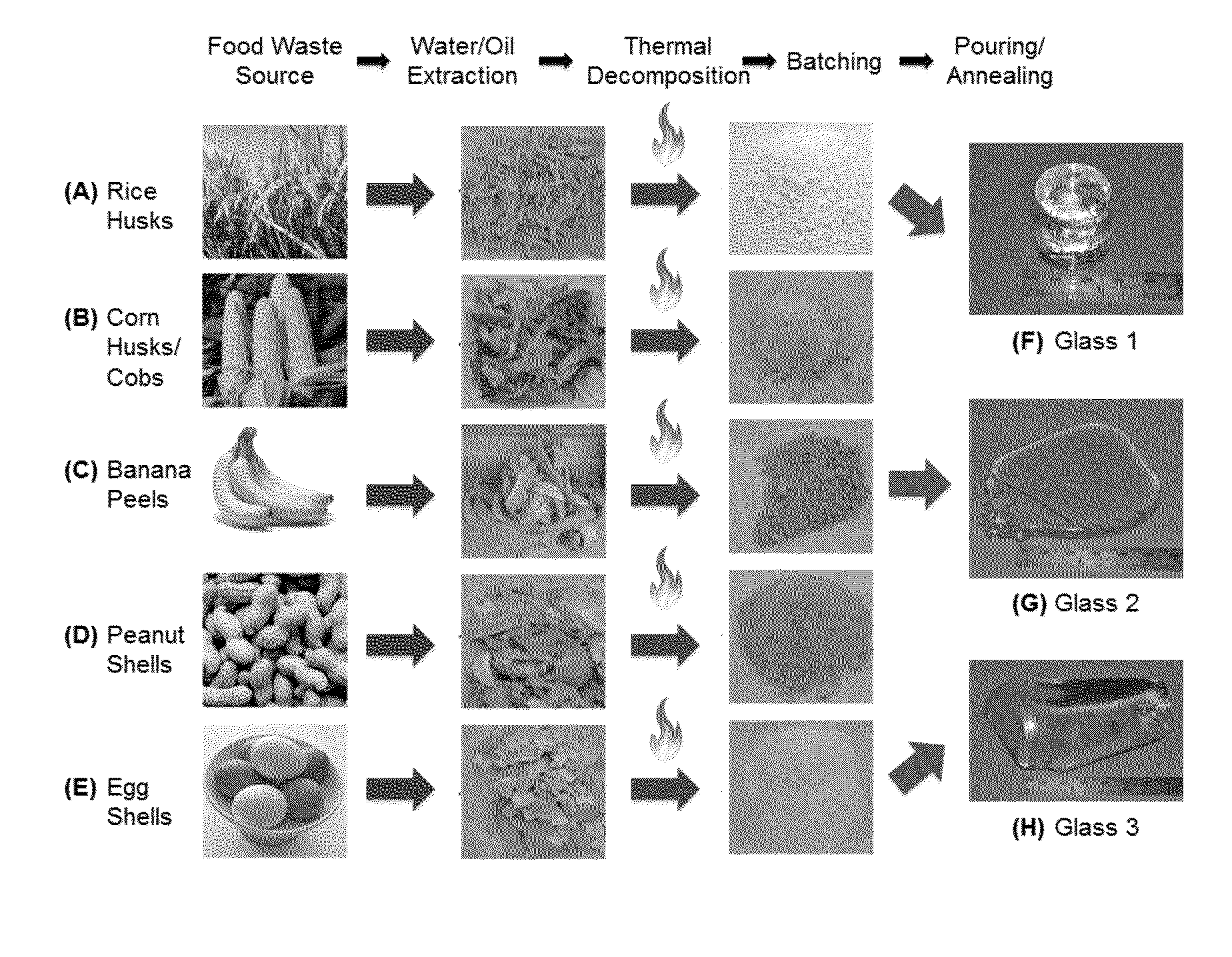

Methods of making glass from organic waste food streams

InactiveUS20150065329A1SameImproved mechanical propertyBlowing machine gearingsWaste processingChemistryAgricultural waste

The invention introduces new glasses, and new methods for making glass, glass-ceramics, and / or ceramic articles from inorganic compounds extracted from organic waste streams, including food waste streams, agricultural waste streams, and other organic waste streams with high inorganic oxide content. The organic waste stream can also be extended to human and animal wastes. These glasses will have the same, or improved physical, chemical, and mechanical properties as glasses made from mined minerals, however, the methodology disclosed in this invention will produce a renewable and sustainable inorganic product manufactured from organic waste streams.

Owner:COLORADO SCHOOL OF MINES

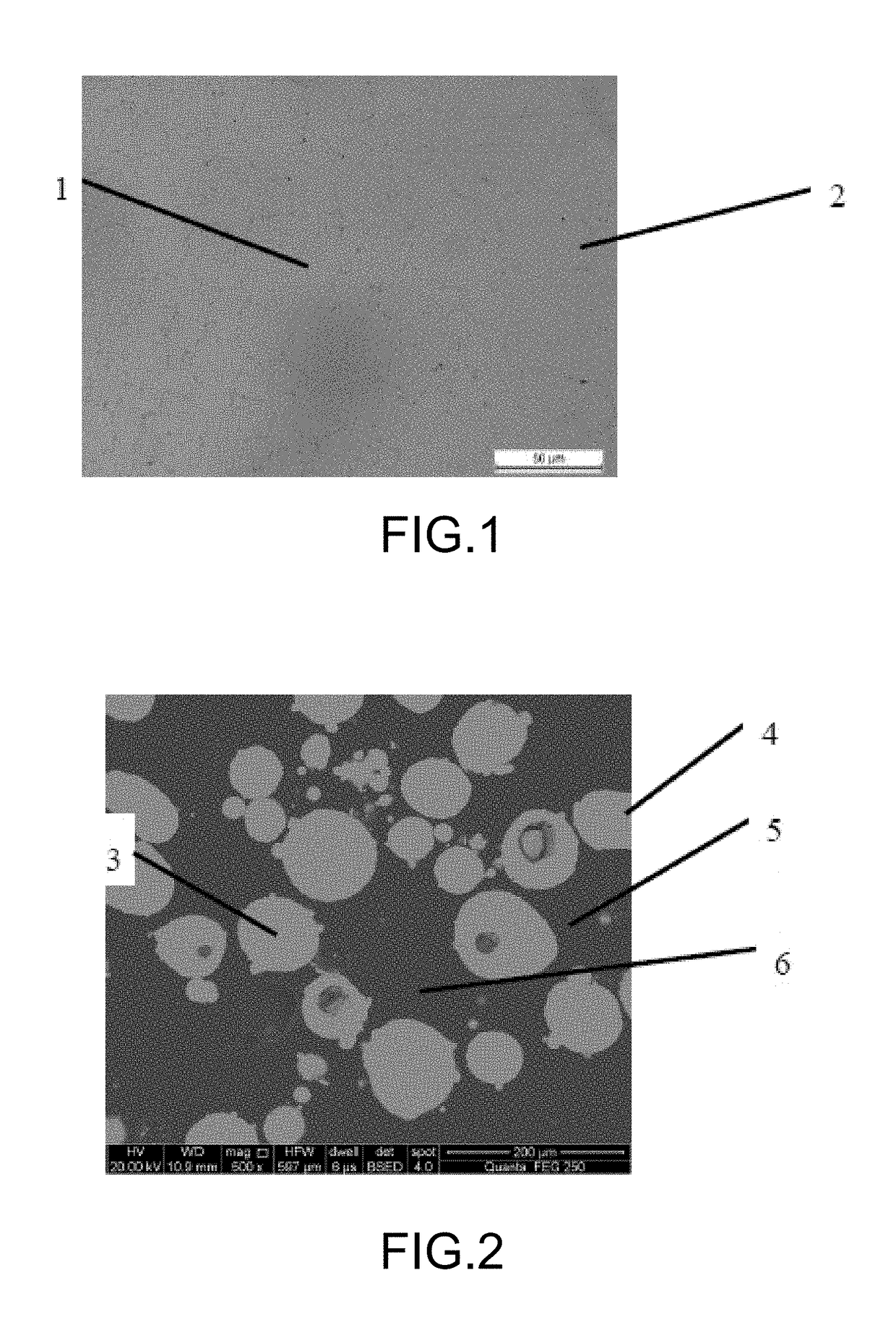

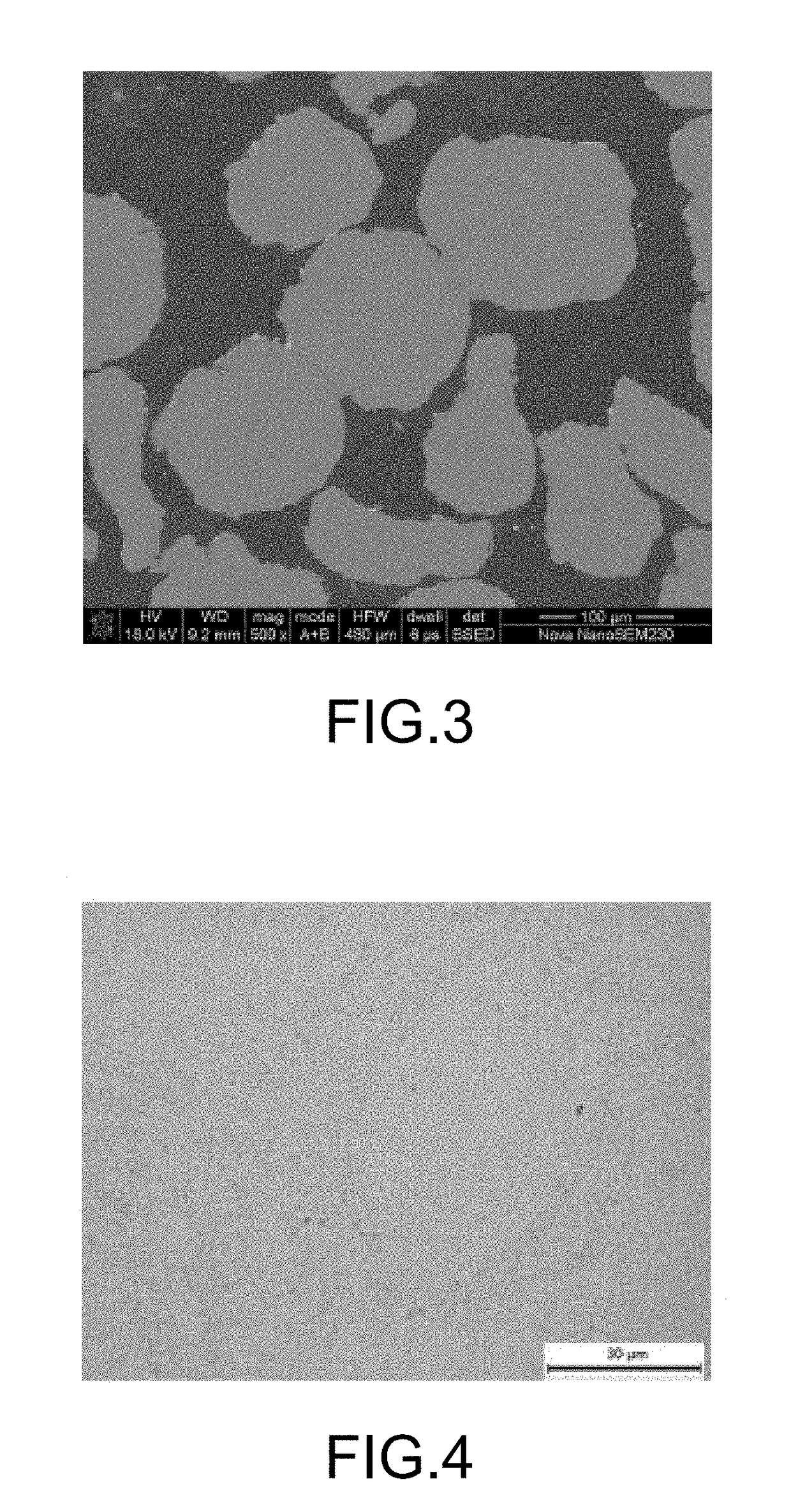

Method for removing prior particle boundary and hole defect of powder metallurgy high-temperature alloy

InactiveUS20170216919A1Improve surface activityImproved mechanical propertyCoatingsPowder metallurgyPrill

A method for removing prior particle boundaries and hole defects of a powder metallurgy high-temperature alloy. The method includes performing mechanical ball milling treatment on an atomized powder, thermosetting the powder to form a shape, and preparing a powder metallurgy high-temperature alloy.

Owner:CENT SOUTH UNIV

Multilayer film resistant to linear tear propagation

InactiveUS20160016392A1Improved mechanical propertyLow tear propagation forceDecorative surface effectsDuplicating/marking methodsLow-density polyethyleneThermoplastic polymer

A multilayer film comprising a layer sequence made of (a) a layer (a) composed of at least one polyethylene of low density or a mixture of a polyethylene of relatively low density and at least one aliphatic C3-C6 olefin homo- or copolymer, (b) a layer (b) composed of a mixture of at least one polyethylene of low density and at least one thermoplastic polymer, a layer (c) composed of at least one polyethylene of low density or a mixture of at least one polyethylene of low density and at least one aliphatic C3-C6 olefin homo- or copolymer.

Owner:LOPAREX GERMANY GMBH & CO KG

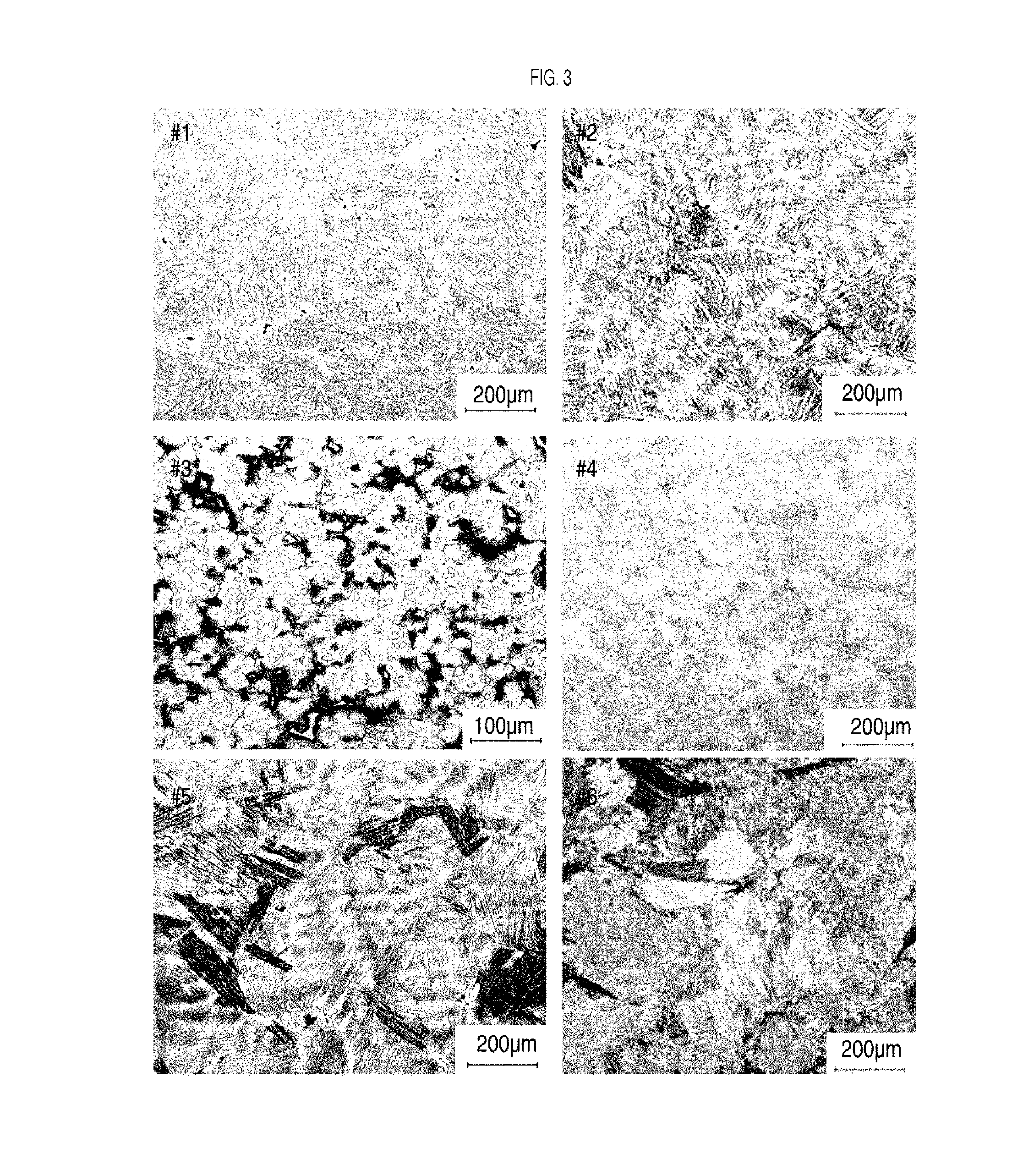

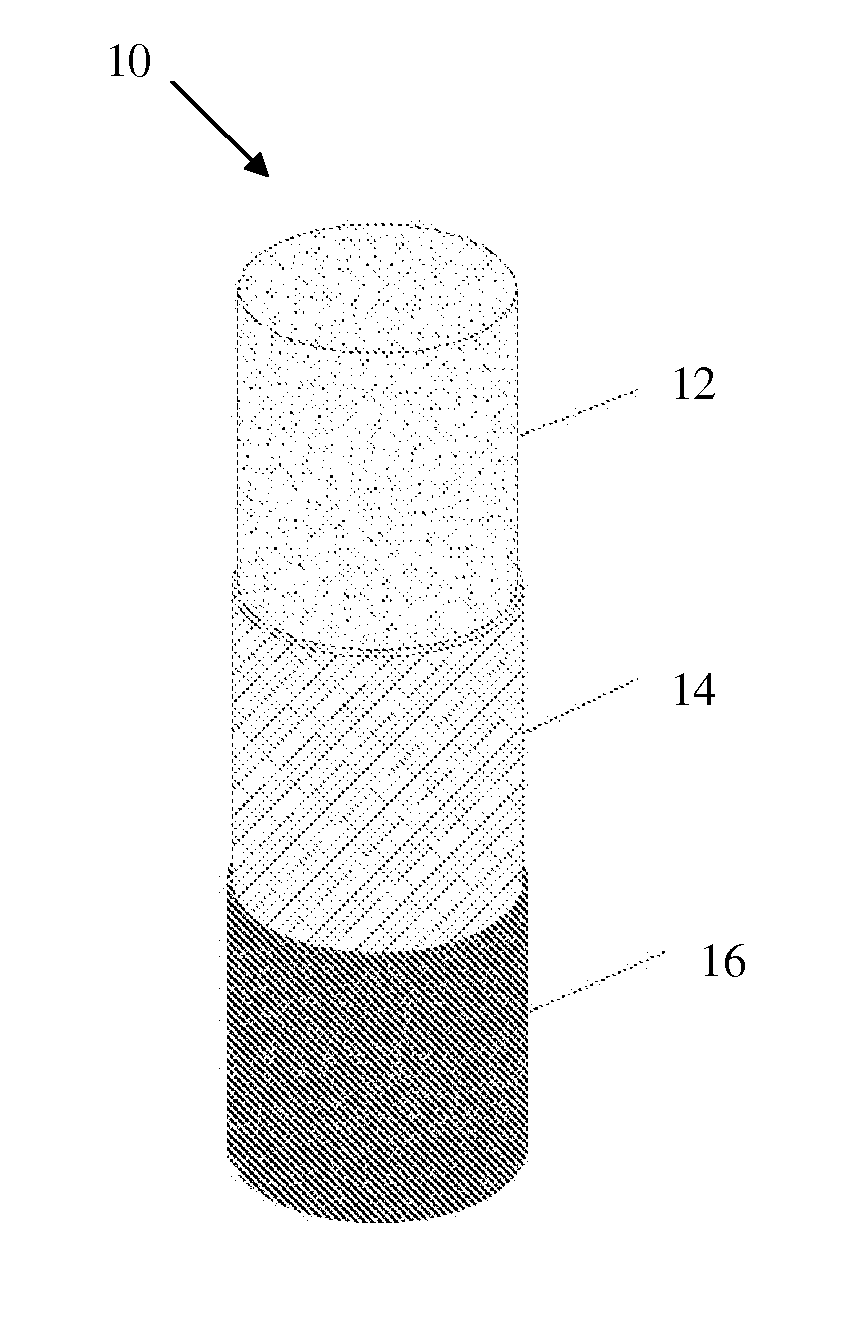

Lamellar-structure titanium-aluminum based alloy having a beta-gamma phase

A lamellar titanium-aluminium (TiAl) alloy having a beta-gamma phase according to the present invention contains aluminum (Al) of 40˜46 at %, niobium (Nb) of 3˜6 at %, a creep resistance enhancer of 0.2˜0.4 at %, a softening resistance enhancer of 2 at %, and the balance of titanium (Ti) and is manufactured by vacuum arc melting.

Owner:KOREA INST OF MASCH & MATERIALS

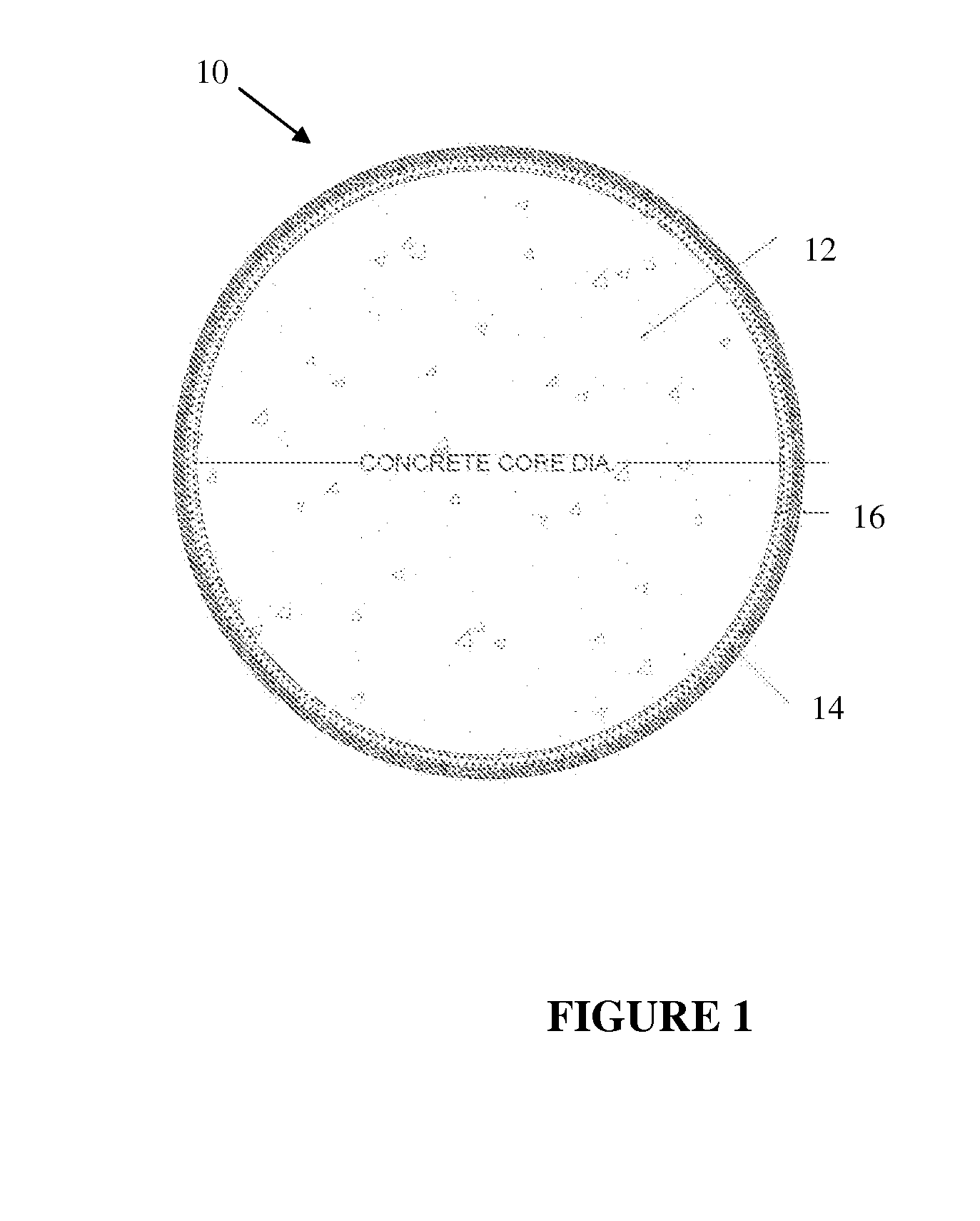

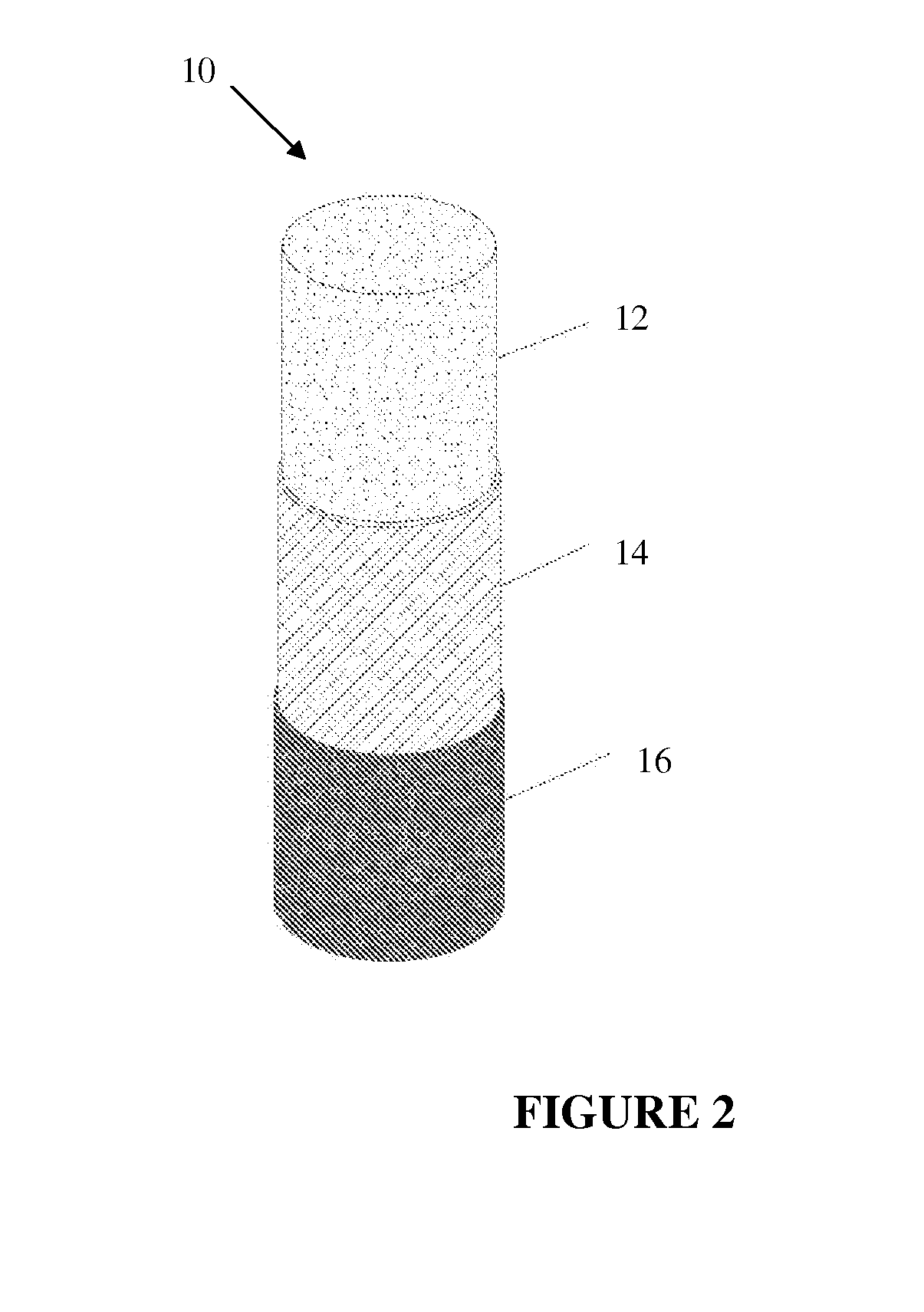

Reinforced Structural Column System

InactiveUS20160002927A1Improved mechanical propertyImprove resistanceStrutsBuilding reinforcementsPolymerFiber reinforcement

Improved structural column assemblies and related fabrication methods are provided. More particularly, the present disclosure provides improved systems / methods for the design and fabrication of structural column assemblies having improved mechanical properties and / or improved resistance to multiple hazards (e.g., earthquakes, blasts, high temperatures, etc.). Disclosed herein is a structural column assembly having a uniquely designed fiber reinforced polymer (FRP) tube filled with concrete to be used as a structural column (e.g., in bridge and / or building construction). The exemplary composite or FRP tube can include layers of metallic and / or non-metallic fibers wound at improved / optimized angles. A multi-hazard resilient column system which can negate the need for additional concrete reinforcement or formwork at construction sites is provided. The novel tube is highly resistant to corrosive environments, and will facilitate accelerated bridge construction (ABC), while providing a solution for columns at risk from multiple hazards.

Owner:UNIV OF CONNECTICUT

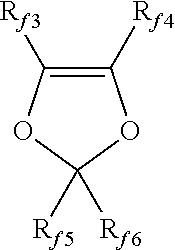

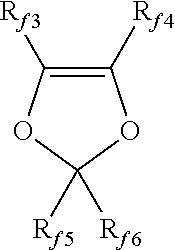

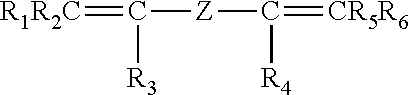

Fluoroelastomer compositions

The invention pertains to a (per)fluoroelastomer composition comprising: —a (per)fluoroelastomer [fluoroelastomer (A)]; and —at least one (per)fluoropolyether additive [polymer (E)] comprising a (per)fluoropolyether chain comprising recurring units having at least one catenary ether bond and at least one fluorocarbon moiety, and comprising at least one chain end comprising at least one per(halo)fluorinated aromatic group [group (AO], said polymer (E) being comprised in the composition in an amount of 0.5 to 30 phr, with respect to fluoroelastomer (A).

Owner:SOLVAY SOLEXIS

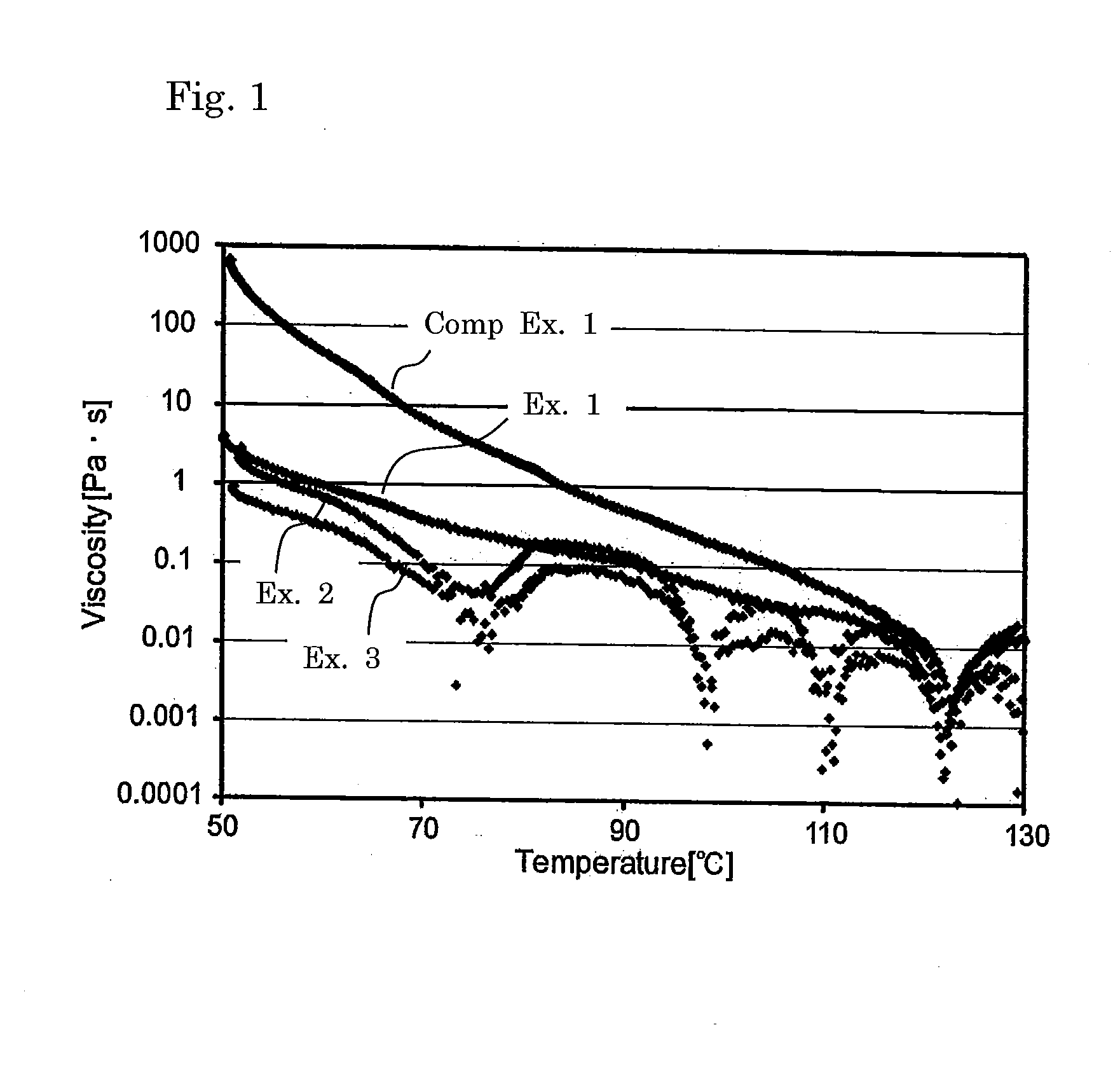

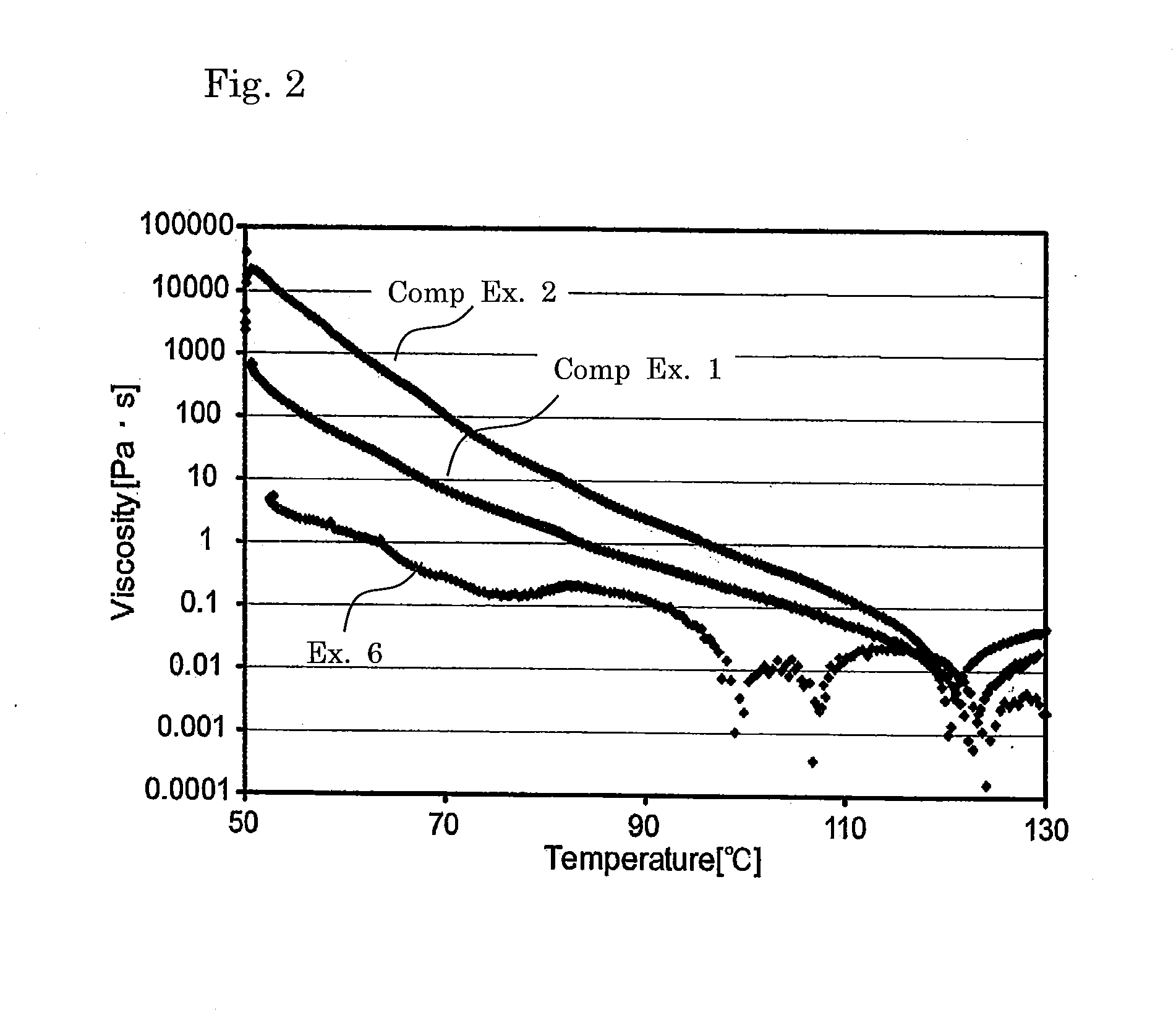

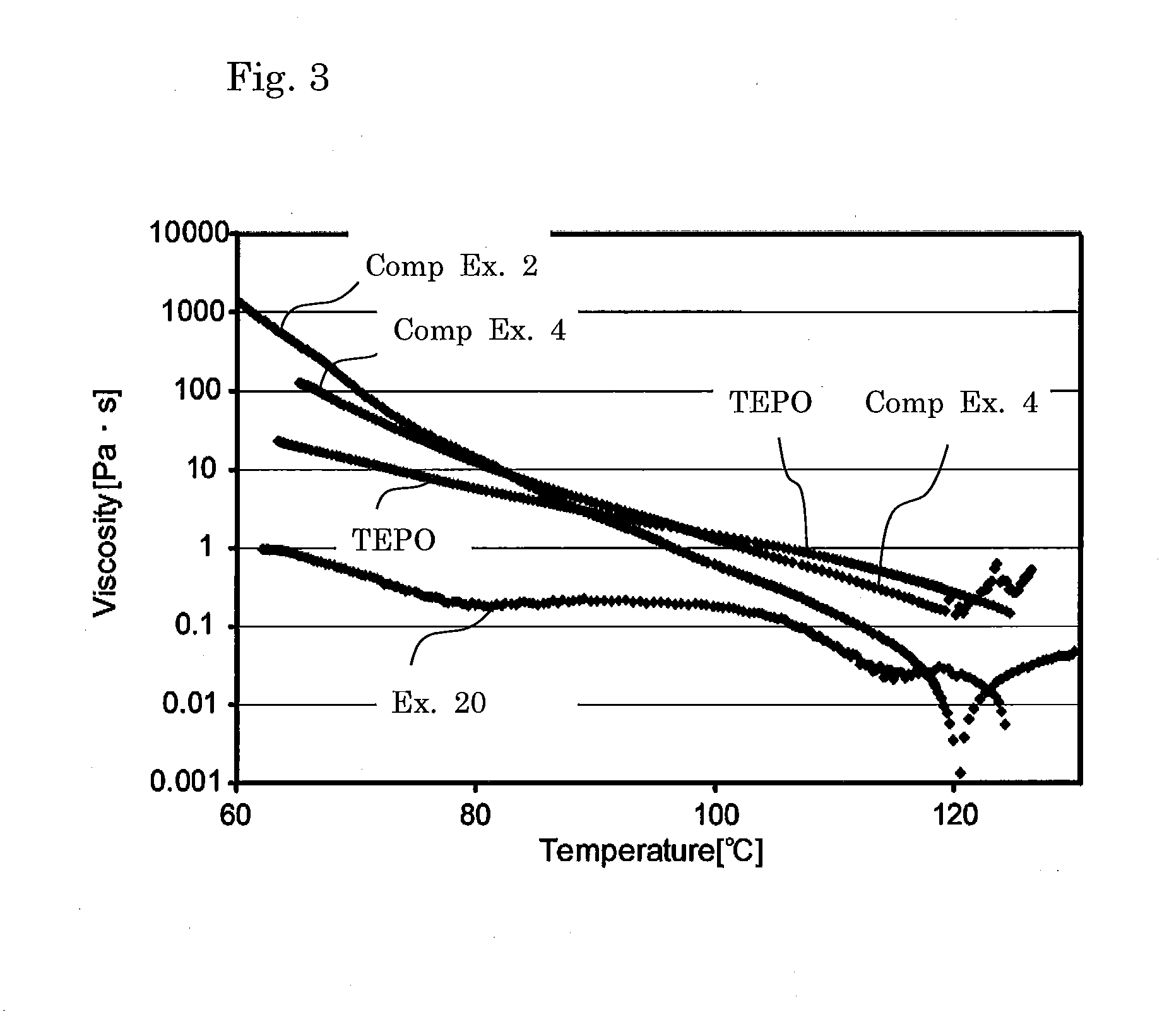

Curable resin composition, cured product and method of producing a cured product

A curable resin composition contains (a) a matrix resin component containing a benzoxazine compound (a1), (b) a radically polymerizable component containing a radically polymerizable monomer having solubility parameter (SP) value that is different by 1.0 to 4.1 from the SP of the matrix resin component, and (c) a radical polymerization initiator. The composition has a low viscosity, and its cured product has an improved toughness and excellent mechanical properties.

Owner:NAT UNIV CORP YOKOHAMA NAT UNIV +1

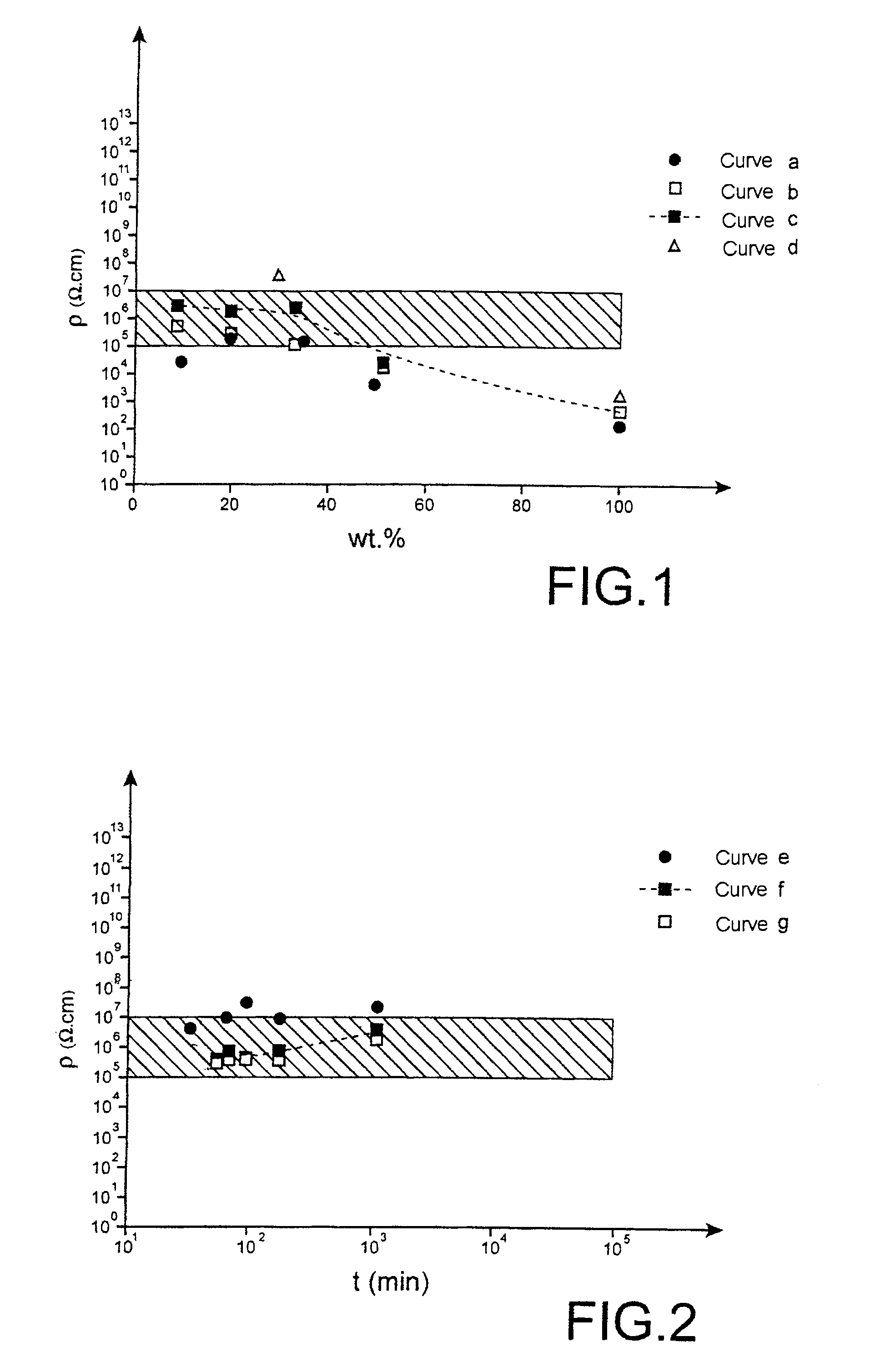

Adhesive composite material with controlled resistivity

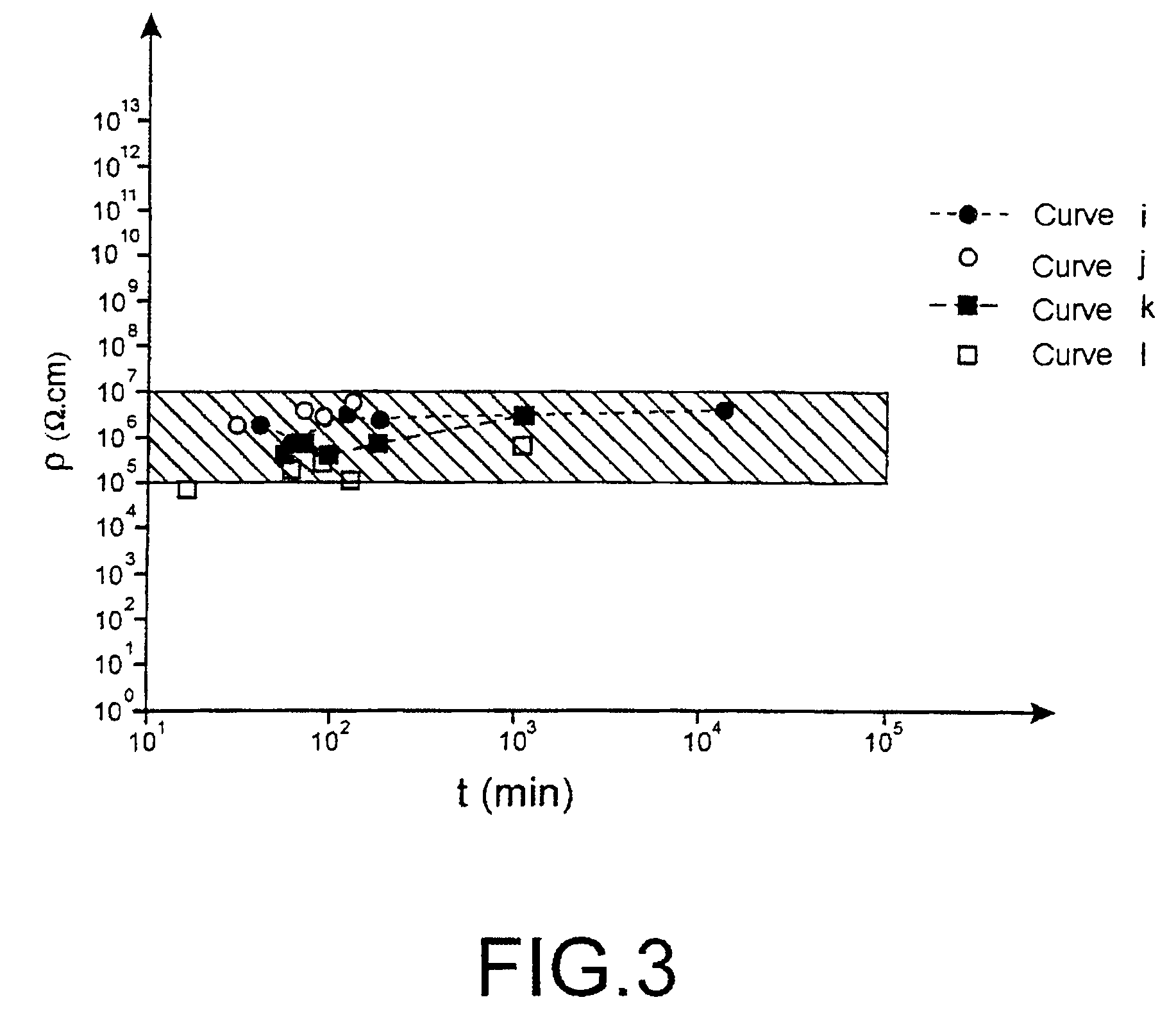

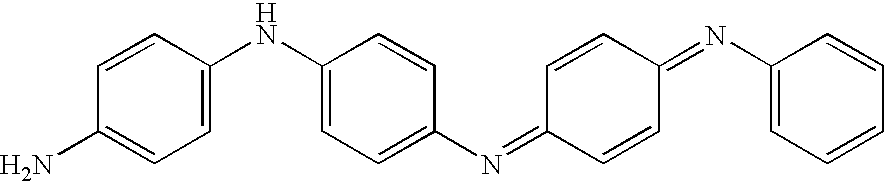

InactiveUS20080251766A1Improved mechanical propertyReduce molecular weightConductive materialNon-conductive material with dispersed conductive materialElectrically conductiveRepeat unit

The invention relates to a composite polymer material comprising an adhesive resin matrix and an electrically-conductive filler that consists of an oligoaniline in an electrically-conductive form comprising from 4 to 30 repeat units and present in an amount ranging from 15 to 40% by weight relative to the total weight of the material, said material having a resistivity ranging from 105 to 107 Ω.cm.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

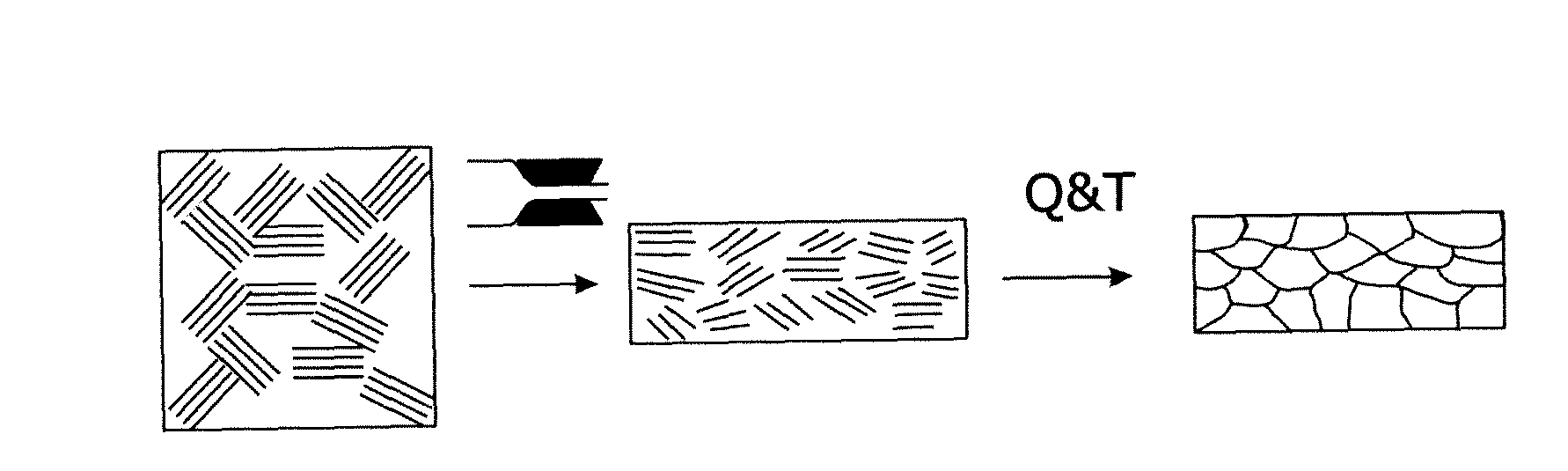

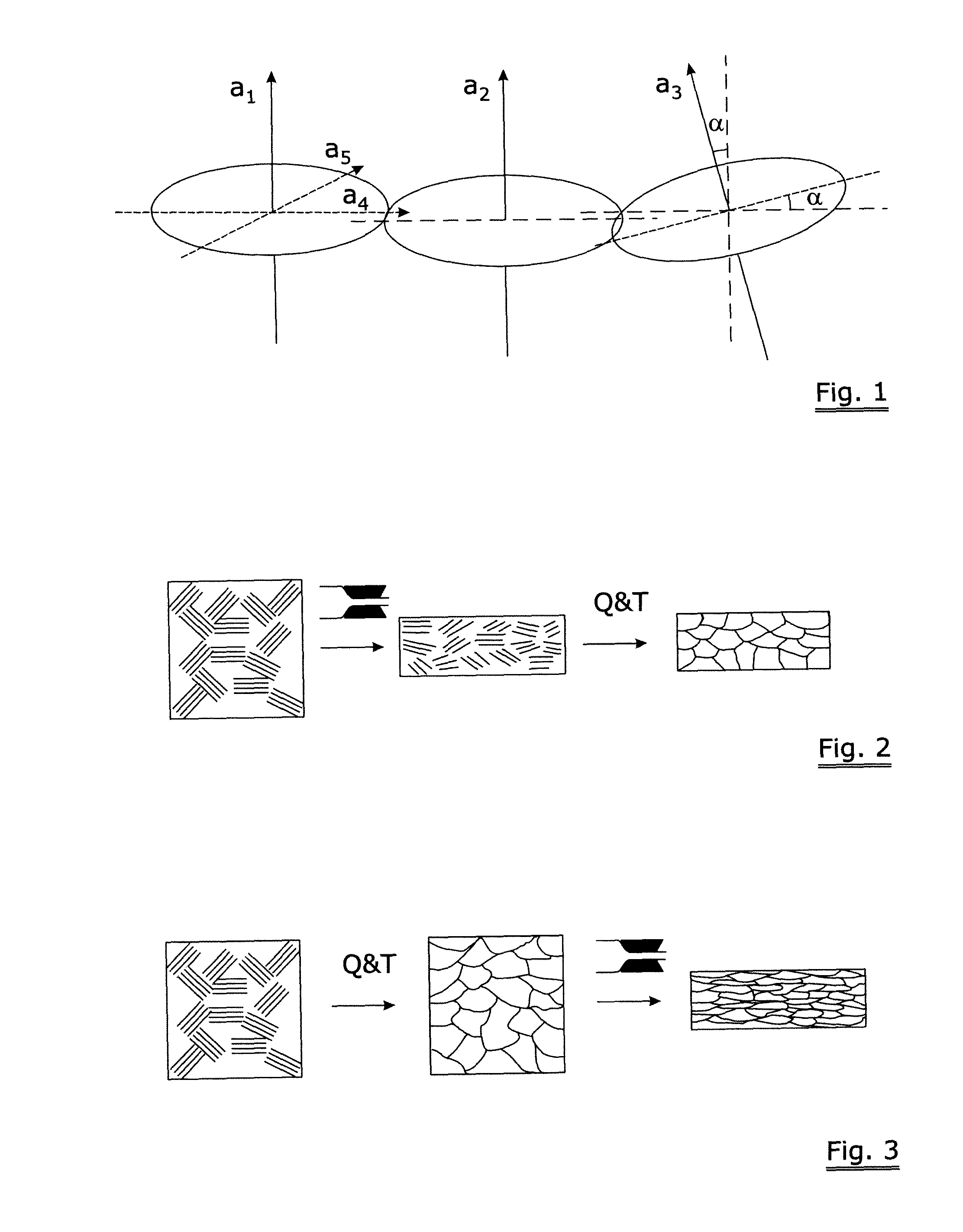

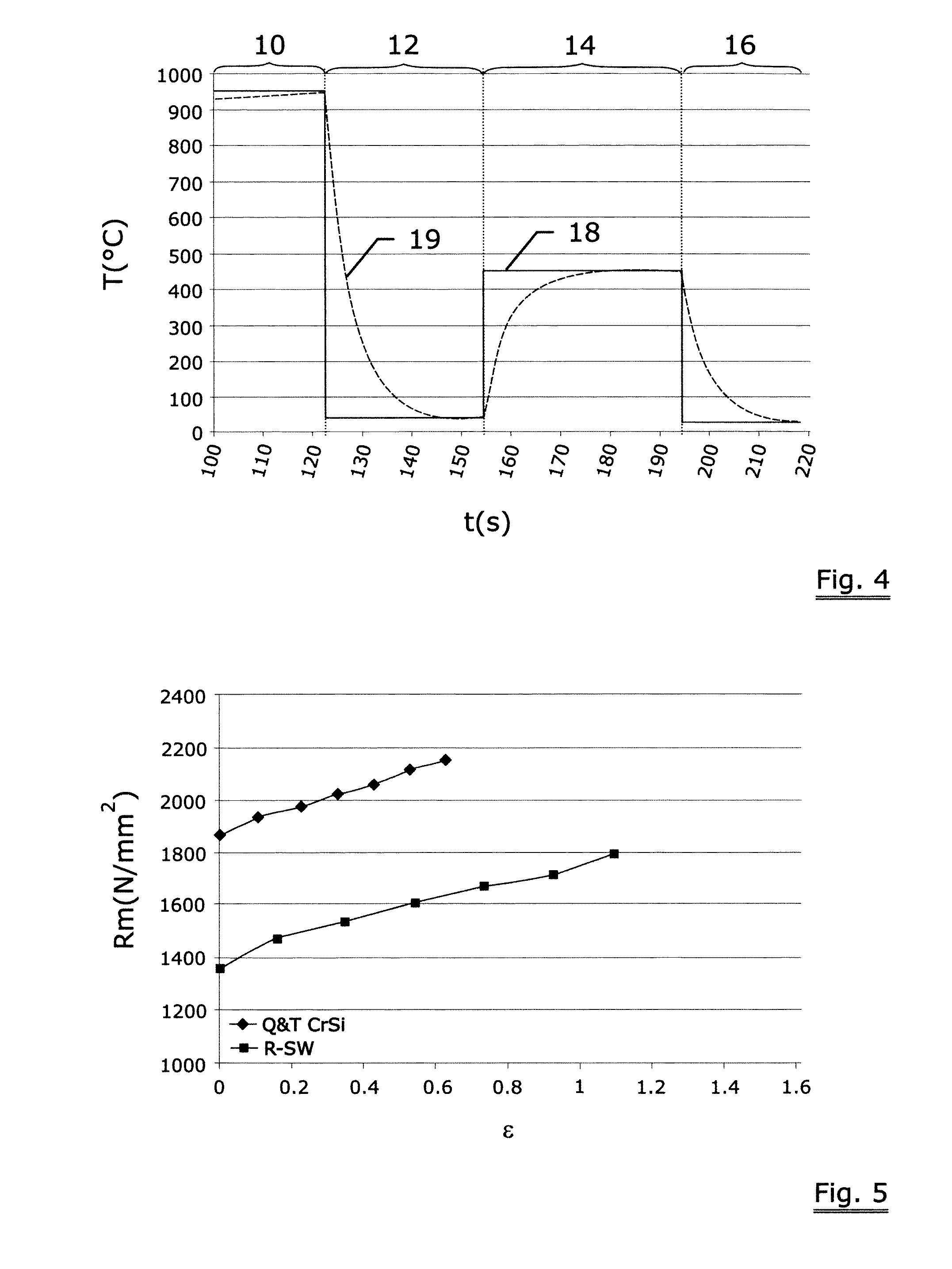

High tensile strength steel wire

InactiveUS20160237518A1Improved mechanical propertyImprove surface finishFurnace typesHeat treatment furnacesVolume PercentageMartensite

A high tensile strength steel wire having as steel composition: a carbon content ranging from 0.20 weight percent to 1.00 weight percent, e.g. from 0.3 weight percent to 0.85 weight percent, e.g. from 0.4 weight percent to 0.7 weight percent, e.g. from 0.5 weight percent to 0.6 weight percent, a silicon content ranging from 0.05 weight percent to 2.0 weight percent, e.g. from 0.2 weight percent to 1.8 weight percent, e.g. from 1.2 weight percent to 1.6 weight percent, a manganese content ranging from 0.40 weight percent to 1.0 weight percent, e.g. from 0.5 weight percent to 0.9 weight percent, a chromium content ranging from 0.0 weight percent to 1.0 weight percent, e.g. from 0.5 weight percent to 0.8 weight percent, a sulfur and phosphor content being individually limited to 0.05 weight percent, e.g. limited to 0.025 weight percent, contents of nickel, vanadium, aluminum, copper or other micro-alloying elements all being individually limited to 0.5 weight percent, e.g. limited to 0.2 weight percent, e.g. limited to 0.08 weight percent, the remainder being iron, said steel wire having martensitic structure, wherein at least 10 volume percent of martensite are oriented.

Owner:NV BEKAERT SA

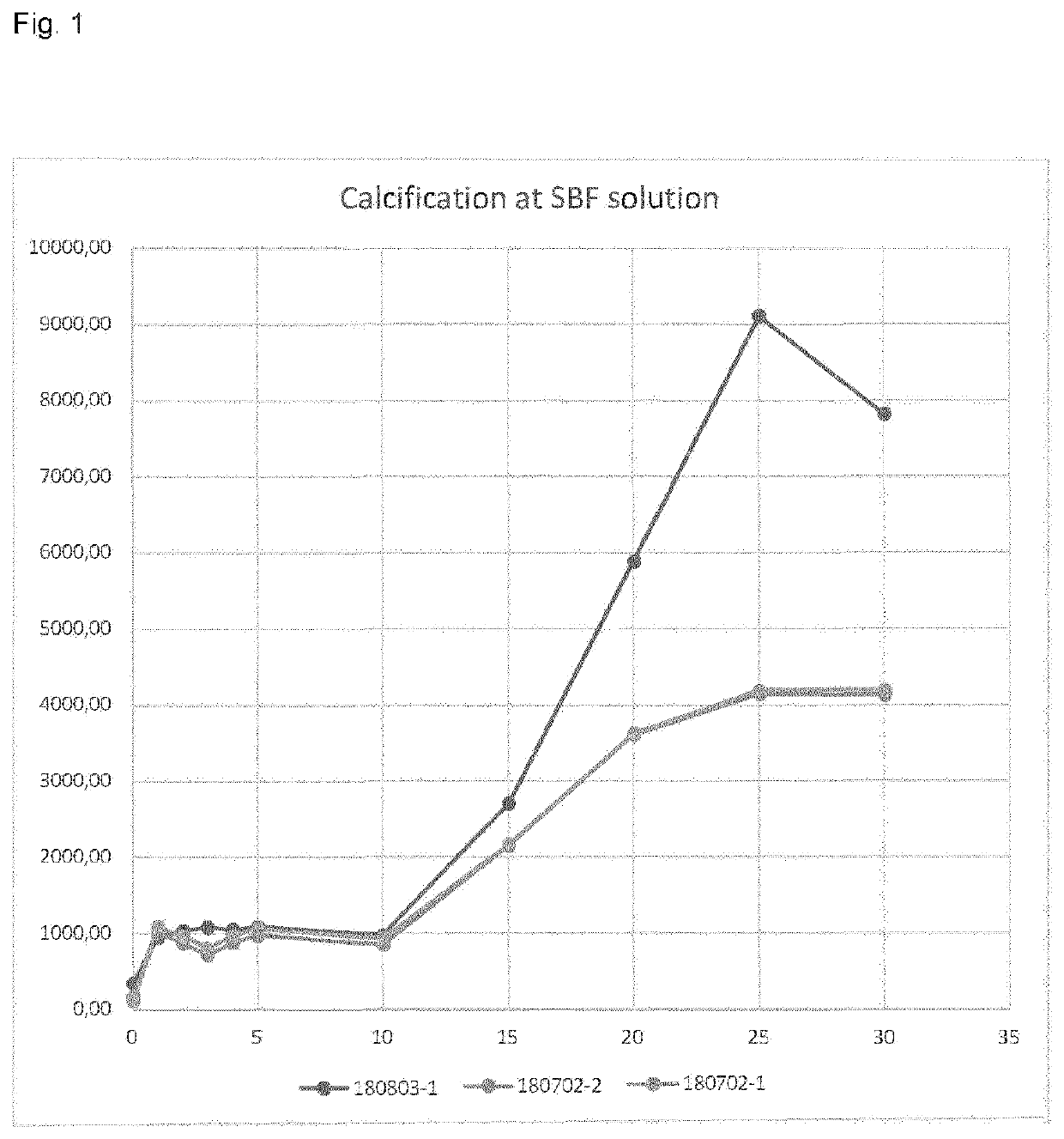

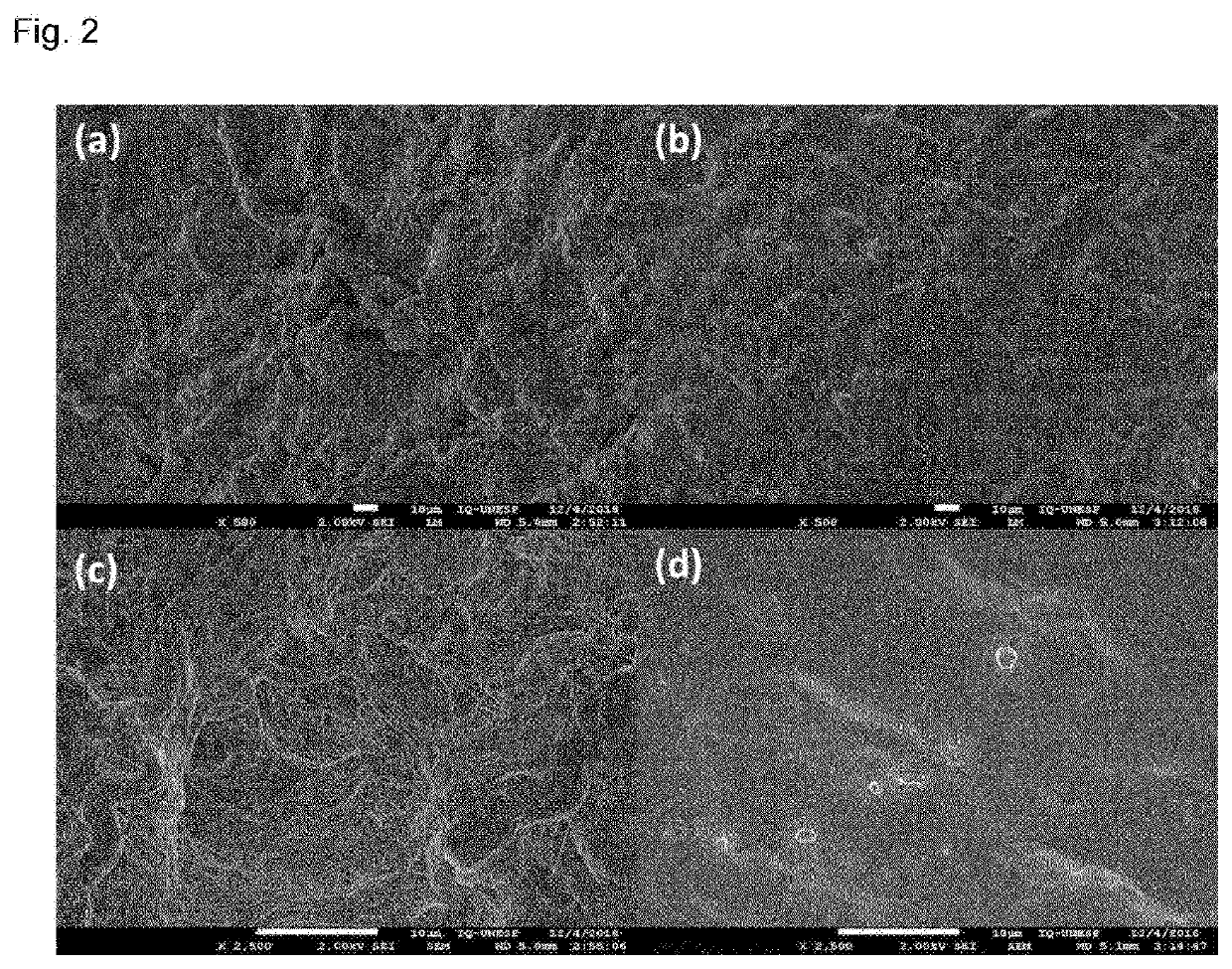

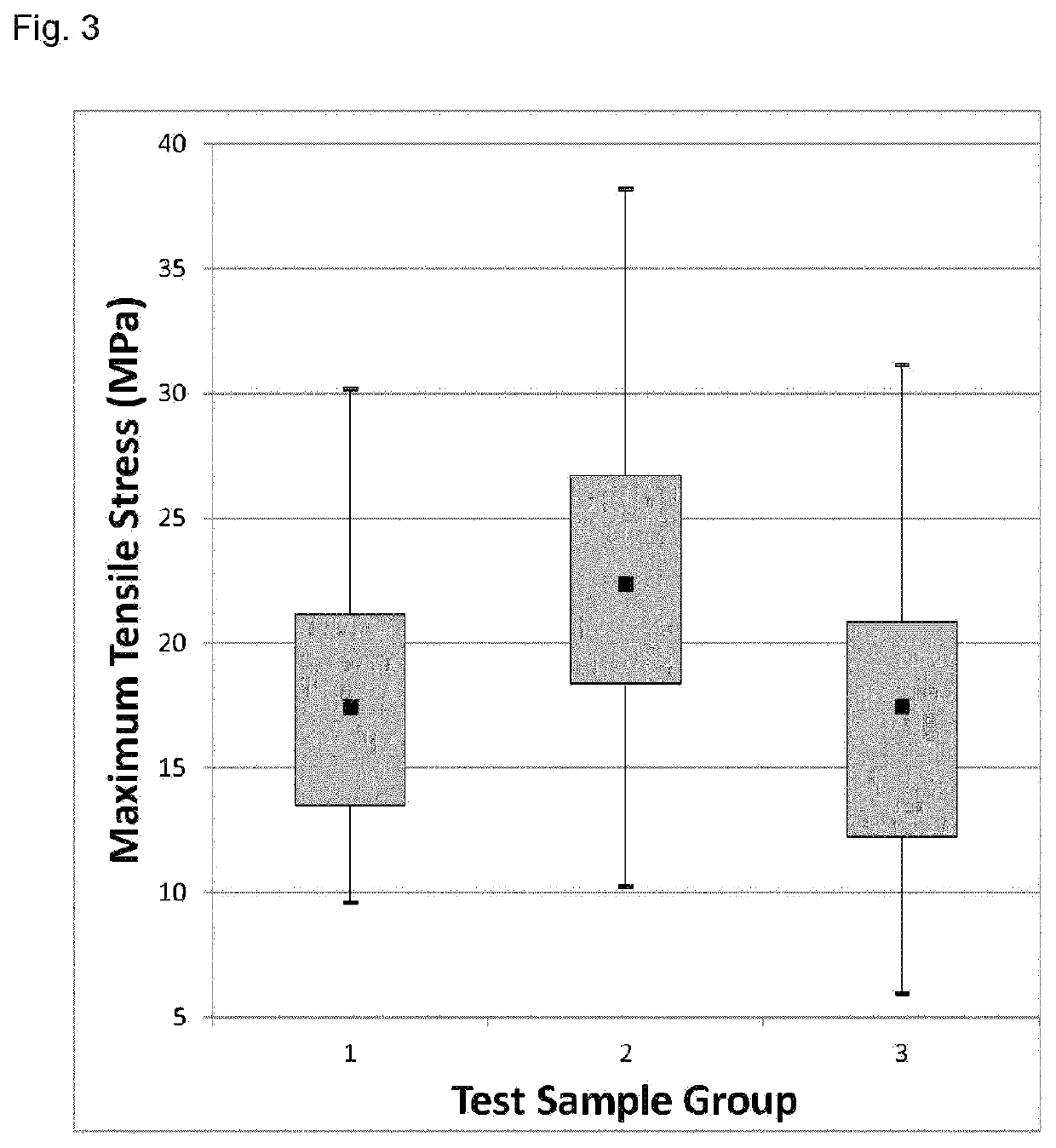

Method for preparing biological tissue for surgical implantation

PendingUS20220072202A1Reduce calcificationImproved mechanical propertyPharmaceutical delivery mechanismTissue regenerationBiological tissueRat heart

The present invention relates to a method for treating biological tissue and a biological tissue obtained by the treatment method, and specifically to a method for treating biological tissue so as to suppress the calcification, risk of biofilm adherent over pericardium and strength reduction of the tissue due to treatment. The invention is also directed to bioprosthesis and transcatheter heart valves containing the biological tissue.

Owner:PF PROD FEATURES GMBH

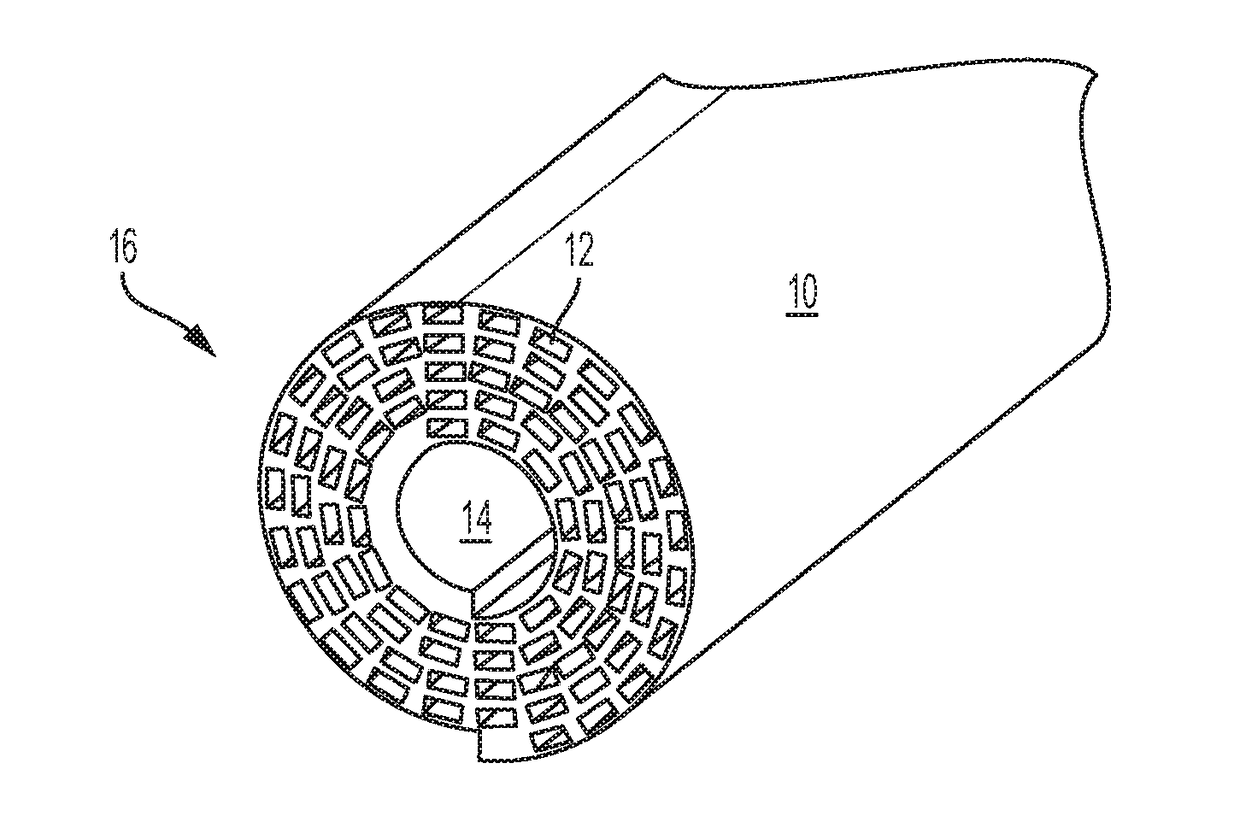

Medical devices containing dry spun non-wovens of poly-4-hydroxybutyrate and copolymers with anisotropic properties

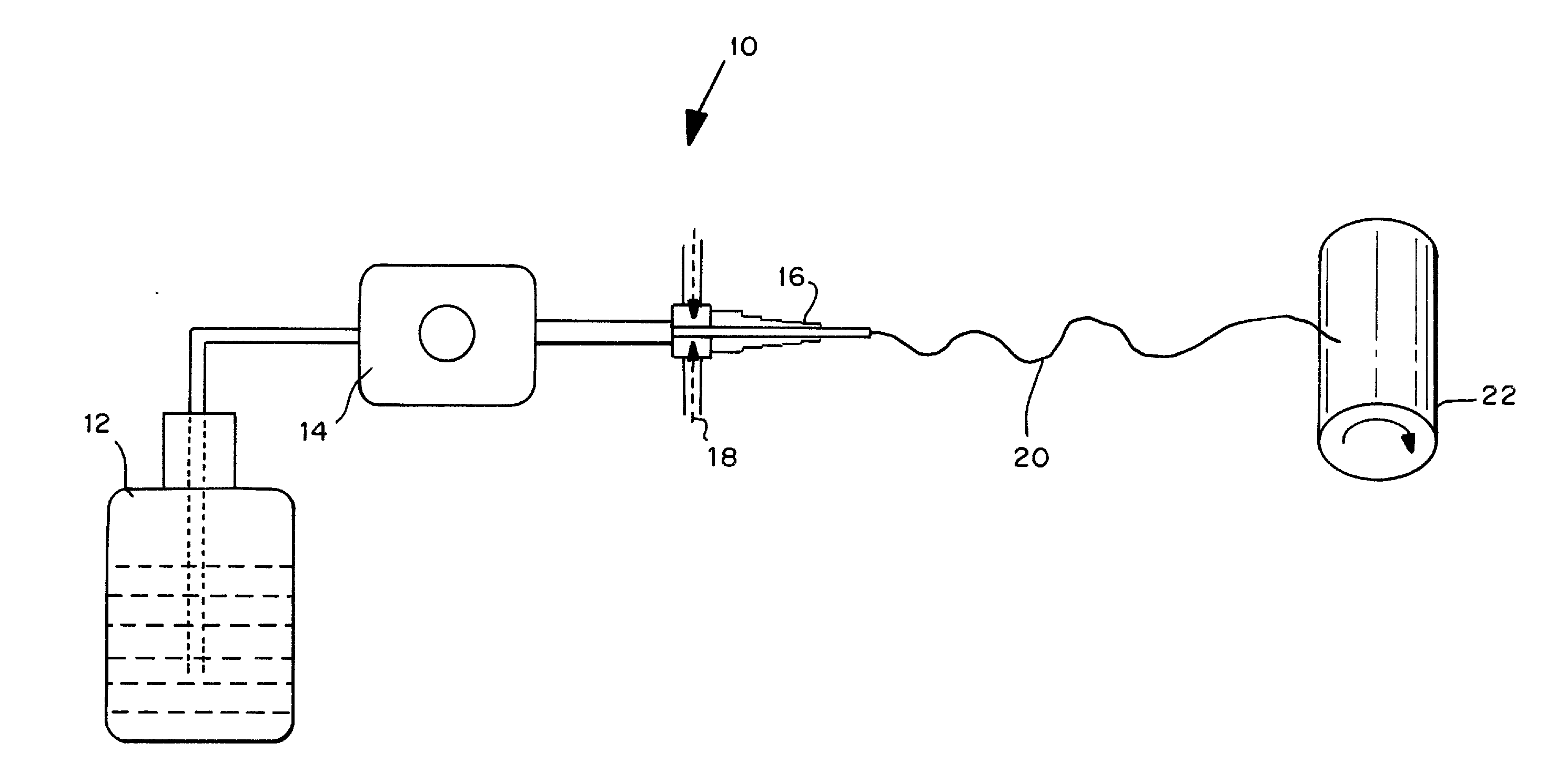

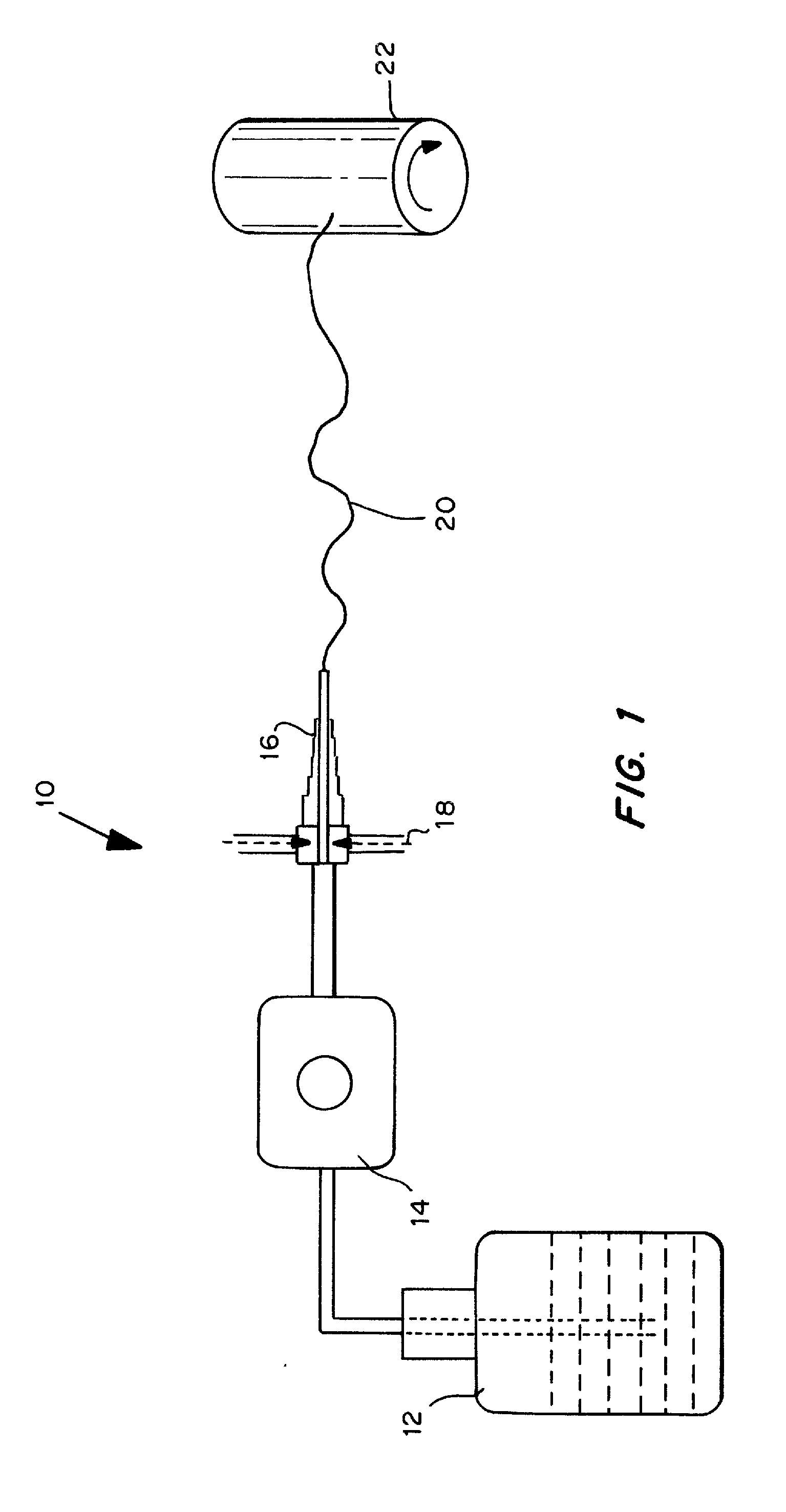

ActiveUS20150012018A1Improved mechanical propertyLoss in molecular weightCatheterWoven fabricsEngineeringFiber

Continuous processing methods are used for making absorbable polymeric non-wovens, with anisotropic properties, improved mechanical properties and without substantial loss of polymer molecular weight during processing. The method includes producing dry spun-non wovens from a polymer, and collecting the fibers using a rotating collector plate, preferably a rotating cylinder, to collect the non-woven instead of a fiberglass stationary collector plate. The non-wovens can be used for a variety of purposes including fabrication of medical devices.

Owner:TEPHA INC

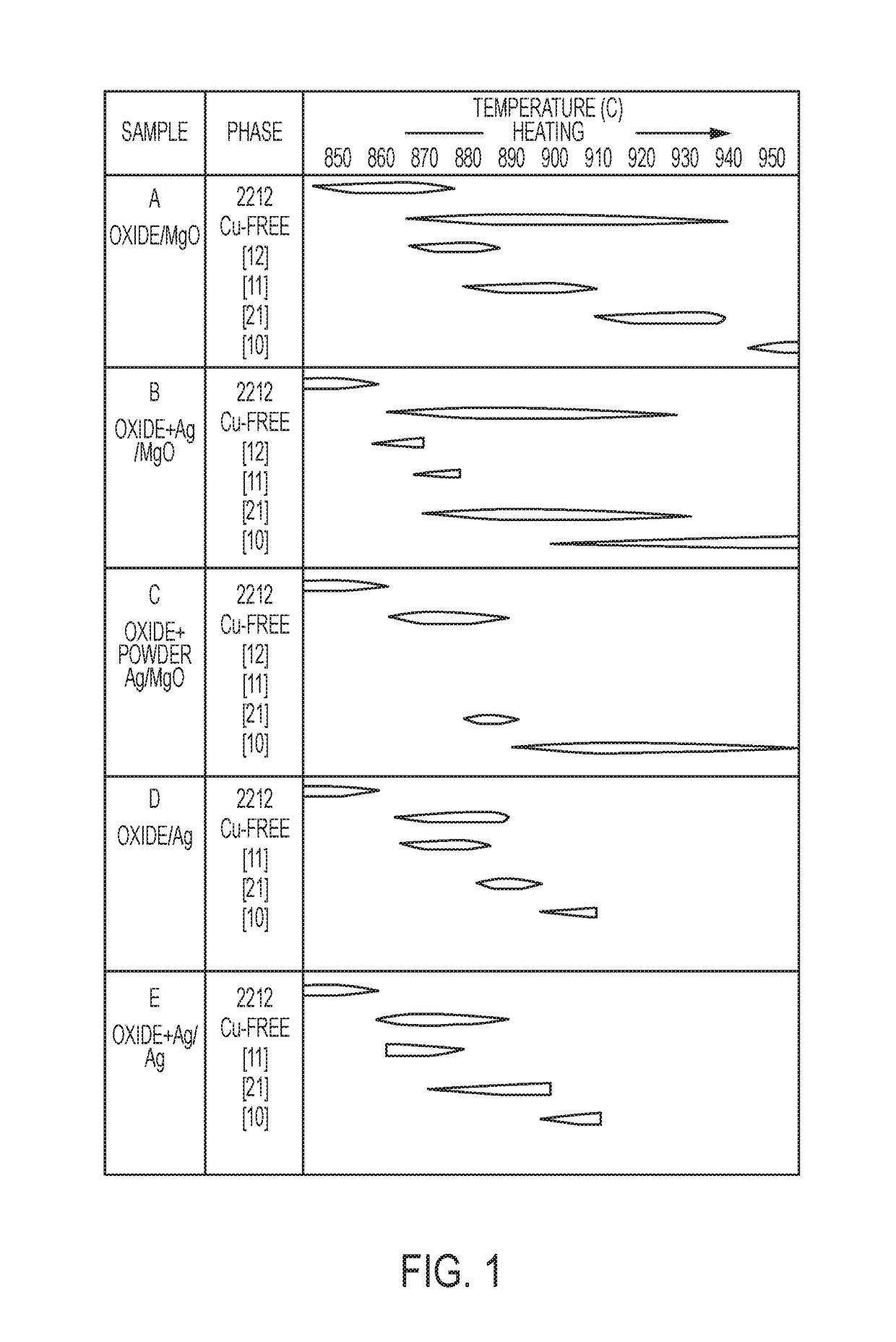

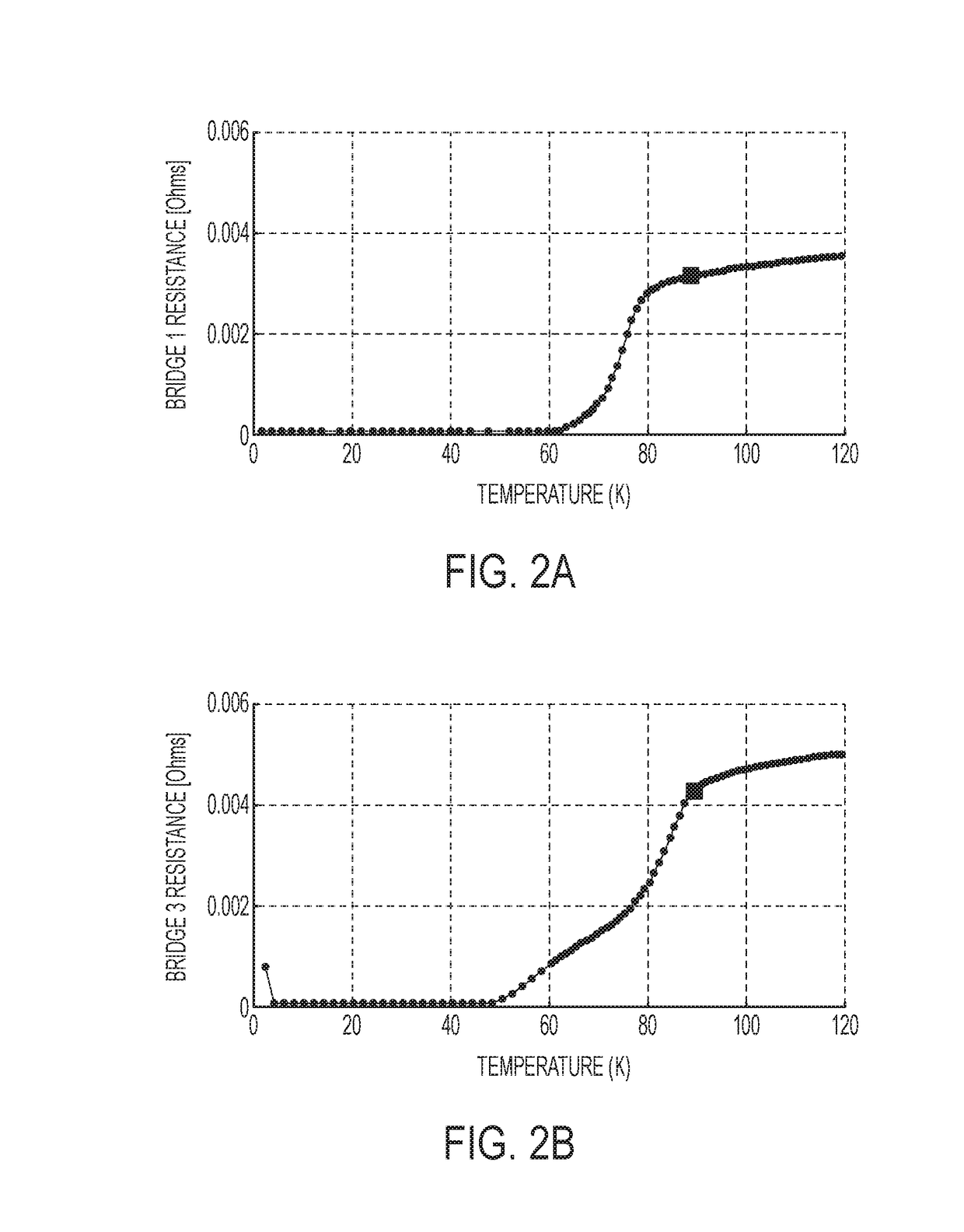

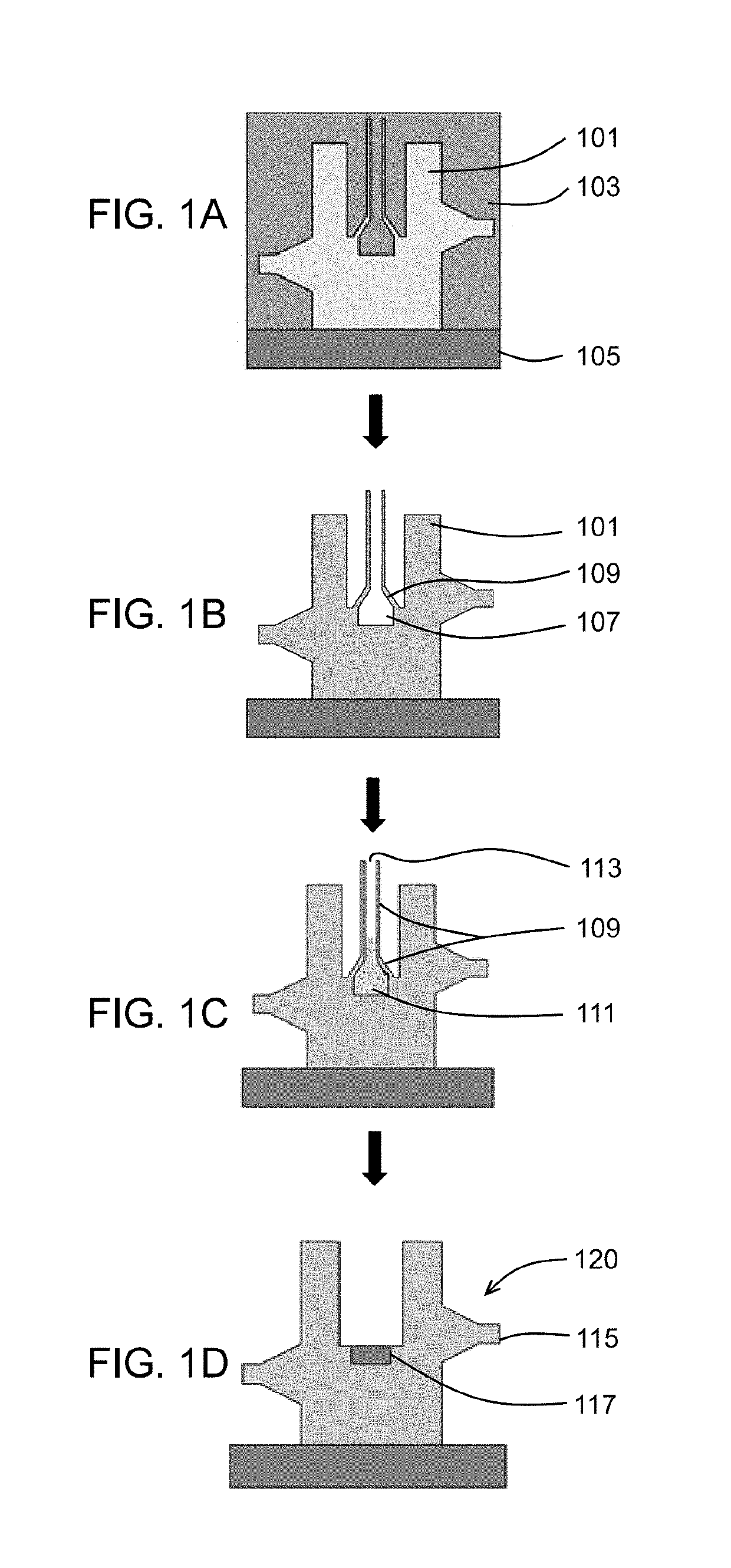

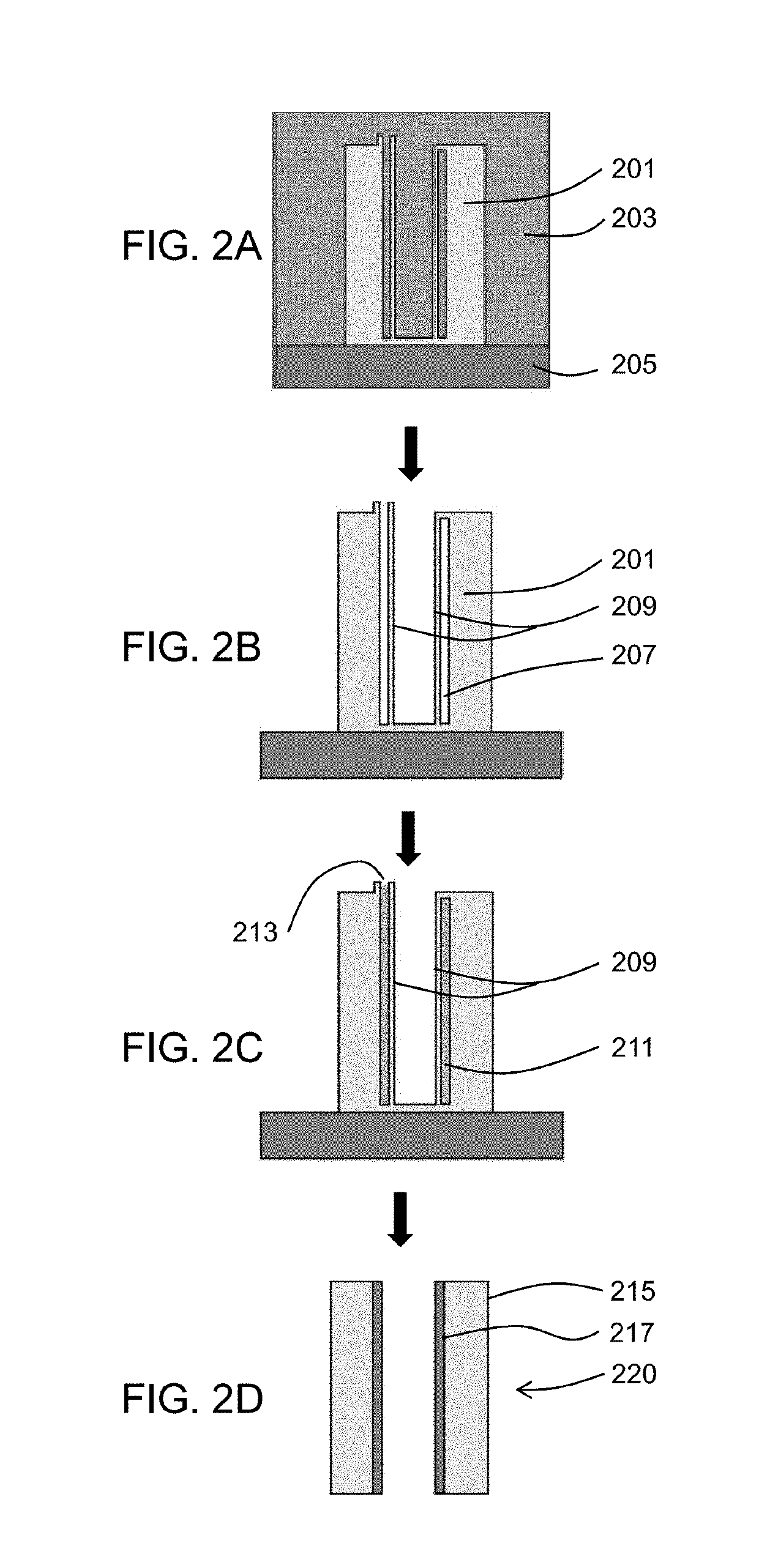

Improved methods and compositions for fabrication of superconducting wire

ActiveUS20170287583A1Improved mechanical propertyLess susceptibleSuperconductors/hyperconductorsConductive materialMicaHigh-temperature superconductivity

The present disclosure relates generally to wires and more particularly to textured powder wires containing nanoscale metallic silver powder. The invention presents an improvement of the process of making compressed cores of textured-powder high-temperature superconductor previously using the micaceous high-temperature superconductor Bi-2212. Embodiments of the claimed methods are useful with the micaceous high-temperature superconductors, notably Bi2Sr2CaCu208+x (Bi-2212) and Bi2S-r2Ca2Cu3O10+x (Bi-2223) and rare earth barium copper oxide (REBCO).

Owner:TEXAS A&M UNIVERSITY

Manufacturing method

InactiveUS20190193161A1Improved mechanical propertyReduce supplyAdditive manufacturing apparatusCeramic shaping apparatusMulti materialHot isostatic pressing

There is provided a method of manufacture of a component from multiple materials, and a consolidated component formed thereby. The method includes the steps of forming a component body comprising a first material, the component body defining a cavity, filling at least a portion of the cavity with a second material, and performing hot isostatic pressing of the component body and second material to form a consolidated component. The process offers a reduced-complexity, reduced-part-count method of manufacture for components formed of multiple materials.

Owner:ROLLS ROYCE PLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com