Method for removing prior particle boundary and hole defect of powder metallurgy high-temperature alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0043]Gas atomized Rene 104 nickel-based pre-alloyed powder is put into a ball mill pot with a ball-to-powder ratio of 10:1, and ball milling is performed in a planetary ball mill for 1.5 h at a ball milling rotation speed of 250 r / min under protection of argon, to obtain ball milling nickel-based high-temperature alloy powder.

[0044]Plasma sintering is performed on ball milling nickel-based high-temperature alloy powder at 1150° C. / 40 MPa, and heat preservation is performed for 5 min, then solution treatment is performed; the solution treatment is performed at 1180° C. for 1 h, and furnace cooling is performed; then, aging treatment is performed at 815° C. for 8 h to obtain a nickel-based high-temperature alloy.

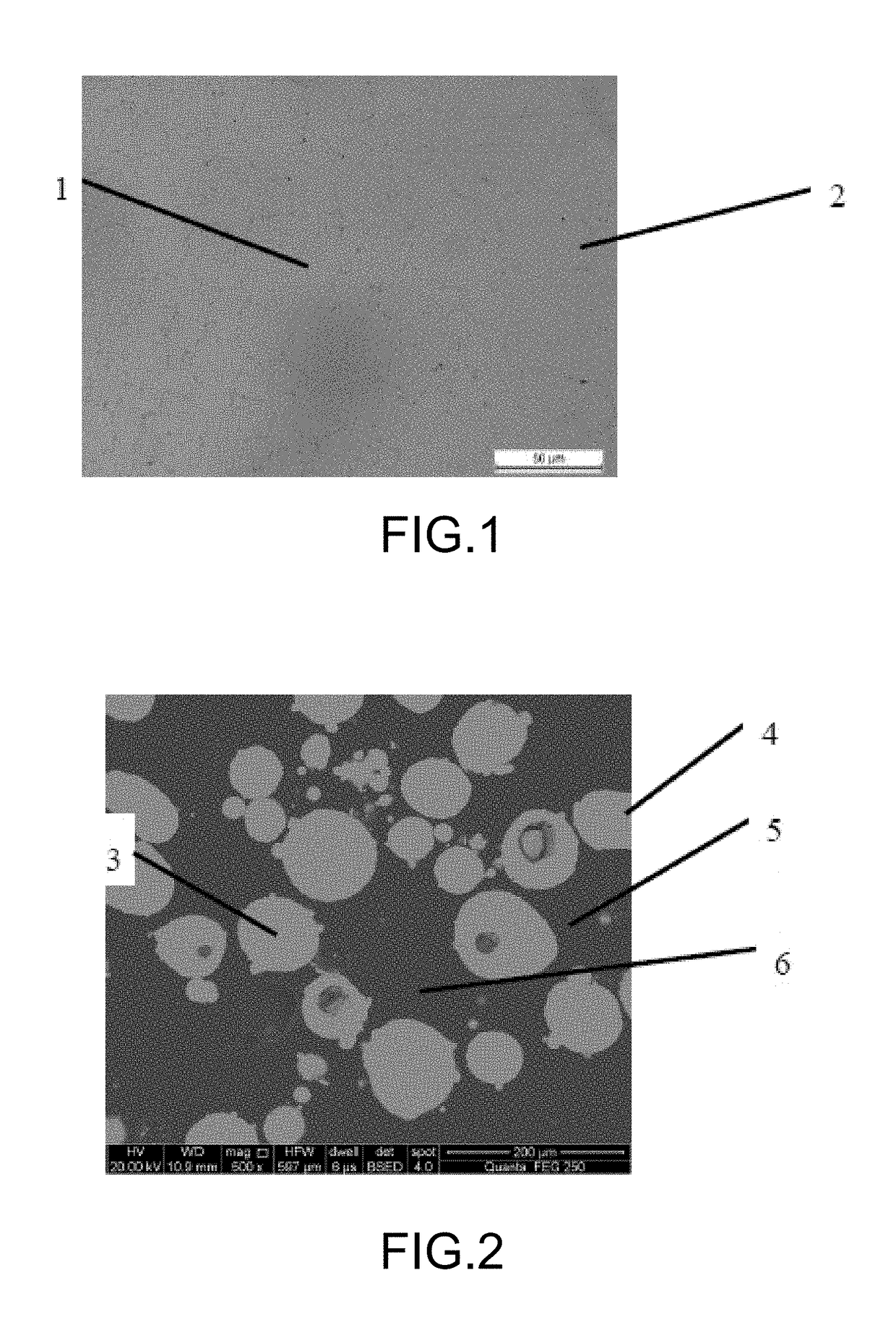

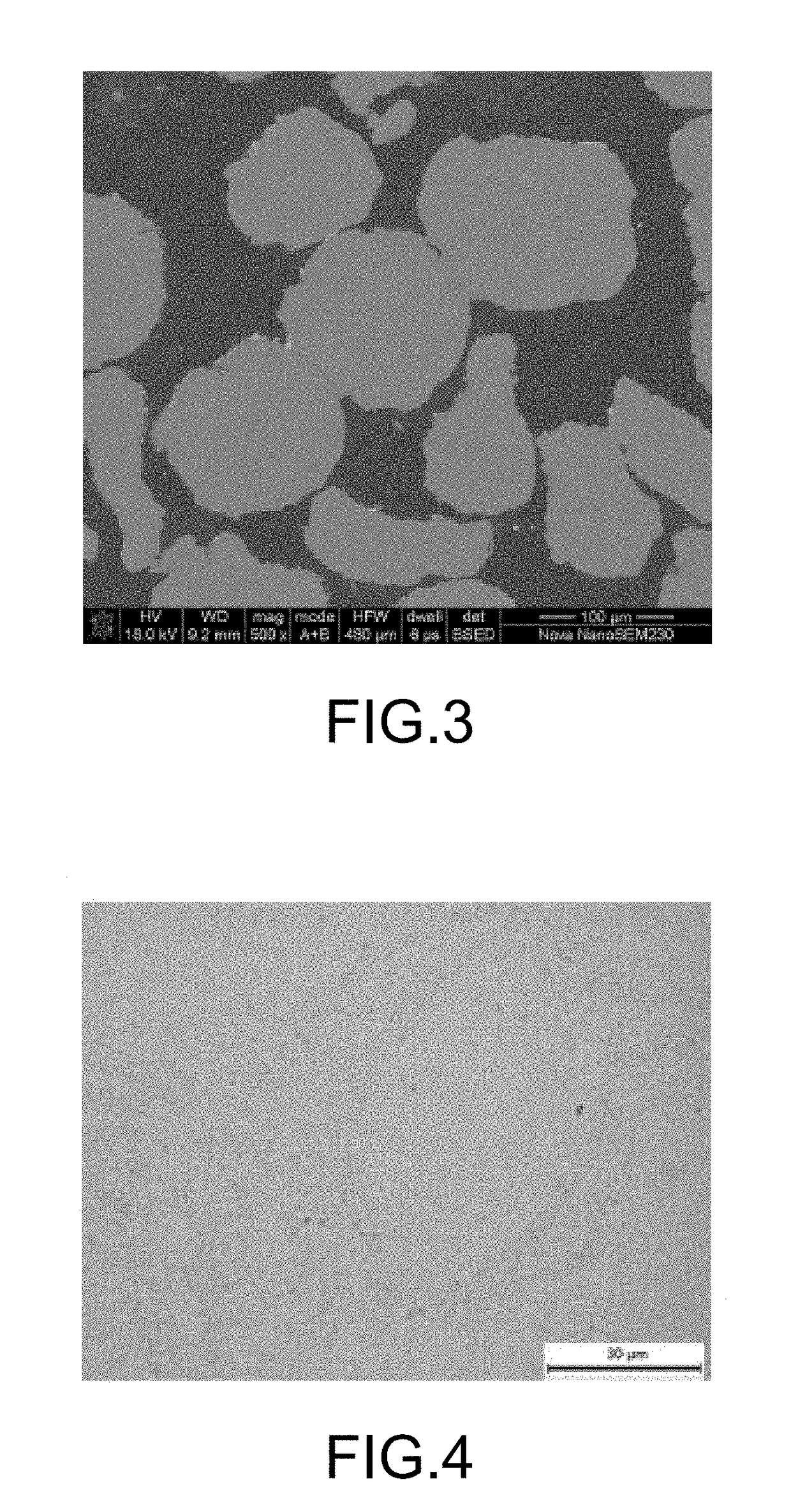

[0045]FIG. 2 is a scanning electronic microscope (SEM) diagram of a cross section of atomized powder of the present embodiment, and obvious hollow defects occur to some powder in FIG. 2. See parts indicated by 3, 4, 5, and 6 in FIG. 2. FIG. 3 is an SEM diagram of a cross sect...

embodiment 2

[0046]Gas atomized Rene 104 nickel-based pre-alloyed powder is put into a ball mill pot, and ball milling is performed in a stirring ball mill for 3 h at a ball milling rotation speed of 100 r / min under protection of argon, to obtain ball milling nickel-based high-temperature alloy powder.

[0047]Ball milling powder is put into a steel capsule; vacuuming and sealing welding are performed on the steel capsule; hot extrusion forming is performed at 1100° C. with an extrusion ratio of 10:1 to obtain a highly compact nickel-based alloy bar; finally, solution treatment is performed at 1115° C. for 1 h and performed at 1170° C. for 3 h and air cooling is performed; aging treatment is performed at 845° C. for 4 h and performed at 760° C. for 8 h and air cooling is performed, to obtain a nickel-based high-temperature alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com