Patents

Literature

64results about How to "Improve surface finish" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alumina coated cutting tool

ActiveUS20170008092A1Improve surface finishReduce surface roughnessPolycrystalline material growthSynthetic resin layered productsCemented carbideTotal thickness

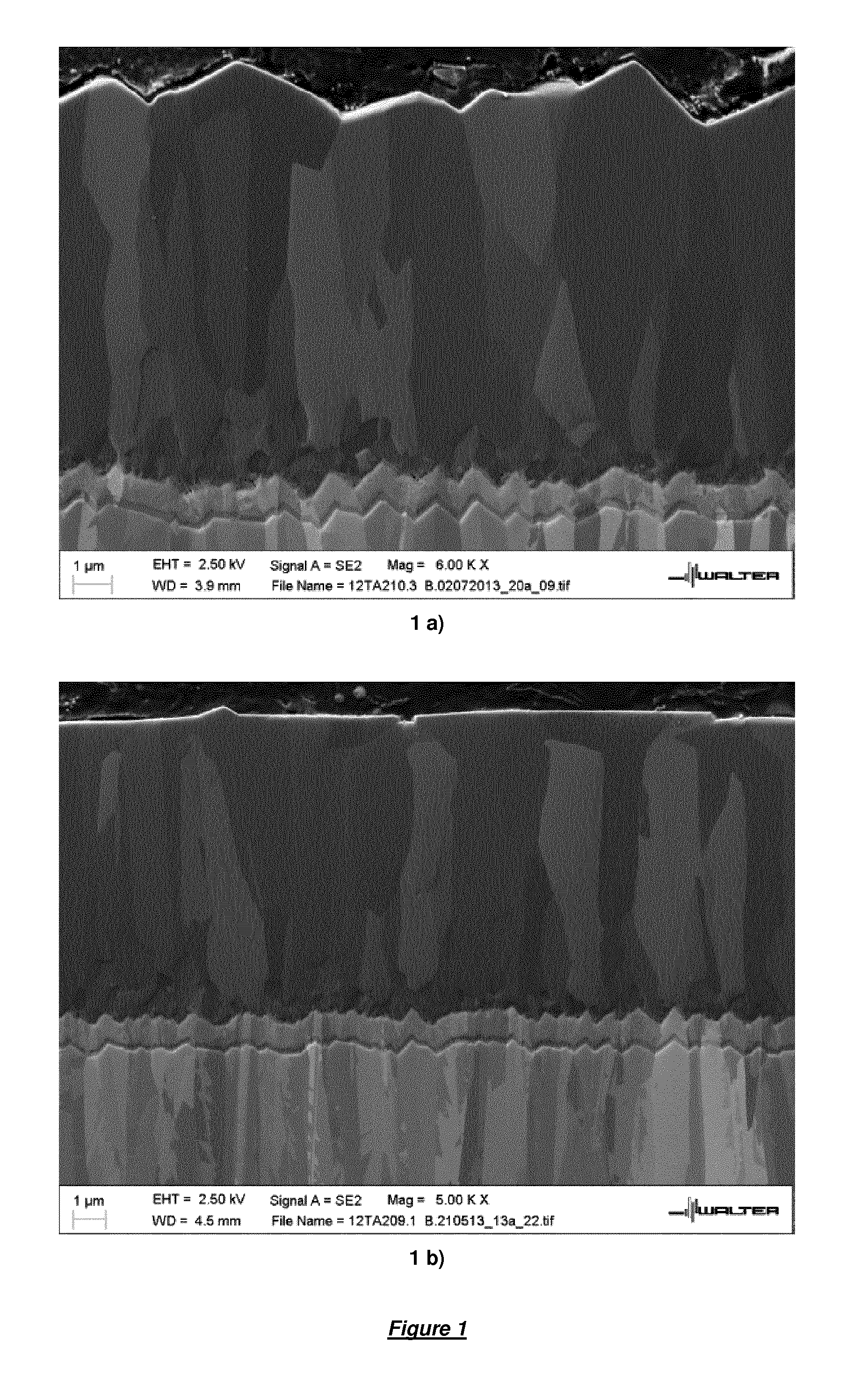

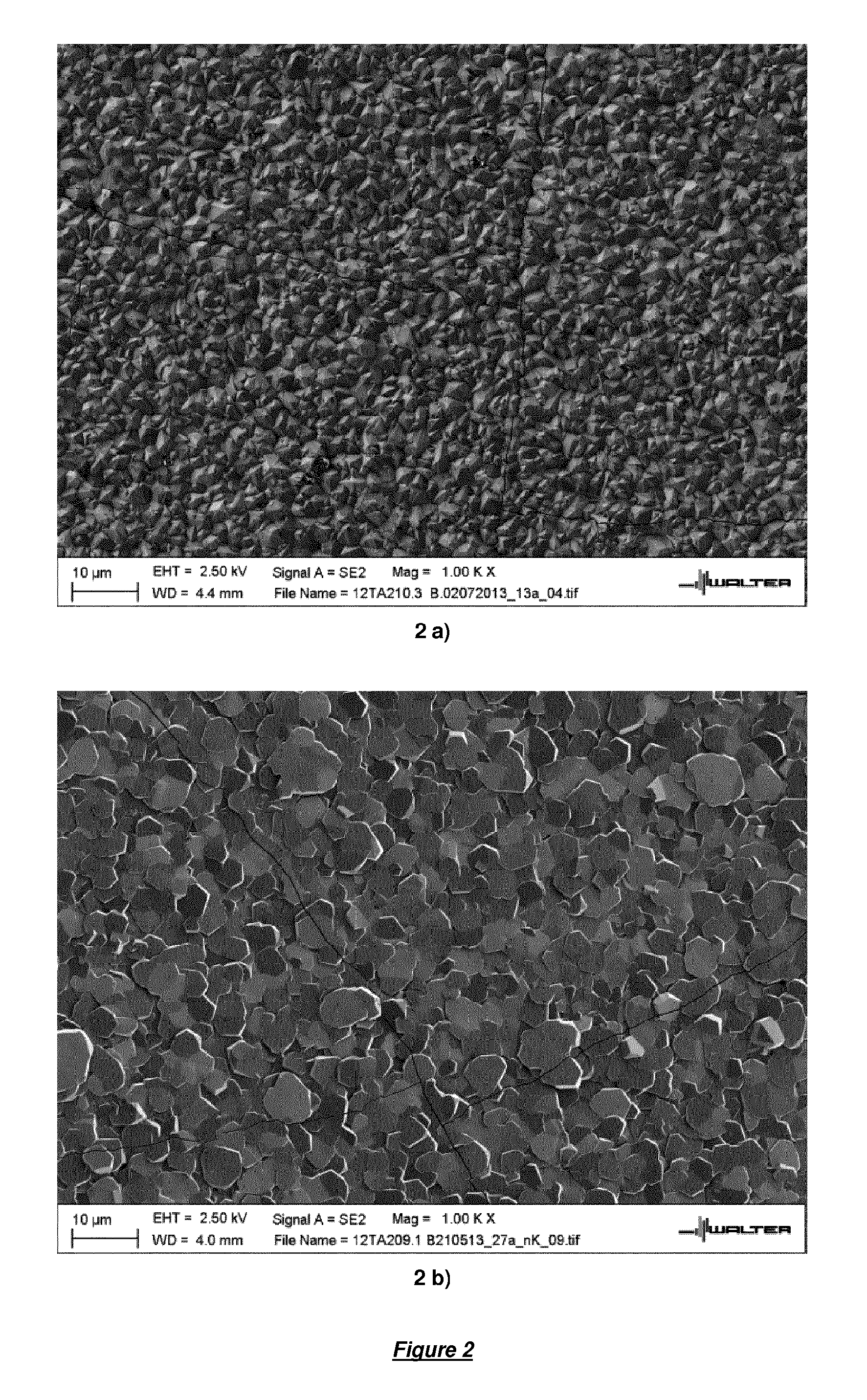

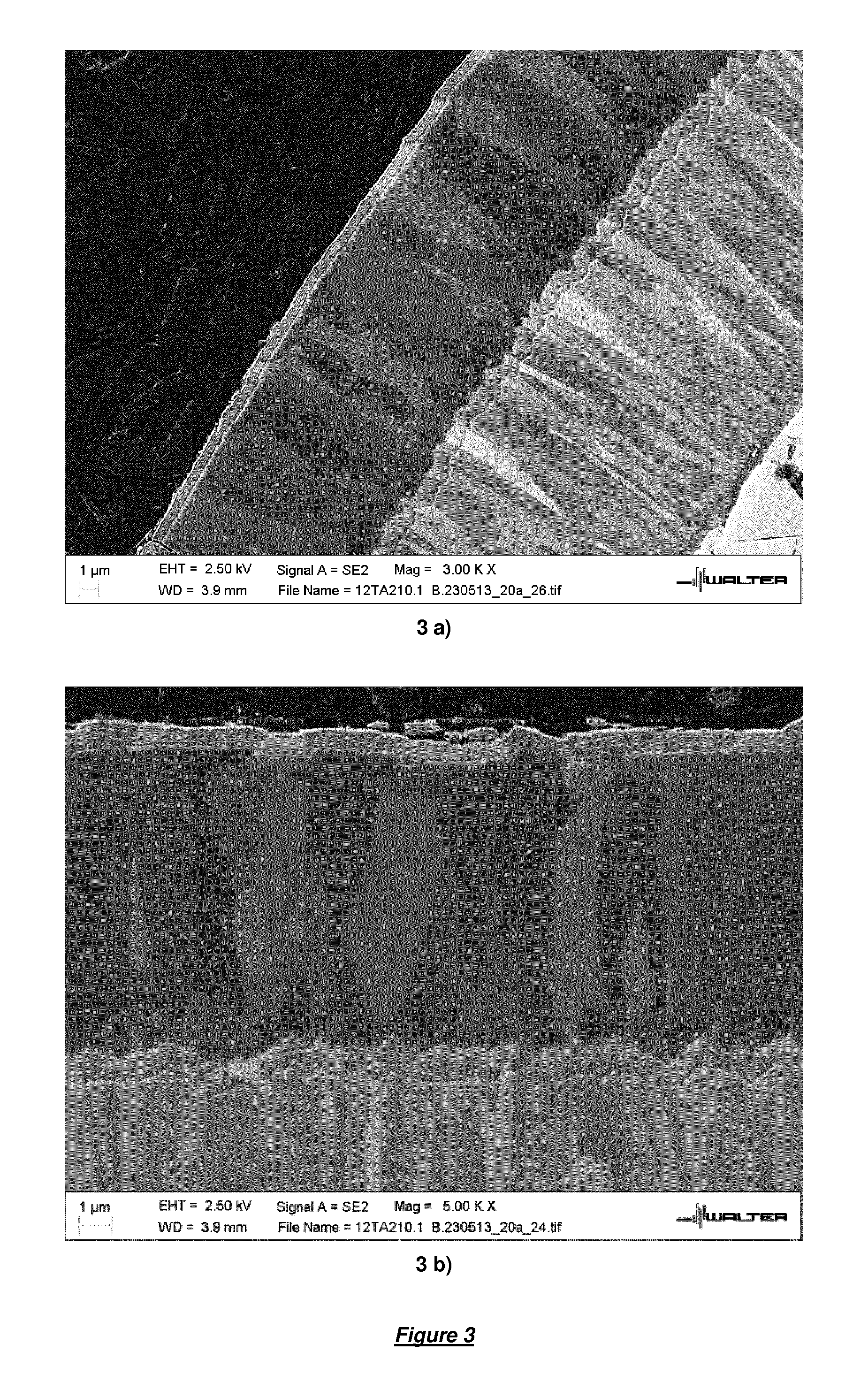

A coated cutting tool insert includes a substrate of cemented carbide, cermet, ceramics, steel or cubic boron nitride having deposited thereon a coating having a total thickness of 60 μm, including one or more layers having a wear resistant layer of α-Al2O3 of a thickness of 1 to 45 μm deposited by chemical vapour deposition (CVD). The α-Al2O3 layer includes at least two portions, a first thickness portion and a second thickness portion immediately on top of the first thickness portion. The first thickness portion has an essentially columnar α-Al2O3 grain structure, and at a transition from the first thickness portion to the second thickness portion the grain boundaries of at least 1 out of 25 neighboring grains of the α-Al2O3 grains undergo a directional change into a direction that is essentially perpendicular, 90±45 degrees, to the grain boundaries in the first thickness portion.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

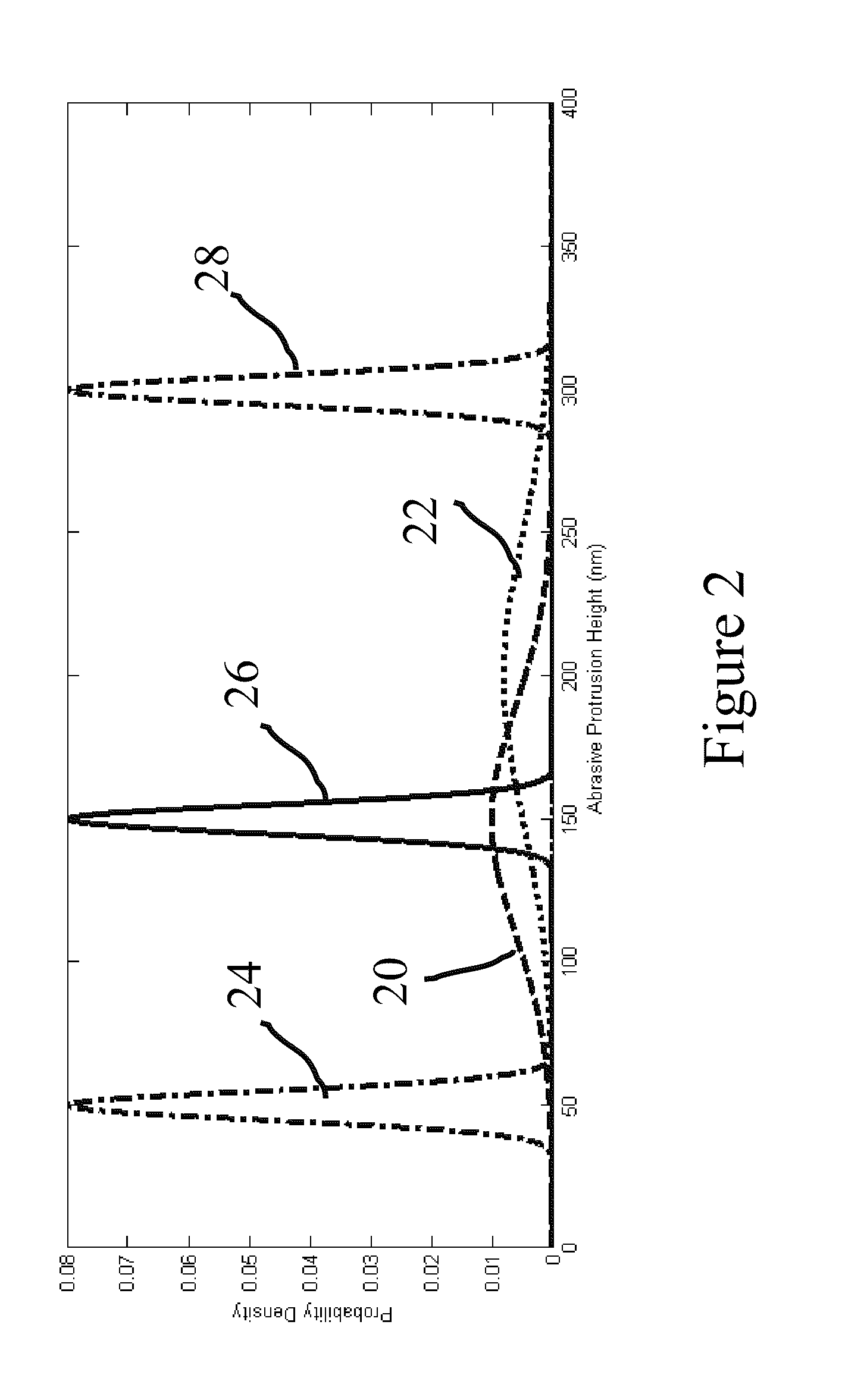

Abrasive slurry formulations containing NANO and micro spheres additives or self-assembled monolayers

InactiveUS20110244770A1Improve heightImprove surface finishPigmenting treatmentGrinding machine componentsMicro nanoNanometre

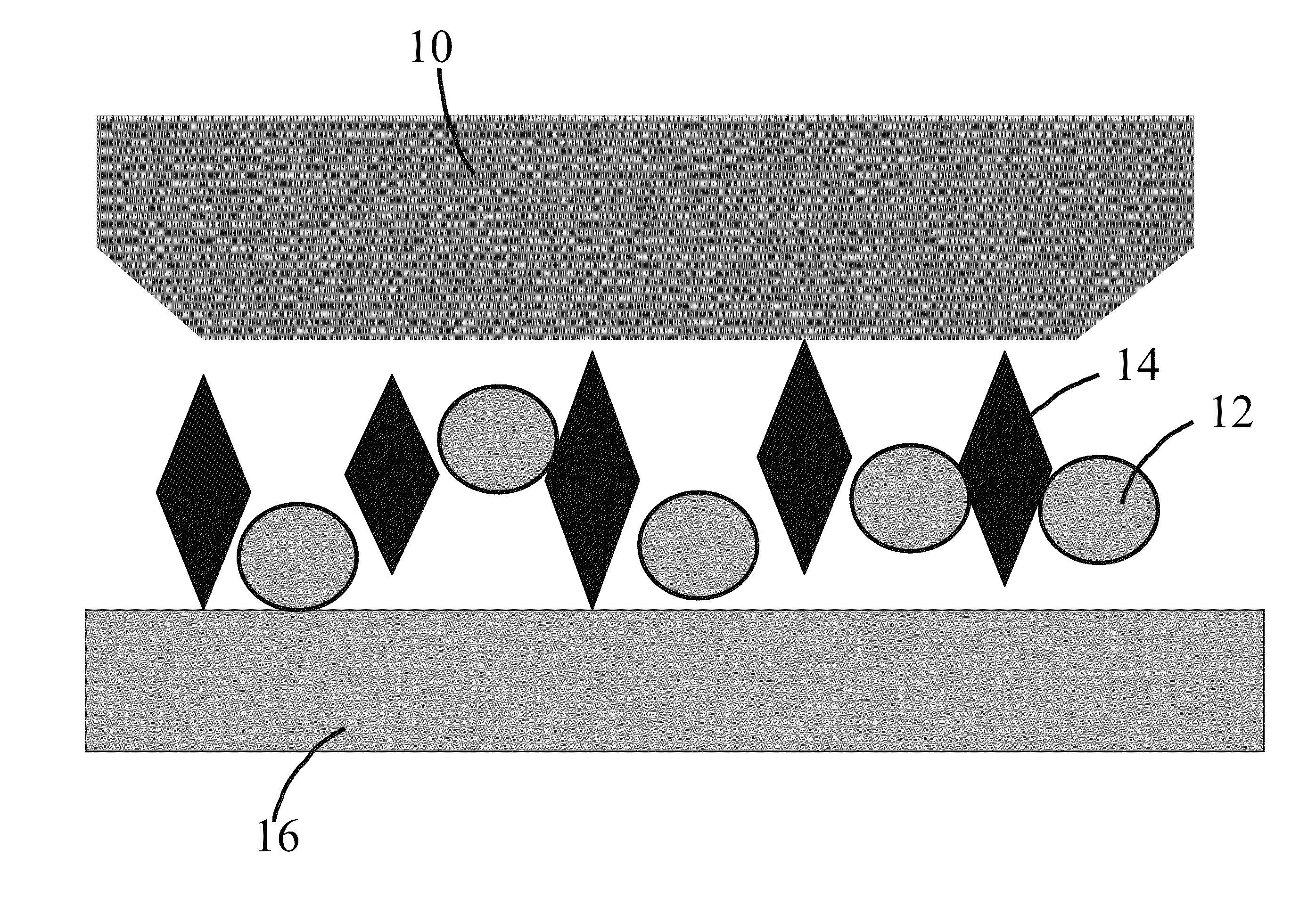

This invention relates to methods for plate dressing using slurry charged with abrasives and soft polymeric or metallic micro-nano spheres additives to produce substantially uniform abrasive height. Additionally, methods for plate dressing using slurry charged with abrasives and self-assembled polymers to produce substantially uniform abrasive height are disclosed.

Owner:SCHWAPPACH KARL

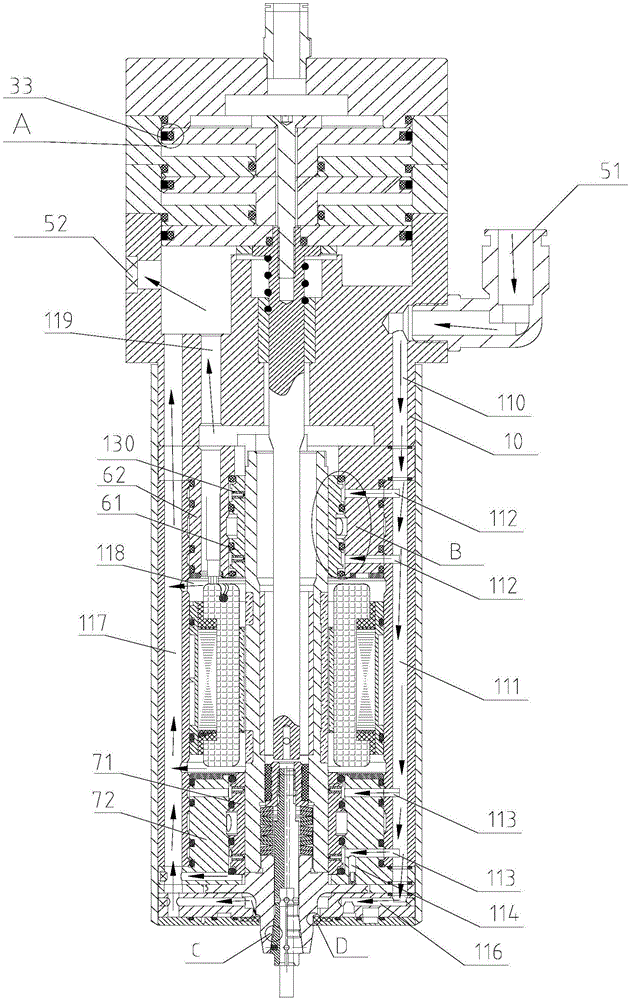

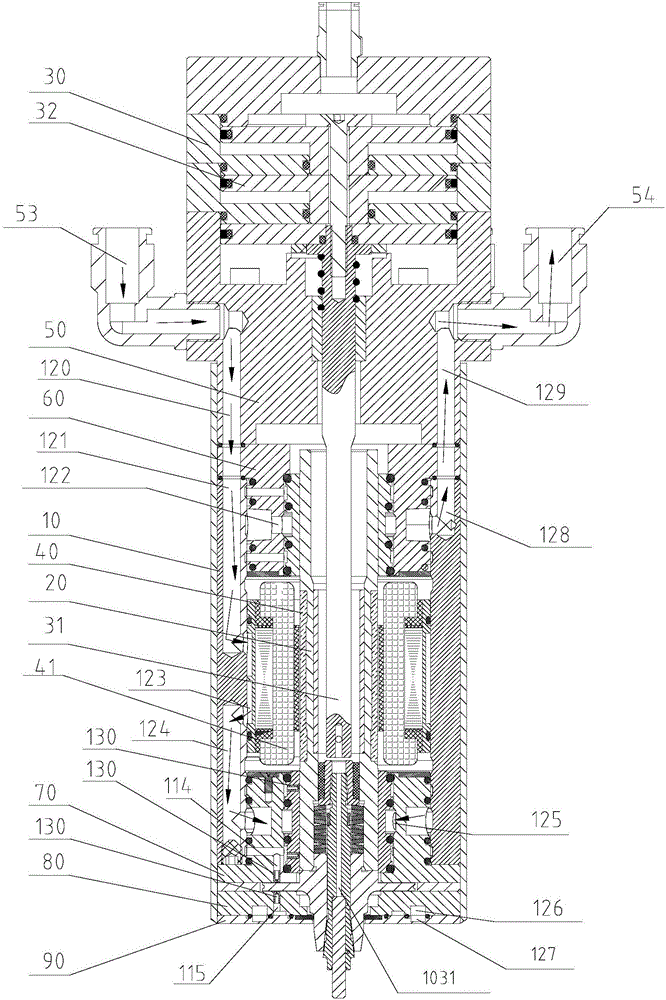

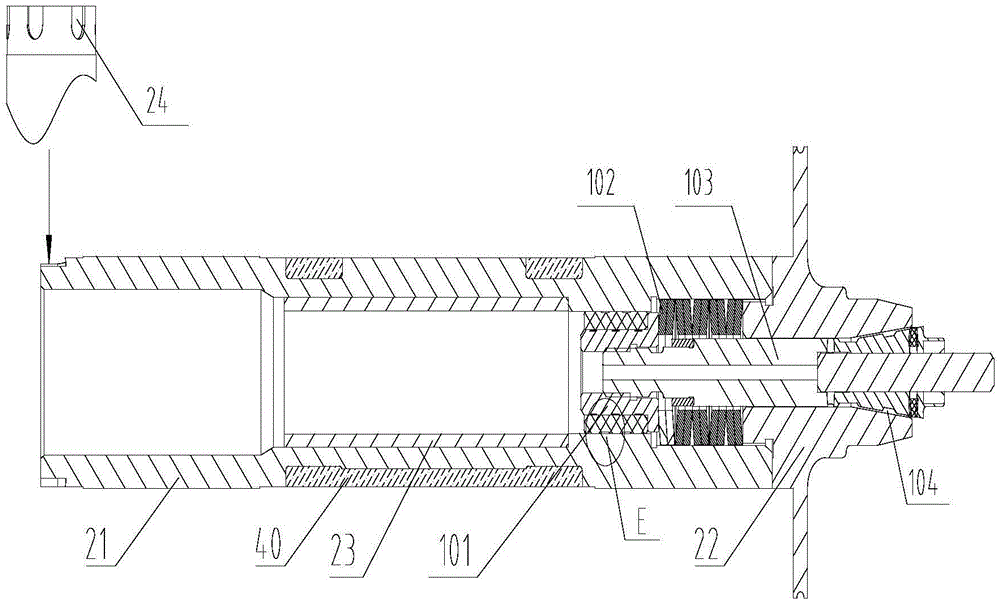

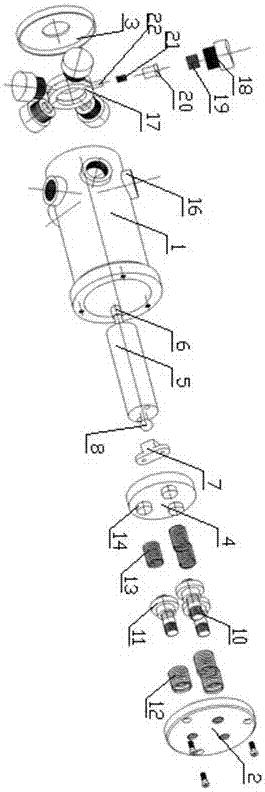

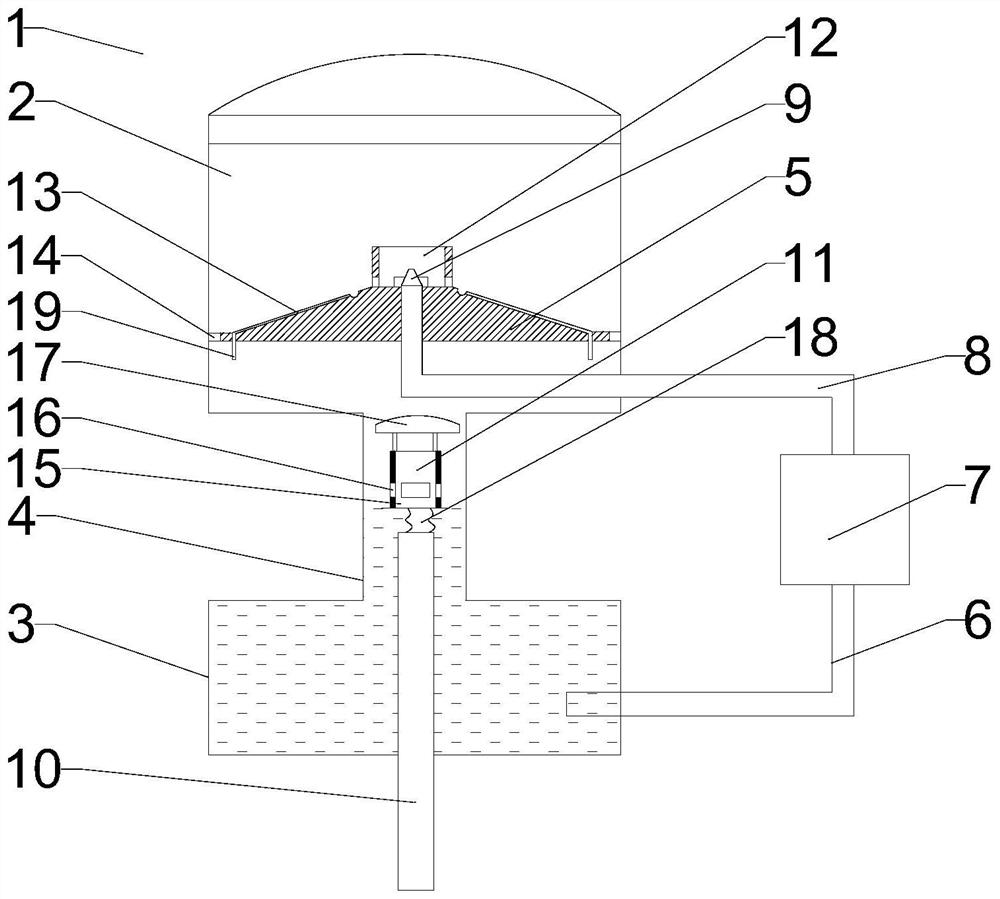

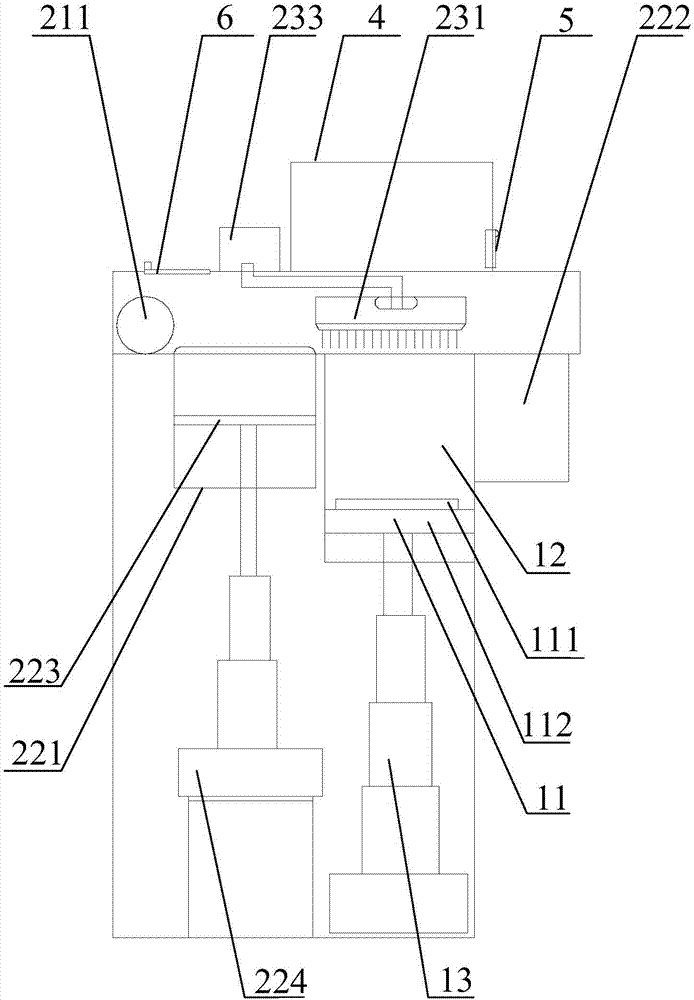

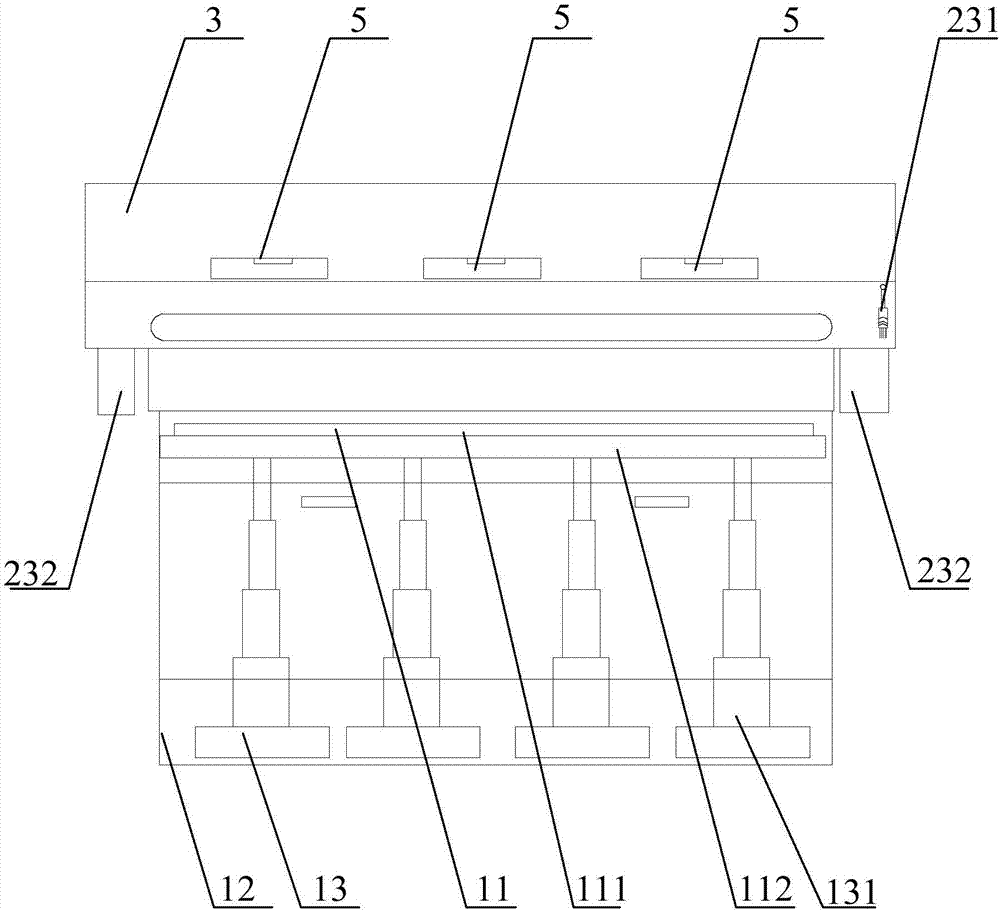

Air bearing spindle with speed measurement function

ActiveCN106563818AWith speed measurement functionReasonable designMeasurement/indication equipmentsLarge fixed membersAir bearingThrust bearing

The invention discloses an air bearing spindle with a speed measurement function. The air bearing spindle with the speed measurement function comprises a body, a spindle core assembly, a power assembly, an aluminum water jacket, a cylinder, an upper bearing assembly, a lower bearing assembly, a thrust bearing assembly and a cover plate assembly, wherein the body is of a cavity structure; the spindle core assembly comprises a rotating shaft section and a chuck section; the rotating shaft section sleeves the chuck section; speed measurement grooves are formed in the rotating shaft section; the power assembly comprises a copper bordered rotor and a stator assembly; the copper bordered rotor is inlaid into the rotating shaft section; the stator assembly is arranged in the body and is opposite to the copper bordered rotor; the upper bearing assembly is arranged on the upper part of the rotating shaft section; speed measurement sensors are arranged on the upper part of the upper bearing assembly and correspond to the speed measurement grooves; the lower bearing assembly is arranged on the lower part of the rotating shaft section; the thrust bearing assembly is arranged on the chuck section; the cover plate assembly is arranged at the bottom of the thrust bearing assembly; the aluminum water jacket is arranged on the top of the upper bearing assembly; and the cylinder is arranged on the top of the aluminum water jacket. The air bearing spindle with the speed measurement function is easy to process, simple in structure and good in heat dissipation effect, and runs stably.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

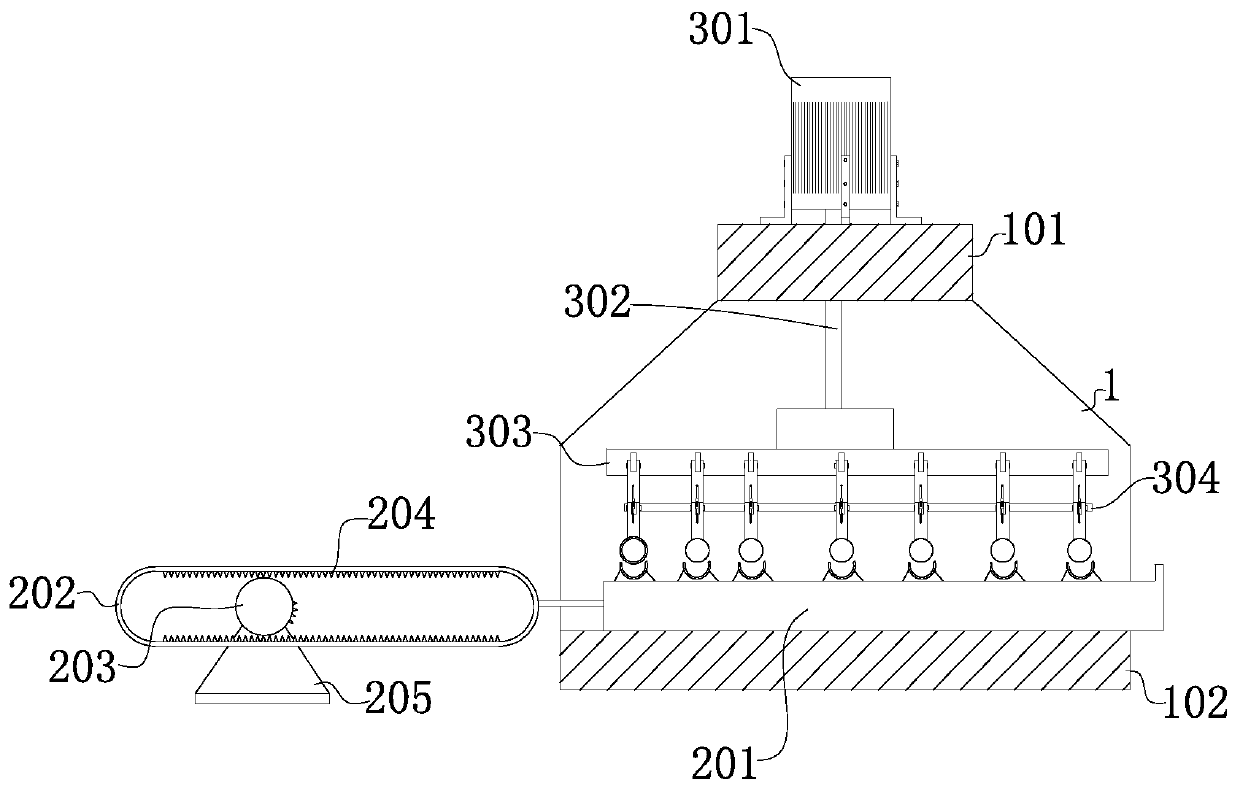

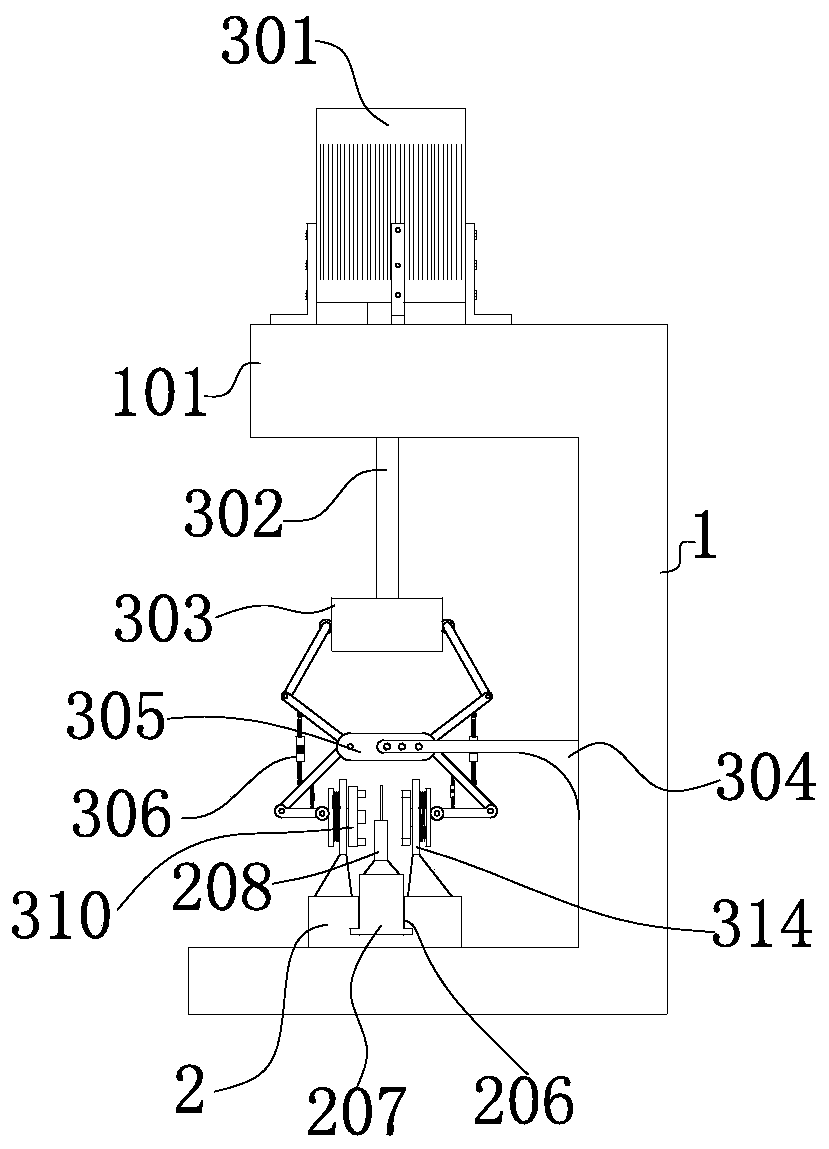

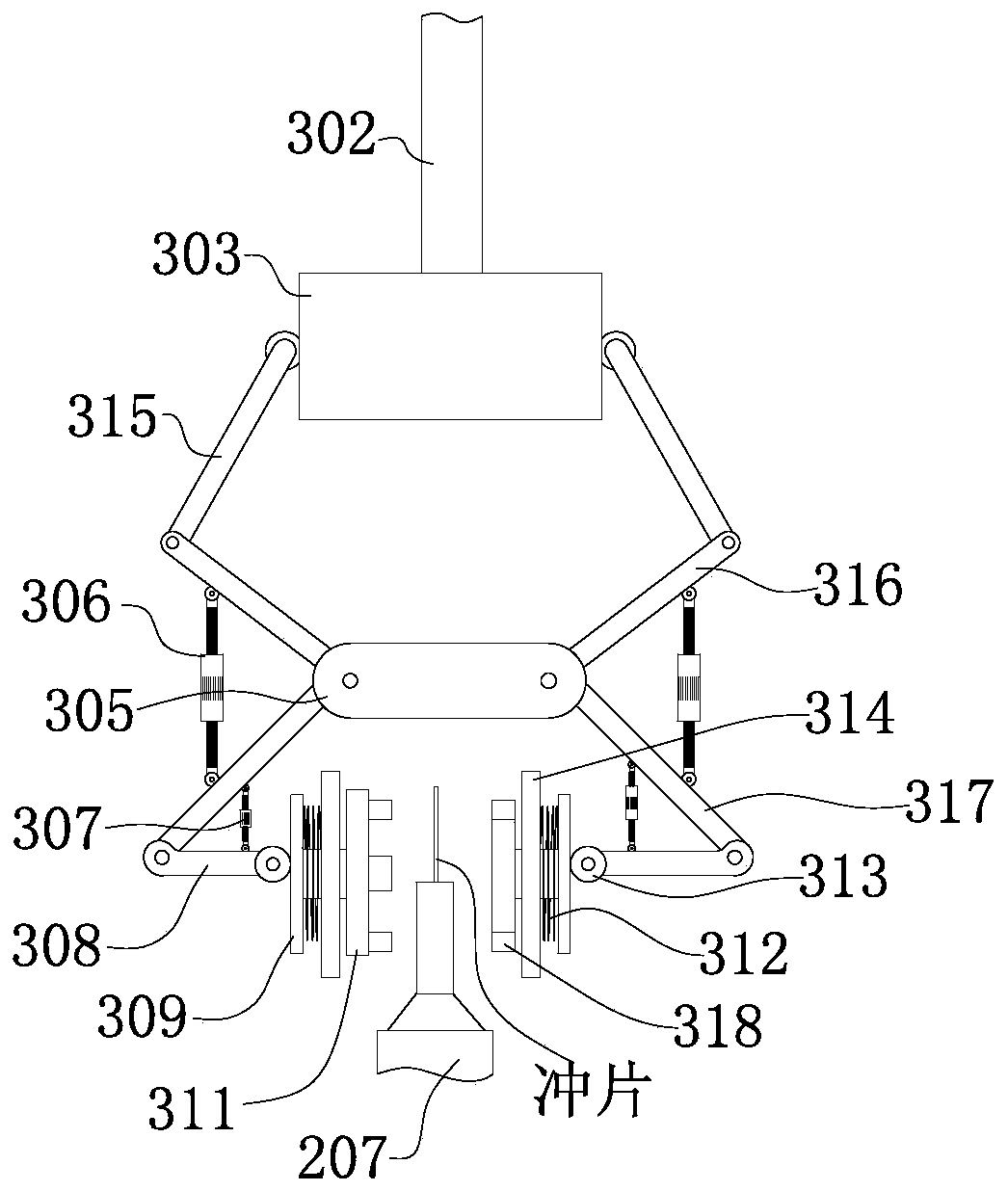

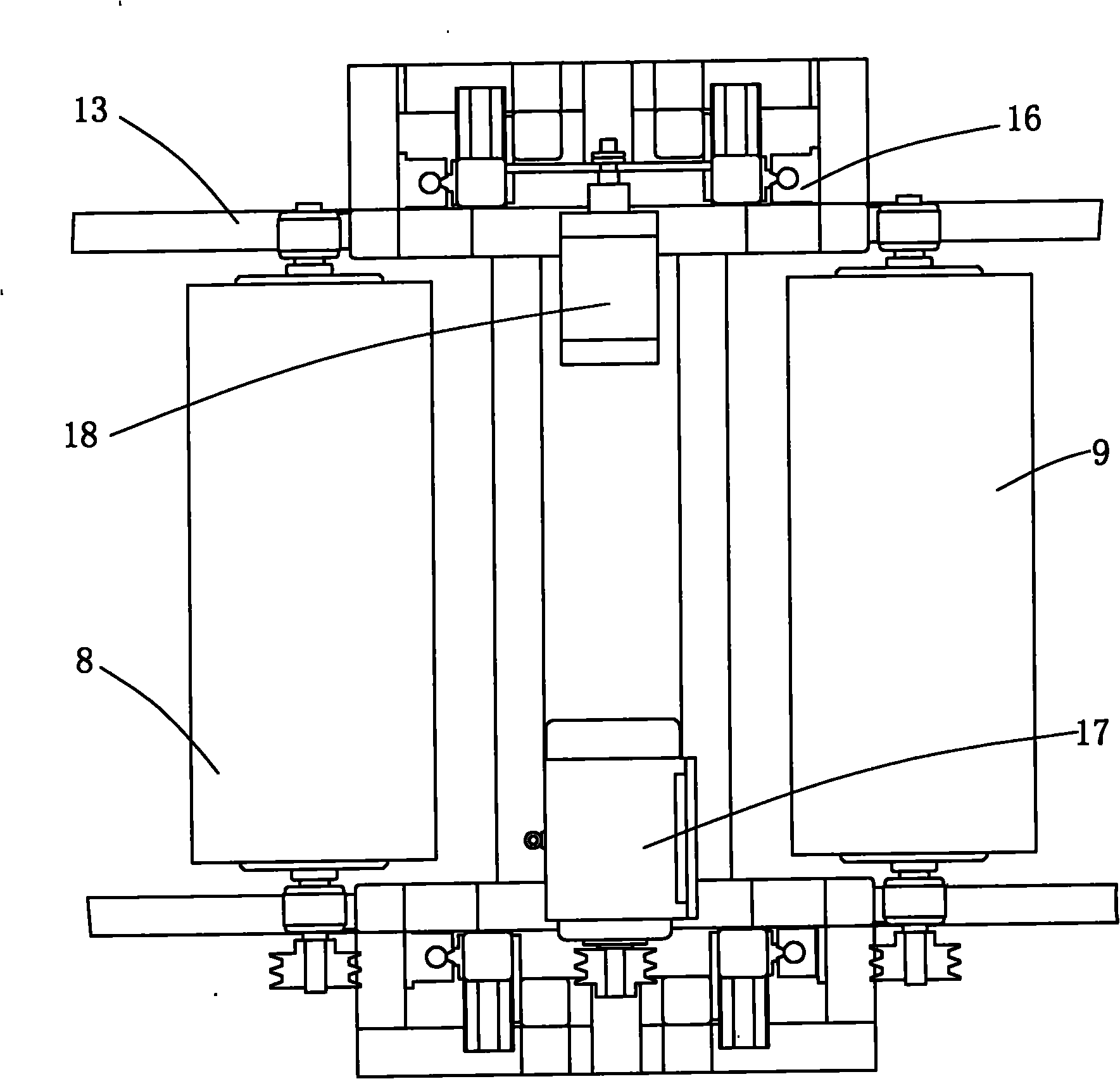

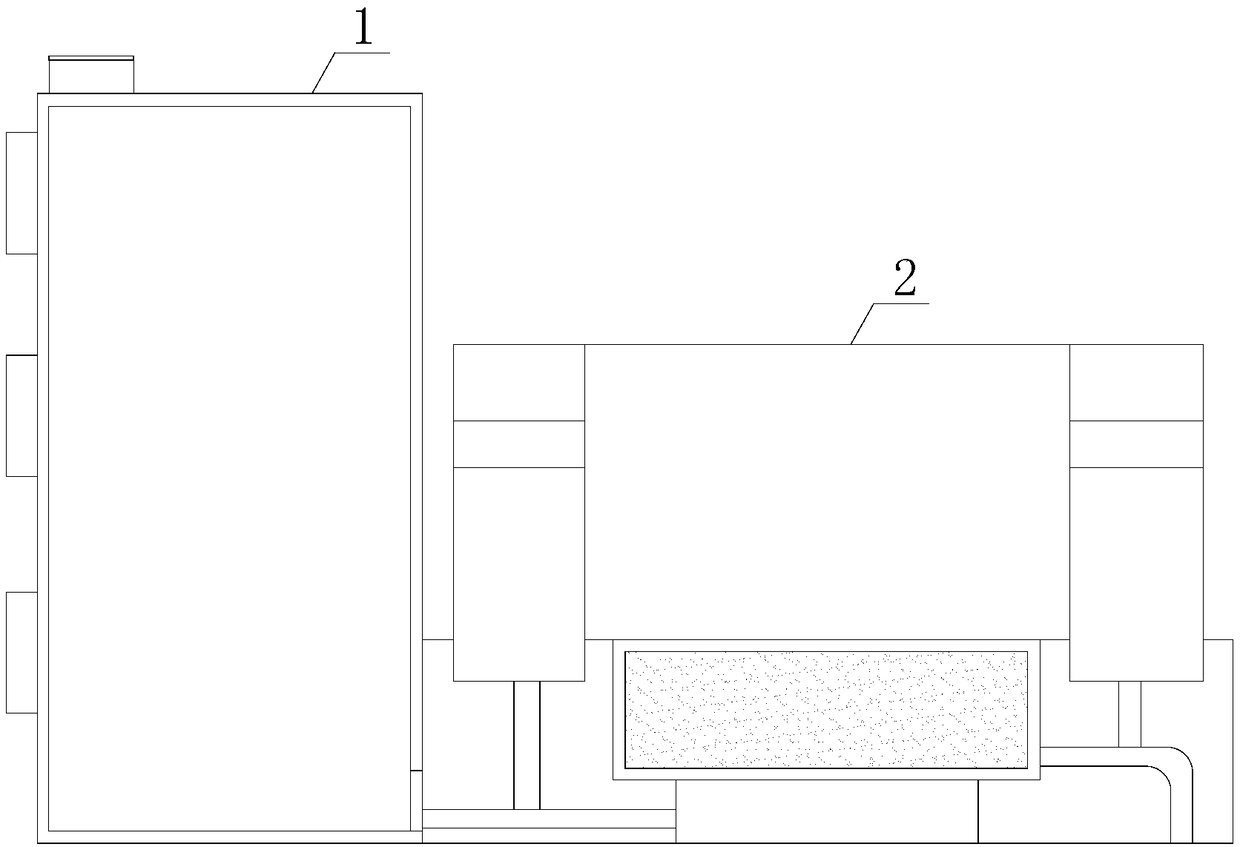

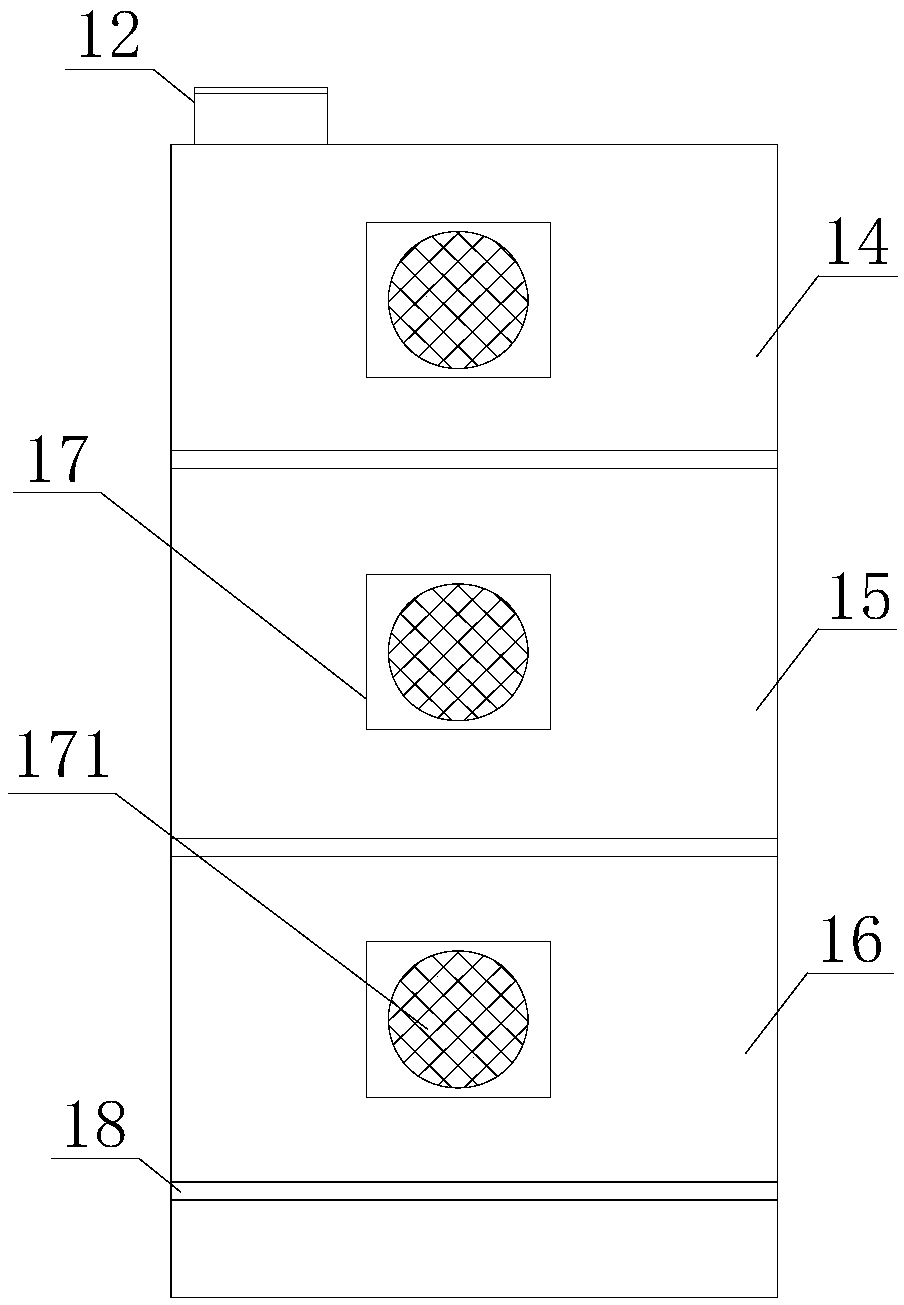

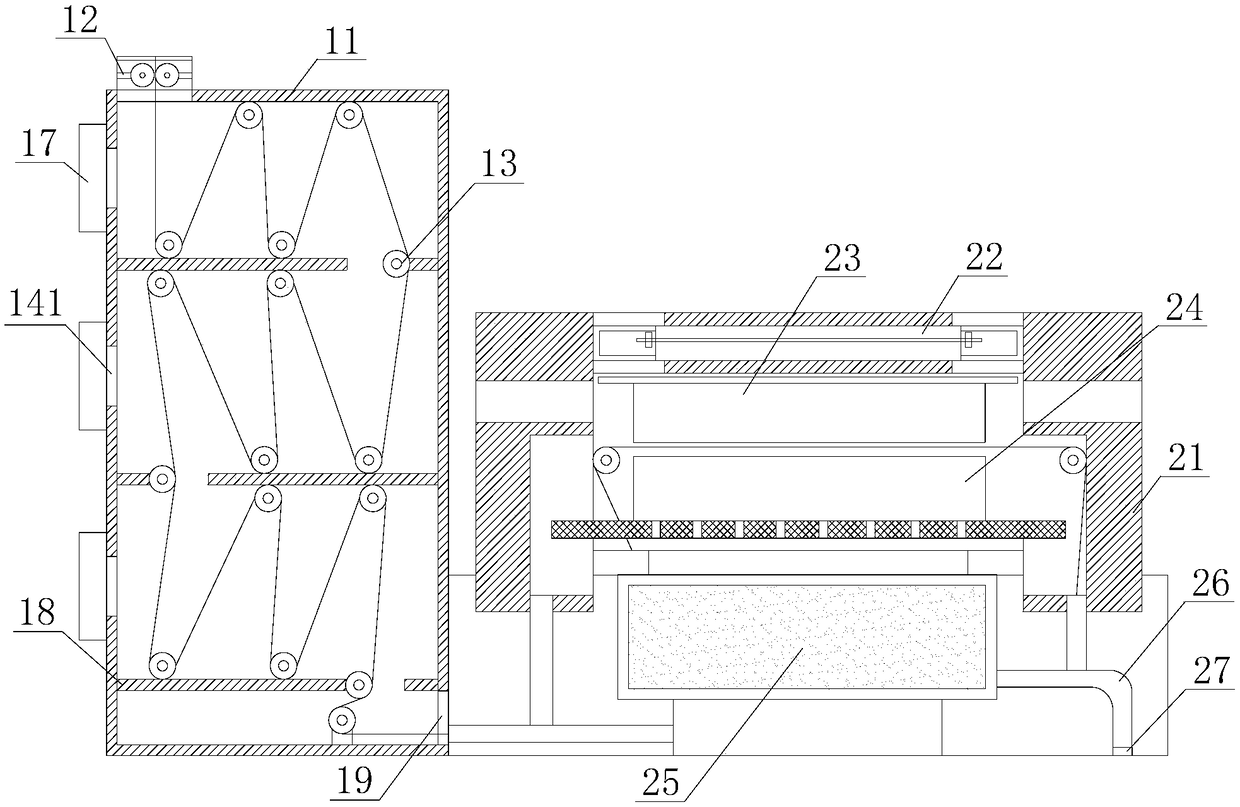

Motor stator punching sheet manufacturing process

ActiveCN110535304AImprove surface finishUniform thicknessManufacturing stator/rotor bodiesStatorPunching

The invention discloses a motor stator punching sheet manufacturing process, and relates to the technical field of punching processing. The process comprises the steps that S1 punching sheet fixing: asheet-shaped silicon steel sheet is fixed in the clamping device of a punching machine to wait for silicon steel sheet punching by a punching die; S2 punching and filmmaking: the silicon steel sheetfixedly clamped in step S1 is punched by the punching machine, and after the silicon steel sheet is punched and formed, a motor stator punching sheet is acquired; S3 burr removing: burrs on the slot cavity and the end surface of the motor stator punching sheet acquired in step S2 are removed; and S4 debris cleaning is carried out on the deburred motor stator punching sheet in step S3. According tothe invention, rollers are hinged on both sides of a push plate and the tail end of a bottom support rod; the rollers are arranged to push the push plate to move, so that the movement of the bottom support rod and the push plate is flexible; the return speed of the push plate is improved; and the movement flexibility of the bottom support rod is improved.

Owner:湘潭华通机电制造有限公司

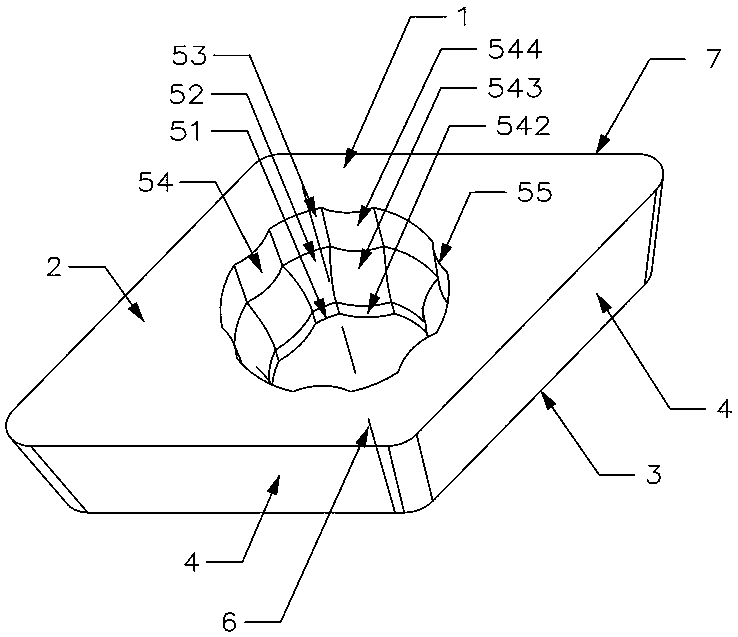

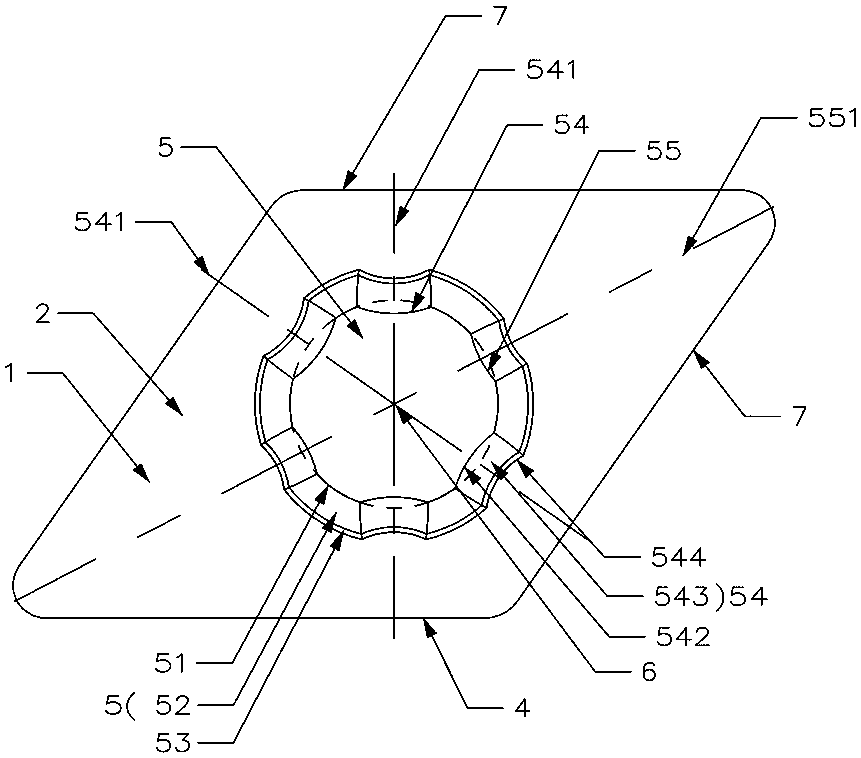

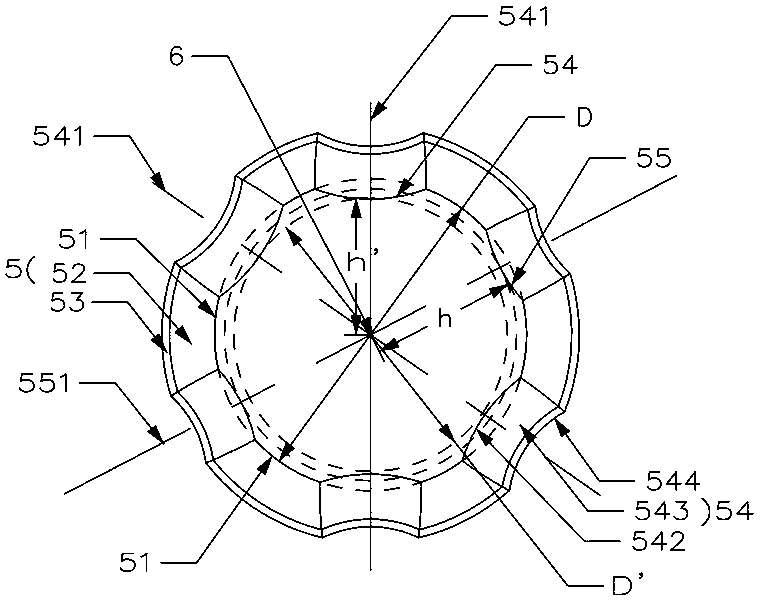

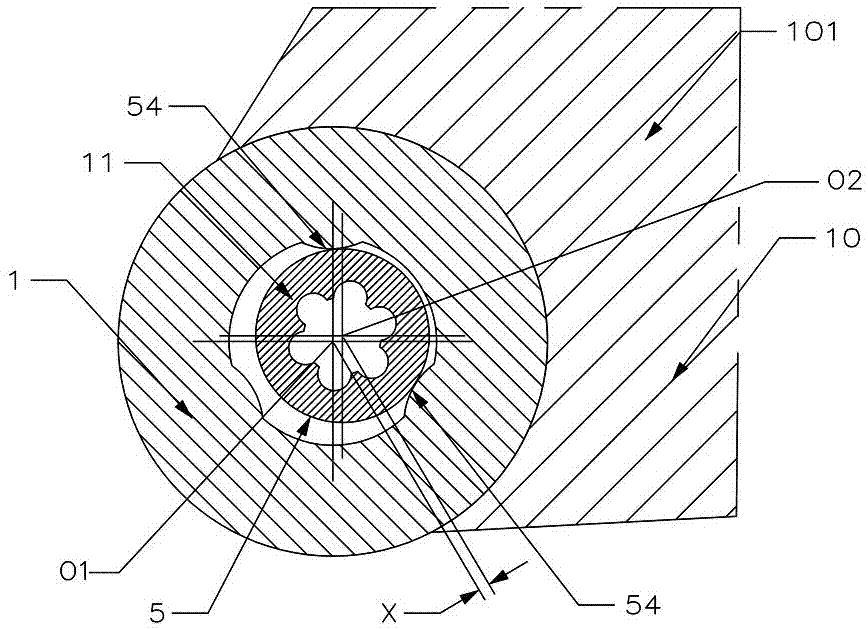

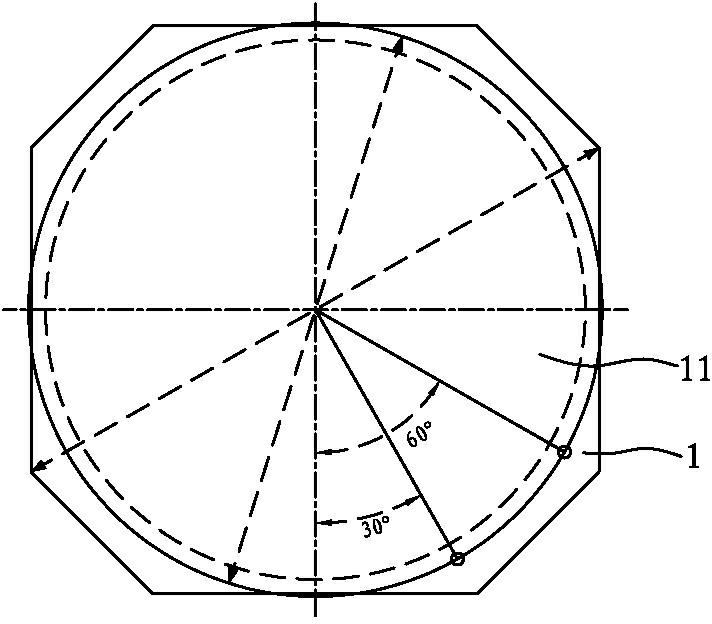

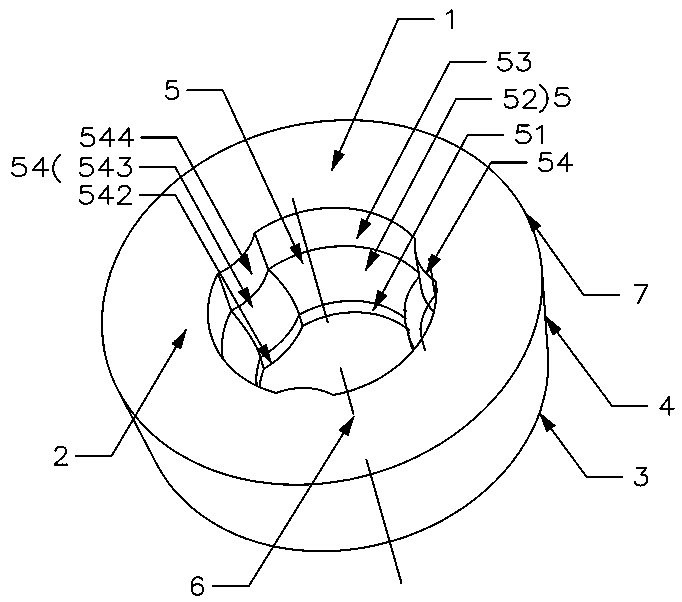

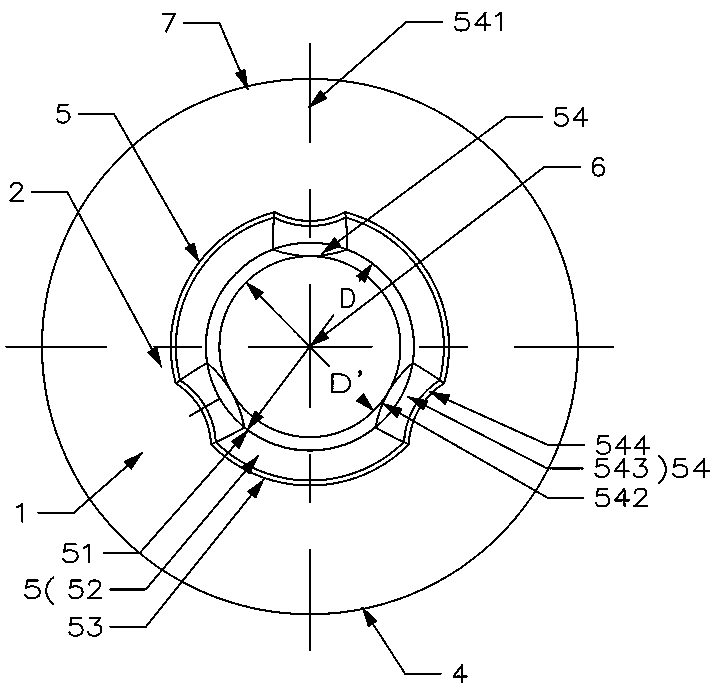

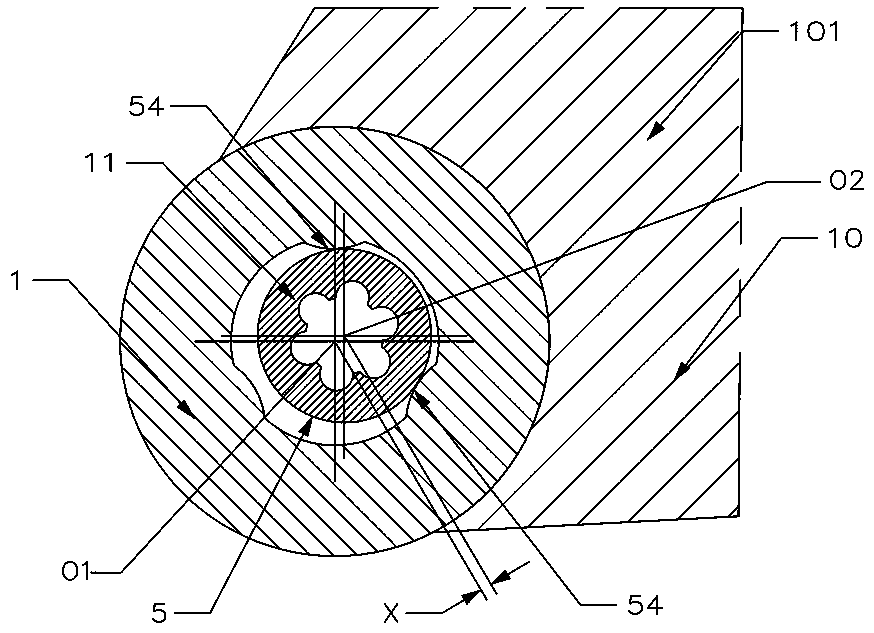

Polygonal cutting blade with bulge parts in hole and cutter

ActiveCN107775019AImprove clamping rigidityHigh strengthCutting insertsTurning toolsEngineeringFastener

The invention discloses a polygonal cutting blade with bulge parts in a hole and a cutter. The polygonal cutting blade comprises a blade body consisting of an upper surface, a lower surface and a plurality of side surfaces connected with the upper surface and the lower surface, wherein a center hole penetrating through the upper surface and the lower surface is formed in the blade body, the bladebody is in central symmetry about the central axis of the center hole, each side surface and the upper surface intersect to form a plurality of cutting edges, one bulge part is arranged in the position, corresponding to each side surface, of the inner surface of the center hole, and the bulge parts directly face the corresponding side surfaces. The cutting blade has the characteristics of positioning reliability and stability, multiple clamping and long service life. The cutter comprises the cutting blade, fastening screws and the center hole of the cutting blade produce over-positioning multidirectional clamping under multiple constraints, deformation directions and areas unfavorable for fasteners are effectively controlled, the vibration of the cutting blade can be effectively attenuated during cutting, and the service life of the cutter is prolonged.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

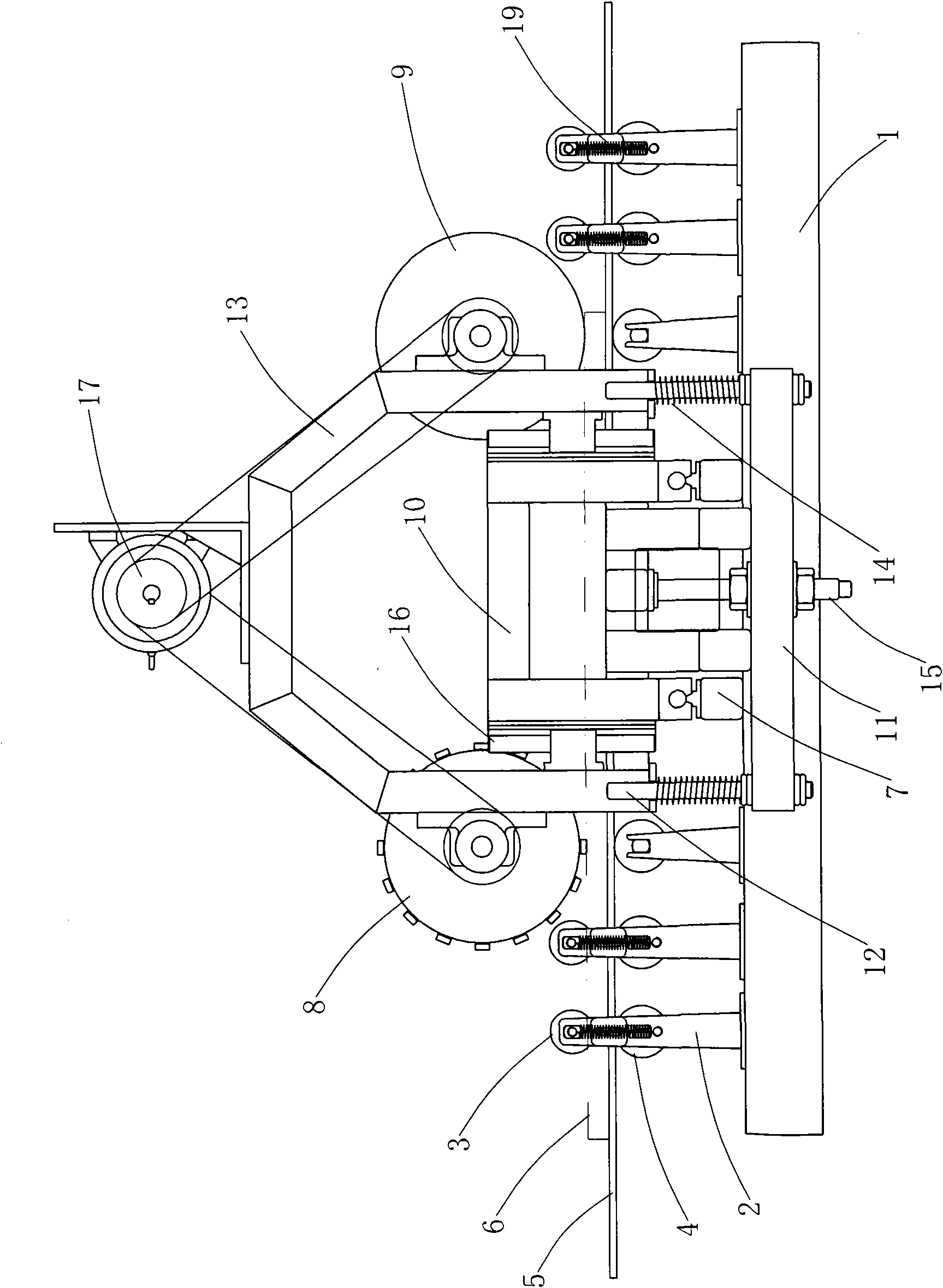

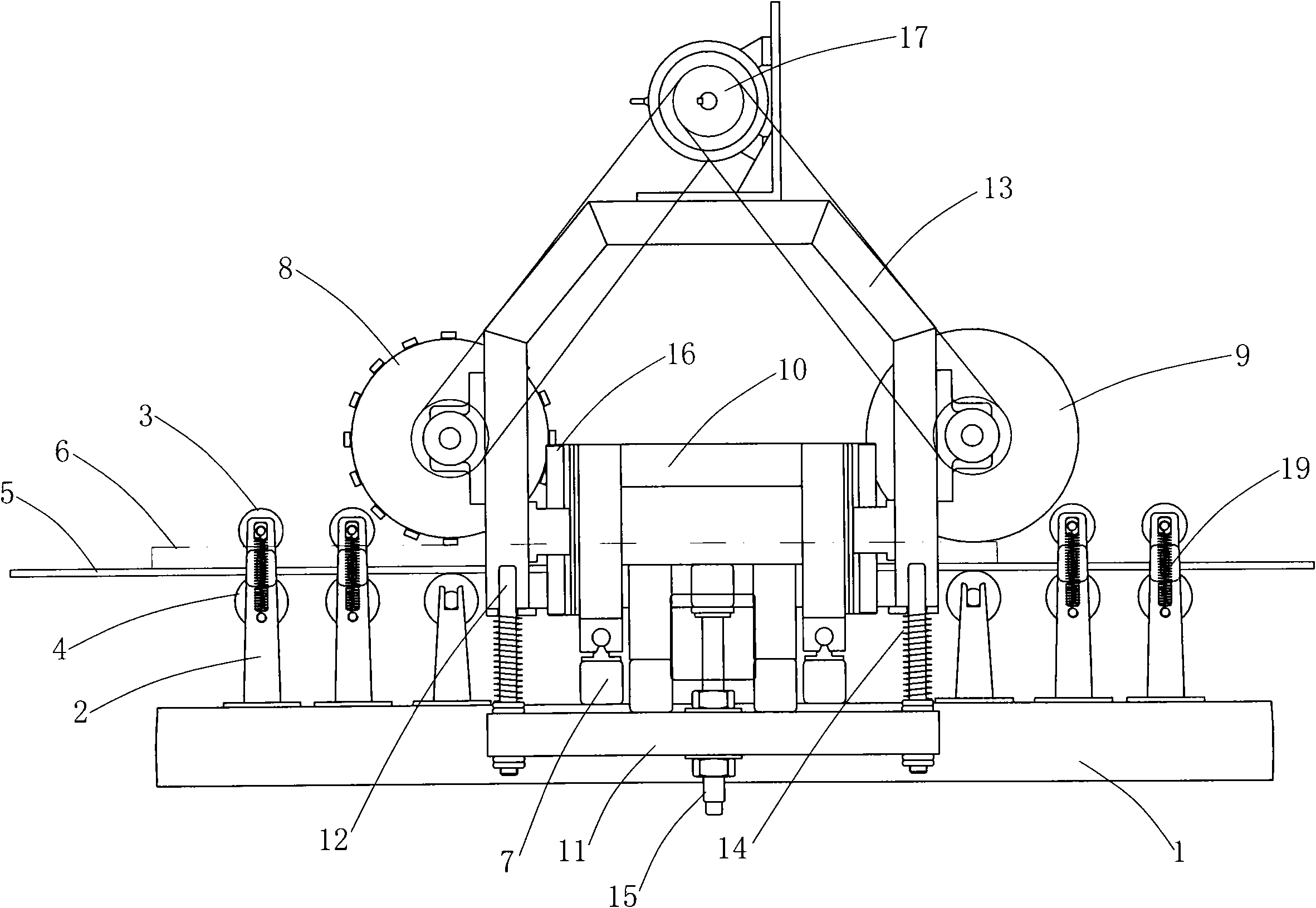

Polisher of external wall insulation board

InactiveCN101823222AImprove surface finishExtended service lifePlane surface grinding machinesEngineeringCutting force

The invention discloses a polisher of an external wall insulation board. The insulation boards are conveyed forwards one by one through being clamped by paired delivering rollers arranged on a rack. A cutting wheel and a polishing wheel are arranged above the rack to cut and polish cement surface of the insulation boards. The support, on which the cutting wheel and polishing wheel are mounted, can reciprocate horizontally along the direction of width of the insulation board. Thus, the support can further improve the surface smoothness of the insulation board to be processed, and prolong the service life of cutter of the cutting wheel. The support can also vertically slide in the direction vertical to the insulation boards. When the cutting wheel works on the insulation boards, the amount of cutting may be too big, a micro pressure spring can automatically uplift the support of the cutting wheel from the oversize layer of the insulation boards, then the cutting wheel uplifts correspondingly, thus ensuring that the cutting force exerted on the insulation boards can not jump to damage motors or work pieces.

Owner:合肥乐千年涂料有限公司

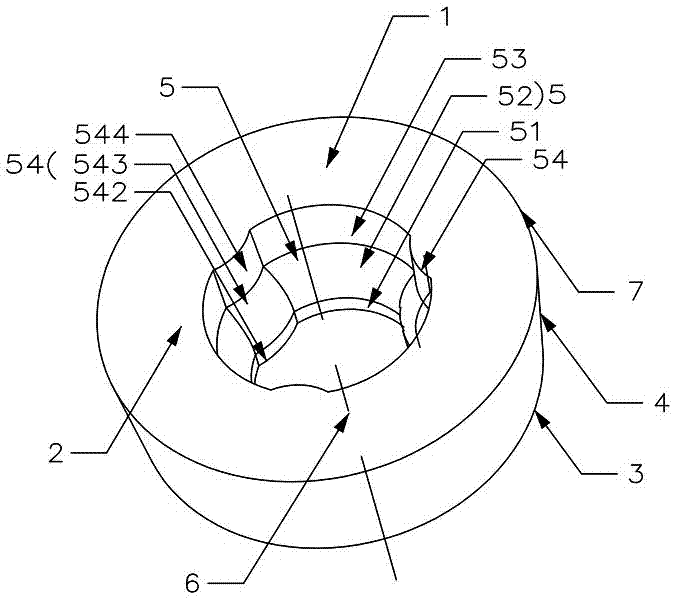

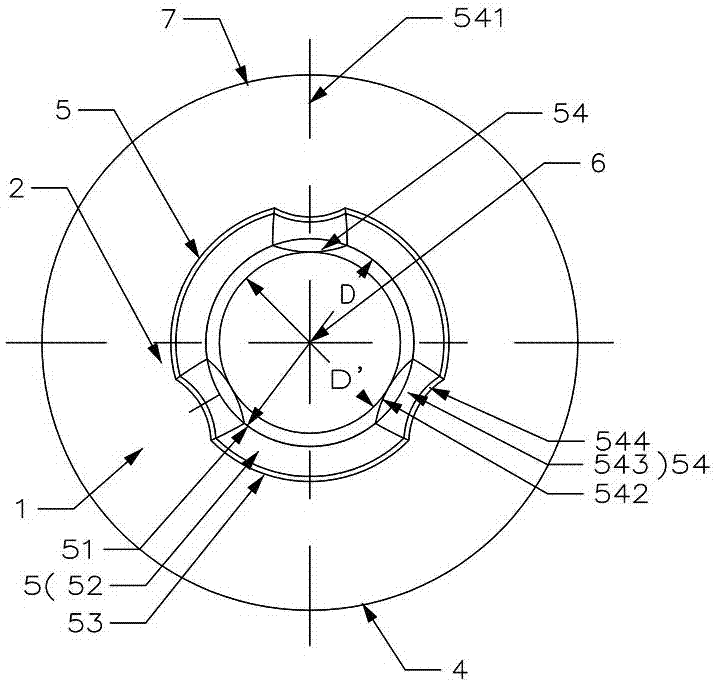

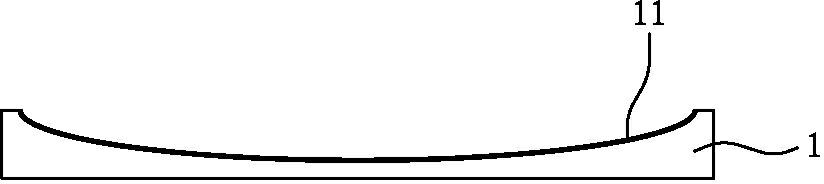

Circular blade with accurate positioning structure and cutting tool

ActiveCN107498610AEasy to installImprove clamping rigidityMetal working apparatusTurning toolsEngineeringMechanical engineering

The invention discloses a circular blade with an accurate positioning structure and a cutting tool. The circular blade comprises a blade body, wherein the blade body is composed of an upper surface, a lower surface and a side face which is used for connecting the upper surface with the lower surface; and the blade body is provided with a center hole which penetrates through the upper surface and the lower surface, the blade body is centrosymmetric relative to the central axis of the center hole, the upper surface intersects with the side face to form a cutting edge, the inner surface of the center hole is provided with at least two lug bosses, and the included angle between every two adjacent lug bosses is smaller than 180 degrees. The cutting blade has the advantages that positioning is reliable and stable, multi-ply clamping can be achieved, and the service life is long. The cutting tool is provided with the circular blade, sliding or rotating of the circular blade in the peripheral direction in the using process can be eliminated, the stability of the cutting edge in a cutting region is guaranteed, other cutting processes are prevented from participating in one cutting process, the usable frequency of the circular blade on the cutting tool is effectively stabilized, and then the service life of the cutting tool is prolonged.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Manufacturing method of aromatic mouldproof shaving board

InactiveCN110103310AReasonable preparation processSimple preparation processNon-macromolecular adhesive additivesMacromolecular adhesive additivesWood shavingsSurface layer

The invention discloses a manufacturing method of an aromatic mouldproof shaving board. The manufacturing method includes the following steps: S1, shaving is conducted; S2, distilled bamboo vinegar issprayed; S3, a raw material obtained in the step S2 is conveyed into a high-temperature heat treatment machine, and treatment is conducted for 30 min to 150 min under the condition of 120 DEG C to 200 DEG C; S4, drying is conducted; S5, a first aromatic mouldproof adhesive is applied; S6, paving is conducted; S7, a board blank of the shaving board is pre-pressed; S8, an upper surface layer and alower surface layer are prepared, the bonding face of the upper surface layer and a core layer and the bonding face of the lower surface layer and the core layer are evenly coated with an appropriateamount of second aromatic mouldproof adhesive; and S9, hot pressing is conducted. The aromatic mouldproof shaving board has the lasting aromatic odor, has the refreshing effect, has no toxic and sideeffects, serves as an indoor decoration material, is wide in applicability, and can widely replace artificial boards such as plywood, laminated wood boards, shaving boards and medium density fiberboards, and the quantitative shaving board is reasonable and simple in preparation technology, low in cost, good in surface processing performance, and suitable for industrial production.

Owner:李珂

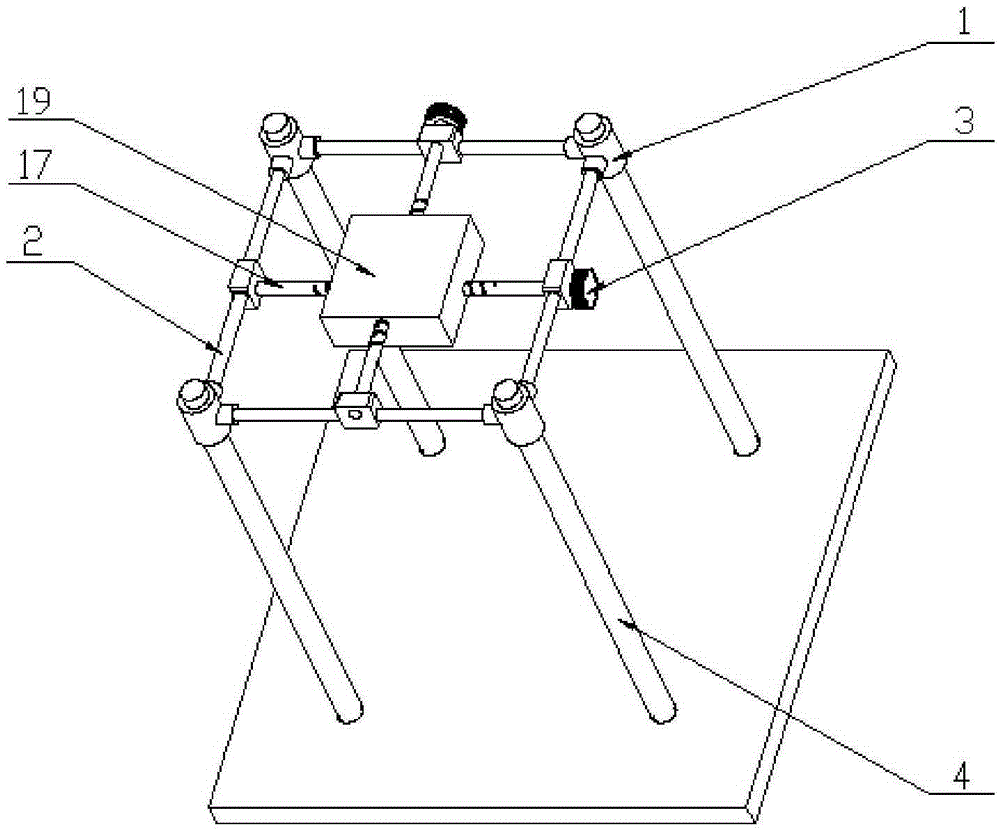

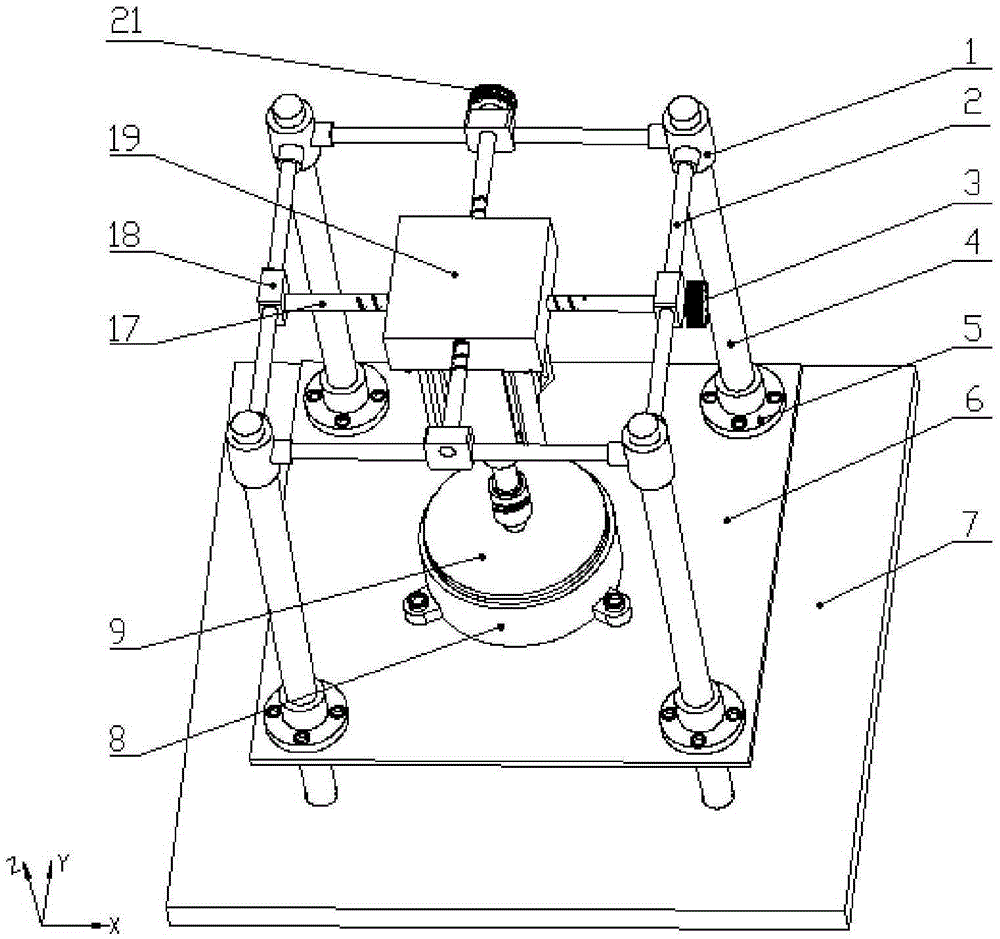

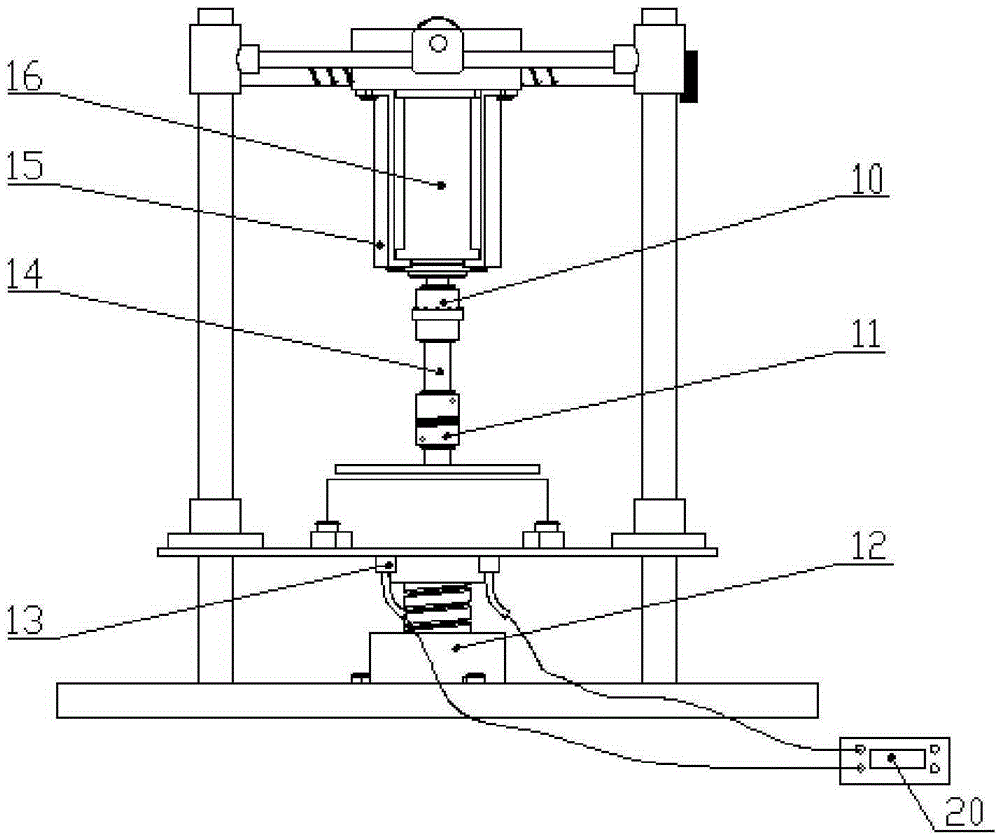

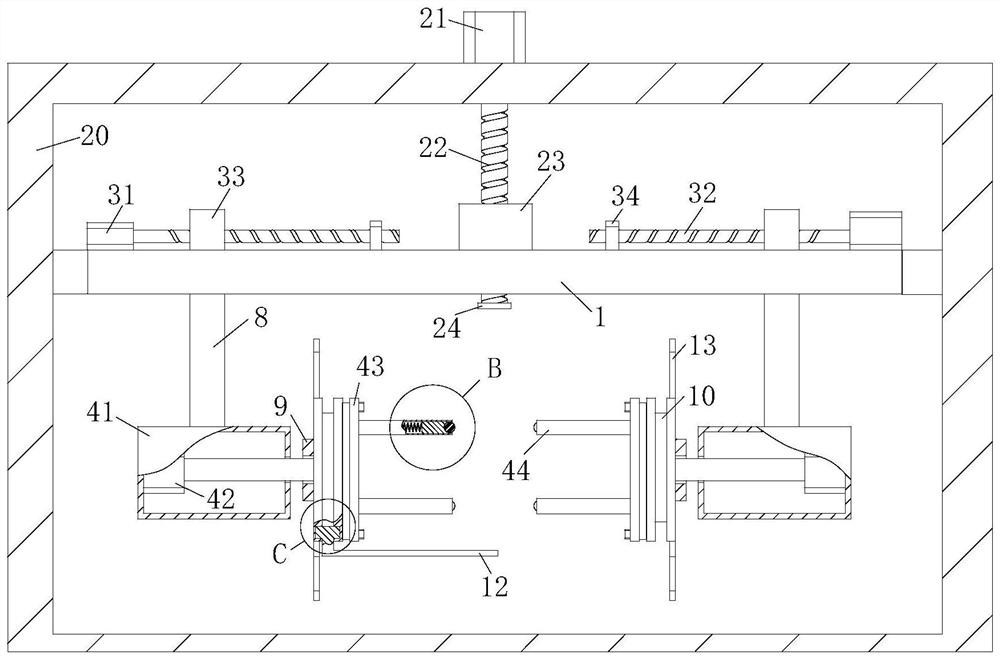

Hydraulic pressure suspension polishing device with controllable fluid boundary

The invention discloses a hydraulic pressure suspension polishing device with a controllable fluid boundary. The hydraulic pressure suspension polishing device comprises a horizontal workbench, a polishing system, a lifting system, a fine adjustment system and a pressure detection system. The polishing system comprises a polishing disc, a polishing liquid container, a first coupling, a spindle, a second coupling, a motor support and a serve motor. The hydraulic pressure suspension polishing device has the advantages that a gap between the polishing disc and the wall of the polishing liquid container is small, a good condition is provided for forming good hydraulic pressure, and accordingly the machining efficiency and the surface machining effect can be improved; a polishing tool is separated from a workpiece, and the workpiece is immersed in the polishing liquid, so that the abrasion of the polishing tool is relieved easily, and negative effects caused by friction heat in the polishing process are reduced; the polishing disc is directly driven by the servo motor, error accumulation caused by complex transmission links is avoided, and the machining precision is improved.

Owner:ZHEJIANG UNIV OF TECH

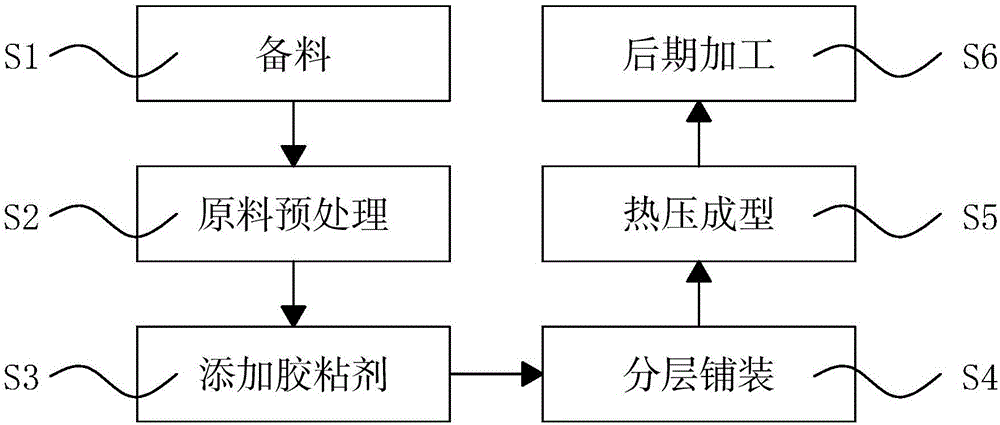

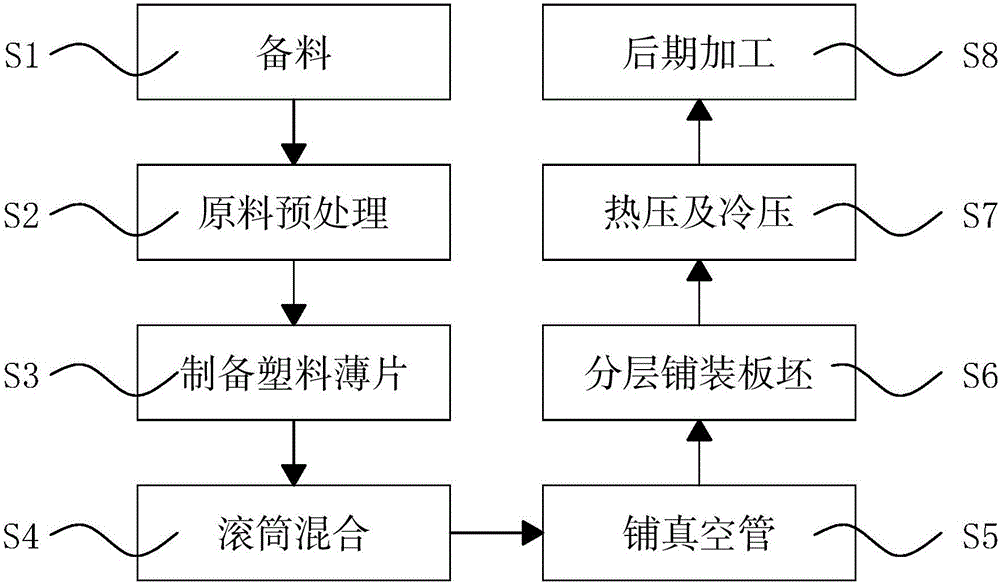

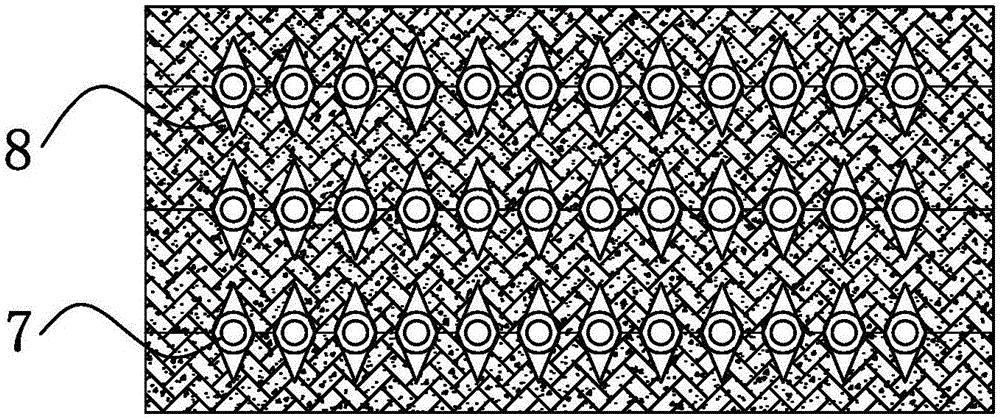

Manufacturing method of heat and sound insulation particle board

ActiveCN106514829AWith heat and sound insulationImproved heat and sound insulationFlat articlesDomestic articlesMaterials preparationMetallurgy

The invention discloses a manufacturing method of a heat and sound insulation particle board, aims to realize manufacturing of a high-strength sound and heat insulation particle board and solving of difficult formation of a closed vacuum environment by such wood composite materials as particle boards, aims to the problem that the particle boards cannot achieve better heat and sound insulation effect in the prior art, and proposes the manufacturing method of the heat and sound insulation particle board. The manufacturing method comprises the steps of: (S1) material preparation; (S2) raw material pretreatment; (S3) adhesive adding; and (S4) layered pavement: wood raw materials added with adhesive are divided into multiple parts; one part is taken out to uniformly pave in a mold; then, vacuum pipes prepared beforehand are paved in an oriented manner; another part of wood raw materials added with the adhesive is taken out to pave on the vacuum pipes paved in the oriented manner; and a plate blank is obtained by prepressing; (S5) hot-press forming; and (S6) later machining. The manufacturing method has the following beneficial effects: the closed vacuum environment is formed in the particle board, so that the particle board has part characteristics of a vacuum material, and the heat and sound insulating performance of the particle board is promoted.

Owner:BEIJING FORESTRY UNIVERSITY

Green sand for nonferrous alloy casting and preparation method thereof

InactiveCN103567354AAvoid sticky sand defectsImprove surface finishFoundry mouldsFoundry coresPolystyreneKaolin clay

The invention discloses green sand for nonferrous alloy casting and a preparation method thereof. The green sand is prepared from the following raw materials in parts by weight: 65-75 parts of recycling sand, 25-35 parts of kyanite sand, 5-10 parts of kaolin, 3-6 parts of waste tourmaline powder, 2-4 parts of composite powder, 3-5 parts of polystyrene powder, 1.5-2.5 parts of corn flour, 2-3 parts of castor oil, 0.5-1.5 parts of glass fiber, 1-2 parts of sodium polyacrylate, 2-3 parts of desulfurized fly ash and 4-8 parts of water. The molding sand is reasonable in formula and low in cost, the sand adhesion defect on the surface of the casting can be overcome, and the surface smoothness of the casting can be improved. Moreover, the green sand is high in strength, low in air release amount, high in air permeability effect and high in liquidity and has huge economic benefits, and the yield of the green sand for nonferrous alloy casting is greatly improved.

Owner:TONGLING JINGWEI FLUID SCI & TECH

Production process of reinforced melamine facing medium density fiberboard

InactiveCN110039630AFlame retardantReasonable preparation processDomestic articlesFlat articlesGlass fiberFiber

The invention discloses a production process of a reinforced melamine facing medium density fiberboard. The production process comprises the following steps of S1, pretreating raw materials; S2, crushing the raw materials obtained in S1 and conveying the crushed raw materials to a stirring machine, spraying a flame retardant in the stirring process, wherein the additive amount of the flame retardant is 5%-15% of the absolute dry mass of the raw materials; S3, carrying out high-temperature heat treatment; S4, forming a medium density fiberboard; S5, placing a glass fiber net layer in a mold frame of the medium density fiberboard layer, spreading and prepressing; S6, preparing a fiberboard layer; and S7, pressing and pasting melamine glue-impregnated paper at high temperature on the upper surface of the fiberboard layer and the lower surface of the medium density fiberboard. According to the production process of the reinforced melamine facing medium density fiberboard, the medium density fiberboard, the glass fiber net layer and the fiberboard layer are adopted for bonding treatment, the melamine impregnated paper is added, and meanwhile, the raw materials are sprayed with the flameretardant during preparation, and high-temperature treatment is carried out, so that the flame-retardant effect can be effectively achieved, the preparation process is reasonable and simple, the costis low, the surface processing performance is good, and the method is suitable for industrial production.

Owner:李珂

Epoxy resin rubber clothes composition, epoxy resin composite board, and preparation method thereof

The invention belongs to the field of epoxy resin composite material, and discloses an epoxy resin rubber clothes composition, an epoxy resin composite board, and a preparation method thereof. The composition comprises, by weight, 100 parts of a base epoxy resin, 20 to 30 parts of a curing agent, 0.3 to 2.2 parts of an antifoaming agent, 0.3 to 1.1 parts of a leveling agent, 0.6 to 2.2 parts of awetting dispersing agent, 60 to 110 parts of a filler, 1.8 to 2.2 parts of a thixotropic agent, 0.3 to 1.4 parts of a thixotropic enhancer, and 0 to 3 parts of an optional pigment; the base epoxy resin is a liquid bisphenol A epoxy resin with an epoxy equivalent of 184 to 194 g / eq, and viscosity of 10,000 to 15,000cps at 25 DEG C, the curing agent including a curing agent A and a curing agent B, the curing agent A is a fatty amine with an active hydrogen equivalent of 50 to 60 g / eq; the curing agent B is an alicyclic amine with an active hydrogen equivalent of 40 to 95 g / eq; and the weight ratio of the curing agent A to the curing agent B is 1: (1-4). Excellent adhesion performance with glass fiber reinforced epoxy resin composite materials is provided, and the composite board is providedwith better surface processing performance.

Owner:BYD CO LTD

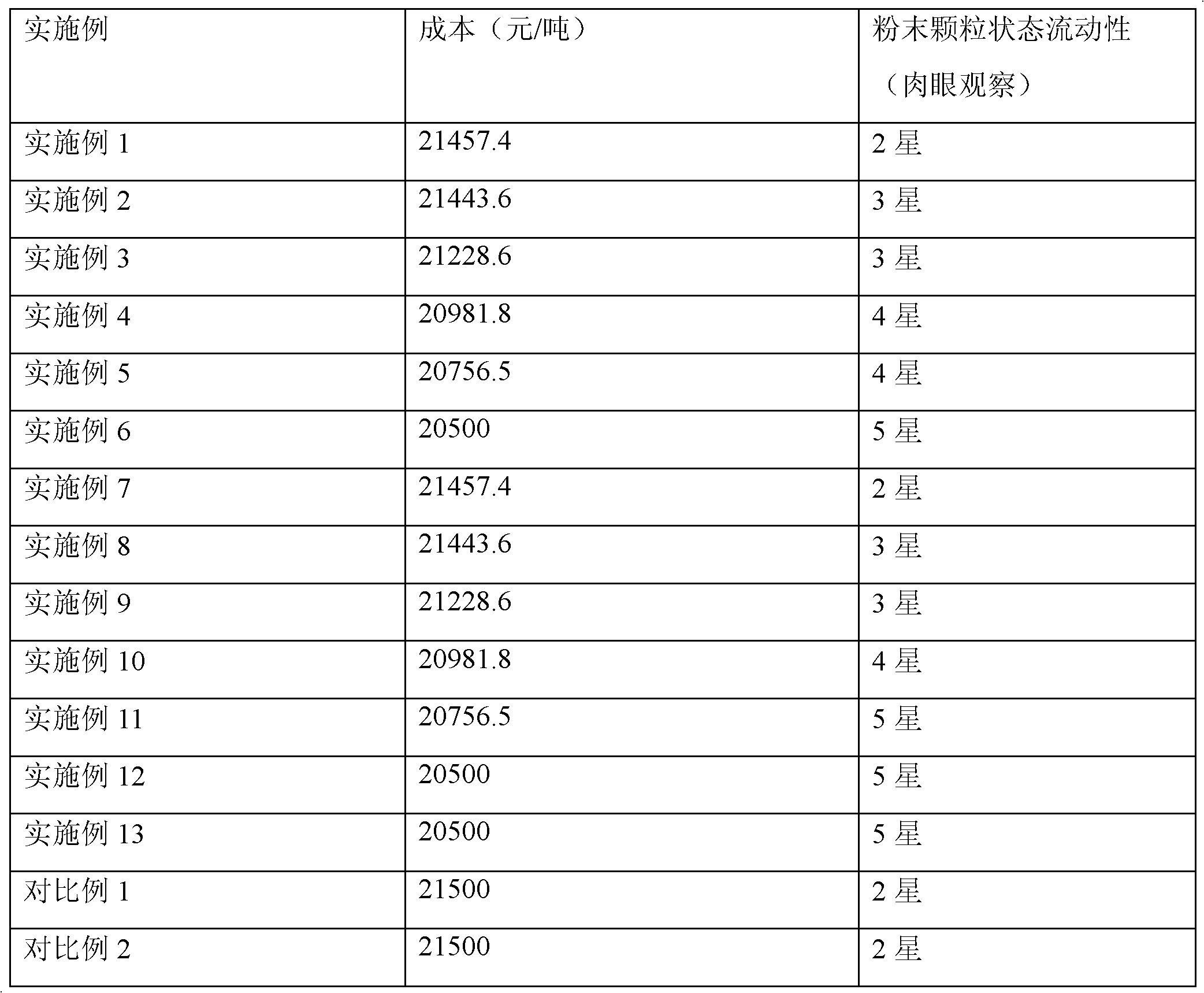

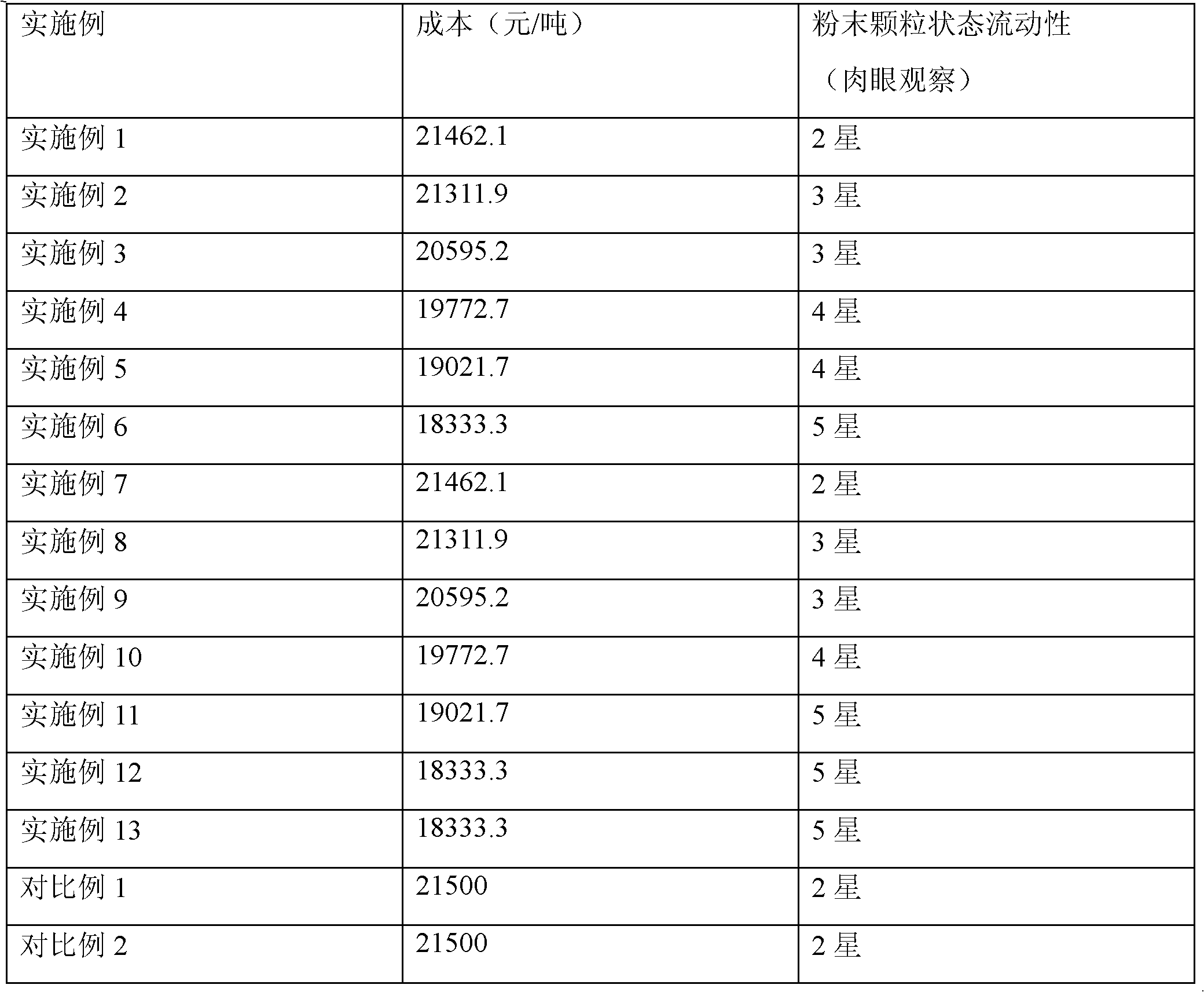

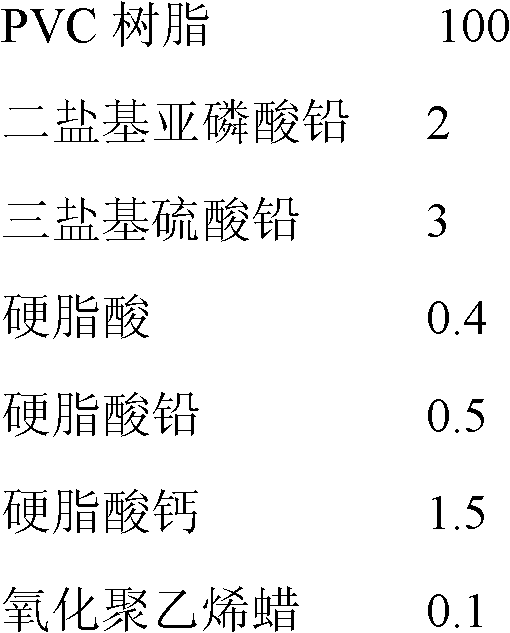

Nano-titania-modified acrylate linear high-molecular polymer and preparation method thereof

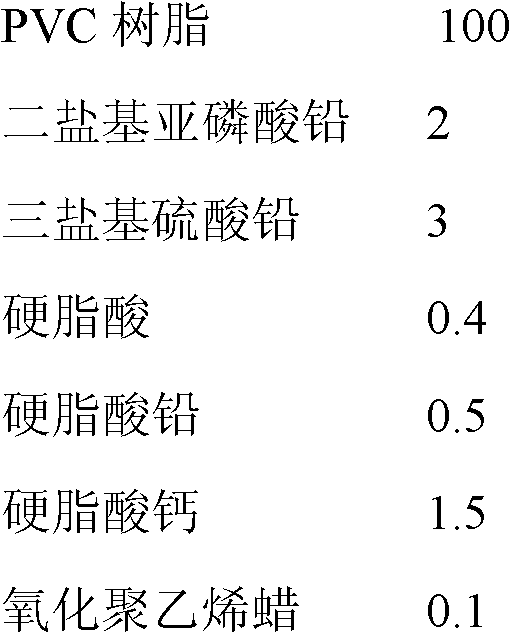

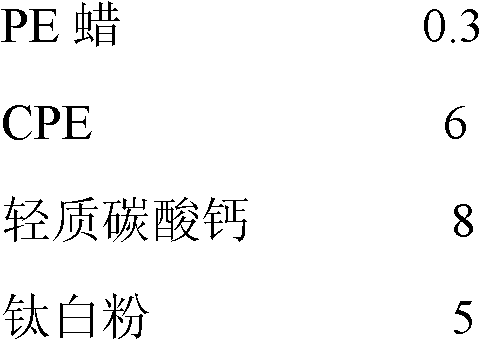

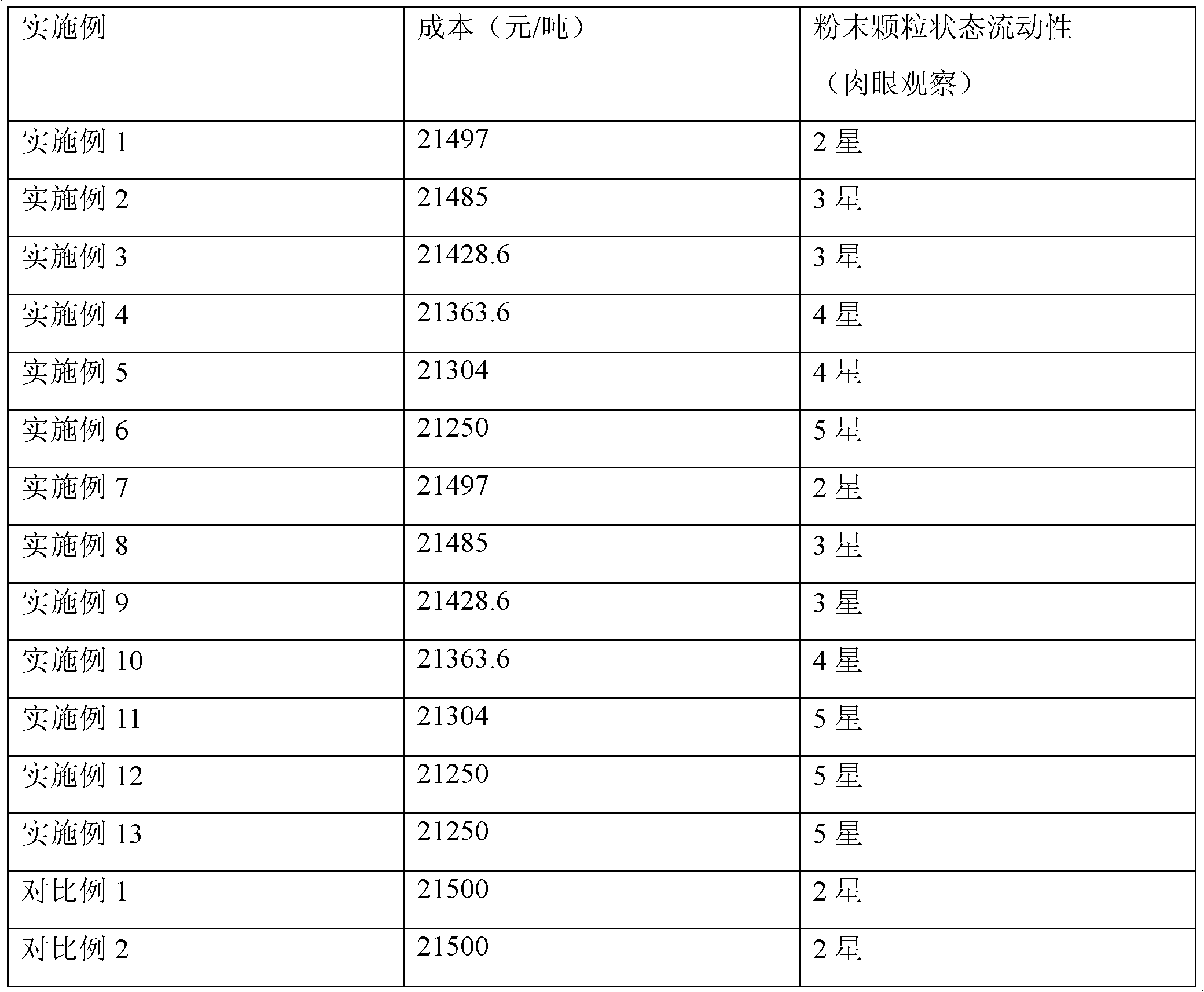

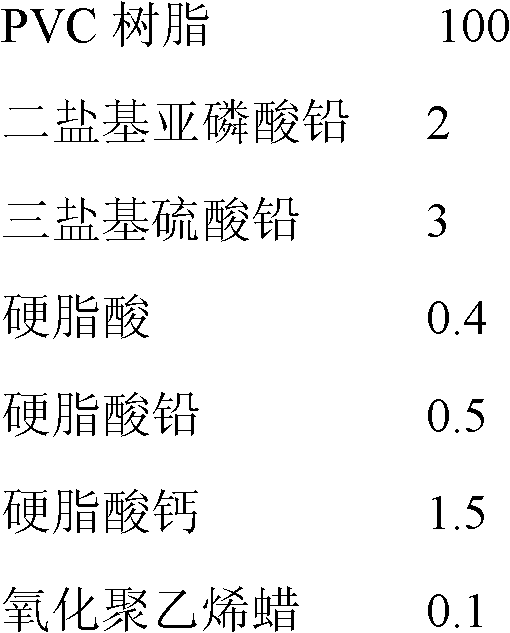

The invention relates to a nano-titania-modified acrylate linear high-molecular polymer and a preparation method thereof. The invention belongs to the technical field of PVC processing auxiliary material. According to the invention, during a methyl methacrylate and butyl acrylate copolymerization process or a methyl methacrylate homopolymerization process, nano-titania is added, such that the acrylate polymer is prepared. A weight ratio of methyl methacrylate to butyl acrylate is 5-100:95-0. A nano-titania dose is 0.1-20% of a polymerization monomer total weight. According to the invention, nano-titania is used for modifying the acrylate high-molecular polymer which is a processing type acrylate linear high-molecular polymer. The acrylate polymer has the advantages of low cost and good particle state fluidity. With the polymer, prepared PVC profile has high surface smoothness. The preparation method is simple and feasible, and is easy to implement.

Owner:SHANDONG SHITUO HIGH MOLECULAR WEIGHT MATERIAL

Nano-ceria-modified acrylate linear high-molecular polymer and preparation method thereof

The invention relates to a nano-ceria-modified acrylate linear high-molecular polymer and a preparation method thereof. The invention belongs to the technical field of PVC processing auxiliary material. According to the invention, during a methyl methacrylate-butyl acrylate copolymerization process or a methyl methacrylate homopolymerization process, nano-ceria is added, such that the acrylate polymer is prepared. The weight ratio of methyl methacrylate to butyl acrylate is 5-100:95-0. The amount of nano-ceria used is 0.1-20% of the total weight of the polymerization monomer. According to the invention, nano-ceria is used for modifying the acrylate high-molecular polymer which is a processing type acrylate linear high-molecular polymer. The acrylate polymer has the advantages of low cost and good particle state fluidity. With the polymer, prepared PVC profile has high surface smoothness. The preparation method is simple and feasible, and is easy to implement.

Owner:SHANDONG SHITUO CHEM TECH CO LTD

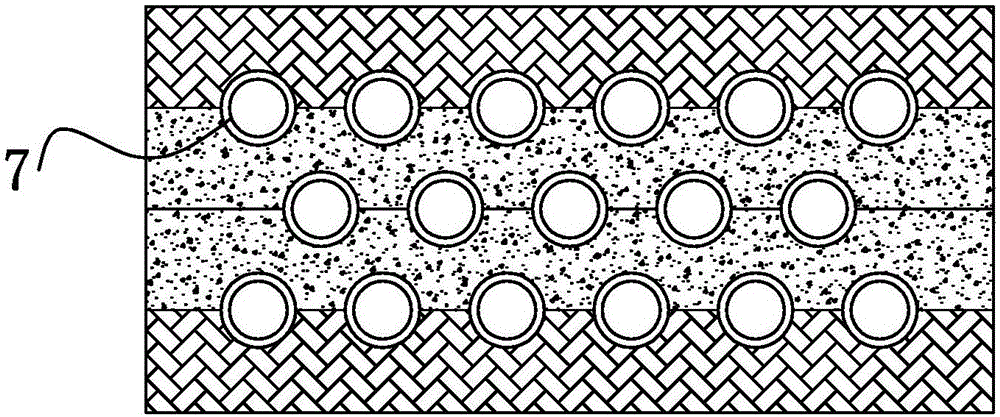

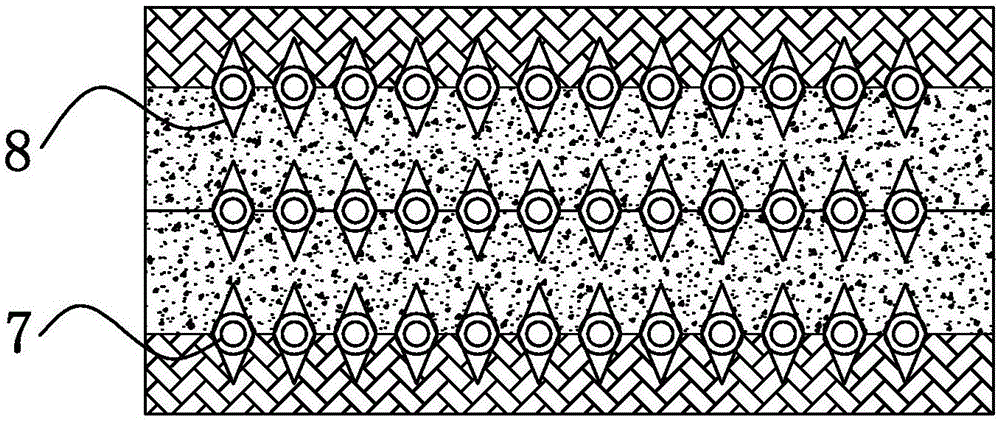

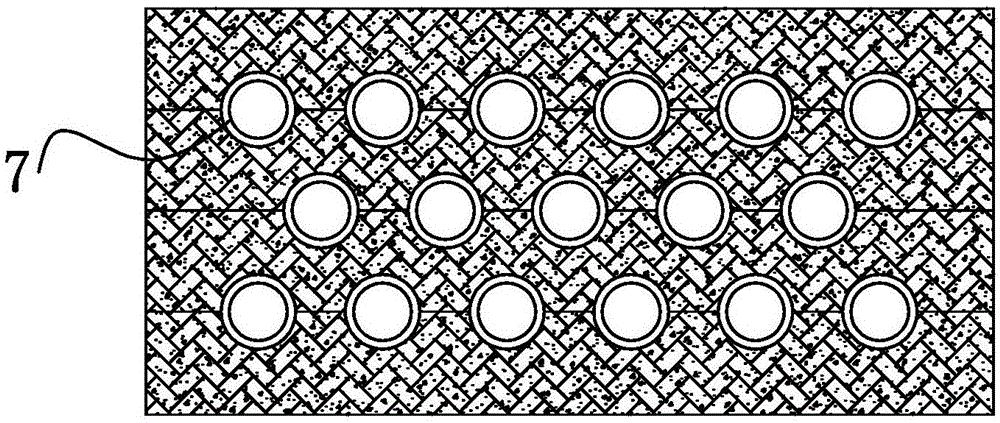

Manufacturing method of hollow microsphere wood plastic composite board

InactiveCN106696311AImprove sound insulationHas some characteristicsFlat articlesMaterials preparationMicrosphere

The invention discloses a hollow microsphere wood plastic composite board and a manufacturing method of the hollow microsphere wood plastic composite board. In order to achieve the aims of manufacturing of a high-strength sound suction heat isolation wood plastic composite board and solving the problem that a vacuum environment cannot be formed in the wood material, the manufacturing method of the hollow microsphere wood plastic composite board is provided. The method comprises steps of material preparation, raw material pretreatment, plastic sheet preparation, roller mixing, vacuum tube paving, slab layered paving, hot pressing and cold pressing and later-period machining. The method has the beneficial effects that the sealed vacuum environment is formed in the wood plastic composite board, and therefore the wood plastic composite board has the part of characteristics of a vacuum material, the temperature and sound isolation property of the wood plastic composite board can be improved, the manufactured hollow microsphere wood plastic composite board has the effects of low density, and temperature and sound isolation, the board has the low average density and high surface density, and it is ensured that the board is small in weight, high in strength and good in surface machining property.

Owner:BEIJING FORESTRY UNIVERSITY

High tensile strength steel wire

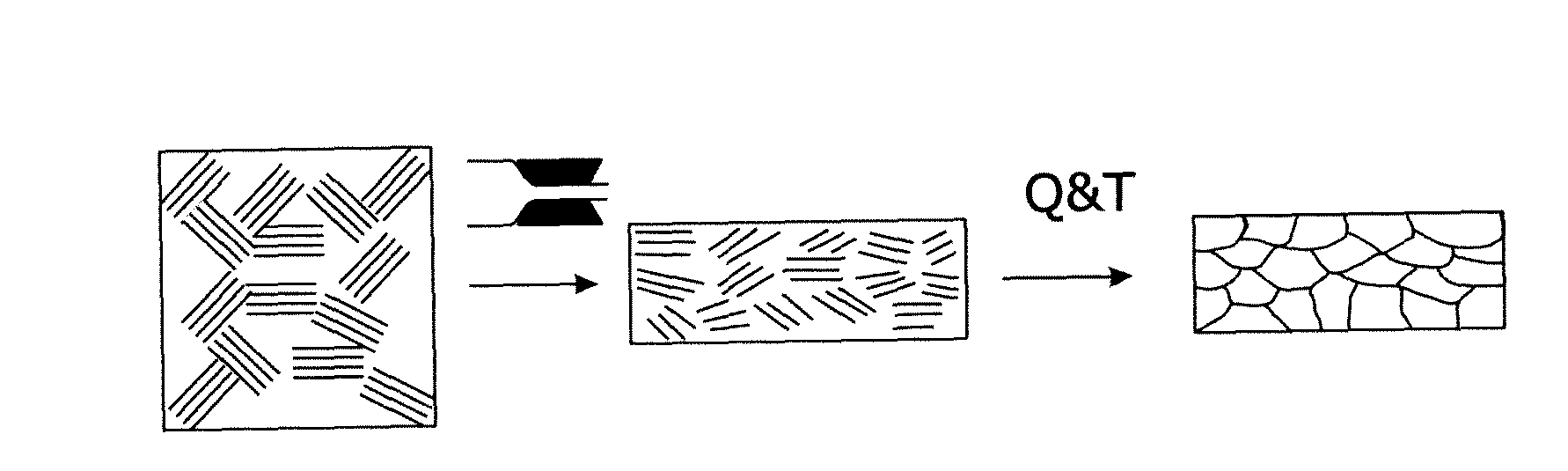

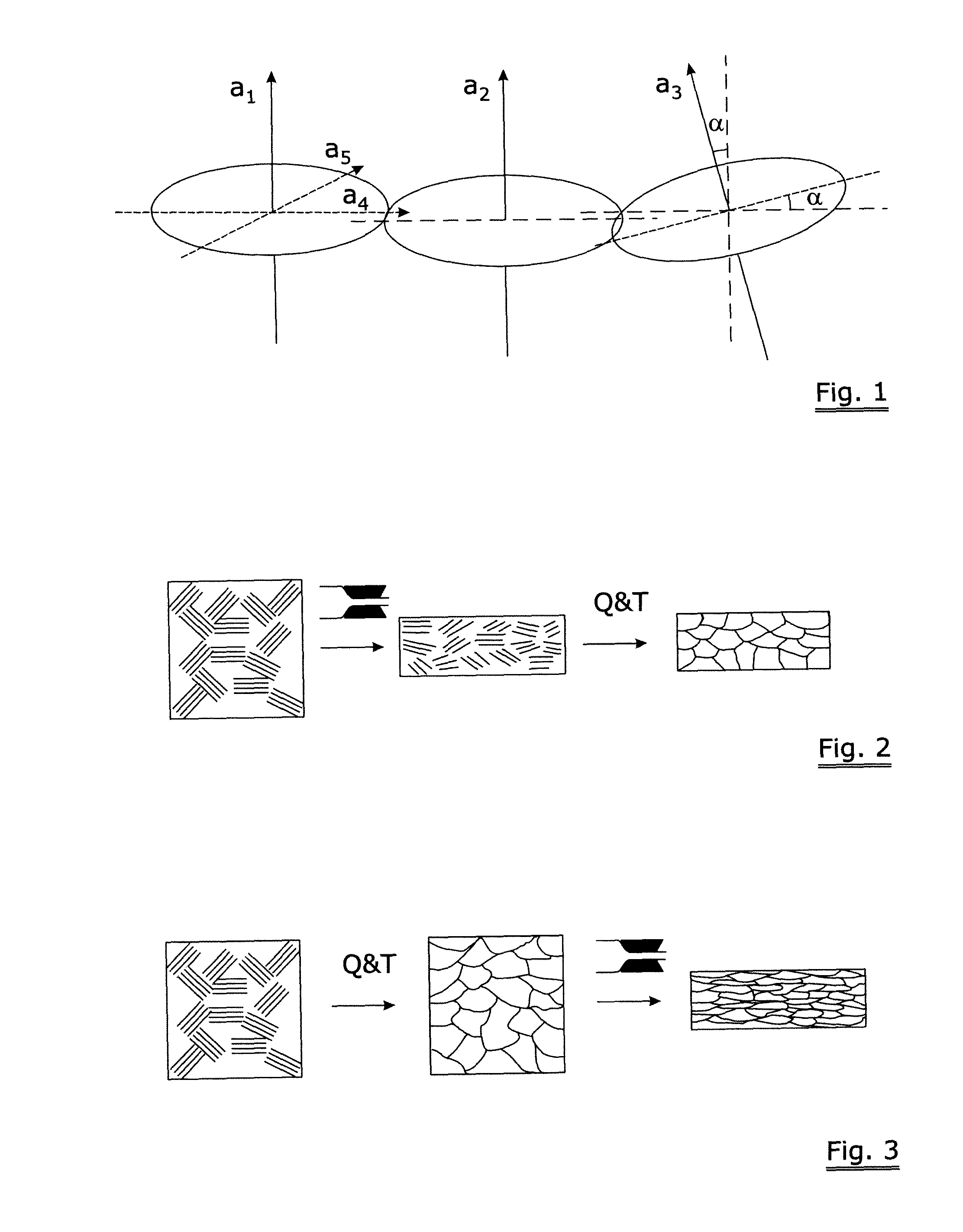

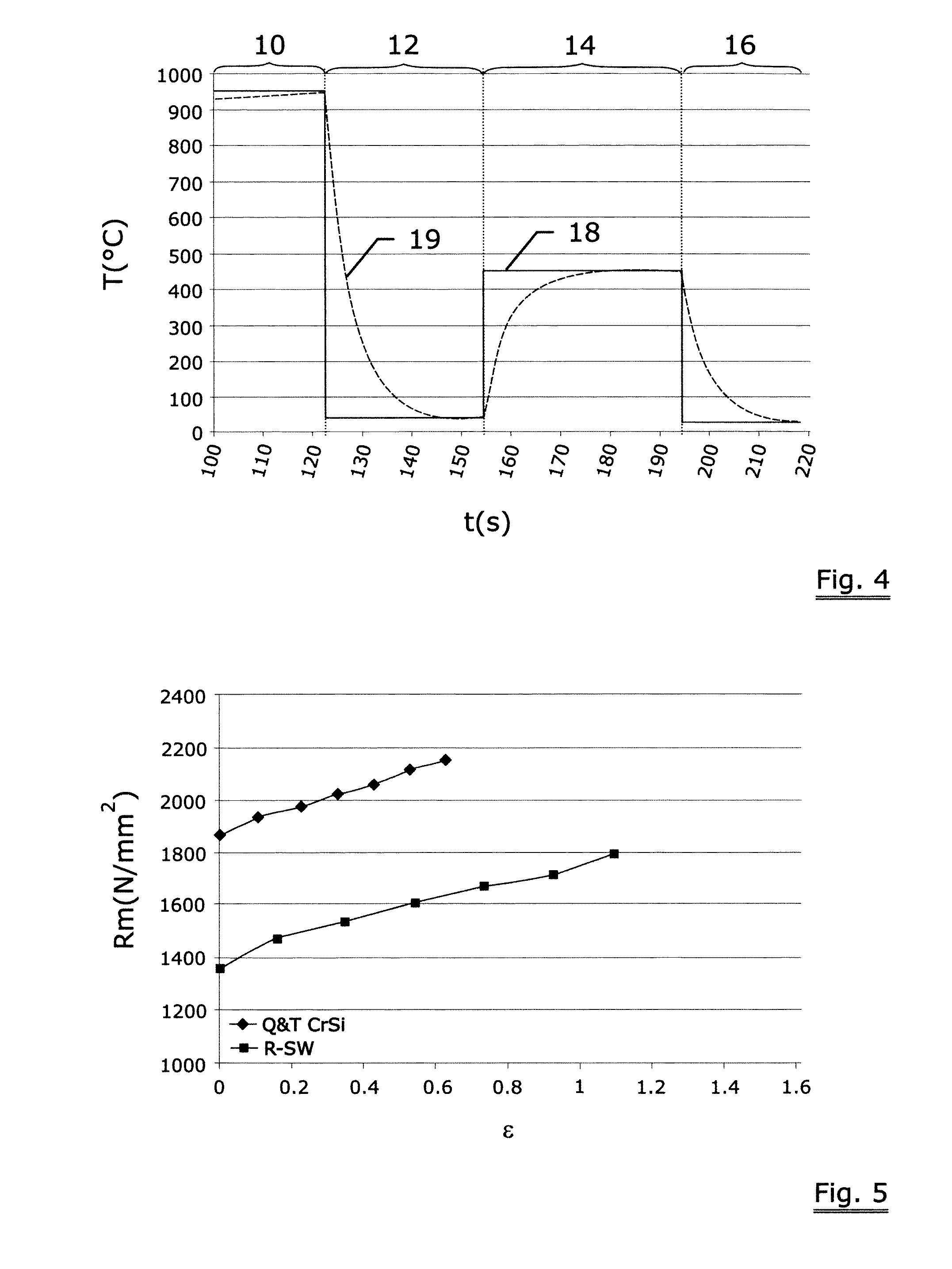

InactiveUS20160237518A1Improved mechanical propertyImprove surface finishFurnace typesHeat treatment furnacesVolume PercentageMartensite

A high tensile strength steel wire having as steel composition: a carbon content ranging from 0.20 weight percent to 1.00 weight percent, e.g. from 0.3 weight percent to 0.85 weight percent, e.g. from 0.4 weight percent to 0.7 weight percent, e.g. from 0.5 weight percent to 0.6 weight percent, a silicon content ranging from 0.05 weight percent to 2.0 weight percent, e.g. from 0.2 weight percent to 1.8 weight percent, e.g. from 1.2 weight percent to 1.6 weight percent, a manganese content ranging from 0.40 weight percent to 1.0 weight percent, e.g. from 0.5 weight percent to 0.9 weight percent, a chromium content ranging from 0.0 weight percent to 1.0 weight percent, e.g. from 0.5 weight percent to 0.8 weight percent, a sulfur and phosphor content being individually limited to 0.05 weight percent, e.g. limited to 0.025 weight percent, contents of nickel, vanadium, aluminum, copper or other micro-alloying elements all being individually limited to 0.5 weight percent, e.g. limited to 0.2 weight percent, e.g. limited to 0.08 weight percent, the remainder being iron, said steel wire having martensitic structure, wherein at least 10 volume percent of martensite are oriented.

Owner:NV BEKAERT SA

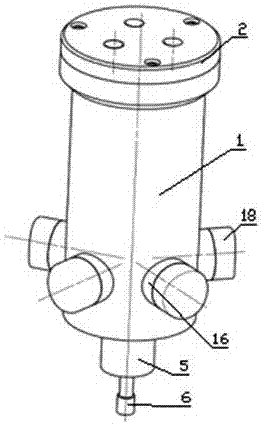

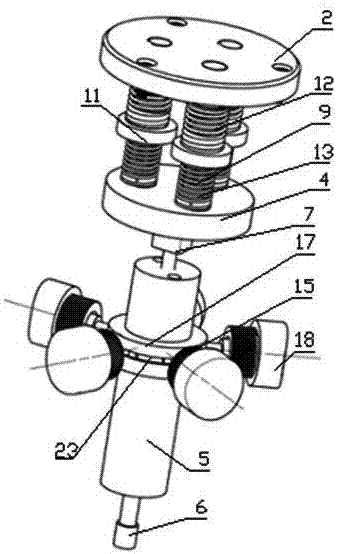

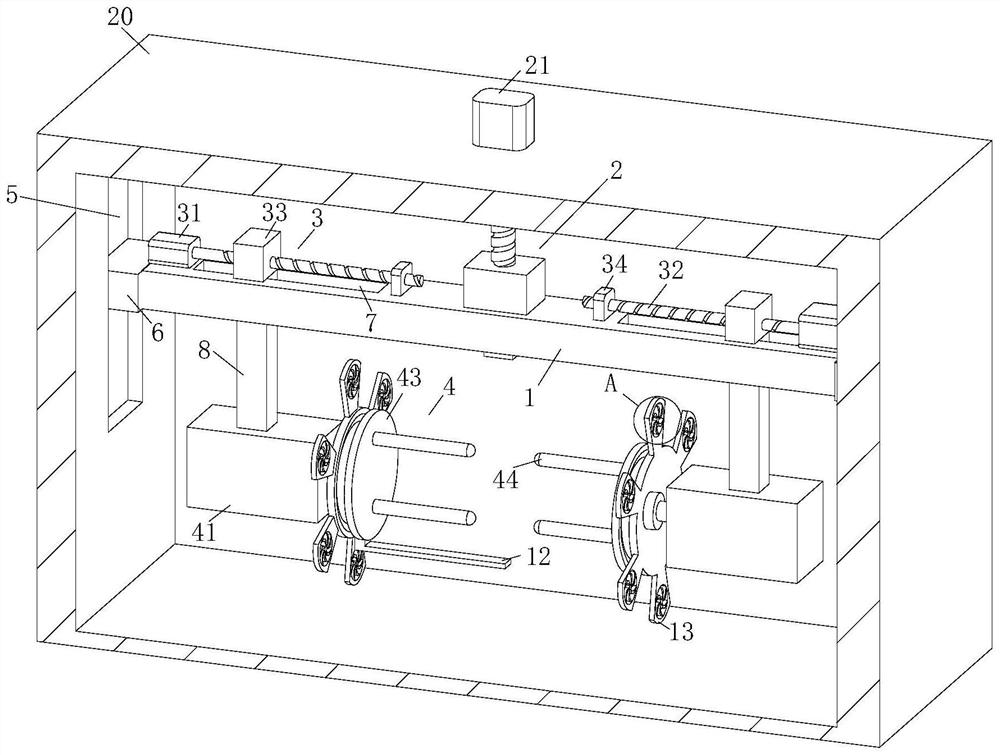

Floating type surface finishing system executer

The invention discloses a floating type surface finishing system executer, and belongs to the technical field of machining. The floating type surface finishing system executer comprises a cylindrical shell with the two ends opened. The upper end of the cylindrical shell is connected with an end cover, and the lower end of the cylindrical shell is connected with a dustproof cover. A buffering gland is arranged in the cylindrical shell in a sliding fit manner. The part, below the buffering gland, of the cylindrical shell is internally provided with a high-speed shaft. The lower end of the high-speed shaft downwards penetrates the dustproof cover and is connected with a tool bit clamp. A radial floating mechanism is arranged between the high-speed shaft and the cylindrical shell. A cavity above the buffering gland is internally provided with an axial floating mechanism. In the work process of the floating type surface finishing system executer, axial force exerted on the executer is transmitted into the inner axial floating mechanism, radial force is transmitted to the radial floating mechanism, a tool can conduct following machining on component burrs, and tool and component damage caused by component and positioning errors can be effectively avoided; and the work efficiency of workpiece surface polishing, mechanical deburring and the like and the surface quality are greatly improved.

Owner:南通理工智能制造技术有限公司 +2

Nano-calcium-carbonate-modified acrylate linear high-molecular polymer and preparation method thereof

The invention relates to a nano-calcium-carbonate-modified acrylate linear high-molecular polymer and a preparation method thereof. The invention belongs to the technical field of PVC processing auxiliary material. According to the invention, during a methyl methacrylate-butyl acrylate copolymerization process or a methyl methacrylate homopolymerization process, nano-calcium-carbonate is added, such that the acrylate polymer is prepared. The weight ratio of methyl methacrylate to butyl acrylate is 5-100:95-0. The amount of nano-calcium-carbonate is 0.1-20% of the total weight of the polymerization monomer. According to the invention, nano-calcium-carbonate is used for modifying the acrylate high-molecular polymer which is a processing type acrylate linear high-molecular polymer. The acrylate polymer has the advantages of low cost and good particle state fluidity. With the polymer, prepared PVC profile has high surface smoothness. The preparation method is simple and feasible, and is easy to implement.

Owner:SHANDONG SHITUO HIGH MOLECULAR WEIGHT MATERIAL

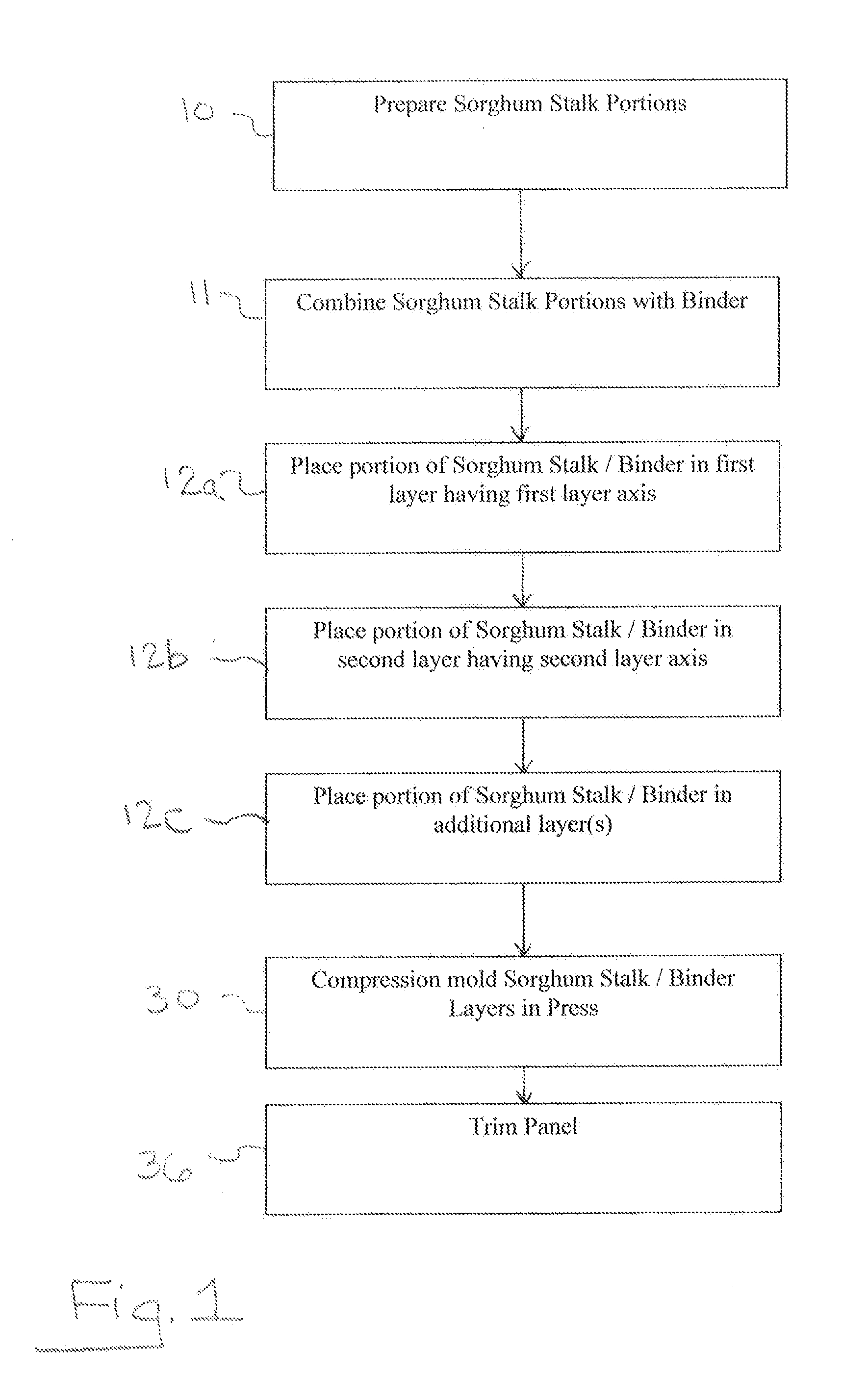

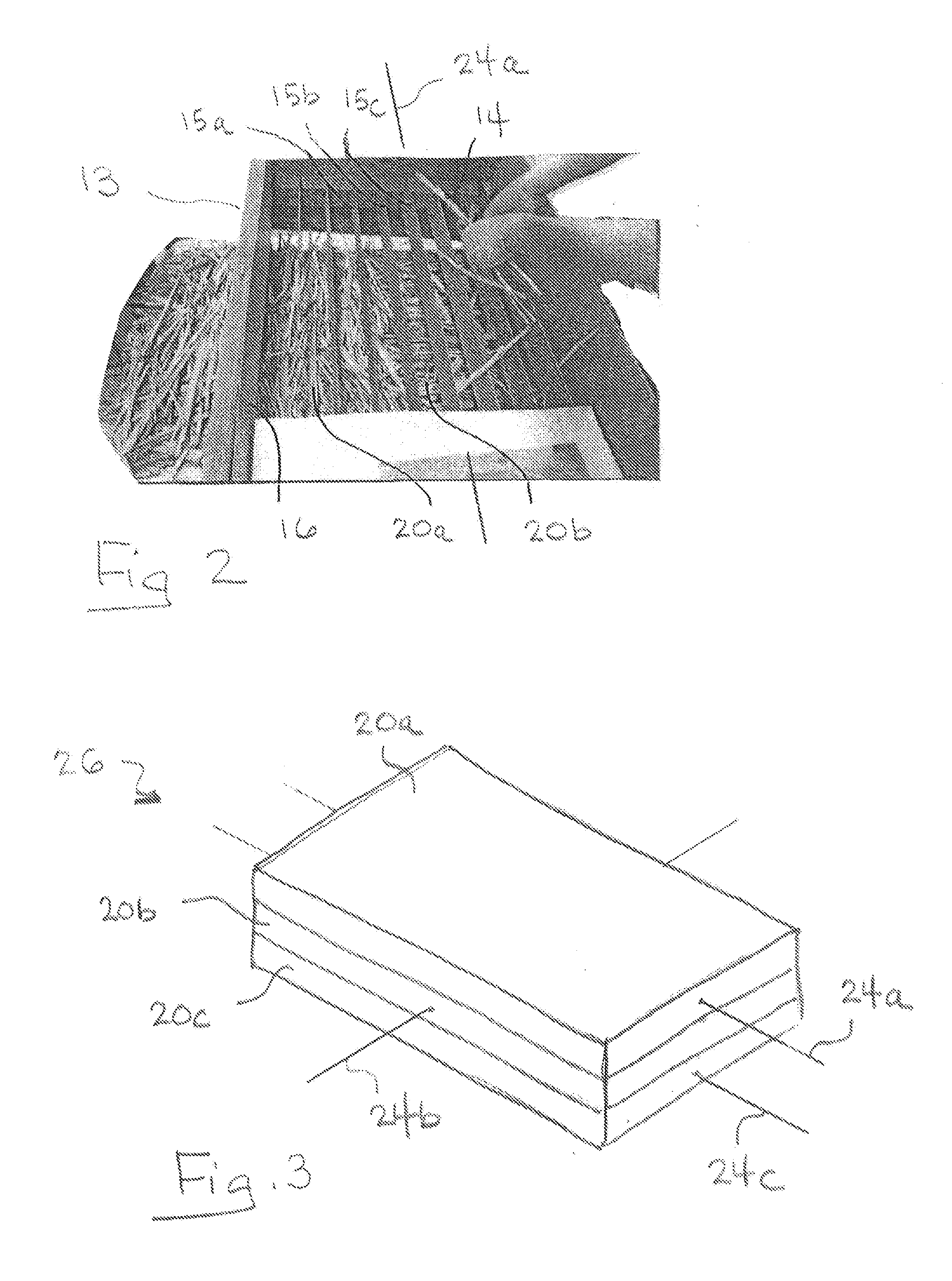

Oriented Sorghum Strand Boards made with Sorghum Stalks and Processes for Making Same

InactiveUS20130089699A1Improve surface finishReduce surface roughnessLaminationLamination apparatusFiberSorghum

A composite board having a sorghum stalk material component and a binder component is disclosed together with a corresponding method of manufacture. To prepare the composite board, the sorghum stalk material is harvested, dried and refined into fibers. The fibers are then combined with a binder such as a thermosetting resin. The resin coated fibers are then arranged into a stack having several layers. Within each layer, the resin coated fibers are aligned along a predetermined layer axis. Next, the stack is thermocompressed in a press at a preselected temperature to compress the resin coated fibers to a preselected board thickness.

Owner:WASHINGTON STATE UNIVERSITY +1

Application technology of novel release agent in centrifugal casting of cylinder liner

InactiveCN102039367AImprove mechanical propertiesImprove the lubrication effectFoundry mouldsMoulding machinesFerrosiliconGraphite

The invention relates to an application technology of a novel release agent in the centrifugal casting of a cylinder liner. The release agent has the following material tissue components in percentage by weight: 70-80% of 200-mesh artificial graphite powder, 3-5% of 200-mesh aluminide, 1-3% of 220-mesh ferrosilicon powder, 4-8% of 200-mesh quartz powder and 2-4% of 75 Si powder.

Owner:韦加伟

Light wall material produced on site

ActiveCN102161581AHigh strengthImprove surface finishSolid waste managementExpanded clay aggregateUltimate tensile strength

The invention provides a light wall material produced on site, belonging to a building material. The wall material is prepared from fly ash, cement, ceramic particles, ceramic sand, oxalic acid and water in proportions. The wall material can be poured on site to form a wall through one-step molding; and the formed wall has high strength and surface smoothness, does not have joints, seams and cracks, is difficult to deform and has good connecting and fixing effects with a main body of a frame. The wall is light; enamel-scratching and puttying processes can be directly performed on the outer surface of the wall; and gate and window components, power lines, tube boxes and the like can be directly casted on the wall firmly, and labor can be saved.

Owner:李子现

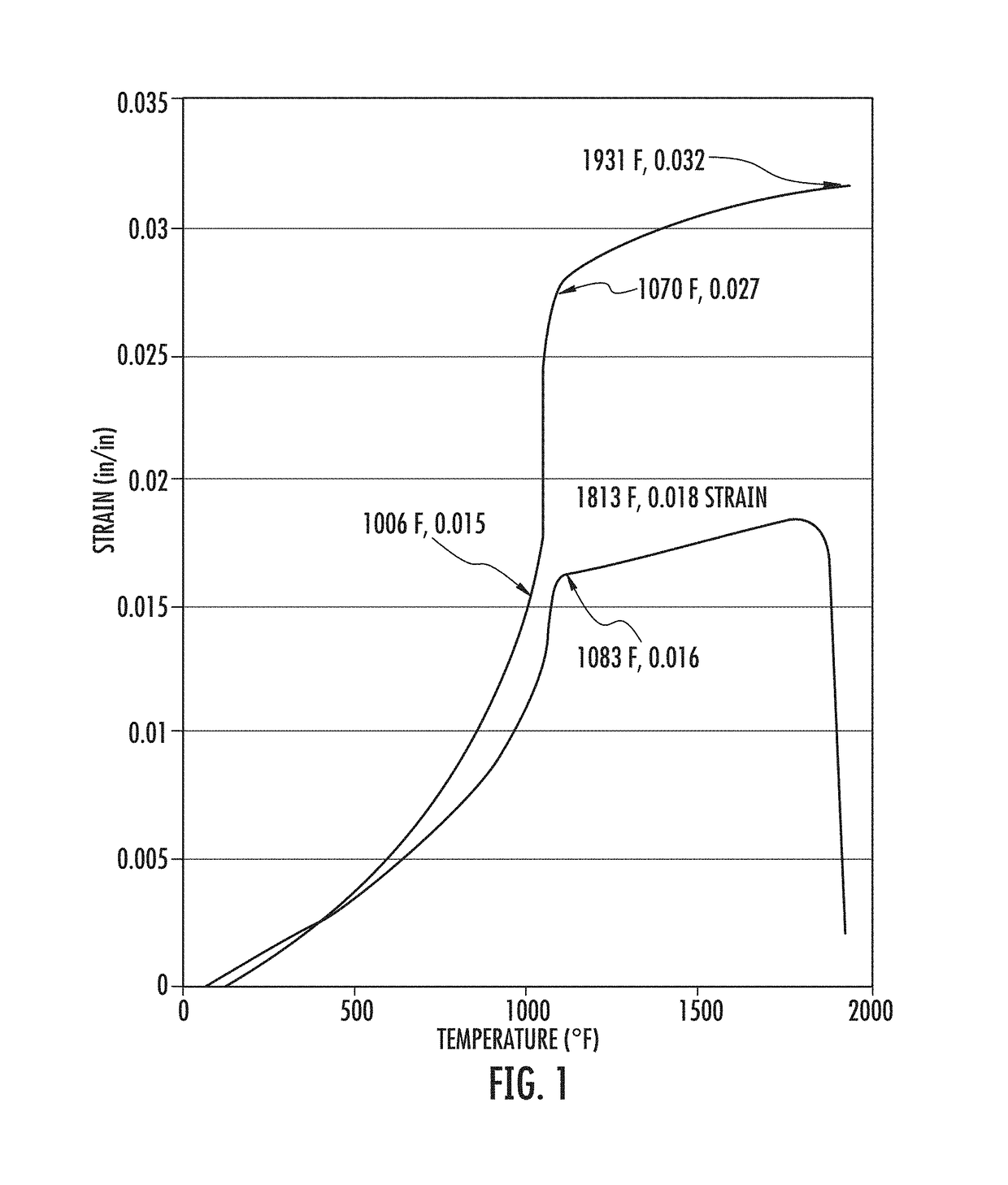

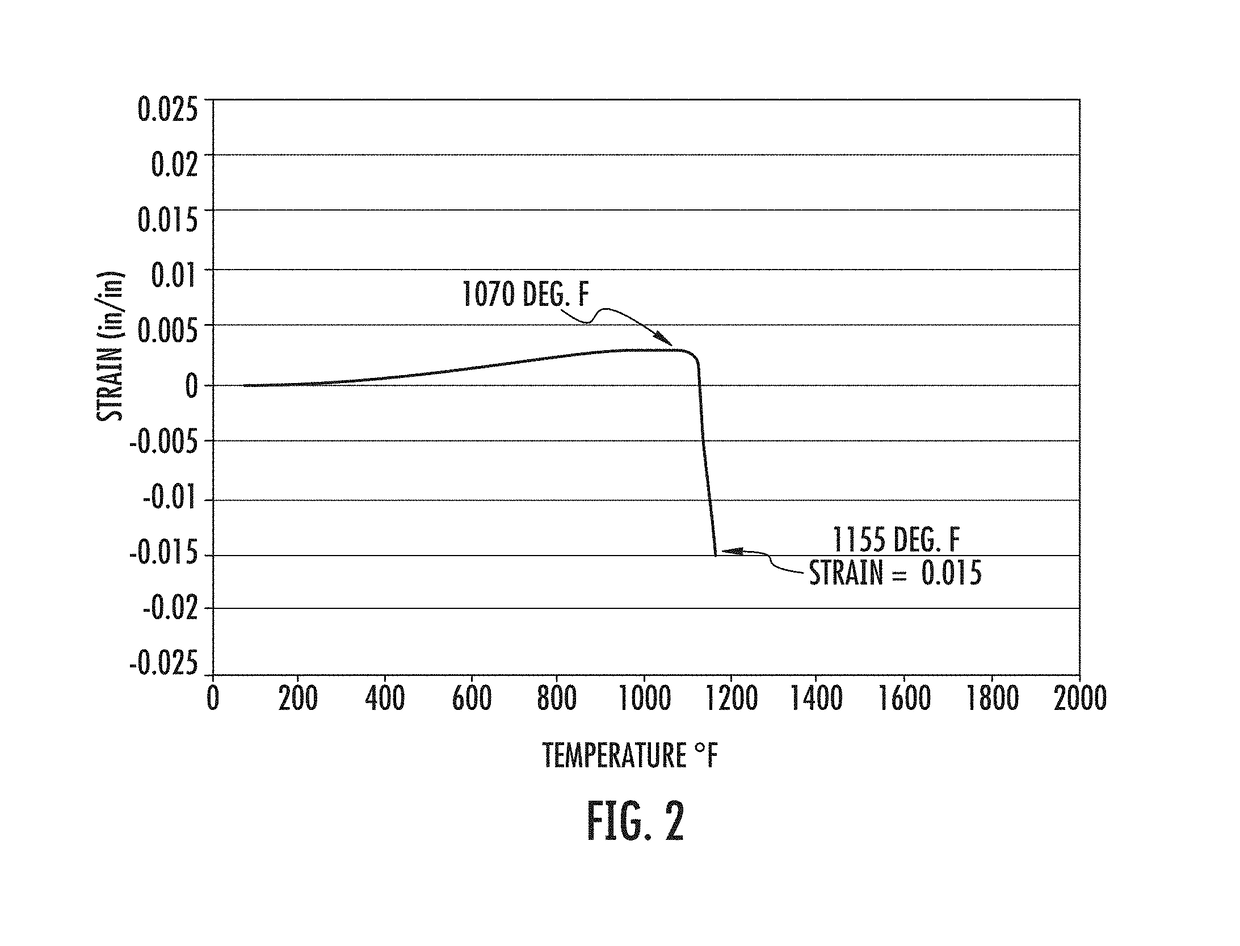

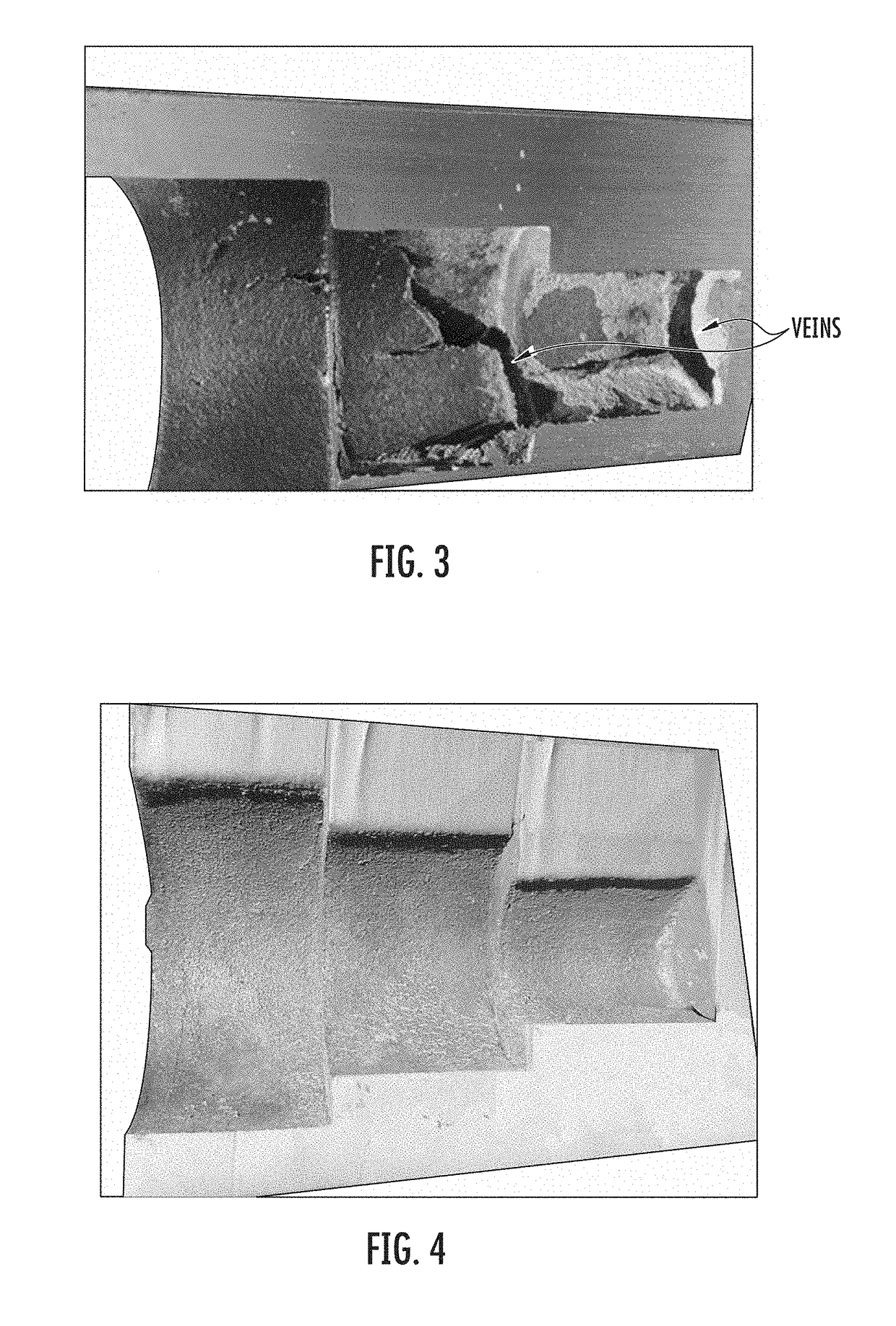

Anti-Veining Additive for Silica Sand Mold

InactiveUS20180056373A1Improve surface finishHigh surface finishFoundry mouldsFoundry coresMechanical forceFire retardant

This invention relates generally to a composition for silica sand cores and molds suitable for in the casting of metals. The sand core composition contains a hinder and a uniformly dispersed anti-veining additive. The mixed metal oxides collapse into a visco-plastic state when the foundry mold / core is heated by the molten metal during casting. A change in state of the MMOx from solid to a visco-plastic at the casting high temperatures provides space and lubricity within the foundry shape sufficient to compensate for the thermally-induced physical expansion of the silica grains. Thereby avoiding the mechanical forces which cause cracks and fissures in the mold or core that produce veins and other surface imperfections associated with the high coefficient of thermal expansion of silica sand.

Owner:BATES CHARLES EARL

Manufacturing technology of fireproof medium density fiberboard

InactiveCN110126056AWith fire performanceLow costWood working apparatusFlat articlesEpoxyManufacturing technology

The invention discloses a manufacturing technology of a fireproof medium density fiberboard. The technology comprises the following steps: S1, preprocessing raw materials; S2, forming the medium density fiberboard; S3, filling seams surrounding the medium density fiberboard with epoxy resin; S4, coating an upper surface layer of the medium density fiberboard obtained in step S3 with a magnesium oxide gel material; S5, coating a lower surface layer of the medium density fiberboard obtained in step S4 with a magnesium chloride gel material; S6, curing; and S7, adhering waterproof fireproof paperon the upper and lower surfaces of the medium density fiberboard obtained in step S6 through a cold pressing machine; filling seams surrounding the medium density fiberboard with the epoxy resin so as to lock water in the medium density fiberboard as well as avoid cracks and bubbles. According to the technology, the upper surface and the lower surface of the medium density fiberboard are correspondingly coated with magnesium oxide gel and magnesium chloride gel, and the waterproof fireproof paper is adhered, so that the medium density fiberboard is fireproof, reasonable and simple in preparation process, low in cost, high in surface processing performance, and suitable for industrial production.

Owner:李珂

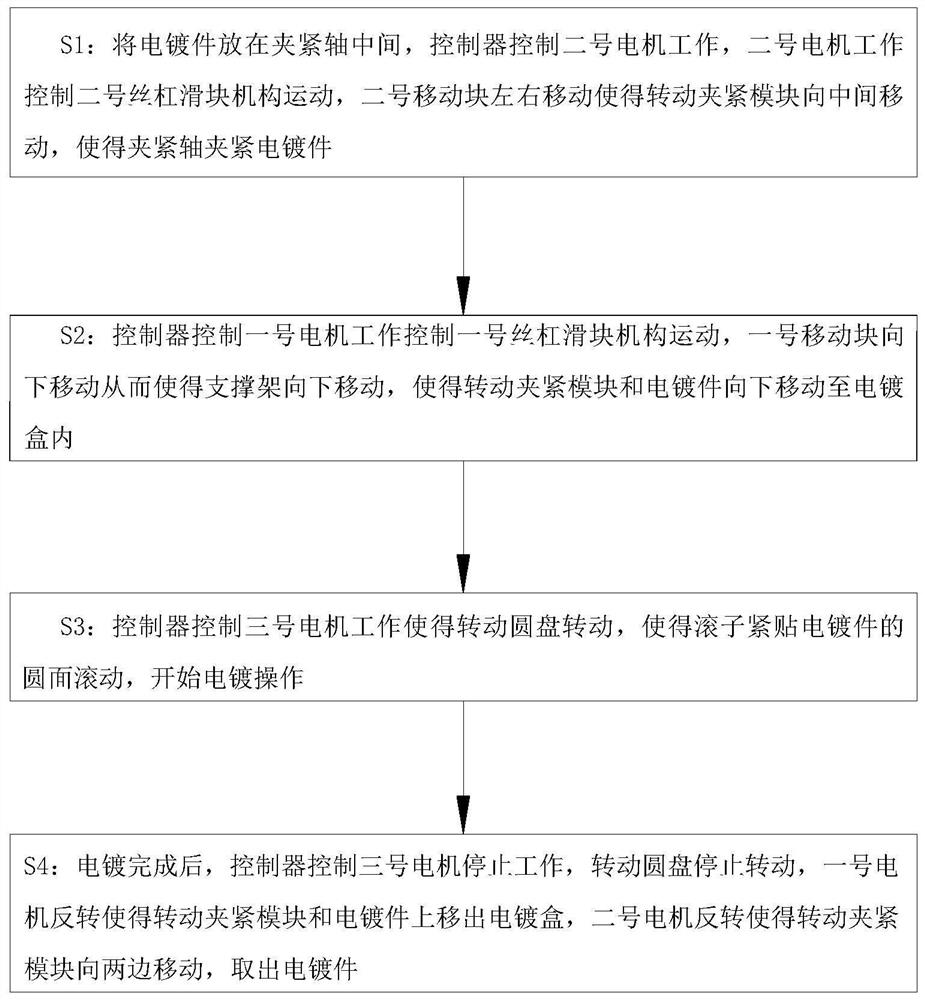

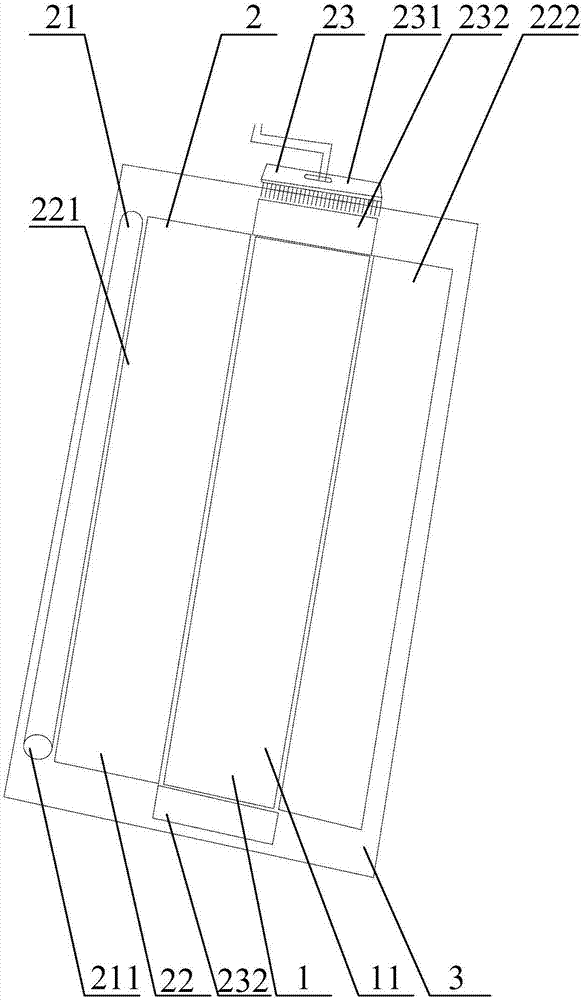

Electroplating machine and electroplating method thereof

The invention belongs to the technical field of electroplating, and particularly relates to an electroplating machine and an electroplating method. The electroplating machine comprises a supporting frame, a first lead screw sliding block mechanism, second lead screw sliding block mechanisms, a controller, a rotary clamping module and an electroplating box, wherein the first lead screw sliding block mechanism comprises a first motor, a first lead screw, a first moving block and a stop block, the stop block is fixedly connected to the lower end of the first lead screw, the first moving block is fixedly connected to the upper end face of the middle of the supporting frame, sliding grooves are formed in the left side wall and the right side wall of the inner side of the electroplating box correspondingly, the left end and the right end of the supporting frame are fixedly connected with limiting sliding blocks, the limiting sliding blocks are in sliding connection with the sliding grooves, and the two second lead screw sliding block mechanisms are arranged. According to the electroplating machine, the controller is used for controlling a third motor to work, so that a rotating disc can rotate, rollers can roll close to the circular face of an electroplated piece, the position of the clamping contact part of the electroplated piece can be changed all the time, the clamping part can also be electroplated, secondary electroplating is not needed during electroplating, and time and labor are saved.

Owner:王兆诚

A casting dewaxing device and its dewaxing process

ActiveCN113134572BEasy to collectImprove recycling ratesFoundry mouldsFoundry coresThermodynamicsWater storage tank

The invention relates to the field of metal processing, in particular to a casting dewaxing device and a dewaxing process thereof, comprising a dewaxing kettle, wherein the dewaxing kettle comprises a steam chamber located above and a water storage tank located below, between which passes A collection pipe is connected to each other, a set table for placing the wax mold of the casting is arranged inside the steam chamber, a water lead pipe is extended outward from the bottom of the reservoir, and the water lead pipe is connected to a steam boiler outside the dewaxing kettle. The output port of the boiler is connected with a steam pipe. The steam pipe passes through the dewaxing kettle and enters the interior of the steam chamber and is provided with a steam output head at its end. A wax collecting pipe is arranged at the center of the bottom of the reservoir. The pipe extends upwards to the inside of the collection pipe, and the upper end of the wax collection pipe is provided with a wax-inducing end. The invention can dewax the wax mold and greatly improve the recycling rate of the wax liquid.

Owner:台州东亚精铸科技有限公司

Cuboid-shaped 3D printing equipment and 3D printer

ActiveCN107008903AImprove levelnessImprove compactnessAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingControl system

The invention relates to the technical field of selective laser melting metal 3D printing, in particular to cuboid-shaped 3D printing equipment and a 3D printer. The cuboid-shaped 3D printing equipment comprises construction-forming device and a powder supplying system. A powder laying device is used for laying metal powder in a powder feeding device on an operation platform in a rolling-type powder laying mode. A powder flattening piece driving mechanism is connected with a powder flattening piece and used for driving the powder flattening piece to move on the operation platform in a reciprocating mode so as to flatten the metal powder on the operation platform. The powder flattening piece driving mechanism is electrically connected with a control system of the 3D printer. The power laying device lays the metal powder on the operation platform in a rolling-type mode, the powder flattening device flattens the metal powder on the operation platform, and accordingly the flatness of a metal powder layer on the operation platform is improved, the density and surface smooth finish of a component can be improved effectively, and the machining condition of a large-size cuboid-shaped component with the forming length being larger than or equal to 3 m is met.

Owner:窦鹤鸿

Lamination type granite substrate heavy-calibre optical reflector

InactiveCN102323631ASmall expansion coefficientEasy accessMirrorsMountingsOptical reflectionManufacturing cost reduction

The invention discloses a lamination type granite substrate heavy-calibre optical reflector which comprises an optical reflection mirror body, wherein the optical reflection mirror body is made of granite with low expansion coefficient. Because a plane reflection mirror body, a spherical surface collimating reflection mirror and a non-spherical surface collimating reflection mirror are made of the granite, and the granite has lower expansion coefficient, mechanical stability close to that of optical glass, better surface processing property and higher surface precision, and can be produced by adopting a processing device and a processing technology of the optical glass, and large-size granite is easy to obtain, thus manufacture cost of the lamination type granite substrate heavy-calibre optical reflector can be greatly reduced.

Owner:SUNCORE PHOTOVOLTAIC TECH +1

Rapid drying device for chemical fiber fabric and processing method thereof

InactiveCN109341297AQuality improvementHigh degree of mechanizationDrying gas arrangementsDrying machines with progressive movementsFiberWrinkle skin

The invention relates to the technical field for producing a chemical fiber fabric and discloses a rapid drying device for the chemical fiber fabric and a processing method; the device comprises a drying machine and a levelling machine; triple drying is obtained through a level-I drying room, a level-II drying room and a level-III drying room so as to quicken the drying efficiency; during a dryingprocess, a part of moisture is evaporated by the high temperature; a part of moisture is absorbed by a moisture guide screen cloth during the process of conveying the chemical fiber fabric; excessivemoisture residue can be avoided in the fabric; the drying degree is improved; the fabric finally dried stops slightly in a vacant area below the level-III drying room; after cooling naturally, the fabric enters the levelling machine from a discharging opening A; the fabric is fixed by a lower plain roller; when driven by a negative pressure piston cylinder, an upper plain roller moves in a reciprocating manner up and down so as to remove wrinkle and level the surface of the dried chemical fiber fabric, increase the surface bright and clean degree of the chemical fiber fabric product and improve the quality of the chemical fiber fabric; the setting of a display screen realizes the controllable and displayable levelling process; the operation difficulty is reduced; and the degree of mechanization of a production workshop is improved.

Owner:马鞍山市永运家纺有限公司

A circular blade and cutting tool with accurate positioning structure

ActiveCN107498610BEasy to installImprove clamping rigidityMetal working apparatusTurning toolsStructural engineeringKnife blades

The invention discloses a circular blade and a cutting tool with an accurate positioning structure. The circular blade includes a circular plate-shaped blade body composed of an upper surface, a lower surface and a side surface connecting the upper surface and the lower surface. The blade body There is a central hole penetrating the upper surface and the lower surface. The blade body is symmetrical about the central axis of the central hole. The upper surface intersects with the side surface to form a cutting edge. The inner surface of the central hole is provided with at least two protrusions. , the angle between two adjacent protrusions is less than 180°. The cutting insert has the characteristics of reliable and stable positioning, multiple clamping capabilities and long service life. The cutting tool has the above-mentioned circular blade, which can eliminate the sliding or rotation of the circular blade in the circumferential direction during use, ensure the stability of the cutting area participating in the cutting edge, prevent other cutting from participating in cutting, effectively stabilize the circular blade on the cutting tool, and increase the number of times the circular blade can be used. improve the life of cutting tools.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com