Manufacturing method of heat and sound insulation particle board

A technology of heat insulation and sound insulation and manufacturing method, which is applied in the direction of manufacturing tools, flat products, pretreatment of molding materials, etc., to achieve the effect of improving heat insulation and sound insulation performance and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

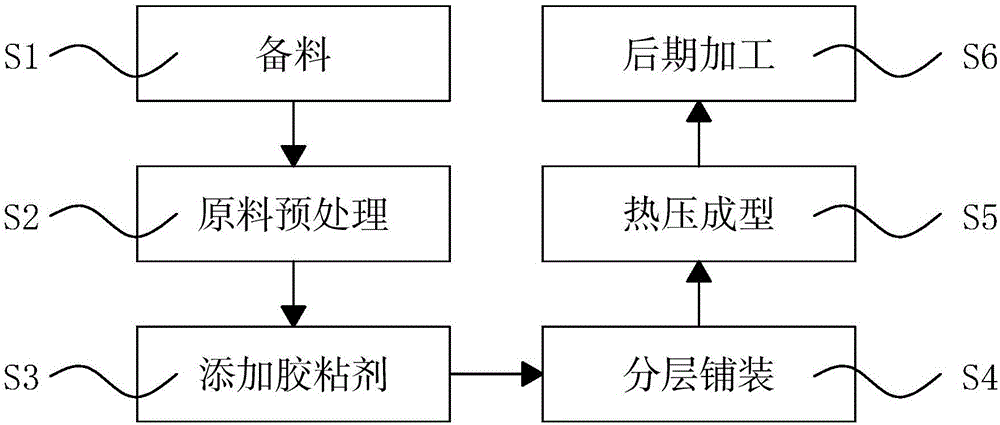

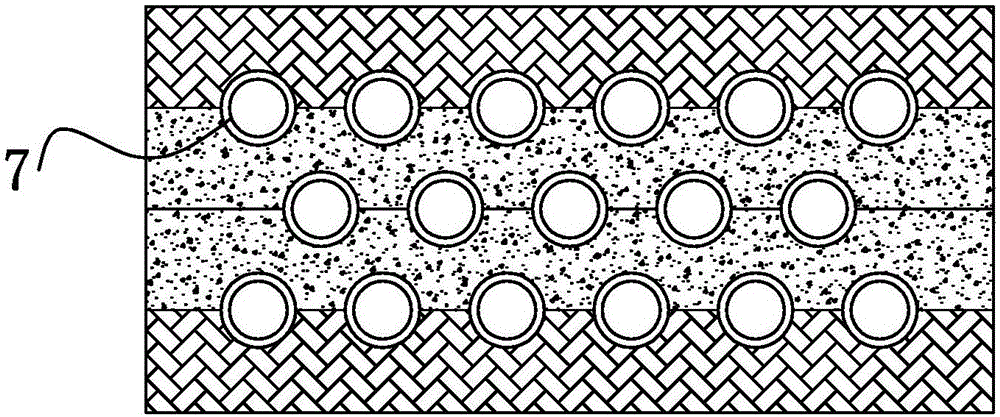

[0033] Specific Embodiment 1: Combining figure 1 Describe this embodiment, a method for manufacturing a heat-insulating and sound-insulating particleboard in this embodiment, including: S1 material preparation, S2 raw material pretreatment, S3 adding adhesive, S4 layered paving, S5 hot-press forming and S6 post-processing steps , specifically: the S1 material preparation step refers to processing wood or straw through one or more of planing, chipping, rolling, sawing and screening to obtain woody raw materials; S2 raw material pretreatment refers to controlling the moisture content of wood raw materials by controlling temperature and humidity equipment; S3 adding adhesive refers to applying liquid adhesive on the pretreated wood raw materials by spraying method; S4 layered paving refers to adding the added The wooden raw material of the adhesive is divided into multiple parts, one of which is evenly paved in the mould, and then the vacuum tube 7 prepared in advance is directio...

specific Embodiment approach 2

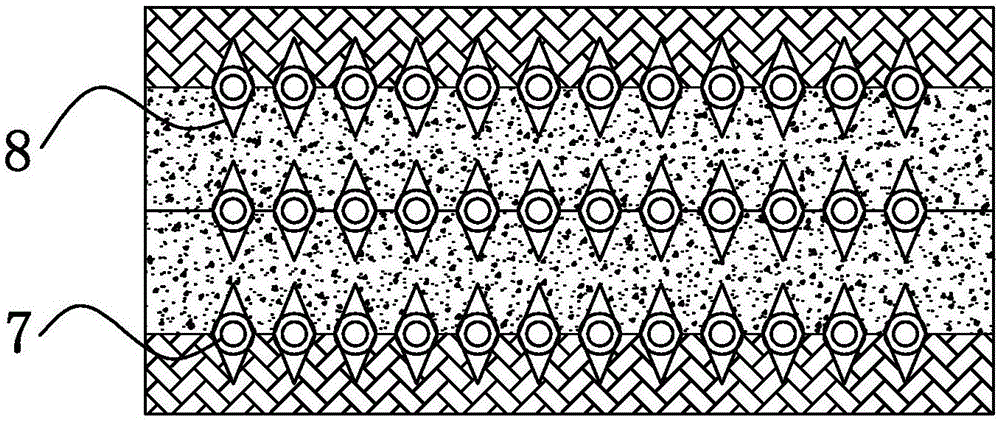

[0035] Specific Embodiment 2: Combining figure 1 and figure 2 Describe this embodiment, the manufacturing method of heat-insulating and sound-insulating particleboard described in this embodiment, the step of directional paving vacuum tube 7 and the step of paving wooden raw materials with adhesive added in step S4 when paving slabs layer by layer Alternately for many times, the vacuum pipe 7 is paved with multiple layers; in the layered paving process, the first layer and the last layer are paved with wooden raw materials with adhesive added; the others are the same as in the specific embodiment 1.

[0036] The technical effect of this embodiment is: due to the adoption of the method, the vacuum tubes can be arranged in multiple layers so that the particle board board can better achieve a low average density and a high surface density, further ensuring the light weight, high strength and good surface processing of the board. Performance; In addition, it is also conducive to...

specific Embodiment approach 3

[0037] Embodiment 3: Combining figure 1 and figure 2 Describe this embodiment, the manufacturing method of heat-insulating and sound-insulating particleboard described in this embodiment, the moisture content of the wood raw material in step S2 is controlled at 10%~15%; the hot pressing equipment described in step S5 is a high-frequency heating Pressure equipment; Others are identical with specific embodiment 1 or 2.

[0038] The technical effect of this embodiment is: controlling the moisture content of the wood raw material and making the wood raw material have a higher moisture content is a method rarely used in the wood processing industry, because the conventional increase of the moisture content will make the performance of the board unstable and unfavorable. The forming of the board generally controls the moisture content of the woody raw material below 5% when the particle board is manufactured, but in the present invention, the moisture content of the board is 10% t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com