Lightweight framework and construction method for manufacturing partition board by using lightweight framework

A skeleton and lightweight technology, applied in building components, structural elements, buildings, etc., can solve problems affecting the quality of walls, achieve the effect of light overall weight, eliminate cracking and cracking problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described below with reference to the separate embodiments.

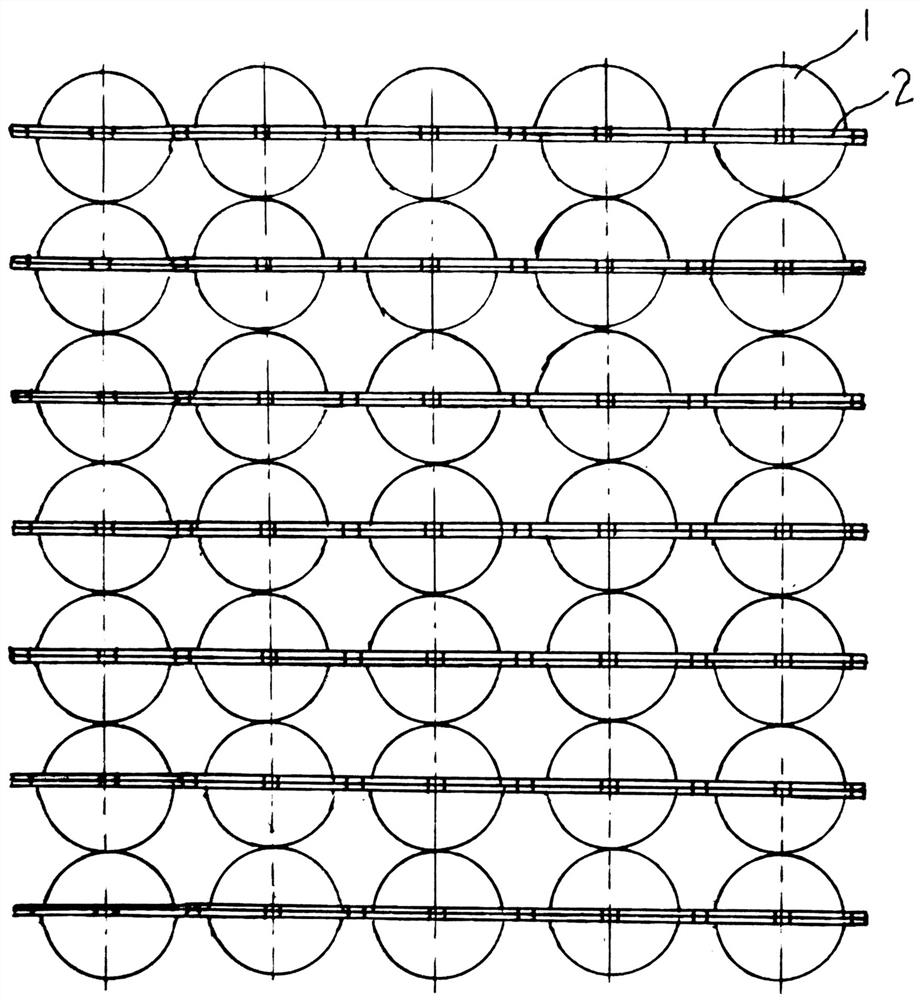

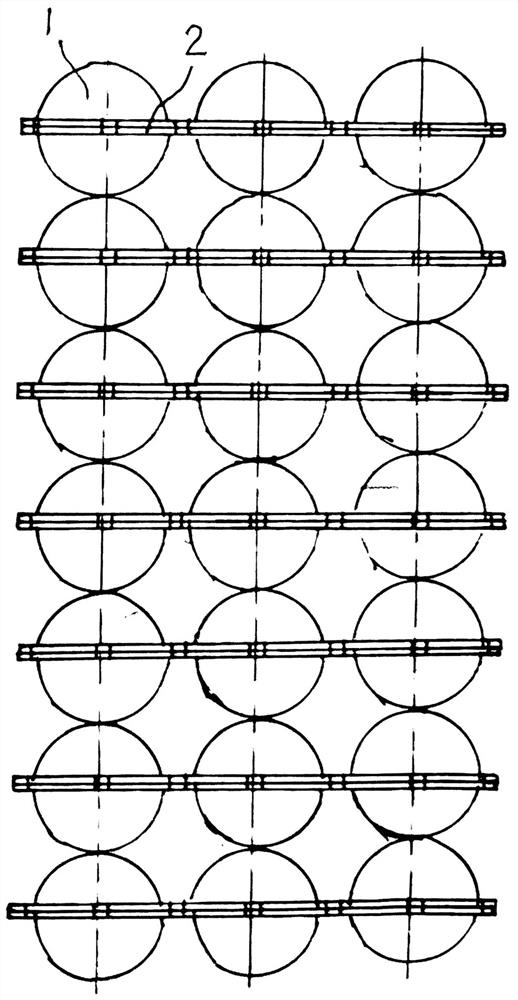

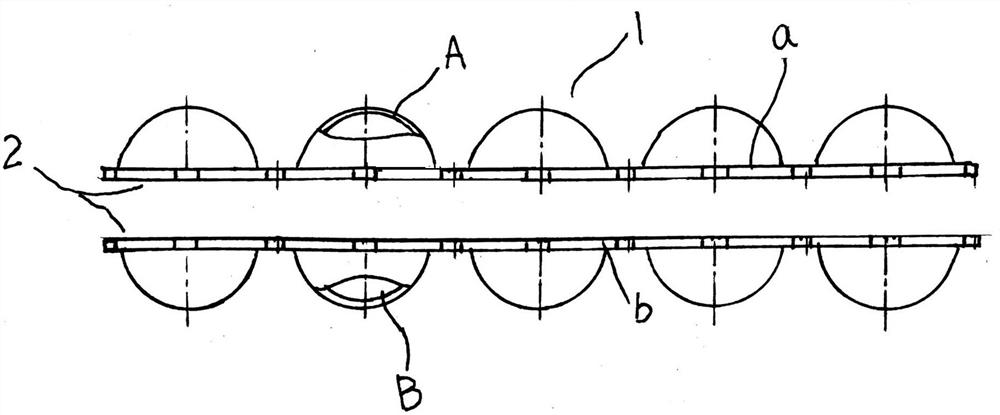

[0027] See Figure 1 to Figure 5 A light-weight skeleton as shown includes an integral skeleton with width, thickness and height composed of multiple layers, three rows of hollow spheres 1 and connecting ribs 2. Each layer, each row of hollow spheres 1 and connecting ribs 2 are between each other. Filler channels are formed for injection of the cured filler. In this embodiment, the overall skeleton is formed by stacking and combining a plurality of hollow spheres 1 and connecting ribs 2 combined skeleton units. Each hollow sphere 1 and connecting rib 2 combined skeleton unit includes a first semicircular hollow sphere A, a first connecting rib a, a second semicircular hollow sphere B, and a second connecting rib b distributed on the same plane with rows and columns. Body structure combination unit. In this embodiment, the first semicircular hollow spheres A and the second semi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com