Light sound-insulation building roof

A sound insulation and construction technology, applied in the direction of construction, building components, building structure, etc., can solve the problems of steel buildings and roof documents that have not been seen in light-weight sound insulation industrialized buildings, so as to improve the degree of civilization and good quality. , the effect of fast installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

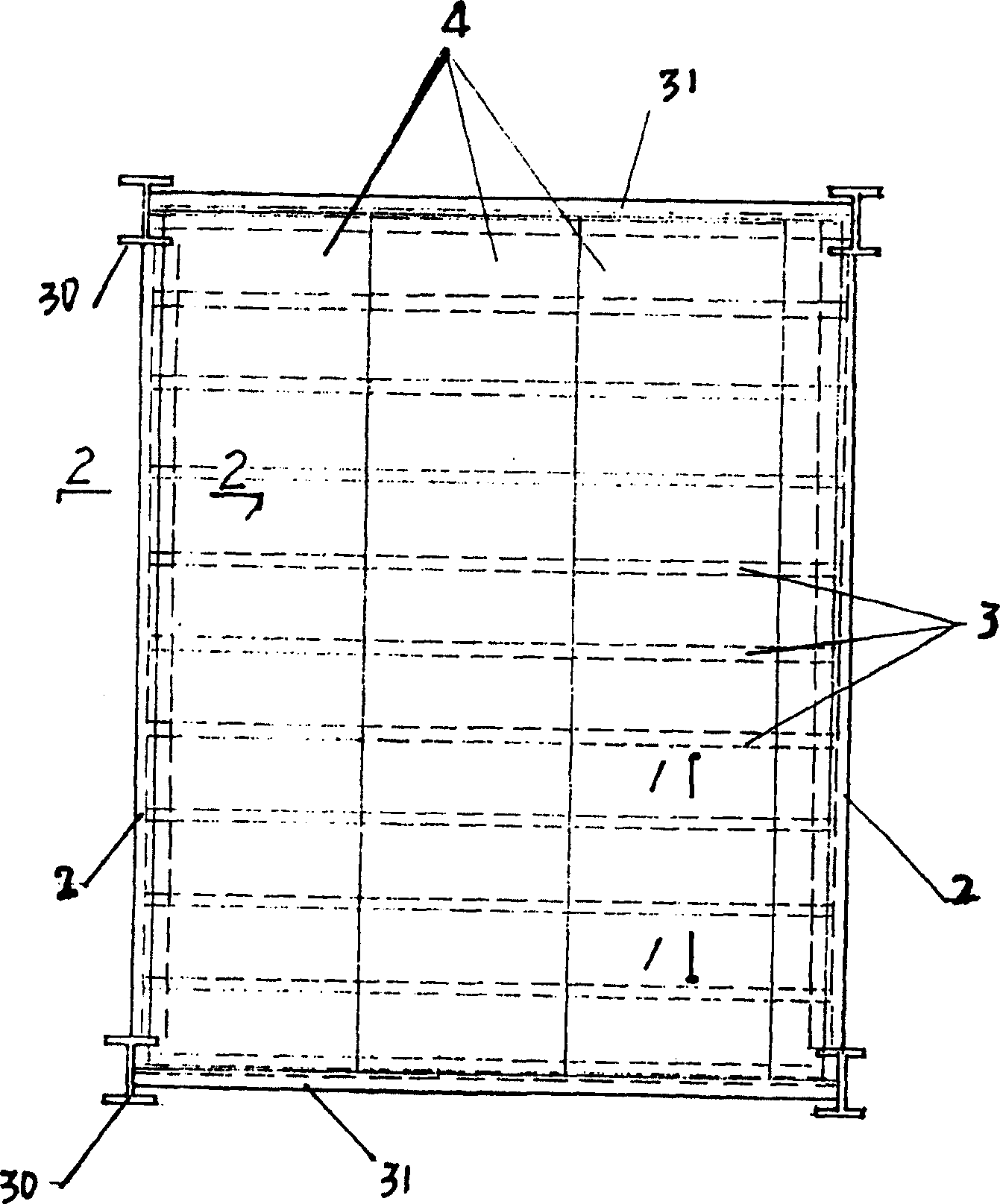

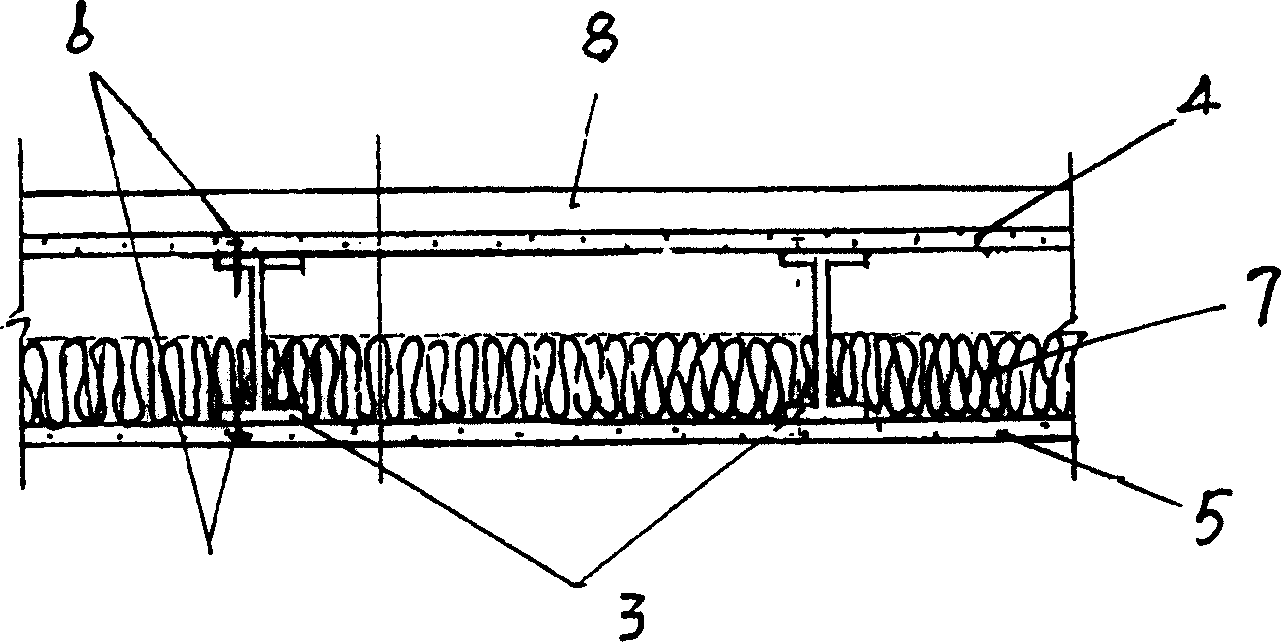

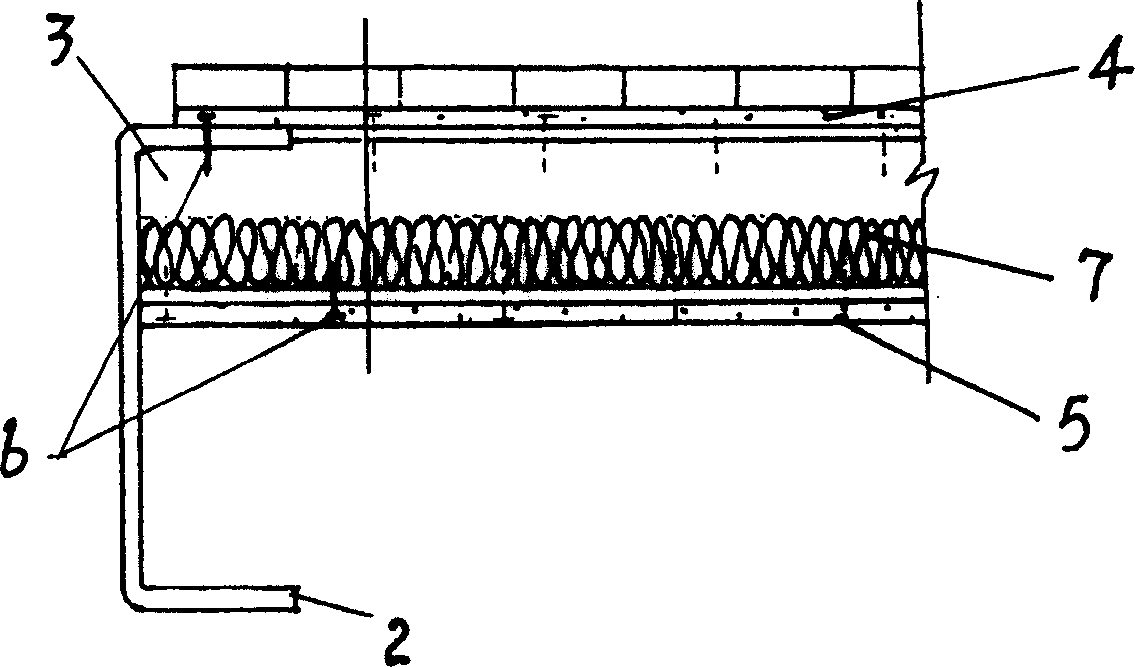

[0014] Such as figure 1 As shown, the floor is taken as a unit, the main beam 1 of the floor is connected with the steel column 30, the front and rear of the floor are connected with steel beams 31, and the steel beam 31 is connected with the steel column 30. The specific structure of the floor is as follows.

[0015] The floor includes two main beams 2 made of channel steel or H-shaped steel. In this embodiment, channel steel is used. The two parallel main beams are connected and distributed at intervals. The material is a secondary beam 3 of profiled steel. The secondary beam 3 can be H-shaped steel or channel steel or keel steel is adopted. In this embodiment, H-shaped steel is used as the load-bearing structure of the floor with hot-rolled light H-shaped steel. The spacing of the secondary beams is determined by the calculation of the thickness, mechanical strength and load of the base plate on the bottom surface. In this embodiment, the 8mm thick plate is used in residen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com