Patents

Literature

42results about How to "With fire insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light heat preservation silicon and calcium compound plate

InactiveCN102888900APromote environmental protectionNo side effectsCeramic shaping apparatusHeat proofingEnvironmental resistanceSide effect

The invention discloses a light heat preservation silicon and calcium compound plate, which consists of an outer layer structure and an inner layer structure. The plate is manufactured by waste coal ash generated by local rich coal mine resources and crop stalks, so that waste is recovered, and the plate is beneficial to environment friendliness. The plate takes inorganic substances such as powder quartz, quartz sand, sanding powder and the like as main raw materials, has the advantages of high strength, aging resistance, ultraviolet resistance, water resistance, fire prevention, heat preservation and the like, is widely applied, does not have toxic or side effect and is pollution-free.

Owner:SUZHOU WANAN NEW ENVIRONMENTAL PROTECTION BUILDING MATERIAL

Lightweight high-strength microcrystal ceramic insulation board and preparation method thereof

The invention discloses a lightweight high-strength microcrystal ceramic insulation board. The lightweight high-strength microcrystal ceramic insulation board comprises the following chemical components in percentage by weight: 30 to 75 percent of silicon dioxide (SiO2), 5 to 20 percent of aluminium oxide (Al2O3), 1 to 20 percent of calcium oxide (CaO), 1 to 15 percent of magnesium oxide (MgO), 1 to 10 percent of ferric oxide and ferrous oxide (Fe2O3+FeO), 1 to 10 percent of sodium oxide, potassium oxide and lithium oxide (Na2O+K2O+Li2O) and 1 to 8 percent of nucleating agent. The lightweight high-strength microcrystal ceramic insulation board is prepared by the following steps of: mixing and crushing waste minerals, a foaming agent and a sintering modifier; mixing the crushed mixture with the nucleating agent; after ball-milling, filter-pressing, pelleting and staling the mixture, directly paving the powder in a fire-resistant mould fully, scraping the mould smoothly and allowing the mould to enter a kiln; and after performing high-temperature sintering, quick cooling, nucleating treatment, quick heating and crystallization, cooling again and then annealing to prepare the product. The lightweight high-strength microcrystal ceramic insulation board has the advantages that: the average grain diameter is between 0.5 and 5 mu m; and crystal grains are dense and uniformly distributed and develop well.

Owner:NANJING UNIV OF SCI & TECH

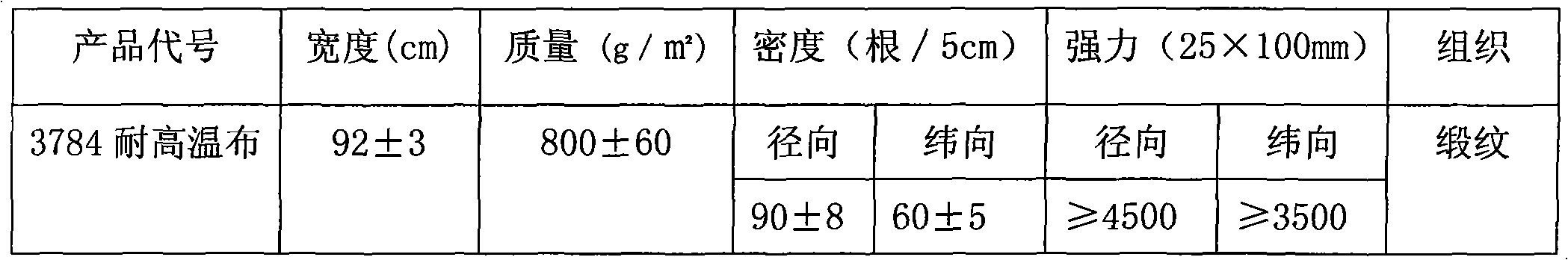

High-temperature resistant glass fiber cloth and fabricating technique thereof

ActiveCN101654854AFlat surfaceUniform colorFibre treatmentHeating/cooling textile fabricsParaffin waxGlass fiber

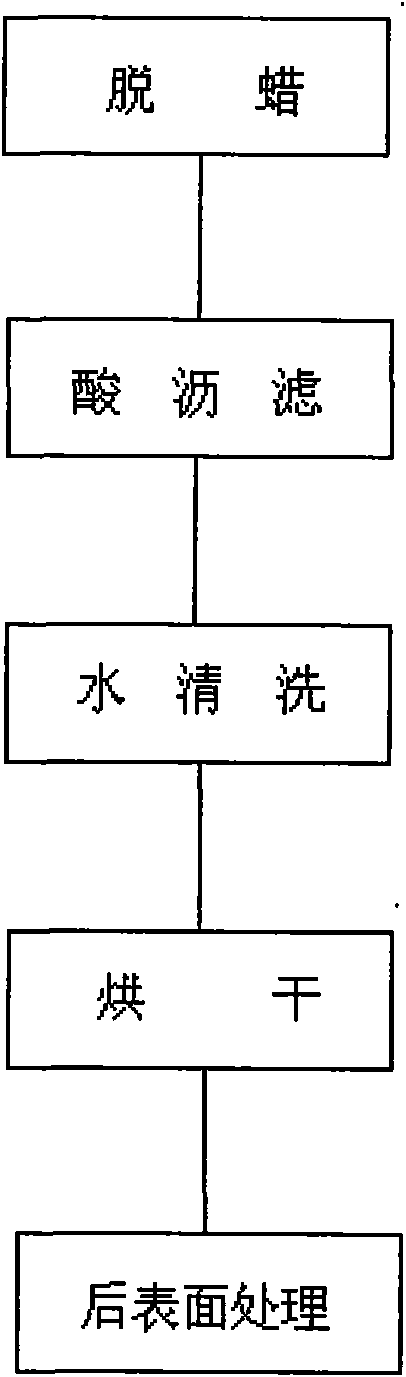

The invention discloses a high-temperature resistant glass fiber cloth and a fabricating technique thereof. Common alkali-free glass fiber cloth is used as raw material and is subject to dewaxing treatment in a continuous type dewaxing furnace, after the treatment, paraffin wax pretreatment agent on the surface of the alkali-free glass fiber cloth is completely wiped out, and the glass fiber is exposed; the alkali-free glass fiber cloth after the dewaxing treatment is put into a tank, an acid-proof pump is used for circular stirring and assistant gas sparging stirring so as to reinforce ion exchange process; afterwards, spraying treatment is carried out on the cloth surface to wipe out the surface residual acid, then the cloth is soaked in clear water to be washed by flowing water; after water washing, primary drying is carried out in the continuous type kiln; after the primary drying, the surface of the alkali-free glass fiber cloth is subject to gum dipping, mudjacking, drying and coiling to obtain the finished product high-temperature resistant cloth.

Owner:JIANGSU HENGZHOU SPECIAL GLASS FIBER MATERIAL

Novel light composite batten exterior wall and assembling method thereof

The invention relates to an exterior wall, particularly relates to a novel light composite batten exterior wall and an assembling method thereof, and belongs to the field of steel structures. The novel light composite batten exterior wall comprises a left light composite plate and a right light composite plate, wherein inner grooves are respectively formed in the left end of the left light composite plate and the left end of the right light composite plate; external projections are respectively arranged at the right end of the left light composite plate and the right end of the right light composite plate; the external projection of the left light composite plate is connected with the inner groove in the right light composite plate in a matched manner; lightgage steel joists are arranged on the outer wall of the left light composite plate and the outer wall of the right light composite plate; and decorative composite plates are arranged on the outer walls of the lightgage steel joists. The novel light composite batten exterior wall is compact in structure, and has good performance of light weight, high strength, waterproofness, damp proofing, fire insulation, thermal insulation, environmental protection, high economical efficiency, quick construction and the like. The problems that the traditional exterior wall is troublesome during construction, and time and labor are wasted. Development tendency of assemblage and industrialization is met, and promotion and using value is quite high.

Owner:浙江东南网架股份有限公司

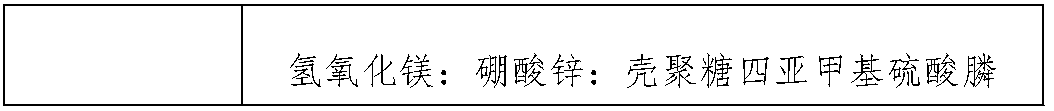

Fireproof type gypsum-based spraying material and preparation method thereof

The invention relates to the technical field of building materials and in particular relates to a fireproof type gypsum-based spraying material and a preparation method thereof. The fireproof type gypsum-based spraying material is prepared by grinding modified cellulose ether, a thixotropic lubricant, pearlite, a composite retarder, a flame retardant and a chlorine ion controlling agent until thegranularity is 0.6 to 1.0mm, and mixing powder with gypsum, sand and portland cement, so that the fireproof type gypsum-based spraying material provided by the invention has characteristics of convenience for working, water prevention and heat insulation, high temperature resistance, no hollowing, no cracking, strong binding power, good anti-sagging performance, bug and ant biting resistance, metal rusting prevention, greenness and environment protection and the like; furthermore, the flame retardant has the effect of keeping the average breaking strength of the gypsum-based spraying materialbeing 2.2MPa or more and the average compressive strength being 4.6MPa or more through a reasonable design and a dosage test of magnesium hydroxide, zinc borate and chitosan tetramethylene phosphine sulfate; the fireproof type gypsum-based spraying material keeps relatively good mechanical strength and also has the fireproof effect with the average fireproof degree of 560 DEG C or more.

Owner:深圳摩盾环保新材料有限公司

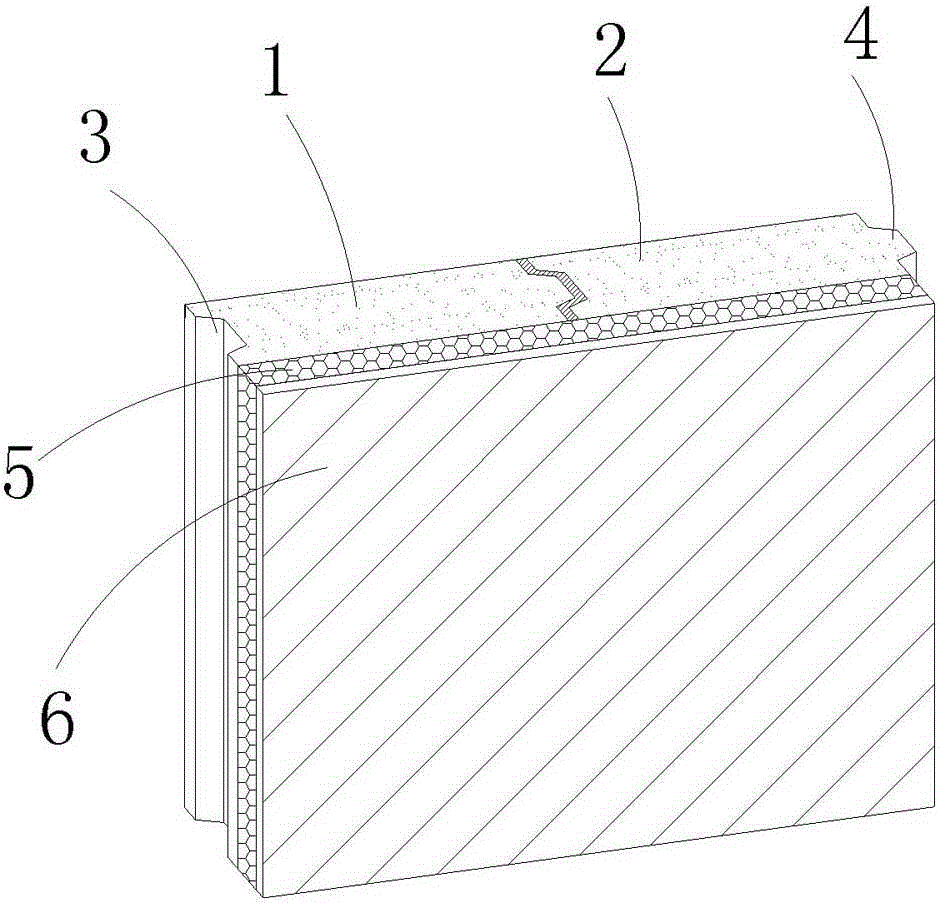

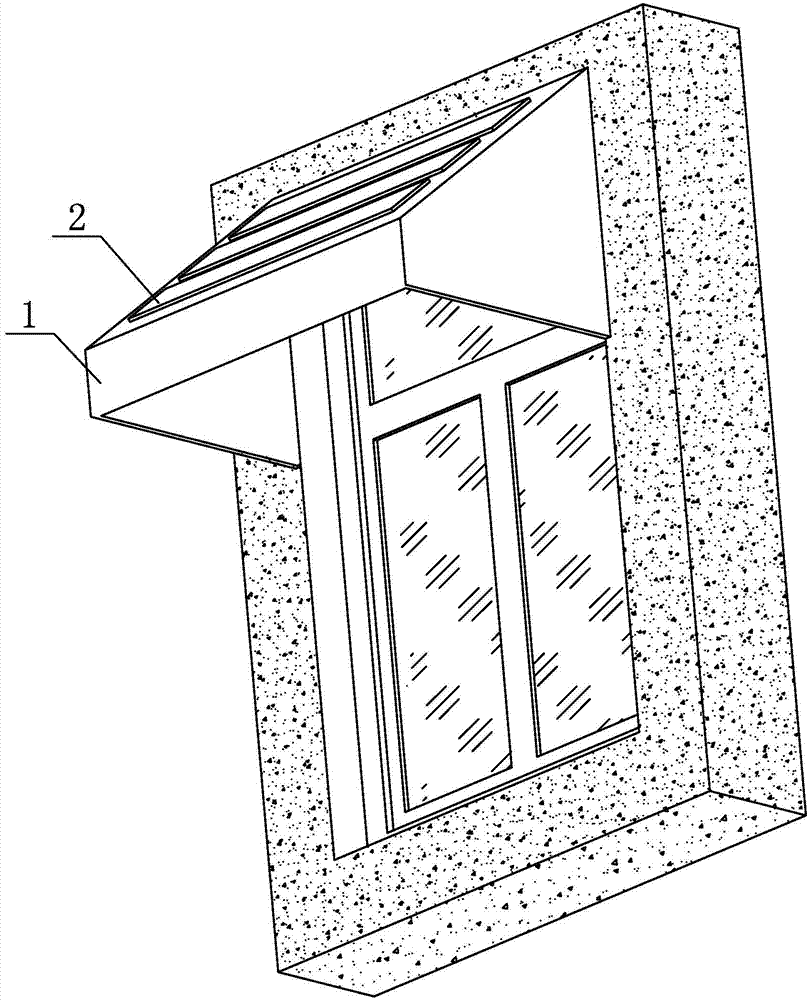

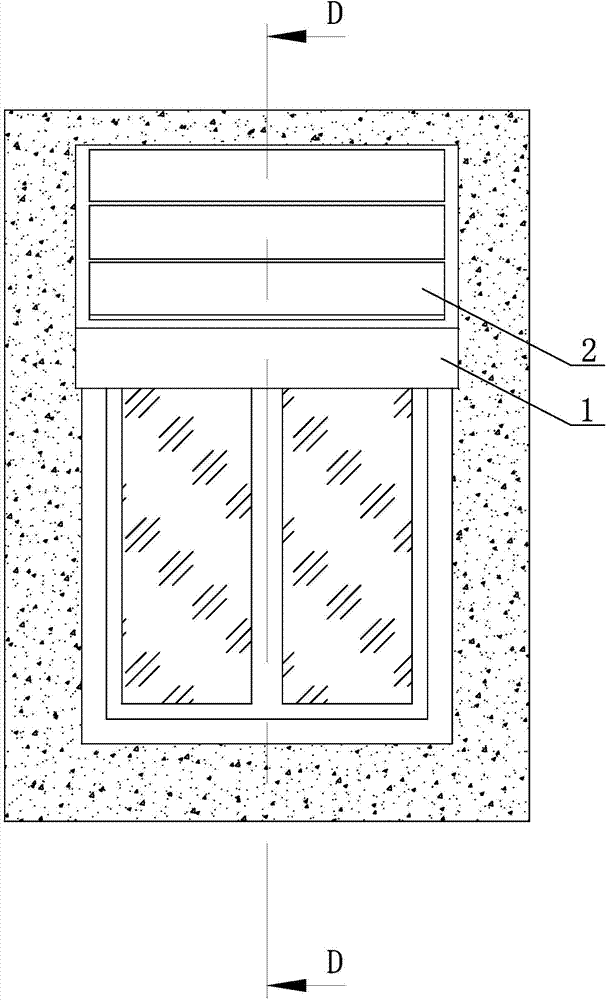

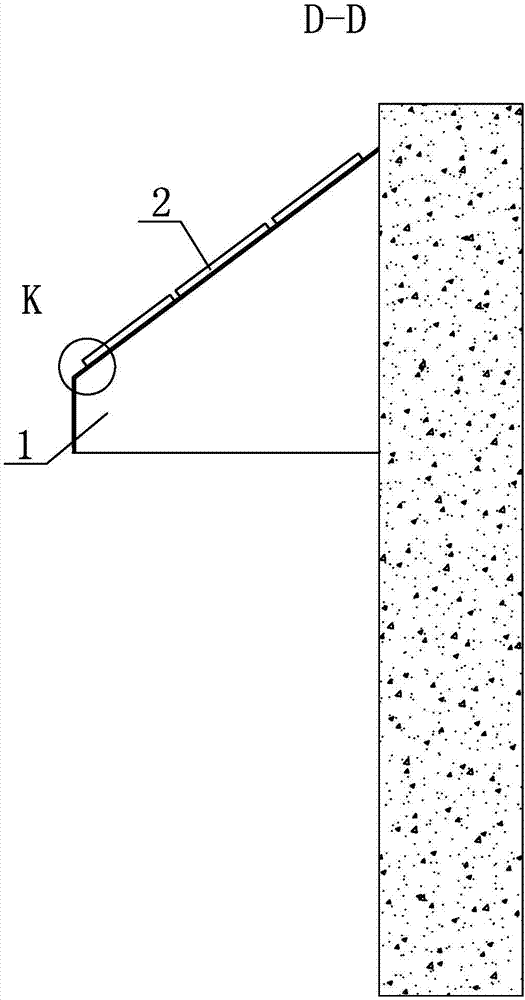

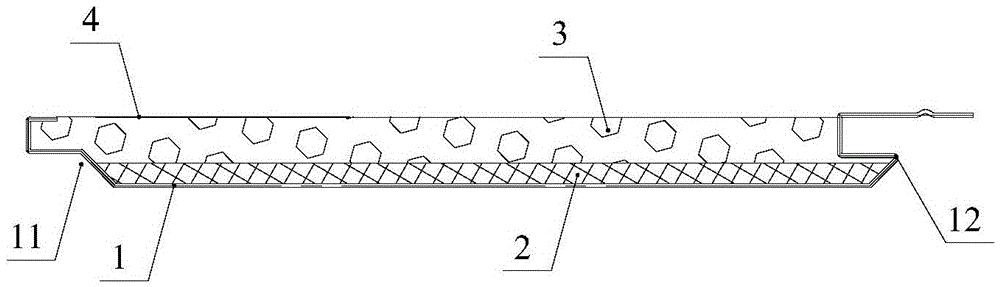

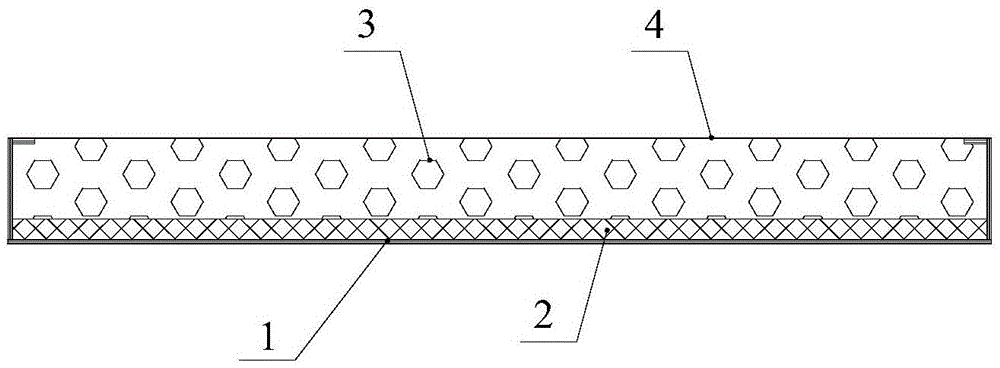

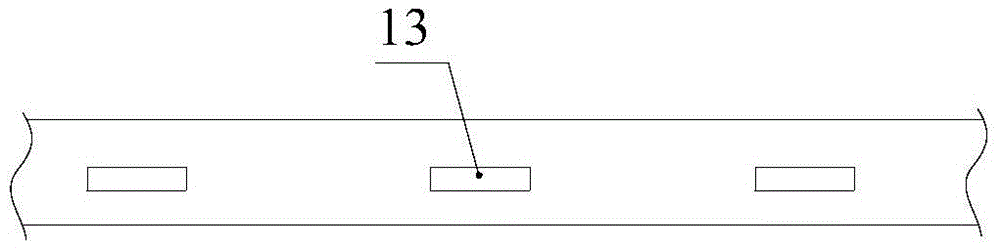

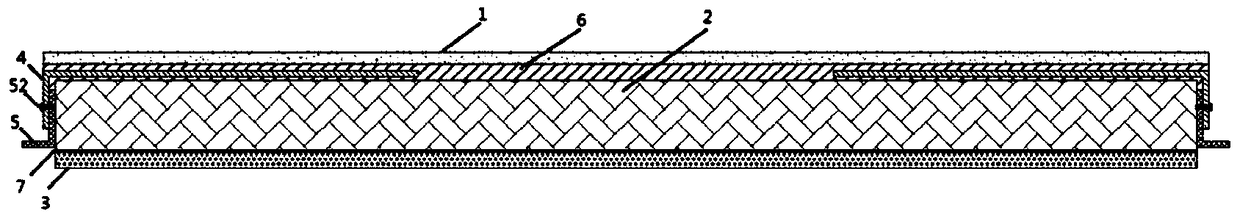

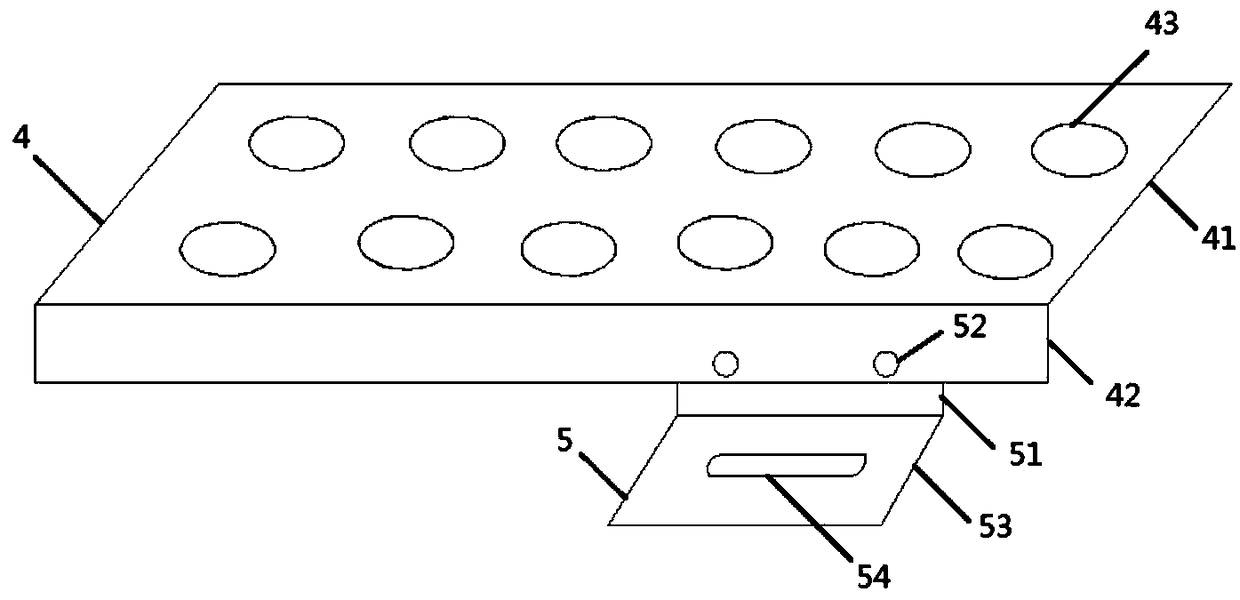

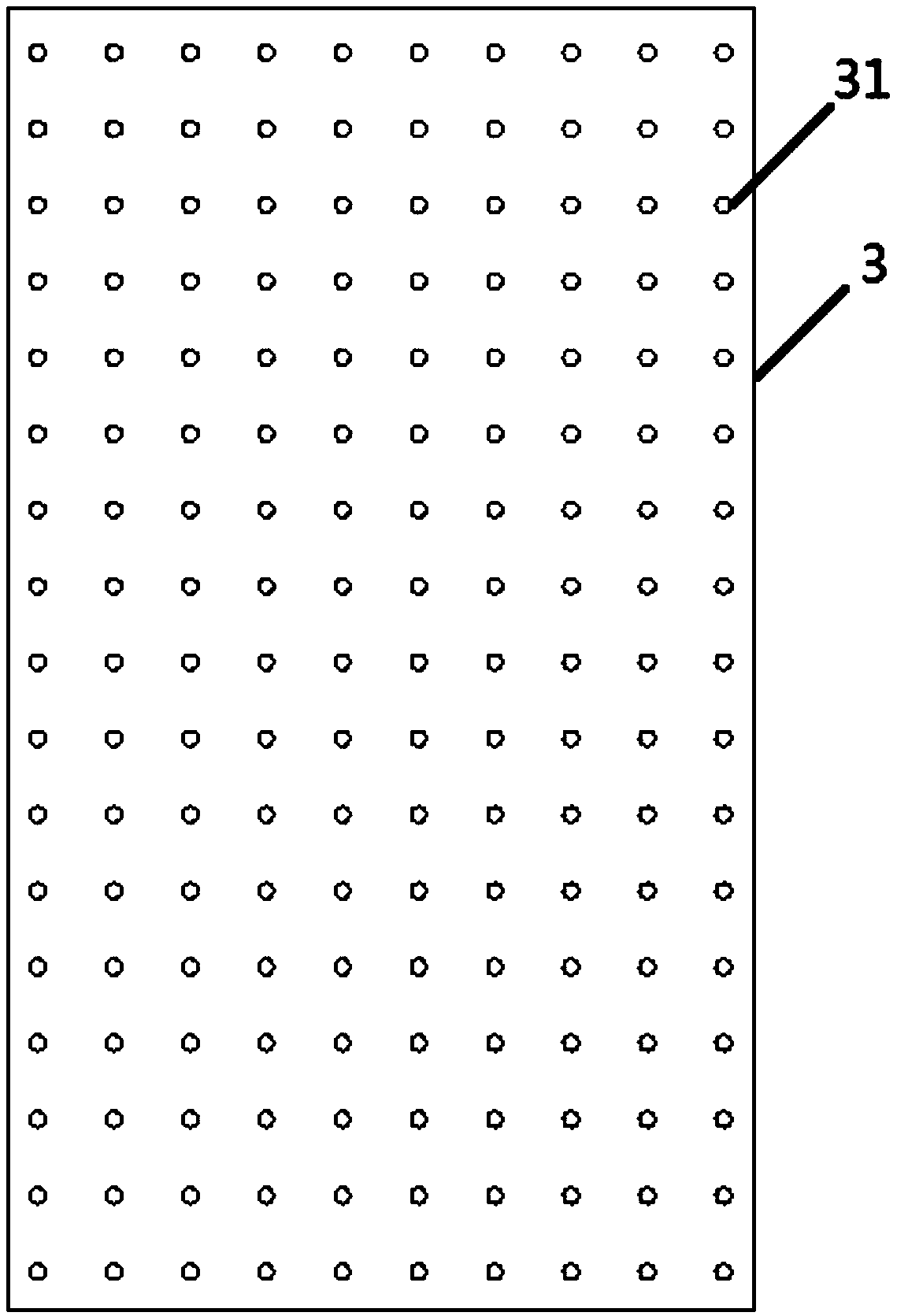

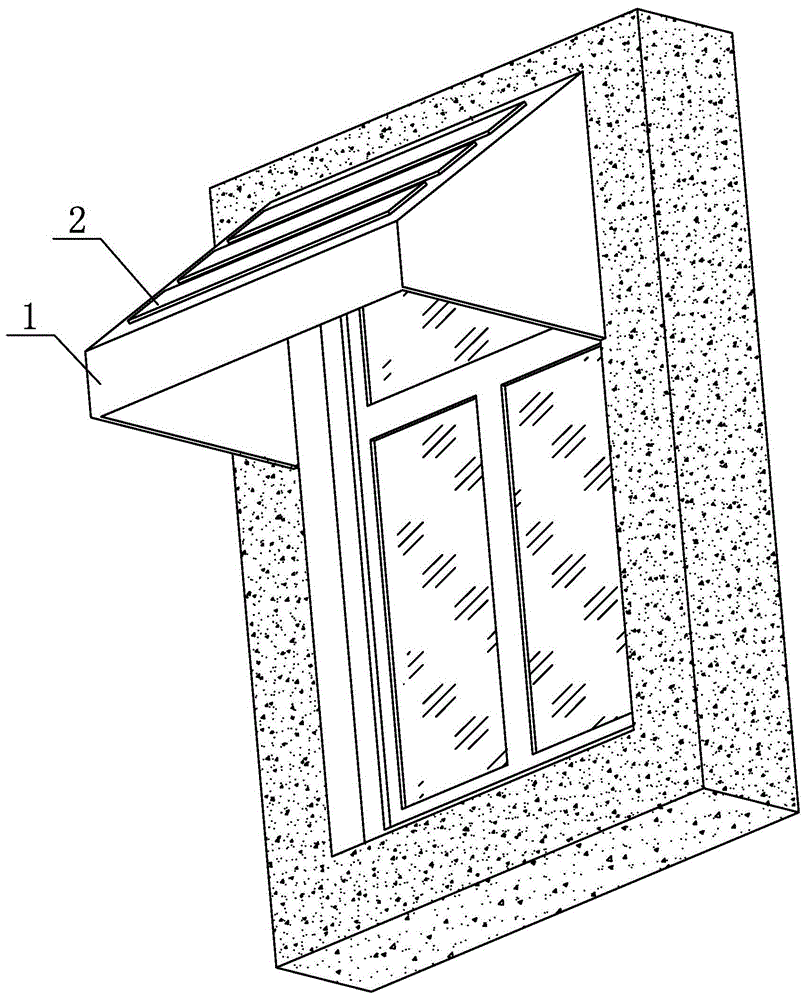

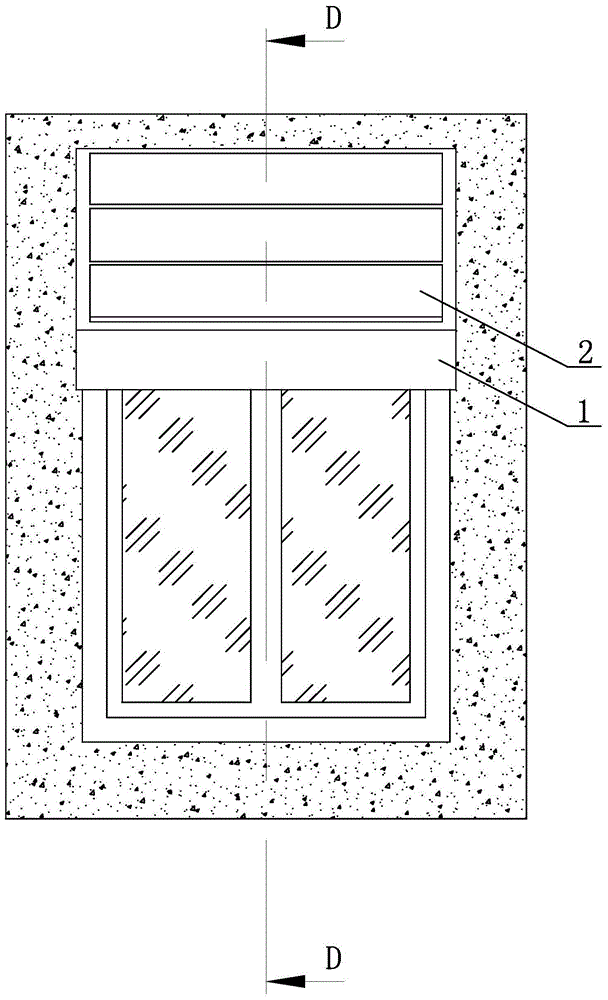

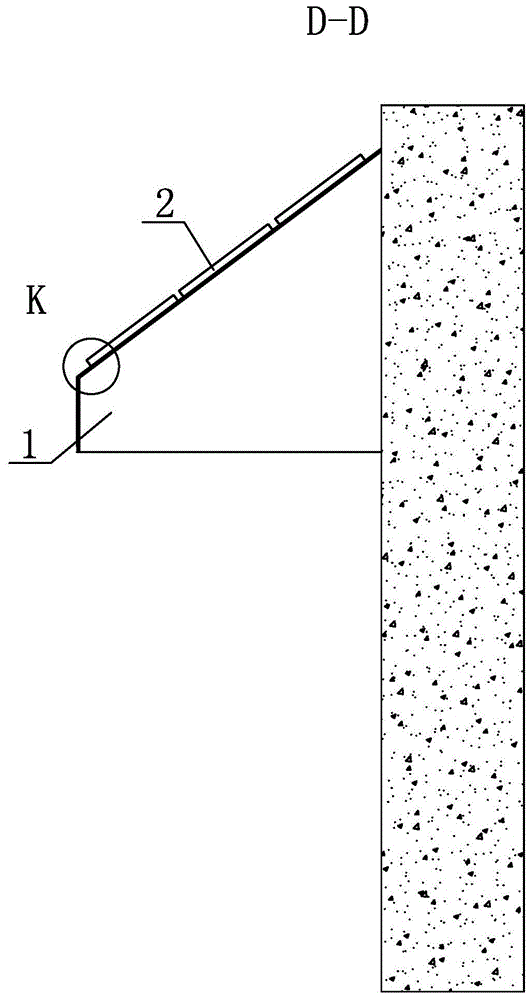

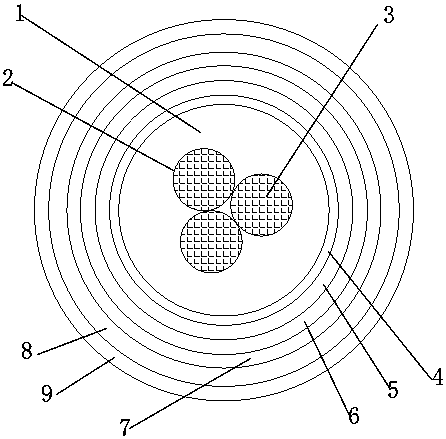

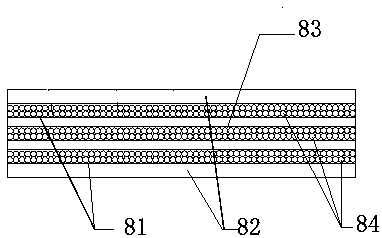

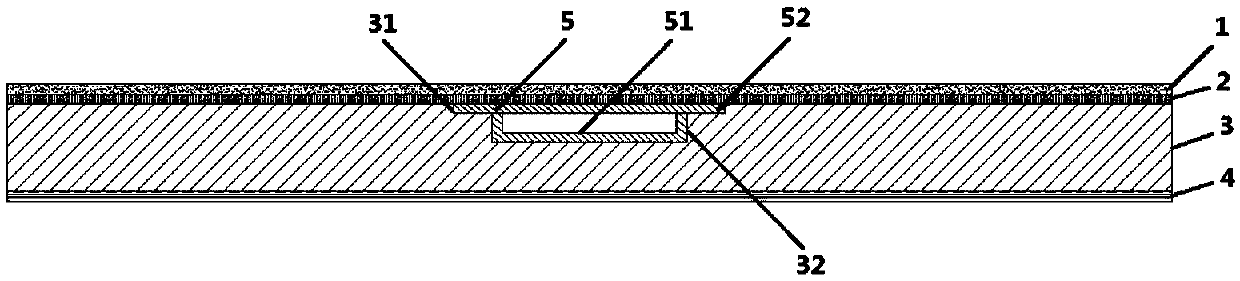

Photovoltaic sun-shading system and manufacturing method thereof

ActiveCN103938810AWith photovoltaic power generation functionWith fire insulationRoof covering using slabs/sheetsRoof covering using tiles/slatesElectric energyEngineering

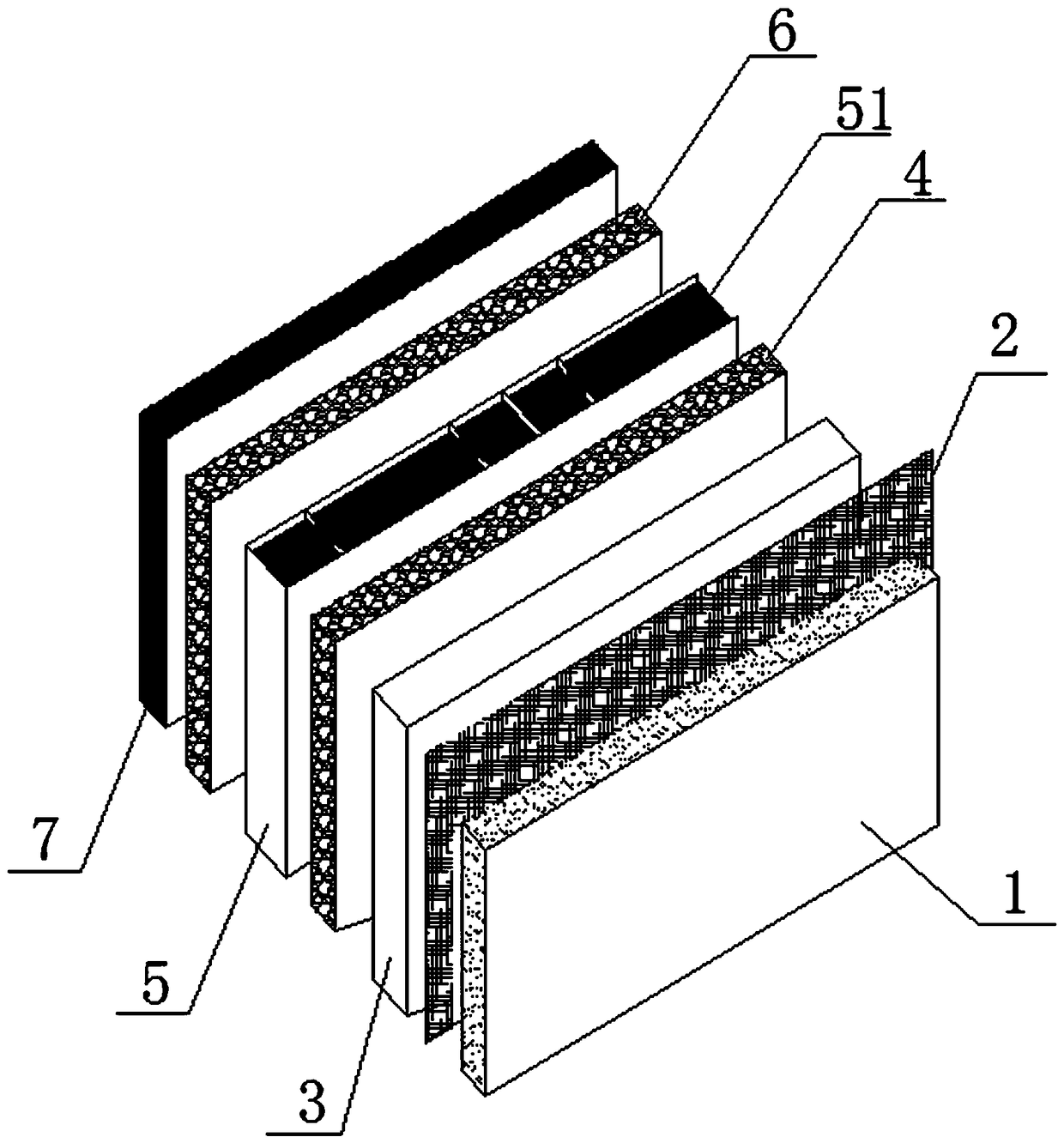

The invention discloses a photovoltaic sun-shading system which comprises a supporting frame and a sun-shading plate (1) fixed to the supporting frame. A photovoltaic layer (2) is fixed to the sun-shading plate (1), and the photovoltaic layer (2) comprises a flexible thin-film battery pack (3), a film layer (4) and a coating layer (5) sequentially from bottom to top. The sun-shading plate (1) is a carbon fiber plate. According to the photovoltaic sun-shielding system, the photovoltaic sun-shading plate is light, safe, resistant to fire, insulative and good in durability, the sun-shading plate is organically combined with a solar photovoltaic module, sun shading can be achieved, photovoltaic power generation can also be achieved, and the photovoltaic sun-shading system conforms to the idea of green buildings according to which energy is saved, emission is reduced and energy consumption is zero. According to the photovoltaic sun-shading system, solar batteries can be used for outputting electric energy, the function of a rain shelter and the function of sun shading are achieved, and meanwhile a new installation manner is provided for domestically using solar energy.

Owner:威都能源科技有限公司

Environment-friendly and impact-resistant composite decoration plate and manufacturing method thereof

The invention discloses an environment-friendly and impact-resistant composite decoration plate and a manufacturing method thereof. The composite decoration plate comprises a face plate layer, a filling layer, an isolation layer and a damp-proof layer which are sequentially arranged from outside to inside. The filling layer is made from inorganic materials and formed by sealing a piece of wood plywood, a glass magnesium plate and an enhanced fiber plate or a cement foaming plate in a composite mode. The isolation layer is made from organic materials including phenol, modified phenol or polyurethane. The face plate layer sequentially surrounds the filling layer, the isolation layer and the damp-proof layer from side faces so as to form an installation part beneficial to splicing of two composite decoration plates. According to the environment-friendly and impact-resistant composite decoration plate, the face plate layer, the filling layer, the isolation layer and the damp-proof layer are sequentially arranged from outside to inside, and therefore the hardness, strength and impact resistance of the face plate layer are greatly improved through the filling layer; the environment-friendly and impact-resistant composite decoration plate is formed by compositing multiple layers, is resistant to impact, has the advantages of being resistant to fire, capable of preserving heat, resistant to dampness, good in sound isolation effect and the like, saves energy and is environmentally friendly.

Owner:WENZHOU CHENXING MACHINERY

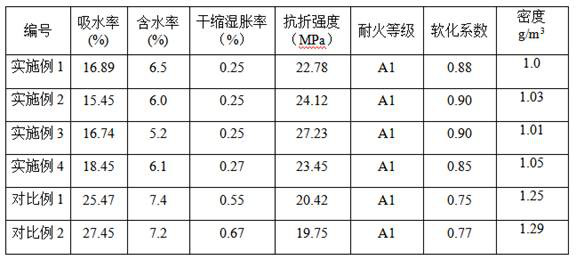

Prefabricated foamed lightweight insulation mineral polymer wallboard and preparation method thereof

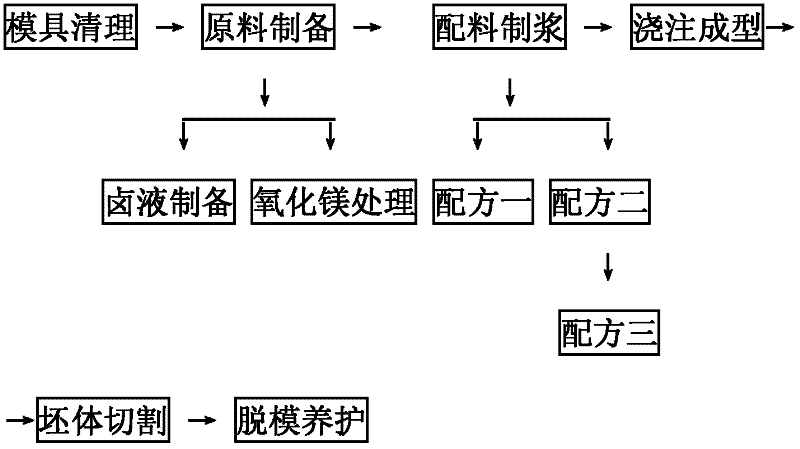

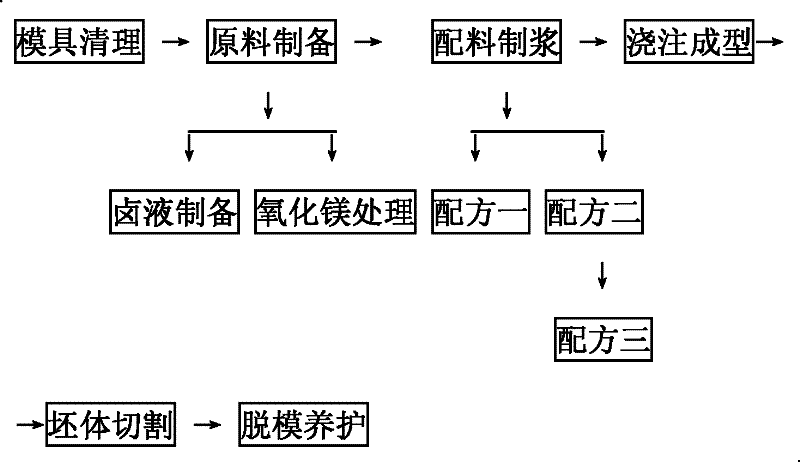

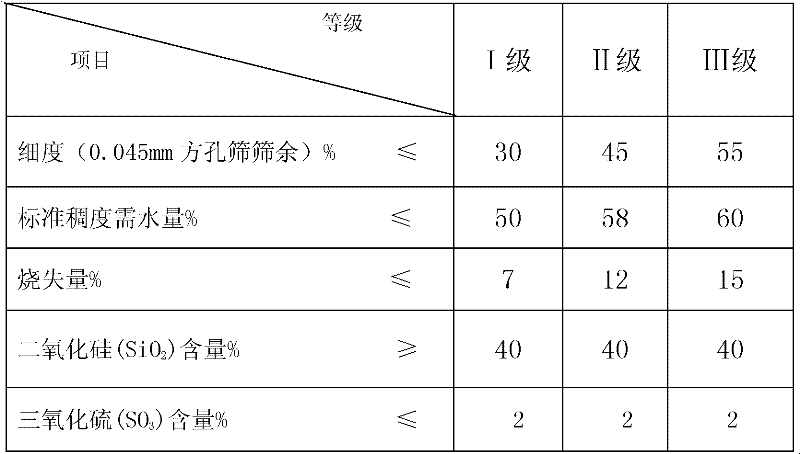

InactiveCN109206114ASolve the problem of unstructured claddingIncreased folding ratioCeramic shaping apparatusFiberProduction line

The invention discloses a prefabricated foamed lightweight insulation mineral polymer wallboard and a preparation method thereof. The wallboard comprises the following raw materials (by weight): 200-500 parts of fly ash, 5-50 parts of mineral powder, 1-50 parts of metakaolin, 100-300 parts of water glass, 5-50 parts of caustic soda, 1-30 parts of a foaming agent, 1-300 parts of a water-proofing agent, 1-20 parts of fiber, 5-100 parts of water, and reinforcing mesh slice. The reinforcing mesh slice is laid in a mold, the above raw materials are fully stirred to prepare slurry and the slurry ispoured into the mold pulped; and after solidification at room temperature, steam curing is conducted at 40-95 DEG C for 3-24 hours to prepare a mineral polymer foamed lightweight high-strength self-insulation wallboard. The product has the characteristics of light weight, high strength, heat preservation, fireproofness, durability and one-time molding of large board. The method can be convenientlyrealized in the traditional prefabricated concrete wallboard production line, and is particularly suitable for external wallboards for steel structure buildings.

Owner:BEIJING ACAD OF BUILDING ENG

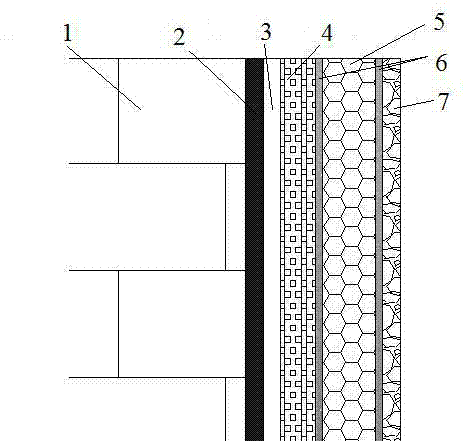

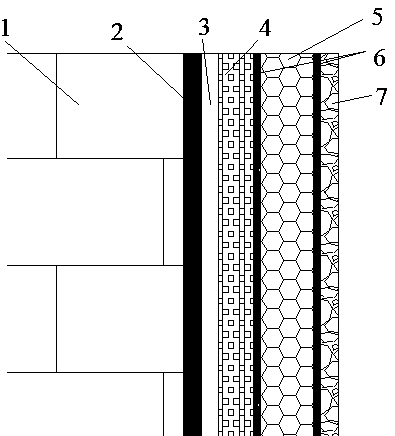

Wall of light steel structural house

The invention discloses a wall of a light steel structural house. The wall is divided into an inner wall and an outer wall, wherein the inner wall is composed of gypsum boards, wall surface OSBs and alight steel keel, with the light steel keel as a bearing framework, the two sides of the light steel keel are each provided with one wall surface OSB, and the gypsum boards are located on the outermost layers; the outer wall is composed of a gypsum board, one wall surface OSB, a light steel keel, the other wall surface OSB, an insulating layer, a ventilation layer and an outer wall hanging platefrom inside to outside. The middle of each light steel keel is filled with a heat preserving and insulating material, a wood keel is arranged in the middle of the ventilation layer, breathing paper isattached to the surface, close to the insulating layer, of the ventilation layer, and all layers of the inner wall and the outer wall are connected together by cold-rolled steel nails from the two sides in a fastened mode. The wall is low in weight and good in wind and quake resistance, has good features of heat preserving and insulating, sound insulating, fire resistance, moisture prevention, corrosion prevention and the like, and can be widely applied to office buildings, villas, storehouses, stadiums, entertainment venues and tourism buildings.

Owner:黎金莲

Environmentally-friendly hollow brick used for buildings and preparation method thereof

The invention discloses an environmentally-friendly hollow brick used for buildings. The environmentally-friendly hollow brick is prepared from the following raw materials in parts by weight: 15-25 parts of cement, 25-35 parts of ore tailings, 15-20 parts of purified filler, 3-5 parts of plant powder, 2-4 parts of sulphur powder, 0.5-1.5 parts of nano-zinc oxide, 2-4 parts of glass fiber, 1-2 parts of carbon fiber, 30-40 parts of coal ash, 10-16 parts of emulsion powder and 6-8 parts of industrial mildew preventive. The environmentally-friendly hollow brick used for building decoration has the characteristics of abrasion resistance, high compressive strength, high water absorption, fire prevention and temperature preservation. In addition, the environmentally-friendly hollow brick also has functions of emitting aromatic odor and purifying air, a great quantity of industrial wastes are used as raw materials so as to perform effects on saving energy, reducing emission, preventing environment pollution and being ecological and environmentally friendly. Meanwhile, the preparation method for the hollow brick has the advantages of lower material cost, abundant raw material, simple and clear technology, easiness in operation, easiness in realizing industrial production, higher practical value and good application prospect.

Owner:合肥易美特建材有限公司

Polyester vinyl plastic-steel plate

InactiveCN101885883AMeet high standardsMeet the requirements of seamless weldingPolyesterSynthetic resin

The invention relates to a PB plastic-steel plate which comprises main raw material of synthetic resin and auxiliary material polyfluortetraethylene; the PB plastic-steel plate also comprises stabilizing agent and filler; the synthetic resin accounts for 62% of the total material; and the PB plastic-steel plate is characterized in that the polyfluortetraethylene accounts for 30% of the total material, and the filler accounts for 3% of the total material.

Owner:XINXIANG XINYUAN CORROSION INSULATION PROD CO LTD

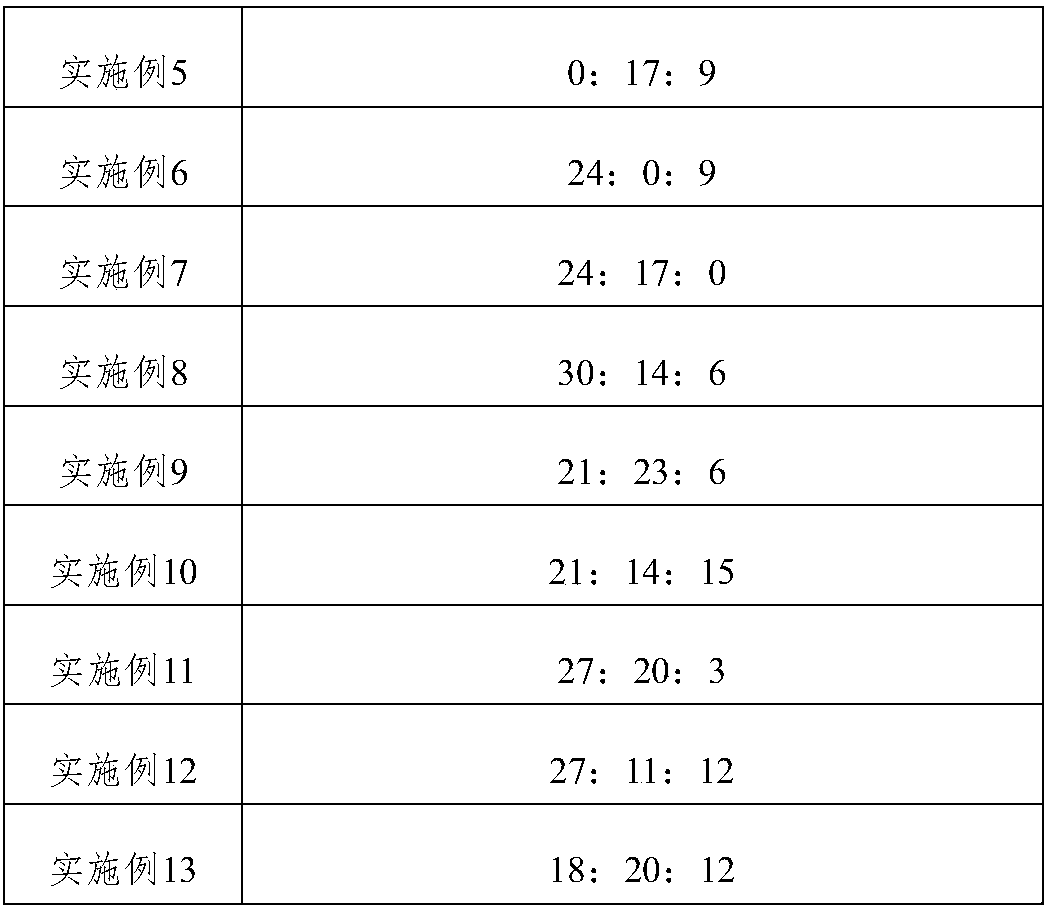

Material formula of inorganic fireproof core layer

The invention relates to the technical field of building materials, in particular to a material formula of an inorganic fireproof core layer. The material formula of the inorganic fireproof core layer comprises, by weight, 5%-15% of silicon dioxide, 5%-15% of magnesium oxide, 5%-15% of magnesium chloride, 25%-35% of flyash, 15%-25% of saw dust , 5%-10% of carbon fibers, 5%-10% of loess powder and 5%-15% of curing agents. The inorganic fireproof core layer prepared through the material formula is high in fireproof and water resistant capacity, the used materials can realize waste utilization, and the purposes of being green and environmentally friendly are achieved.

Owner:TAIZHOU WANSHIFA PANEL

Mineral insulating metal shielded monitoring-type coal mine fireproof cable

InactiveCN107767997AStrong fire resistanceGood compression performanceClimate change adaptationInsulated cablesMicaCoal

The invention discloses a mineral insulating metal shielded monitoring-type coal mine fireproof cable, comprising a core; the core is formed by stranding two mineral insulating core wires and a monitoring core wire; voids of the core is filled with glass fibers; an inorganic heat-insulating fireproof layer is extruded outside the core; a third mineral insulating layer is extruded outside the inorganic heat-insulating fireproof layer; a metal conductive tube is arranged outside the third mineral insulating layer; the metal conductive tube is coated with a coating fireproof layer that is wrappedwith nonwoven, an aluminum tin foil is arranged outside the nonwoven and is wrapped with double-side synthetic mica taping, and an outer sheath is extruded as an outermost layer of the cable and is coated with fireproof mud. The mineral insulating metal shielded monitoring-type coal mine fireproof cable has good electrical conductivity, mechanical physical properties and fireproof property, alsohas good noninflammability, can ensure fireproofing power supply in a fire continuation time in case that the cable is on fire, and never experiences continued burning and produces no toxic smoke.

Owner:JIANGSU ZHUYING SPECIAL CABLE

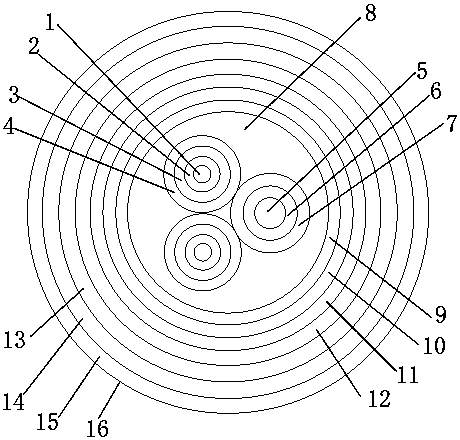

Moxibustion paster utilizing Chinese mugwort Qiai

InactiveCN107595606AGuaranteed stabilityAvoid exposureDevices for heating/cooling reflex pointsCardboardMugwort

The invention discloses a moxibustion paster utilizing Chinese mugwort Qiai. The moxibustion paster comprises a paper drum rack, a mugwort floss drum, a control damper paper board and a double-faced adhesive tape. The lower end of the paper drum rack is adhered to the double-faced adhesive tape. The mugwort floss drum is arranged in the paper drum rack in a penetrating manner and comprises a firsthollow paper drum, a paper drum loaded with mugwort floss, a second hollow paper drum, mugwort floss, steel wire meshes and fire-proof material. The paper drum loaded with the mugwort floss is filledwith the mugwort floss. Upper and lower ends of the paper drum loaded with the mugwort floss are internally fixed with the steel wire meshes. A layer of fire-proof material is arranged on the inner wall of the paper drum loaded with the mugwort floss. The control damper paper board is a circular paper board.By igniting the mugwort floss drum in the paper drum rack, mugwort floss burns inside to generate heat and smoke. Corresponding acupoints or moxibustion parts are treated. The mugwort floss drum is arranged in the paper drum rack. The length at which the mugwort floss drum stretches into the paper drum rack is adjusted according to needs. Therefore, the moxibustion temperature is controlled. The moxibustion paster can adjust different people and symptoms in order to master the degree of moxibustion.

Owner:蕲春李时珍臻艾艾灸养生有限公司

Thermal insulation coating sprayed on surface of Q235B steel under high-temperature condition and using method of thermal insulation coating

PendingCN112029322ALow priceEasy accessFireproof paintsAlkali metal silicate coatingsThermal insulationCement kiln

The invention belongs to the technical field of thermal insulation coatings, and particularly relates to a thermal insulation coating sprayed on the surface of Q235B steel under a high-temperature condition and a using method of the thermal insulation coating. The invention aims to solve the problems that the strength of the existing thermal insulation coating used for Q235B steel cannot meet theactual requirements, and the existing thermal insulation coating cracks and falls off along with the cooling and heating processes of the Q235B steel after being sprayed. According to the invention, light calcium carbonate and glass fibers are added into a common thermal insulation coating formula taking potassium silicate and glass beads as raw materials, so that the coating has a thermal expansion coefficient tending to be consistent with that of Q235B, and meanwhile, the strength of the coating is improved, so that the coating does not crack or fall off along with cooling and heating of theQ235B after being sprayed. The coating can be sprayed on the surface of scorching Q235B under the high-temperature operation condition when thermal equipment such as a cement kiln operates to be rapidly cured, and is tightly combined with the surface of steel.

Owner:吴征

Cement fibrolite plate manufacturing method

The invention relates to the technical field of cement fibrolite plate manufacturing, in particular to a cement fibrolite plate manufacturing method. The cement fibrolite plate manufacturing method comprises the following steps that S1, material selection is performed for making materials, specifically, wood pulp fiber, cement, sulfate-containing salts, calcium salts, calcium hydroxide, distilledwater and carboxylic acid are selected; S2, the sulfate-containing salts are diluted into a solution, added to the wood pulp fiber and then mixed; S3, calcium hydroxide and the calcium salts are diluted into a solution and added to the wood pulp fiber, and then carboxylic acid is added to be fully mixed; S4, the mixed raw materials are dispersed uniformly by a dispersing machine, and paved and stacked; and S5, the uniformly stirred mixture is slowly sprinkled into a base plate in a forming frame, rolling and leveling are performed, water is removed, in order to facilitate demolding, an upper layer of plastic thin film and a lower layer of plastic thin film are additionally arranged, and after manual paving, the mixture is placed in a mold for pressurization. The cement fibrolite plate manufacturing method has the advantages of fireproof insulation, waterproof and moisture proof, light weight and high strength, simple construction, economical and beautiful properties, safe and harmlessproperties, long service life and the like.

Owner:中铁装配科技(吐鲁番)有限公司

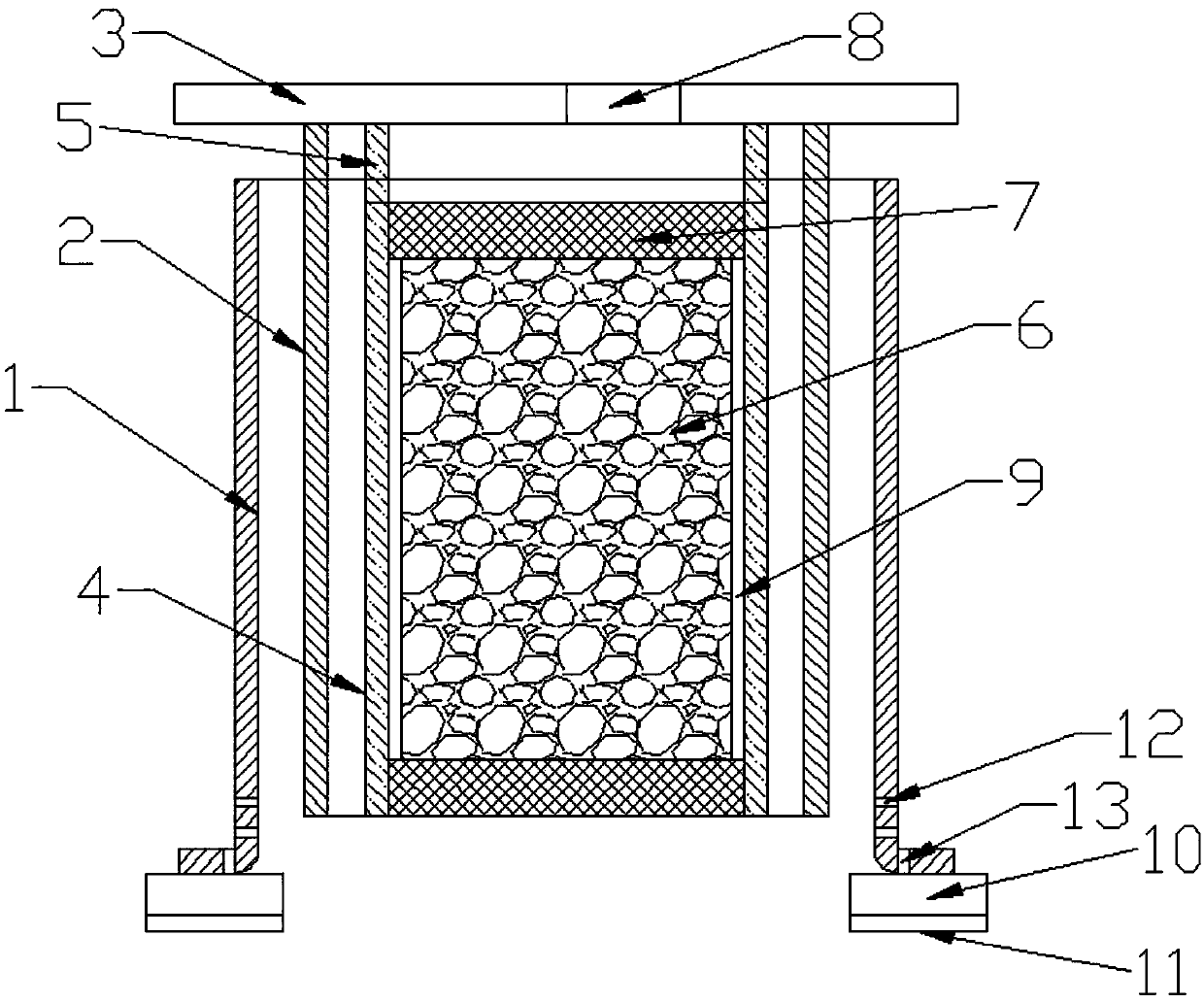

PVC pipe with properties of fireproofness and thermal insulation

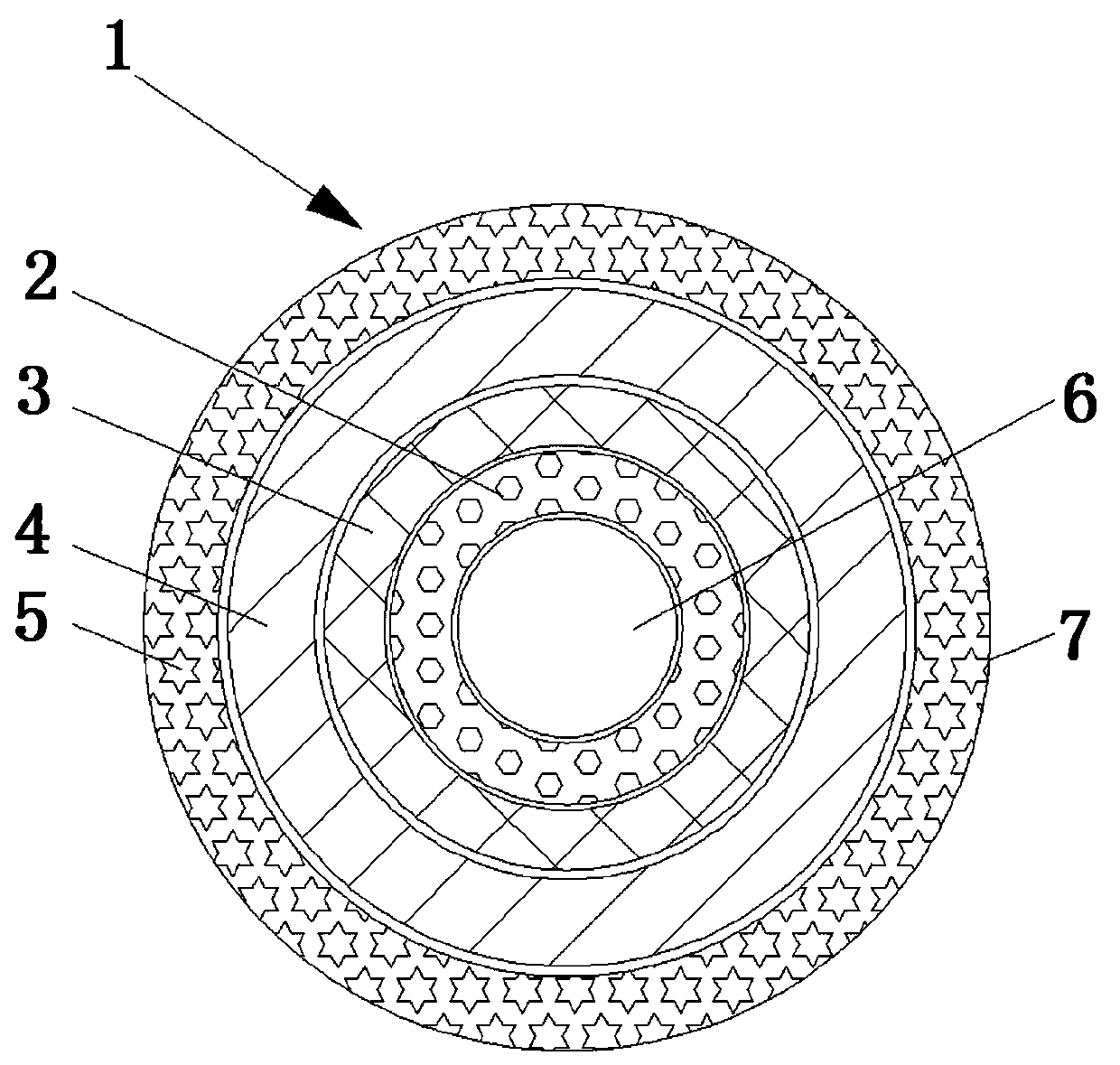

PendingCN109578751AWith fire insulationImprove fire insulation performanceThermal insulationPipe elementsFiberPolyester

The invention discloses a PVC pipe with the properties of fireproofness and thermal insulation. The PVC pipe comprises a pipeline main body, a thermal insulation layer, a steel belt layer and a fireproof coating; the pipeline main body is internally provided with a through hole, through which a medium flows, and sequentially comprises the thermal insulation layer, the steel belt layer, a sound insulation layer and a fireproof layer from inside to outside; the thermal insulation layer internally comprises a first pipe sleeve made of a polystyrene material; the steel belt layer internally comprises a steel pipe sleeve made of steel; the sound insulation layer is internally provided with a second pipe sleeve made of polyester fibers; the fireproof layer is internally provided with a third pipe sleeve made of polyvinyl chloride, perchloroethylene and chlorinated rubber; and the outer wall of the pipeline main body is coated with the fireproof coating. For the PVC pipe provided by the invention, through arrangement of a multi-layer structure, the fireproofness and the thermal insulation performance of the pipeline main body are effectively improved. The PVC pipe with the properties of fireproofness and thermal insulation is reasonable in structure, has the characteristics of high practicability, good safety and the like and can be widely used.

Owner:徐州托普新材料有限公司

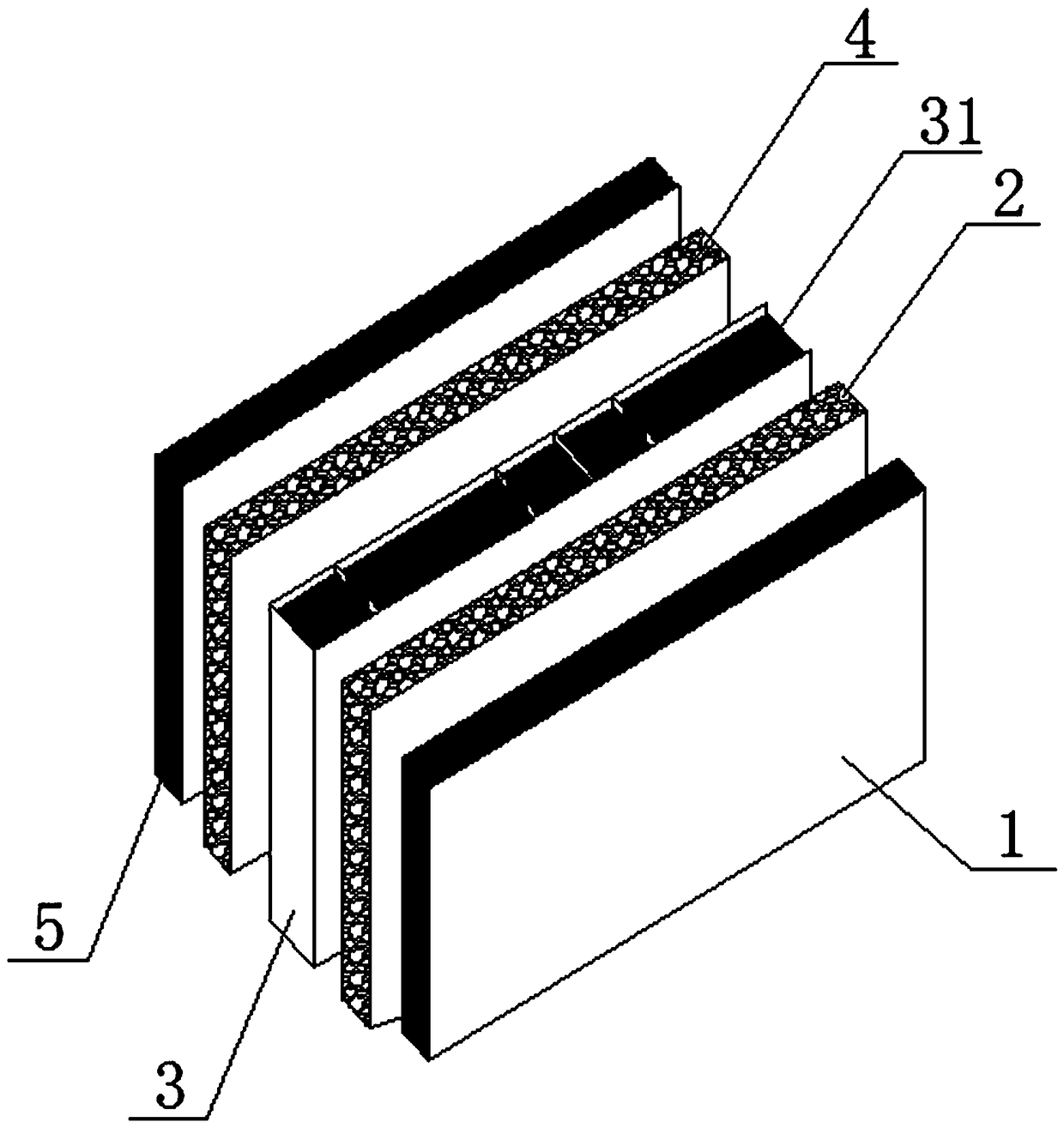

Multifunctional energy-saving composite plate with multi-layer cavity structure

InactiveCN104763064AWith thermal insulationDecorativeHeat proofingWater-setting substance layered productBiochemical engineeringComposite plate

The invention relates to a multifunctional energy-saving composite plate with a multi-layer cavity structure. The multifunctional energy-saving composite plate is arranged on the outer side of a wall body base body and is used for external heat preservation of an exterior wall. The multifunctional energy-saving composite plate with the multi-layer cavity structure comprises a protection layer, an air layer, a filling layer, a partition plate, a heat preservation layer, a partition plate and a decoration layer from inside to outside. The partition plates are arranged on two sides of the heat preservation layer and have good leakproofness and a heat reflection function and play a good heat-insulation role, material diffusion of the heat preservation layer can be further prevented, and the service life is prolonged. The air layer is formed by the gap between the protection layer and the filling layer and has fireproof and heat-insulation performance.

Owner:WUHAN UNIV OF TECH

Soft rock or soft porcelain heat preservation integrated board

The invention discloses a soft rock or soft porcelain heat preservation integrated board. The board comprises a soft rock or soft porcelain layer, a heat preservation material layer, a fiber board layer and an L-shaped supporting plate; the soft rock or soft porcelain layer, the heat preservation material layer and the fiber board layer are sequentially stuck together through adhesives from top tobottom in sequence, a transverse plate of the L-shaped supporting plate is clamped between the soft rock or soft porcelain layer and the heat preservation material layer and adhesively fixed throughan adhesive; a fixing piece is arranged on a vertical plate of the L-shaped supporting plate, and the soft rock or soft porcelain layer is a surface decorative layer. The soft rock or soft porcelain is adopted as the panel, the requirement of the market for stone or porcelain decorative surface heat preservation decorative boards is met, the technical problem that traditional hard stone is likelyto be broken is solved, the fixing piece is more reasonably designed, the structure is stable, installation is convenient, and the quality and practicability of the heat preservation board are greatlyimproved.

Owner:安徽泰升节能科技有限公司

Method for preparing magnesium fireproof plate through low-content light calcined magnesia powder

The invention belongs to the technical field of production of magnesium fireproof plates, and particularly relates to a method for preparing a magnesium fireproof plate through low-content light calcined magnesia powder. The method is characterized in that raw materials comprise a reinforcing material and a coating material attached to the surface of the reinforcing material, and the coating material comprises, by weight, 30-50 parts of the low-content light calcined magnesia powder, 40-60 parts of a magnesium sulfate solution, 2-10 parts of a mineral admixture, 5-15 parts of light filler and 1-2 parts of a modifier; and the reinforcing material is plastic-coated medium-alkali glass fiber cloth, the fireproof plate has the characteristics of being low in dead weight, high in strength, good in toughness, capable of achieving fireproofness and heat insulation, convenient to construct and the like under the chemical action of puffing and intermolecules, the requirements of the fireproof plate for fireproofing, strength, nail-holding power and the like can be ensured, the low cost and high performance of the fireproof plate are realized, meanwhile, the problem about comprehensive application of the low-content light calcined magnesia powder is solved, and the method has far-reaching influence on development of magnesium resources and preparation of magnesium fireproof plates in the future.

Owner:辽宁科大中驰镁建材科技有限公司

Multifunctional energy-saving composite board with multi-layer cavity structure

InactiveCN104763064BWith thermal insulationDecorativeHeat proofingWater-setting substance layered productEngineeringComposite plate

The invention relates to a multifunctional energy-saving composite plate with a multi-layer cavity structure. The multifunctional energy-saving composite plate is arranged on the outer side of a wall body base body and is used for external heat preservation of an exterior wall. The multifunctional energy-saving composite plate with the multi-layer cavity structure comprises a protection layer, an air layer, a filling layer, a partition plate, a heat preservation layer, a partition plate and a decoration layer from inside to outside. The partition plates are arranged on two sides of the heat preservation layer and have good leakproofness and a heat reflection function and play a good heat-insulation role, material diffusion of the heat preservation layer can be further prevented, and the service life is prolonged. The air layer is formed by the gap between the protection layer and the filling layer and has fireproof and heat-insulation performance.

Owner:WUHAN UNIV OF TECH

a decorative board

ActiveCN103193437BLightweight and high strengthWith fire insulationSolid waste managementSpecial ornamental structuresSludgeSoluble glass

The invention discloses a decorative sheet. The decorative sheet is characterized by comprising the following raw materials in parts by weight: 24-26 parts of zinc ore tailings, 12-14 parts of acetylene sludge, 10-12 parts of cement, 9-11 parts of mica flake, 1.5-2.5 parts of aedelforsite, 11-13 parts of jute fibre, 0.5-1 part of soluble glass and 25-27 parts of water. The decorative sheet is prepared through the following steps of: (1) mixing materials; (2) loosening the jute fibre; (3) making slurry; (4) blanking, wherein the pressurizing pressure is 4MPa; (5) pressing decorative patterns; (6) autoclaved curing; (7) trimming; and (8) drying. The decorative sheet has remarkable social benefit and economic benefit.

Owner:徐州宇之阳市场营销策划有限公司

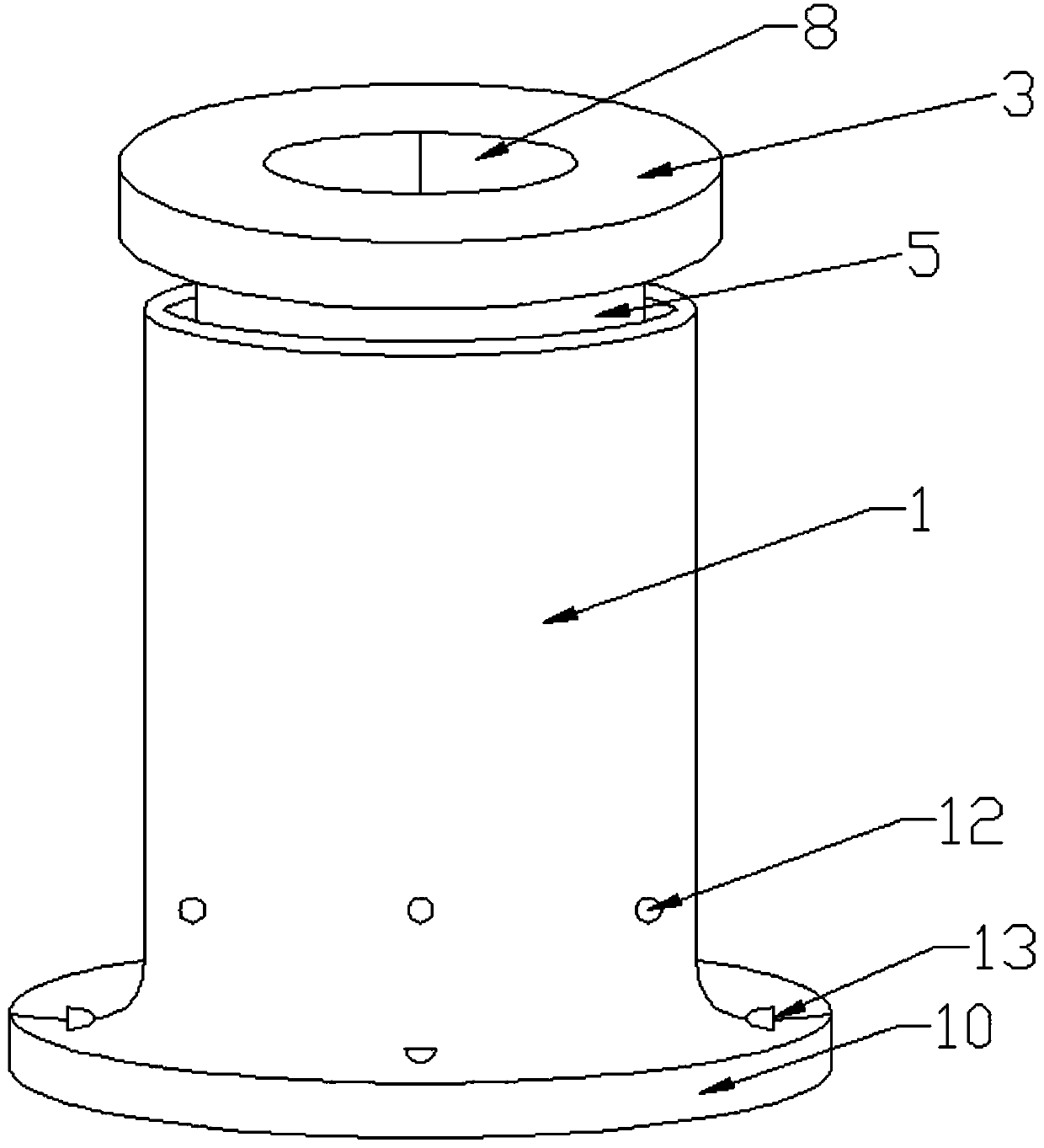

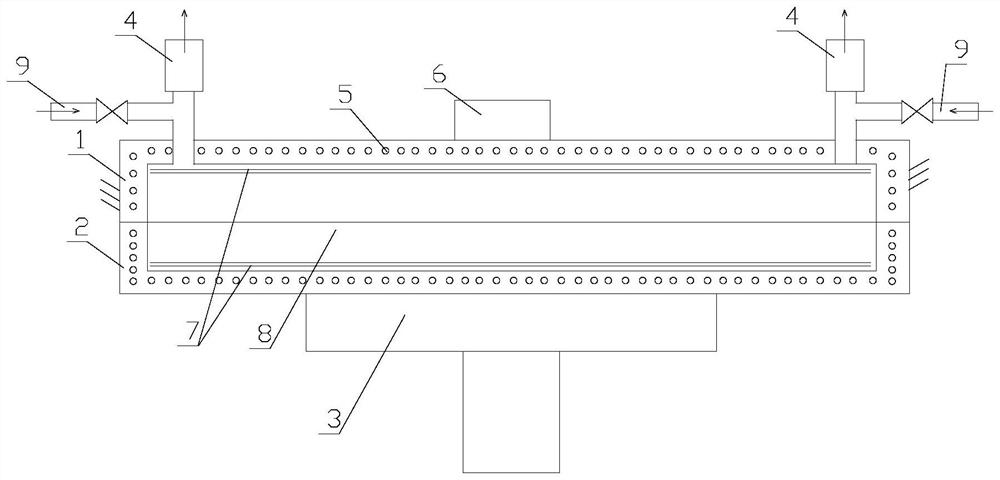

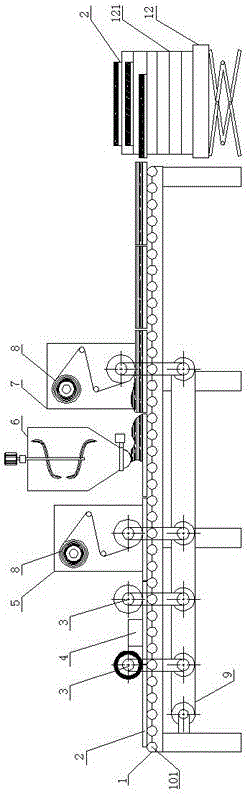

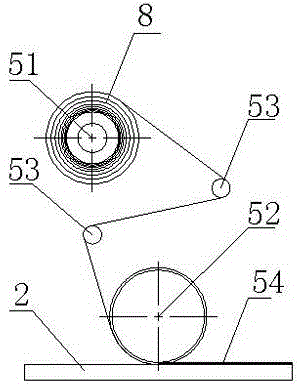

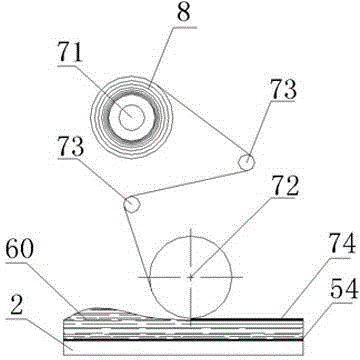

Fiber cement board production device and production method thereof

The invention relates to a fiber cement board production device and a production method thereof. The fiber cement board production device comprises a row of driven rollers, a rail beneficial to bottom formwork conveying, bottom formworks and pressure transmission rollers, wherein the bottom formworks are laid on the rail in sequence, and the pressure transmission rollers are arranged above the rail, can act on the upper surfaces of the bottom formworks and drive the bottom formworks to move; the rail is further provided with sponge used for coating a release agent to the upper surfaces of the bottom formworks, a first glass fiber discharge device for discharging a fiber cement board bottom layer glass fiber net on the bottom formworks, a cement paste discharging device, and a second glass fiber discharge device for discharging a surface layer glass fiber net on the surface layer of a fiber cement board. The fiber cement board production device is reasonable in structure, simple in operation and low in cost, and the produced fiber cement board has the advantages of fire prevention, insulation, water prevention, damp prevention, heat and noise insulation, light weight, high strength, simple construction, economy, attractiveness and the like.

Owner:FUJIAN AGEO NEW BUILDING MATERIALS

A lightweight thermal insulation composite calcium calcium composite board

InactiveCN102888900BPromote environmental protectionNo side effectsCeramic shaping apparatusHeat proofingEnvironmental resistanceUltraviolet

The invention discloses a light heat preservation silicon and calcium compound plate, which consists of an outer layer structure and an inner layer structure. The plate is manufactured by waste coal ash generated by local rich coal mine resources and crop stalks, so that waste is recovered, and the plate is beneficial to environment friendliness. The plate takes inorganic substances such as powder quartz, quartz sand, sanding powder and the like as main raw materials, has the advantages of high strength, aging resistance, ultraviolet resistance, water resistance, fire prevention, heat preservation and the like, is widely applied, does not have toxic or side effect and is pollution-free.

Owner:SUZHOU WANAN NEW ENVIRONMENTAL PROTECTION BUILDING MATERIAL

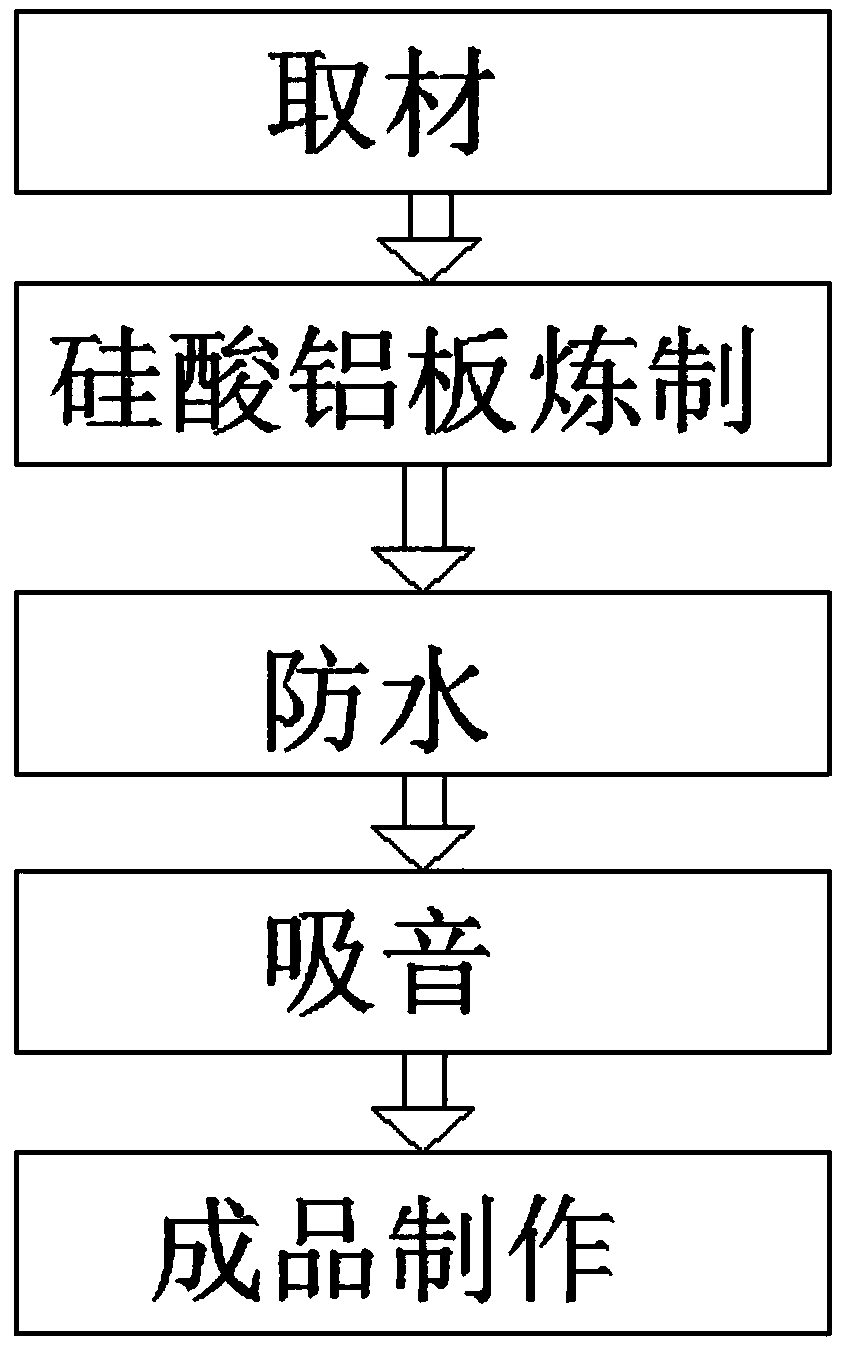

Novel floor board

InactiveCN110295710ATo achieve the effect of fire and heat insulationHigh strengthLaminationLamination apparatusFiberAluminum silicate

The invention discloses a novel floor board. The specific manufacturing steps are as follows: 1, materials are taken, wherein well-chosen high-quality flint clay, binder, an oil-proof agent, water repellent, a well-chosen high-quality PVC board, well-chosen high-quality sound absorbing cotton and well-chosen high-quality rubber are taken; and 2, an aluminum silicate board is refined, wherein a proper amount of the well-chosen high-quality flint clay is taken and placed into a specially-made die, then fused through an electric furnace, and injected into fiber, meanwhile, the binder, the oil-proof agent and the water repellent specially made are added uniformly, and the mixture is heated and cured to form the aluminum silicate board. According to the novel floor board, by arranging the aluminum silicate board, the floor board can achieve the fireproof heat isolating effect beneficially, supporting force is provided, and the strength of the floor board is improved. By arranging the rubberlayer, the principle that the rubber has elasticity and insulativity, and is free of water and air penetration is utilized, and the floor board achieves the waterproof effect. The production technology is concise and convenient, the production efficiency is improved greatly, and the produced floor board has excellent effects of being fireproof, isolating heat, absorbing sounds, reducing noise, being waterproof, reducing vibration and resisting aging.

Owner:安徽瑞业钢构股份有限公司

Photovoltaic sunshade system and preparation method thereof

ActiveCN103938810BWith photovoltaic power generation functionWith fire insulationRoof covering using slabs/sheetsSunshadesFiberElectrical battery

Owner:威都能源科技有限公司

High-strength insulated power cable

PendingCN108461208AAct as a fixed conductorPlay the role of fillingPower cables with screens/conductive layersInsulated cablesCardboardWrinkle skin

The invention discloses a high-strength insulated power cable which comprises a polyethylene insulating filling core, three hole grooves which are tightly connected with each other are formed in the insulating filling core, an aluminum alloy conductor is arranged in each hole groove, a binding belt is wound outside the polyethylene insulatiing filling core, an inorganic heat-insulating fireproof layer is extruded outside the binding belt, a barium titanate thin film is attached outside the inorganic heat-insulating fireproof layer, the carbon-plated polyester fiber cloth wraps the surface of the barium titanate thin film, a flame-retardant corrugated composite paperboard is arranged outside the polyester fiber cloth, and a wrinkle aluminum sheath is arranged outside the flame-retardant corrugated composite paperboard. The method has the characteristics of low smoke, no toxicity, no halogen and flame retardancy; the electromagnetic interference is resisted when the mechanical external force is borne, the cost is low, and the performance index is good.

Owner:JIANGSU LONG E CABLE

Water-based inorganic thermal-insulation thick paste coating

The invention belongs to the technical field of building materials, and particularly relates to a water-based inorganic thermal-insulation thick paste coating. The water-based inorganic thermal-insulation thick paste coating comprises the following components in percentage by weight: 35-48% of ash calcium powder, 2-3% of inorganic rubber powder, 1-2% of bentonite, 10-15% of gypsum powder, 3-4% of 80-mesh polyvinyl alcohol PVA2488, 0.2% of an OC thixotropic agent, 0.1-0.2% of 200,000-viscosity cellulose, 0.01-0.05% of 301 starch ether, 4-6% of inorganic fiber cotton and 19-38.55% of glass beads. The invention aims to provide the passive water-based inorganic thermal-insulation thick paste coating for the interior and exterior walls, wherein the coating has the advantages of energy conservation, emission reduction, thermal insulation, heat preservation, water resistance and fire prevention.

Owner:董志文

Heat-preservation decorative plate

PendingCN107938973AWeather resistantAesthetically pleasingCovering/liningsWater-setting substance layered productSurface layerGranolithic

The invention discloses a thermal insulation decorative board, which belongs to the field of exterior wall decoration building materials, and comprises a soft granite layer, a polymer mortar layer, a rock wool layer, and a cement fiber board layer. The four materials are bonded together in sequence, and the The above-mentioned soft granite layer is used as the surface layer. The invention not only has the functions of heat preservation, fire insulation, sound absorption and heat insulation, etc., but also has the characteristics of thinness, lightness, elasticity, weather erosion resistance, etc., and has the aesthetics of stone materials to meet the market demand for stone decorative surfaces and external walls. Demand for thermal insulation and decorative integrated panels.

Owner:安徽泰升节能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com