Fiber cement board production device and production method thereof

A technology of fiber cement board and production equipment, which is applied in the direction of ceramic molding machines, pressure rollers, manufacturing tools, etc., can solve the problems of high cost and complex structure, and achieve the effect of simple construction, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

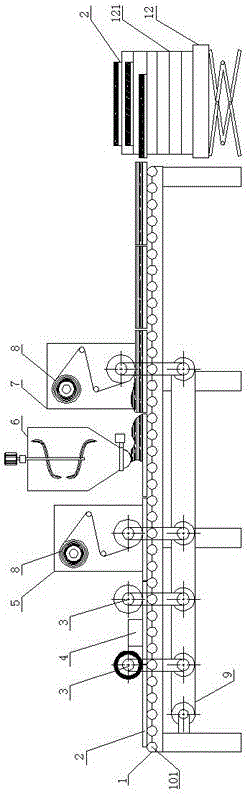

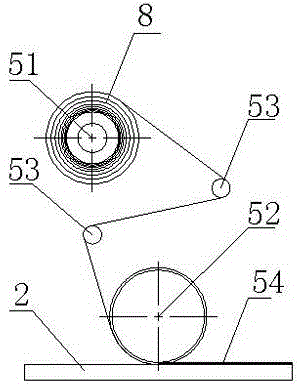

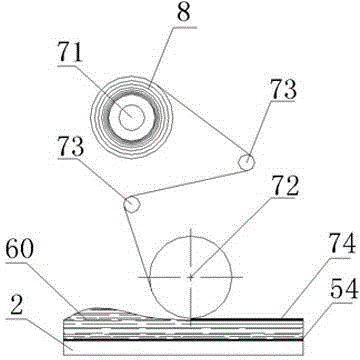

[0027] As shown in the figure, a fiber cement board production device includes a track 1 provided with a row of passive rollers 101, a bottom template 2 laid sequentially on the track, and a pressure transmission roller 3 arranged above the track; A sponge 4, a first glass fiber application device 5, a cement slurry blanking device 6 and a second glass fiber application device 7 are provided; the first glass fiber application device 5 includes a winding drum 51 wound with a glass fiber net 8, Cloth drum 52, tension guide roller 53; the structure of the second glass fiber application device 7 is the same as that of the first glass fiber application device, including a winding drum 71, a cloth drum 72 and a tension guide roller 73; its cloth drum 72 There is a gap between it and the upper surface of the bottom formwork 2, and the gap contains the bottom glass fiber m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com