Environment-friendly and impact-resistant composite decoration plate and manufacturing method thereof

A decorative board and impact-resistant technology, which is applied in the field of environmental protection and impact-resistant composite decorative boards and its production, can solve the problems of composite decorative boards such as weak composite force, impact resistance, and aesthetics, and achieve good sound insulation and increased hardness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

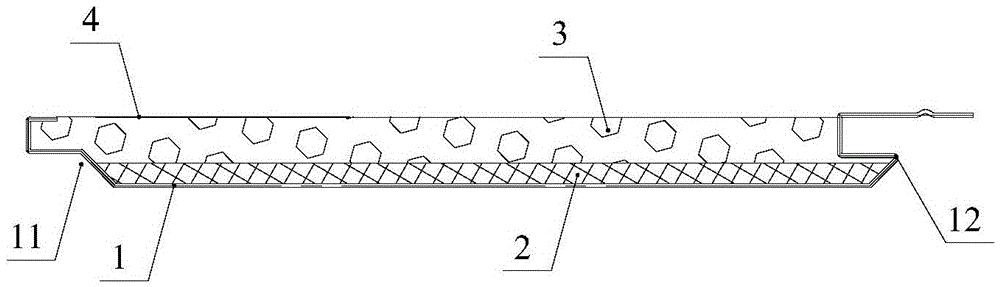

[0023] combine figure 1 , the first installation part is a strip-shaped embossment 11, and the second installation part is a strip-shaped groove 12 adapted to the strip-shaped embossment 11. In the process of use, multiple composite decorative panels are spliced and installed, just splice the strip-shaped convex groove 11 of any one composite decorative panel with the strip-shaped groove 12 of another composite decorative panel, and then splice in turn to complete the whole process. Easy to install and operate, reduce construction difficulty and improve construction speed.

specific Embodiment 2

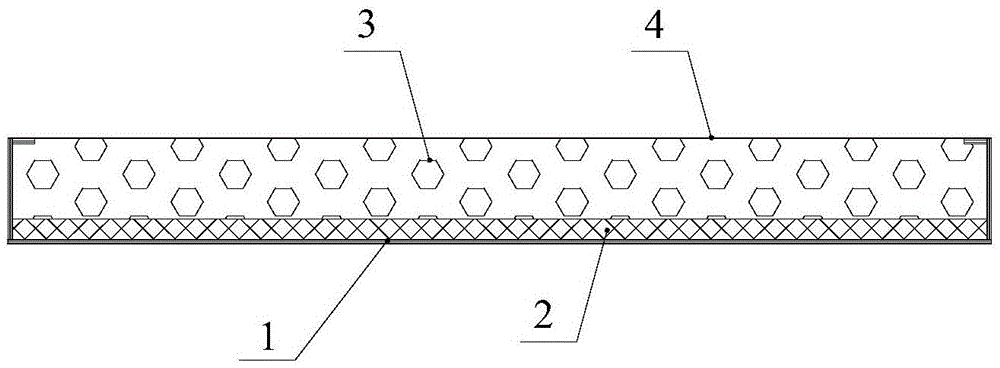

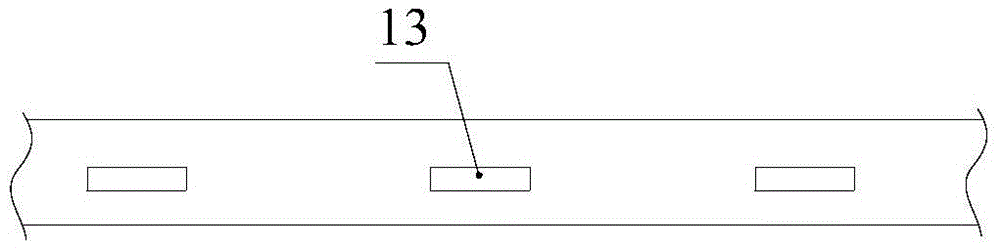

[0024] combine figure 2 , the first installation part is a plurality of first square holes 13, the second installation part is a second square hole (not shown in the figure) which is suitable for the first square hole 13 and corresponding to the position, the first square hole The hole 13 and the second square hole are respectively arranged in the middle of both sides of the composite decorative board. During use, multiple composite decorative panels are spliced and installed, just connect the first square hole 13 of any one composite decorative panel with the second square hole of another composite decorative panel, and insert a matching structure in the middle. The connecting piece can be fixed, and the operation is simple and firm. The number of the first square hole 13 and the second square hole can be set to one or more according to the needs, which is flexible and convenient.

[0025] Filling layer 2 is made of inorganic materials, including wood plywood, glass magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com