High-temperature resistant glass fiber cloth and fabricating technique thereof

A technology of glass fiber cloth and manufacturing method, which is applied in the fields of high temperature resistant glass fiber cloth and its manufacture, high temperature resistant cloth and its manufacturing, which can solve the problems of material brittleness, high production cost, low strength, etc., and achieve smooth and soft surface , the color is uniform and the cloth surface is smooth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

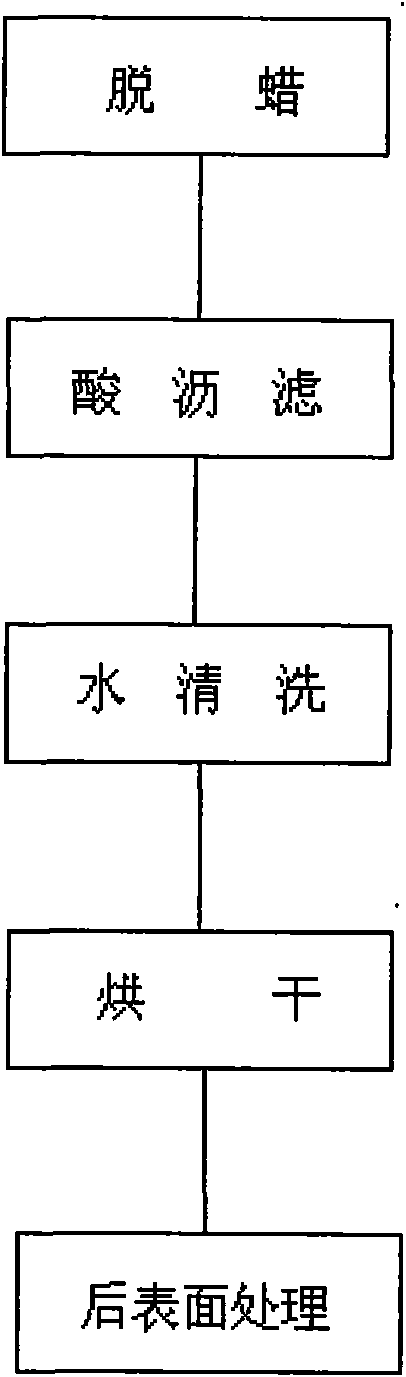

[0015] (1) The non-alkali glass fiber cloth purchased from the market is dewaxed first, and then dewaxed at 300°C in a continuous dewaxing furnace. The paraffin-type surface pretreatment agent contained in the fiber is completely melted away and becomes bare inorganic glass fiber.

[0016] (2) Then carry out acid leaching treatment, inject hydrochloric acid with a concentration of 1.5mol / L into the acid leaching tank, distribute the alkali-free glass fiber cloth after hot-melt treatment on a special frame in an orderly manner, and put it into the acid leaching tank. In the washing tank, use an acid-resistant pump for circulating stirring and auxiliary bubbling stirring to strengthen the ion exchange process, and heat it with steam to control the reaction temperature at 80 ° C. After 1.5 hours of treatment, take it out for washing.

[0017] (3) Washing with water First, spray the surface of the cloth to remove residual acid on the surface of the cloth layer, then soak it in cle...

Embodiment 2

[0021] (1) The non-alkali glass fiber cloth purchased from the market is first dewaxed, and then dewaxed at a temperature of 380°C in a continuous dewaxing furnace. Cloth, the paraffin-type surface pretreatment agent contained in the fiber is completely melted away, and becomes bare inorganic glass fiber.

[0022] (2) Then carry out acid leaching treatment, select hydrochloric acid with a concentration of 3mol / L and inject it into the acid leaching tank, distribute the alkali-free glass fiber cloth after hot-melt treatment on a special frame in an orderly manner, and put it into the acid leaching tank. In the tank, an acid-resistant pump is used for circulating stirring and auxiliary bubbling stirring to strengthen the ion exchange process, and it is heated with steam to control the reaction temperature at 85 ° C. After 2 hours of treatment, it is taken out and washed with water.

[0023] (3) Washing treatment: first spray the surface of the cloth to remove residual acid on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com