Method for preparing magnesium fireproof plate through low-content light calcined magnesia powder

A light-burned magnesia, low-content technology, applied in the manufacture of tools, ceramic molding machines, molds, etc., can solve the problems of underutilization of light-burned magnesia powder, easy moisture absorption and anti-halogen of products, and impact on ecology, etc., to achieve Good economic benefits, improvement of performance problems, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

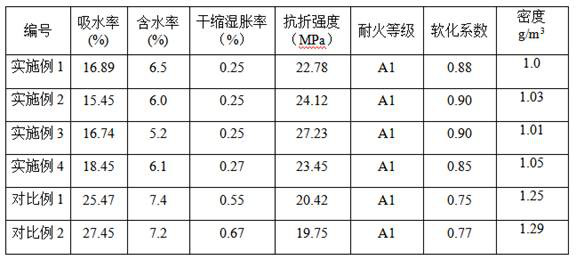

[0033] Raw materials for the formula of magnesia fireproof board: 100g of low-content light-burned magnesium oxide powder, 110g of magnesium sulfate solution, 4g of citric acid (modifier), 28g of wood chips (light filler), and 20g of expanded vermiculite (mineral admixture). The preparation method includes the following steps: 1) preparing a static slurry, mixing magnesium oxide and magnesium sulfate solution according to the formula ratio, stirring and mixing at a speed of 70-90 rpm for 2-5 minutes, and then adding a modifier to prepare a pure magnesium oxysulfate slurry ;

[0034] 2) Mixing and stirring: Add all formula quantities of lightweight fillers and mineral admixtures to the magnesium oxysulfide slurry in sequence, refer to GB / T9142-1988 "Technical Conditions for Concrete Mixers", and stir for 4-5 minutes to obtain slurry;

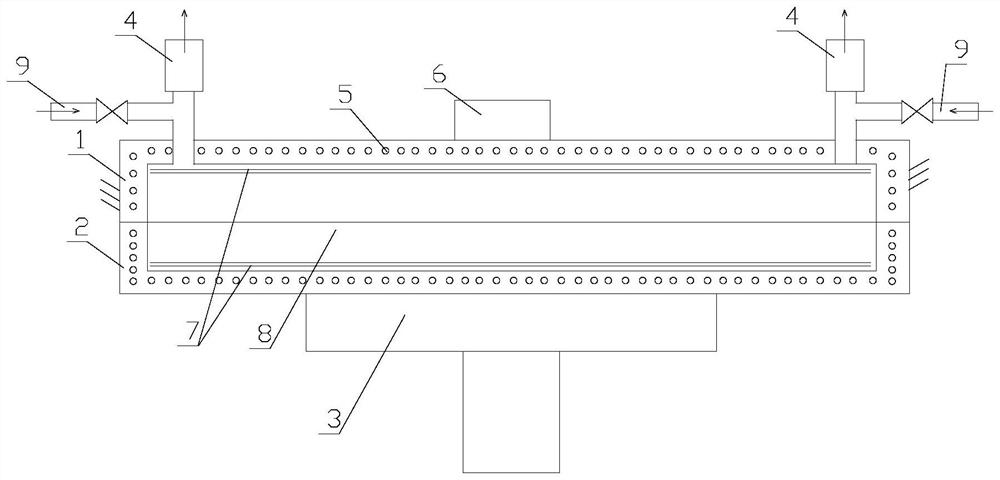

[0035] 3) Forming, spread the uniformly stirred slurry into the mold with one or more layers of medium-alkali glass fiber cloth, after the pavin...

Embodiment 2

[0040]Raw materials for the formula of magnesia fireproof board: 100g of low-content lightly burned magnesia powder, 110g of magnesium sulfate solution, 3g of citric acid (modifier), 26g of sawdust (light filler), and 18g of expanded vermiculite (mineral admixture). The preparation method is the same as in Example 1.

Embodiment 3

[0042] Raw materials for the formula of magnesia fireproof board: 80g of low-content lightly burned magnesia powder, 100g of magnesium sulfate solution, 2.5g of malic acid (modifier), 22g of sawdust (light filler), 20g of fly ash (mineral admixture) . The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com