Hydraulic pressure suspension polishing device with controllable fluid boundary

A fluid boundary and polishing device technology, applied in the field of precision polishing, to improve the surface processing effect, ensure uniformity, and improve processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

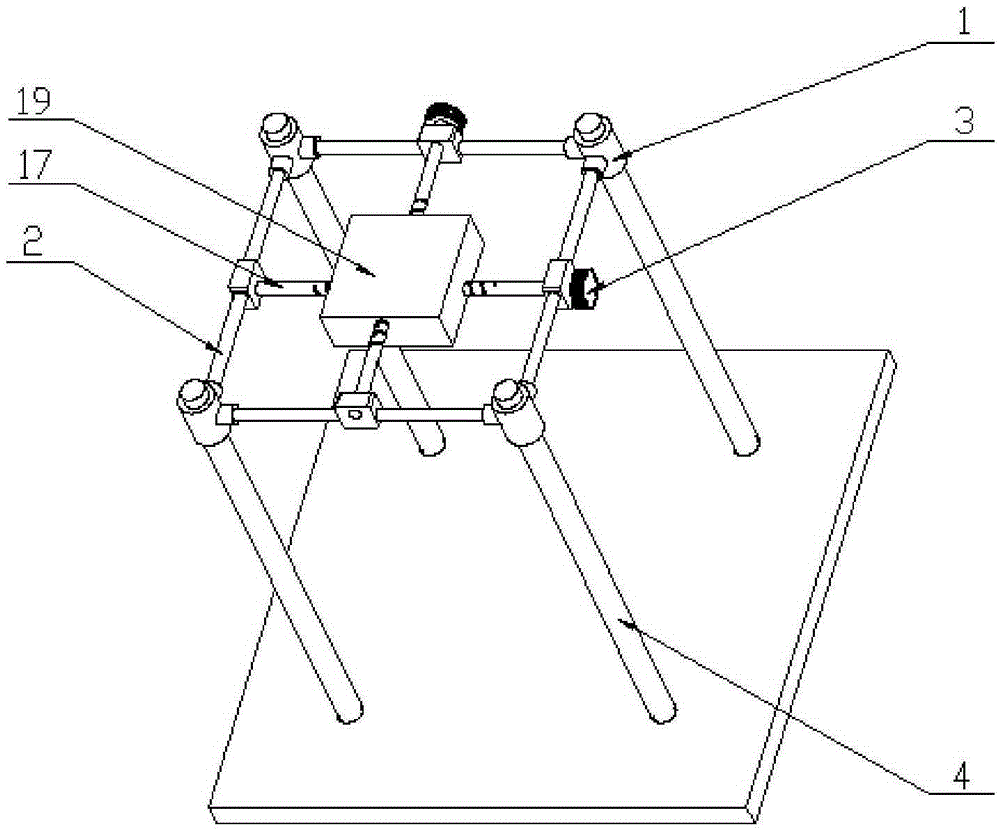

[0023] like figure 1 as shown, figure 1 It is a three-dimensional diagram of the fine-tuning system structure of a hydrodynamic pressure suspension polishing device with controllable fluid boundary in the present invention. The planar movement of the plate 19, that is, the adjustment of the polishing disc 9 to move to the geometric center of the polishing liquid container 8, prepares for the rear lifting device to adjust the position of the polishing liquid container 8 in the Z direction.

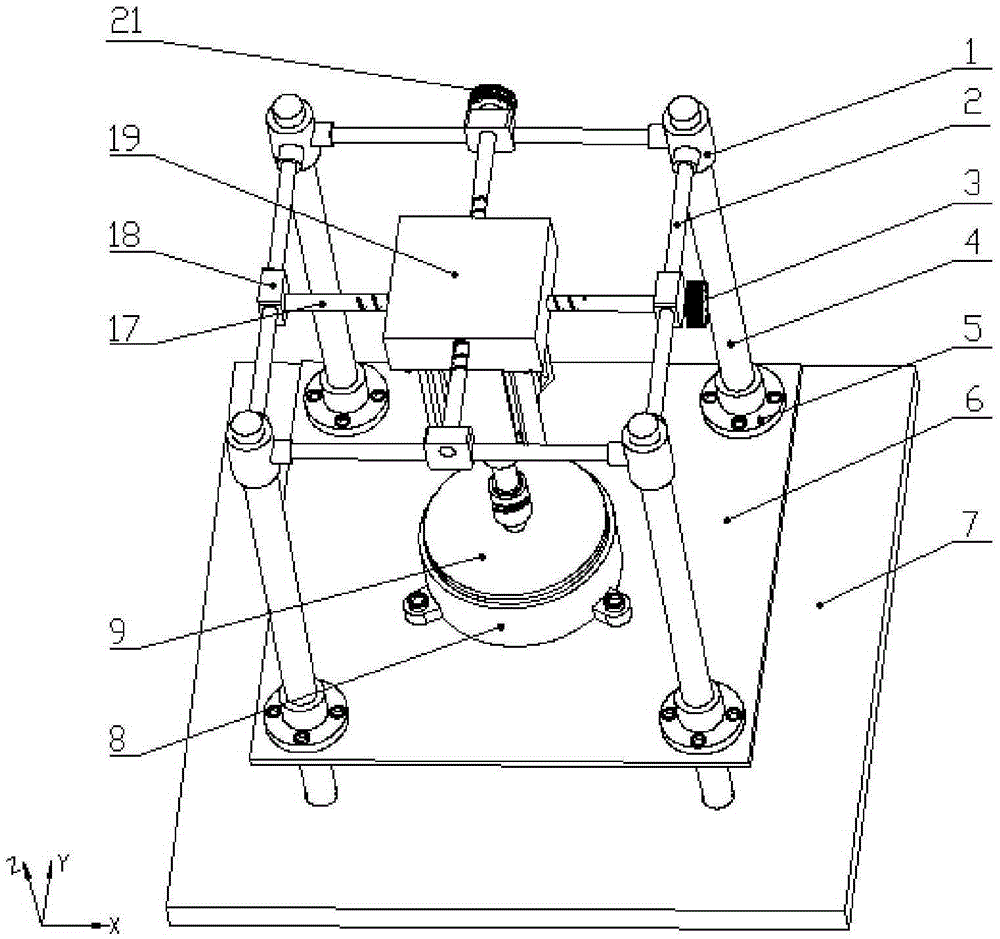

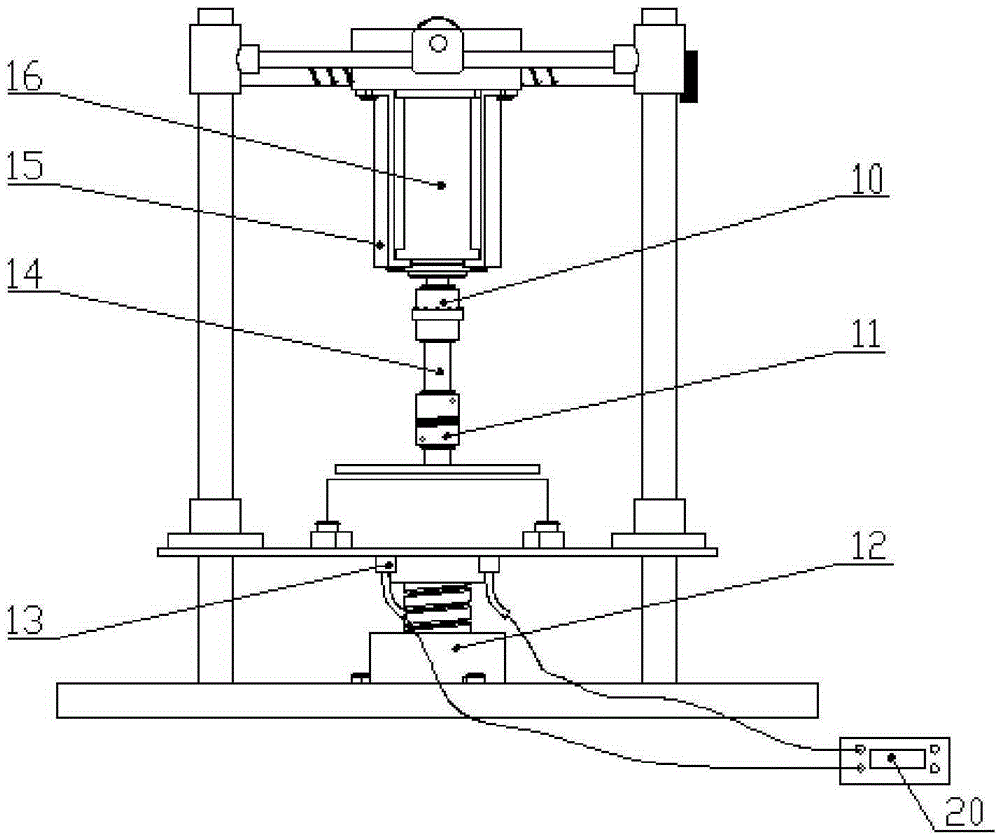

[0024] figure 2 and image 3 It is a structural schematic diagram of a hydraulic suspension polishing device with controllable fluid boundaries. The main components include a horizontal worktable 7, a spiral lifting column 12, a polishing liquid container 8, a polishing disc 9, and a servo motor 16. The polishing liquid container 8 is fixed on On the support plate 6, the load cell 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com