Floating type surface finishing system executer

A floating and actuator technology, applied in the field of machining, can solve the problems of complex structure and difficult to ensure the air tightness of the structure, and achieve the effect of improving flexibility and avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

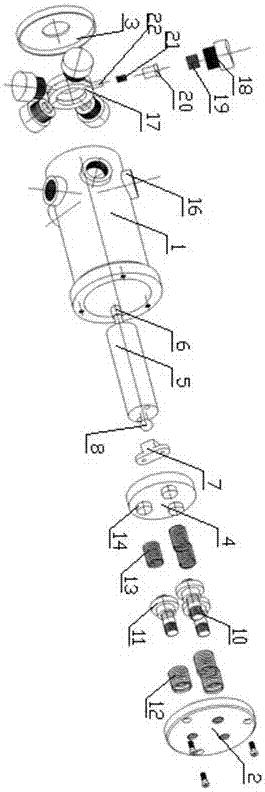

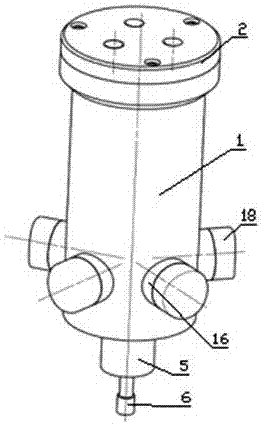

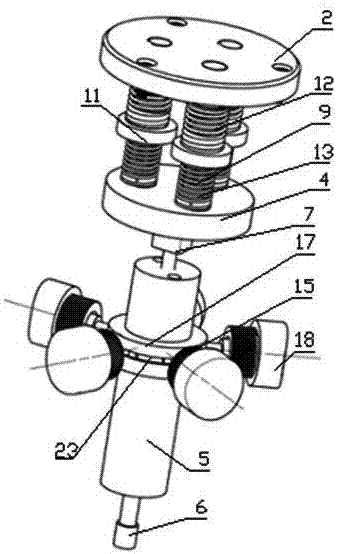

[0019] Such as Figure 1-4 As shown, the present invention comprises a cylindrical shell 1 with openings at both ends, an end cover 2 is connected to the upper end of the cylindrical shell 1, a rubber dustproof cover 3 is connected to the lower end, and a sliding fit is arranged in the cylindrical shell 1. Buffer gland 4.

[0020] A high-speed shaft 5 is arranged in the cylindrical shell 1 below the buffer gland 4, a ball seat 7 is installed in the middle of the lower end surface of the buffer gland 4, and a ball head fitted in the ball seat 7 is connected to the upper end of the high-speed shaft 5 8. The lower end of the high-speed shaft 5 passes through the dust cover 3 downwards and is connected with the cutter head holder 6 .

[0021] The upper cavity of the buffer gland 4 is provided with an axial floating mechanism 9. The axial floating mechanism 9 includes three screw rods 10 uniformly distributed in the cavity below the buffer gland 4. The lower ends of the screw rods...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com