Lamination type granite substrate heavy-calibre optical reflector

An optical reflection and granite technology, applied in the field of applied optics, can solve problems such as poor surface processing performance of aluminum materials, high cost of aluminum castings, and limited optical performance of reflectors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

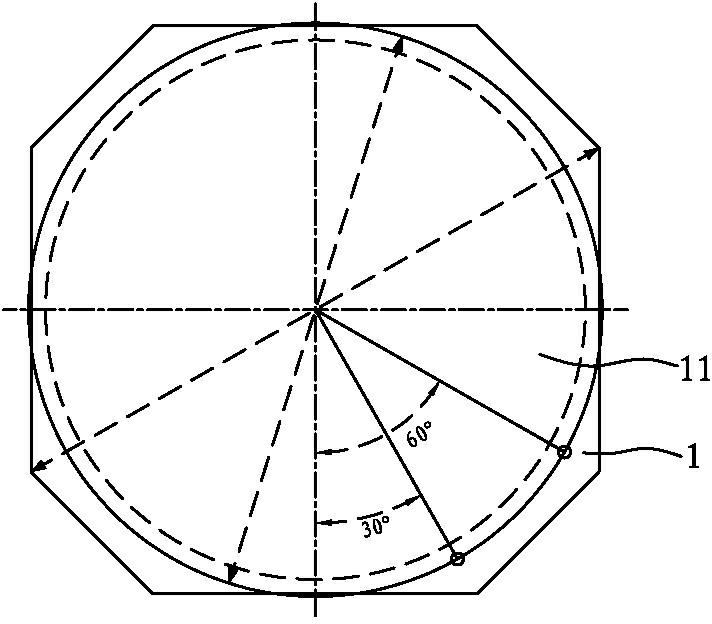

[0017] like figure 1 As shown, the present invention is a film-coated granite base large-diameter optical mirror, which includes an optical mirror body 1, which can be a plane mirror body, a spherical collimating mirror body, or an aspheric surface Collimating mirror body.

[0018] The optical mirror body 1 is made of granite with low expansion coefficient.

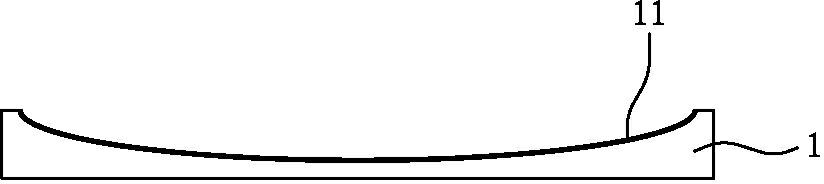

[0019] like figure 2 As shown, the reflective surface of the optical mirror body 1 is physically treated, that is, a high-reflectivity aluminum film 11 is pasted on the reflective surface, thereby forming a high-reflectivity reflective layer 11 on the reflective surface.

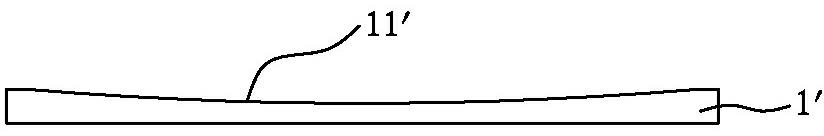

[0020] like image 3 As shown, the reflective surface of the mirror body 1 is physically treated, that is, a metal film system with high reflectivity is coated on the reflective surface, so that a layer of reflective layer 11 with high reflectivity is formed on the reflective surface.

[0021] The invention proposes a method of using granite to rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com