Electroplating machine and electroplating method thereof

A technology of electroplating machine and electroplating parts, applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems of affecting product quality, long time, easy to produce errors, etc., and achieve the effect of improving electroplating effect, improving smoothness and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

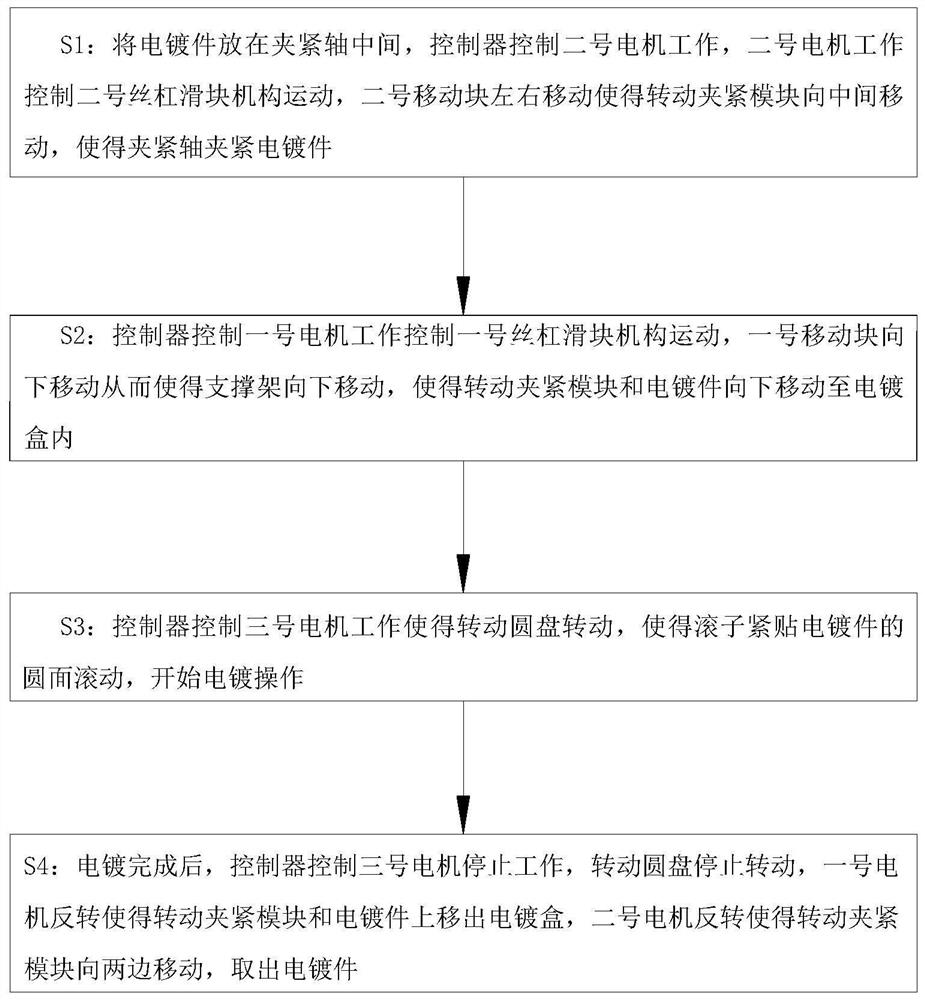

Method used

Image

Examples

Embodiment approach

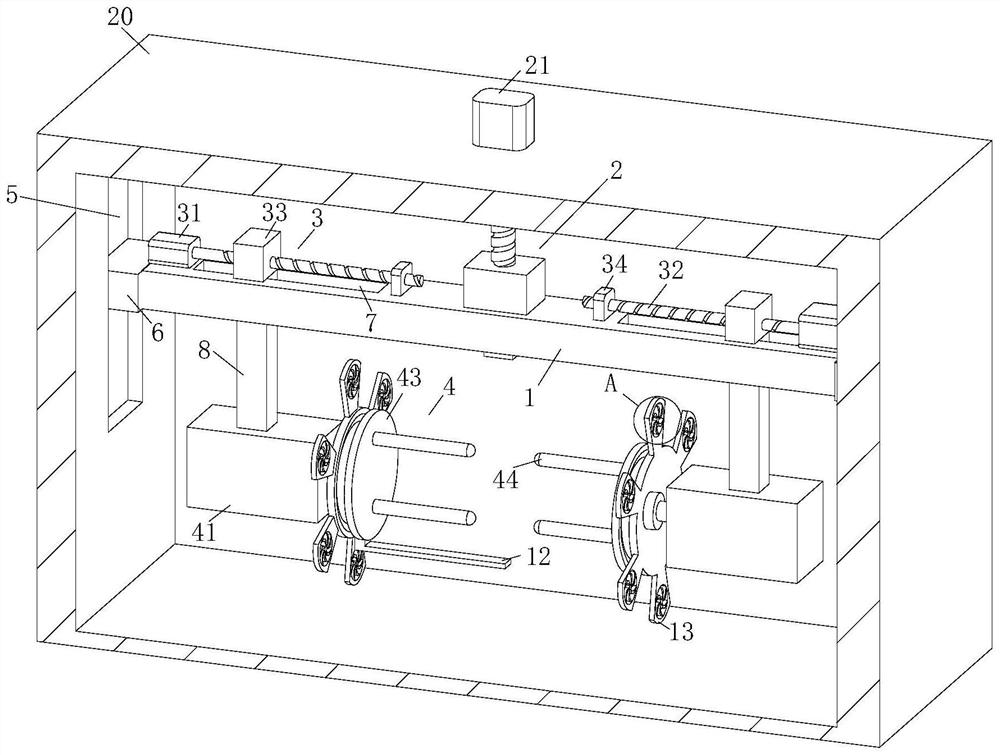

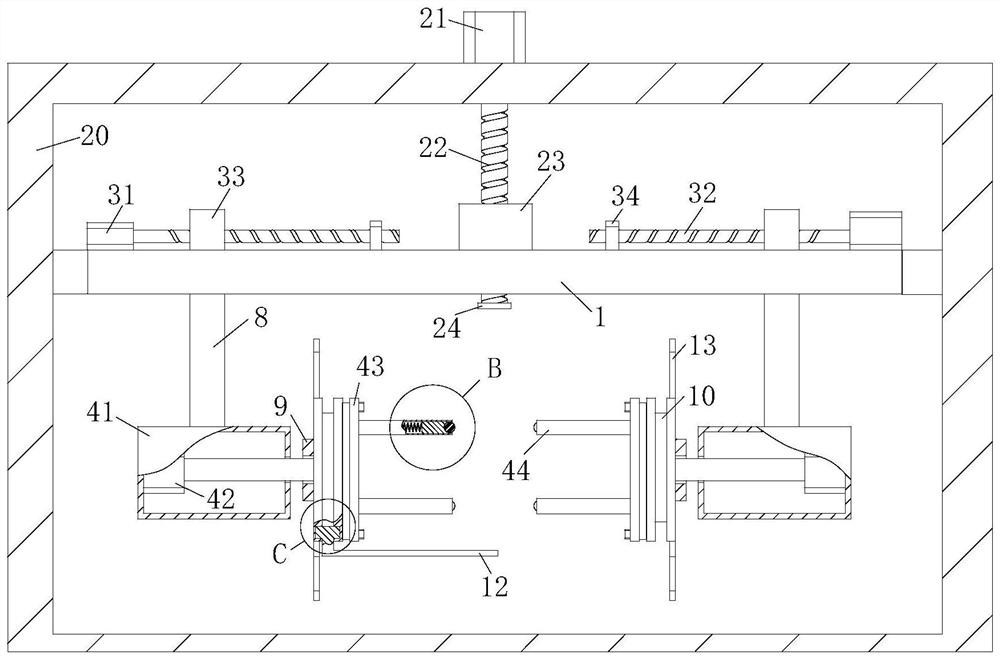

[0038] As an embodiment of the present invention, the clamping shaft 44 is provided with a cavity 441; a sliding rod 442 is slidably connected to the cavity 441; the roller 45 is rotatably connected to the sliding rod 442; One end of the sliding rod 442 away from the roller is fixedly connected with a spring 443; the end of the spring 443 away from the sliding rod 442 is fixedly connected on the inner wall of the cavity 441; during work, by setting the spring 443, the clamping shaft 44 is clamped When electroplating parts, the spring 443 is squeezed by the roller 45 and the sliding rod 442 for buffering to prevent the electroplating parts from being worn during the clamping process, thereby improving the surface finish of the electroplating parts, thereby facilitating the electroplating work and improving the electroplating effect. Improve product quality.

[0039] As an embodiment of the present invention, the side of the rotating disk 43 is provided with a disk groove 10, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com