Polisher of external wall insulation board

A technology of external wall insulation board and polishing machine, which is applied in the direction of grinding/polishing equipment, machine tools suitable for grinding workpiece planes, grinding machines, etc., to achieve the effect of improving the surface finish and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

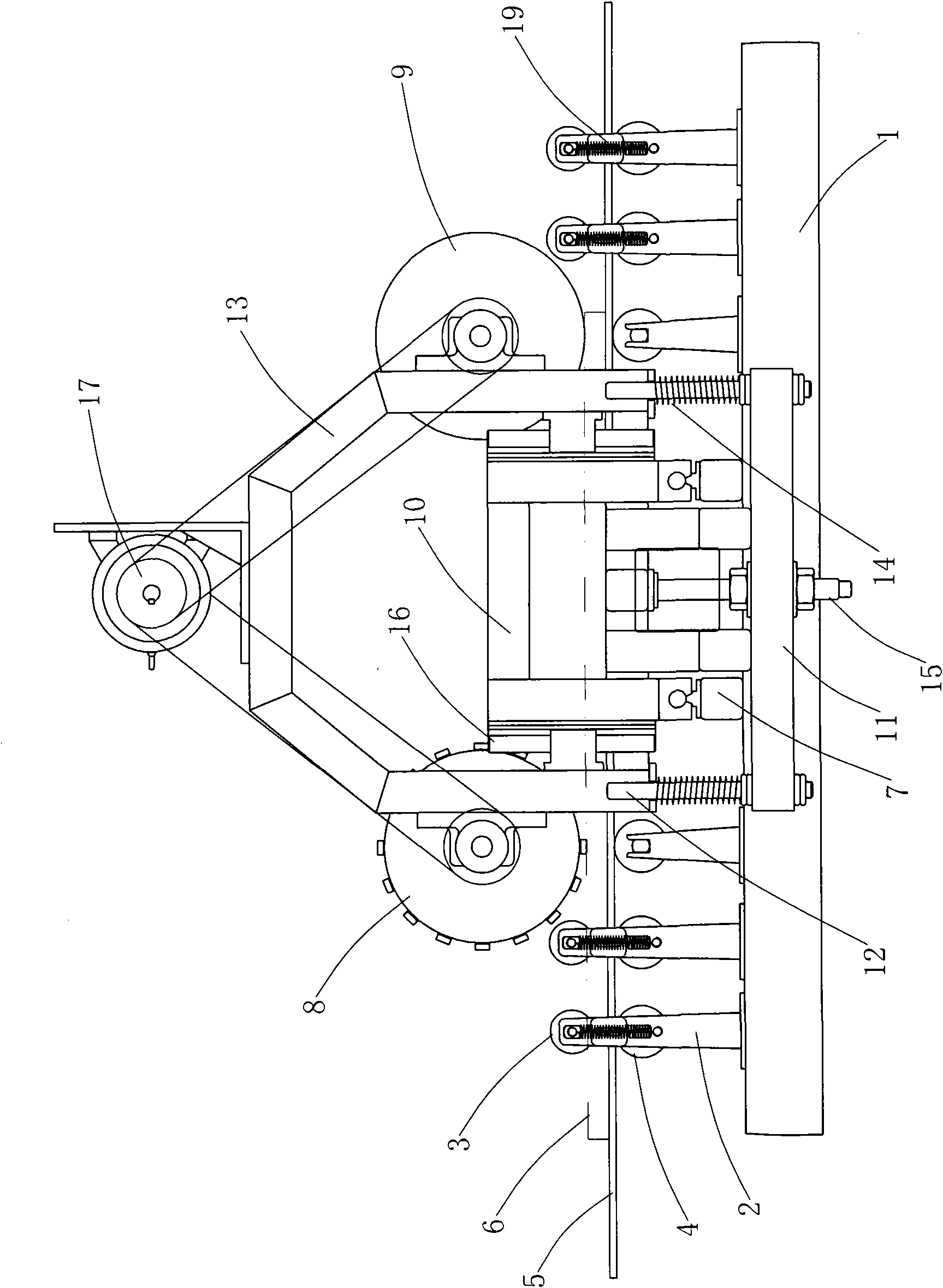

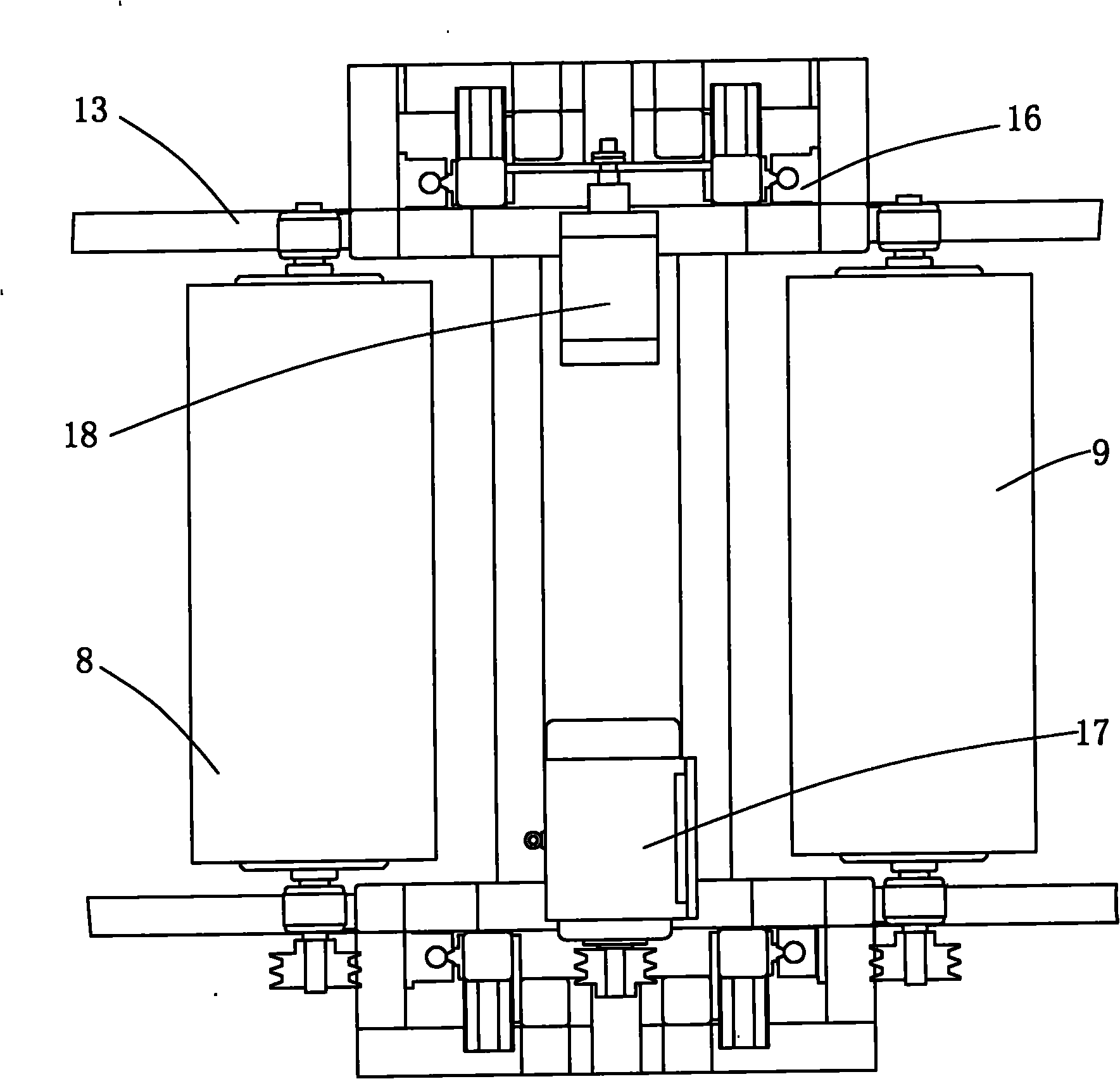

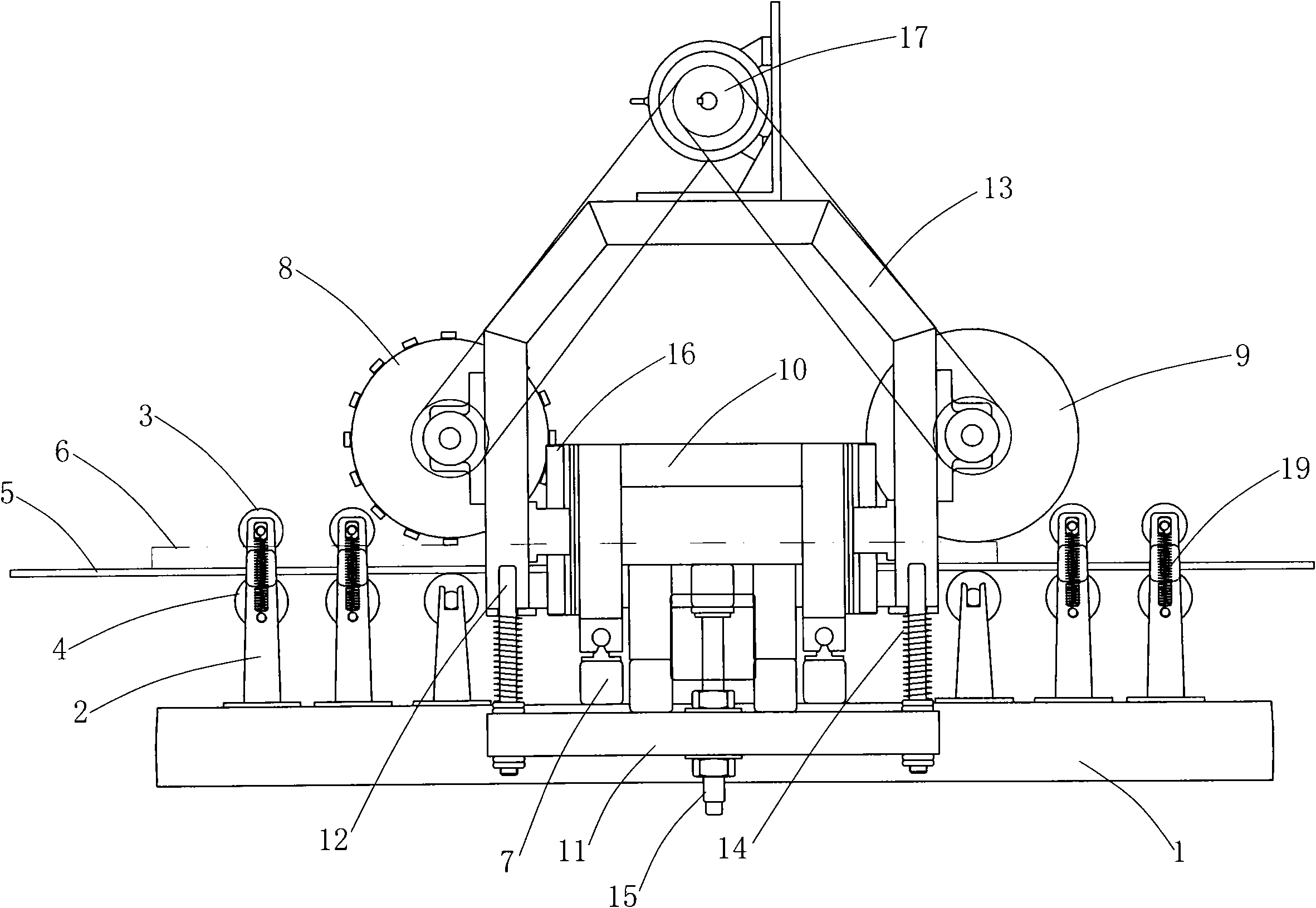

[0023] Example: Combine figure 1 , 2 , the external wall insulation board polishing machine of the present embodiment, on the frame 1, a plurality of columns 2 arranged in a line are fixed, and each column is respectively provided with an upper pressing roller 3 and a lower supporting roller 4, and each upper pressing roller 3 Driven by a power mechanism;

[0024] The conveyer belt 5 driven by the power source passes horizontally between each upper pressing roller and the lower idler roller, and is used to transport the insulation board 6 , and the insulation board is clamped by the upper pressing roller 3 and the lower idler roller 4 and transported forward.

[0025] to combine figure 1 , two horizontal guide rail seats 7 are arranged on the frame 1, which are parallel to the wheel shafts of the cutting wheel 8 and the polishing wheel 9; the bottom of the transition bracket 10 is provided with a horizontal guide rail matched with the horizontal guide rail seat 7, which can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com