Manufacturing method of hollow microsphere wood plastic composite board

A manufacturing method and composite board technology, which is applied in the manufacture of wood-plastic composite boards and hollow microsphere wood-plastic composite boards, and can solve problems such as lack of sealing properties and inability to form a vacuum environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

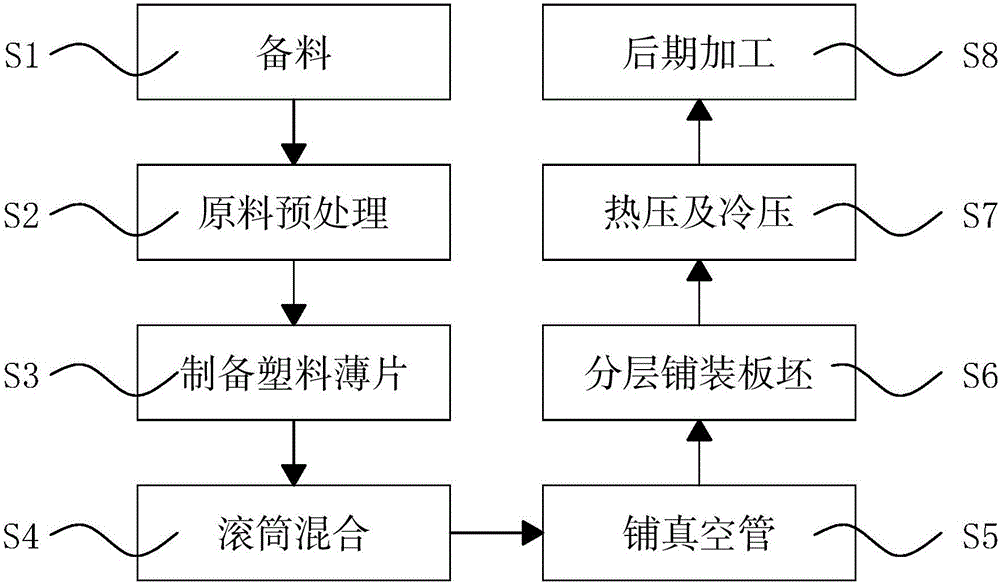

[0030] Specific Embodiment 1: Combining figure 1 To illustrate this embodiment, a method for manufacturing a hollow microsphere wood-plastic composite board described in this embodiment includes the following steps:

[0031] S1. Material preparation: Process wood or straw by one or more methods of planing, chipping, rolling, sawing and screening to obtain woody raw materials;

[0032] S2. Raw material pretreatment: carry out drying treatment on the woody raw material, and dry the moisture content of the woody raw material to below 5%;

[0033] S3. Preparing plastic flakes: processing thermoplastics into thermoplastic flakes;

[0034] S4. Roller mixing: placing thermoplastic flakes, hollow microspheres and the woody raw material in a roller and mixing them evenly to obtain a mixture of the three;

[0035] S5, Laying the vacuum tube: laying the vacuum tube in the mould;

[0036] S6, layered paving slab: divide the mixture into two parts, pave one of them on the directional pa...

specific Embodiment approach 2

[0040] Specific embodiment 2: In S5, the liquid coupling agent is also applied to the mixture of thermoplastic flakes, hollow microspheres and wood raw materials in the process of drum mixing by spraying method, and the obtained mixture is a compound with coupling agent added. Mixture; Others are identical with specific embodiment 1.

[0041] The technical effect of this embodiment is that the coupling agent can be evenly attached to the three materials by using the spraying method, and the mixing by the roller is beneficial to obtain a more evenly dispersed material, which is effective in the subsequent paving and pressing into boards. It ensures the uniform mechanical properties of the board and the quality of the board.

specific Embodiment approach 3

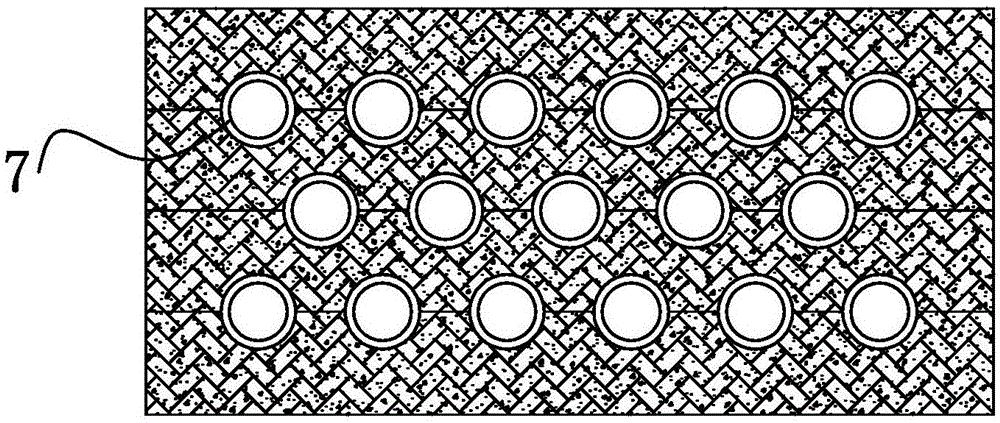

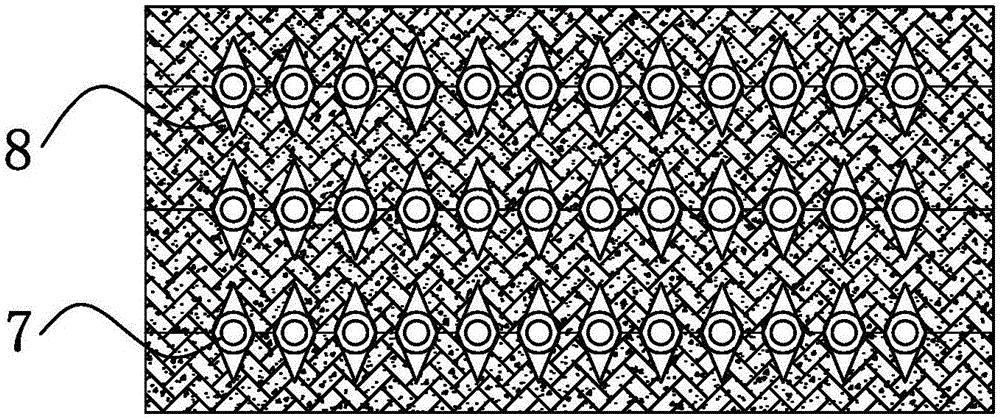

[0042] Embodiment 3: Combining figure 1 , figure 2 and image 3 Describe this embodiment, the manufacturing method of a hollow microsphere wood-plastic composite board described in this embodiment, the specifications of the wood raw material are: length 20~200mm, width 2~20mm, thickness 0.1~2mm; the thermoplastic The specifications of the flakes are: length 60-100mm, width 15-20mm, thickness 0.05-0.2mm; the density of the hollow microspheres is 0.05-0.15g / cm 3 , the particle size is 10-150 microns; the others are the same as in Embodiment 1.

[0043] The technical effect of this embodiment is: the specification of the material determines the uniformity of the material during the mixing process, and is conducive to the chemical reaction between the three materials, thereby forming a strong combination, which can promote the quality of the board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com