Nano-ceria-modified acrylate linear high-molecular polymer and preparation method thereof

A nano-cerium dioxide and acrylate technology, applied in the field of PVC processing aids, can solve the problems of general surface smoothness of PVC profiles, general fluidity in particle state, rising cost, etc. Good, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

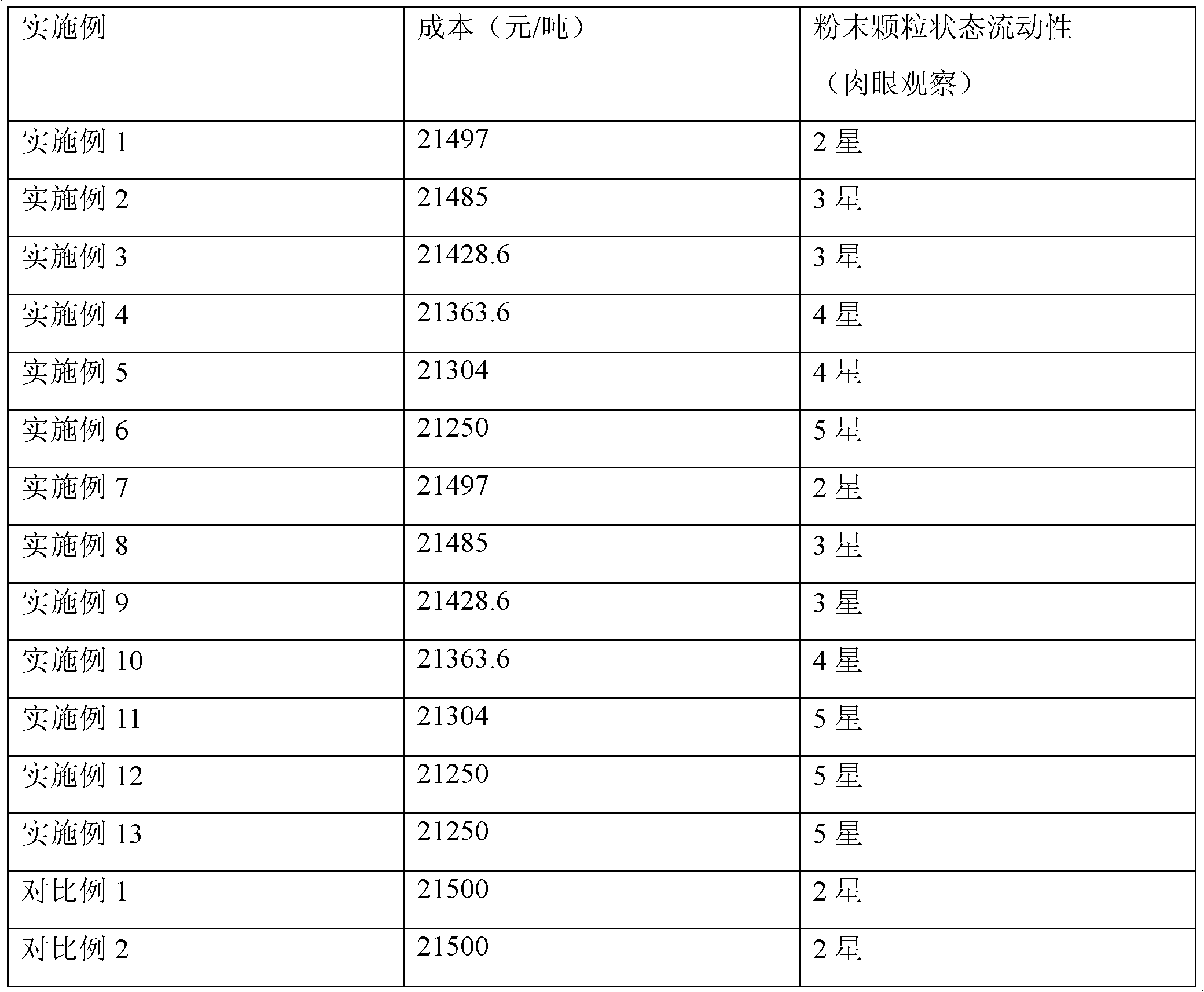

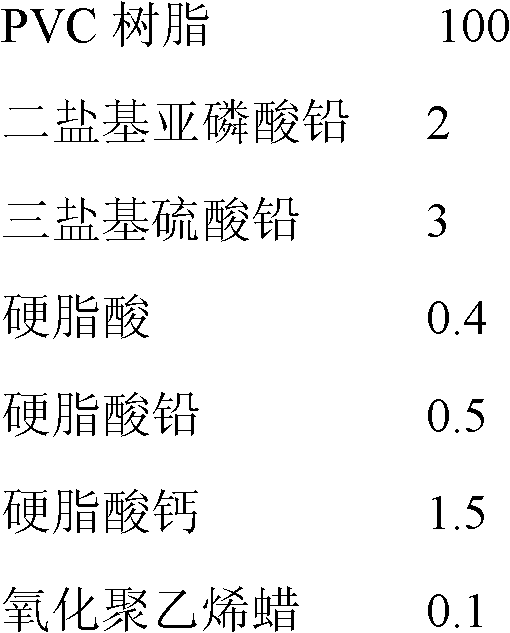

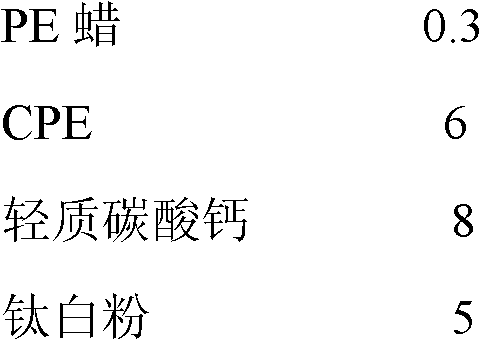

Examples

Embodiment 1

[0015] 1500 kg of demineralized water, 900 kg of methyl methacrylate, 100 kg of butyl acrylate, 1 kg of potassium persulfate, 15 kg of sodium dodecylsulfonate, and 2 kg of nano-cerium dioxide.

[0016] Described copolymer preparation method is as follows:

[0017] Add a set amount of demineralized water into the glass-lined reactor, start stirring at a stirring speed of 75 rpm, add emulsifier, methyl methacrylate and butyl acrylate, close the reactor, and turn on the heating. When the temperature in the reactor When 65°C was reached, the initiator was added. When the temperature in the reactor starts to rise, the polymerization reaction in the reactor has already started, and at this time, the cooling water is turned on to cool down. When the temperature rises to the peak, no longer rises, and starts to drop, add nano-cerium dioxide into the kettle, and when the temperature continues to drop to 65°C, turn off the cooling water, and discharge the material when the temperature ...

Embodiment 2

[0019] 1500 kg of demineralized water, 900 kg of methyl methacrylate, 100 kg of butyl acrylate, 1 kg of potassium persulfate, 15 kg of sodium dodecylsulfonate, and 10 kg of nano-cerium dioxide. The preparation method of embodiment 2 is as embodiment 1.

Embodiment 3

[0021] 1500 kg of demineralized water, 900 kg of methyl methacrylate, 100 kg of butyl acrylate, 1 kg of potassium persulfate, 15 kg of sodium dodecyl sulfonate, and 50 kg of nano cerium dioxide. The preparation method of embodiment 3 is as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com