Oriented Sorghum Strand Boards made with Sorghum Stalks and Processes for Making Same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

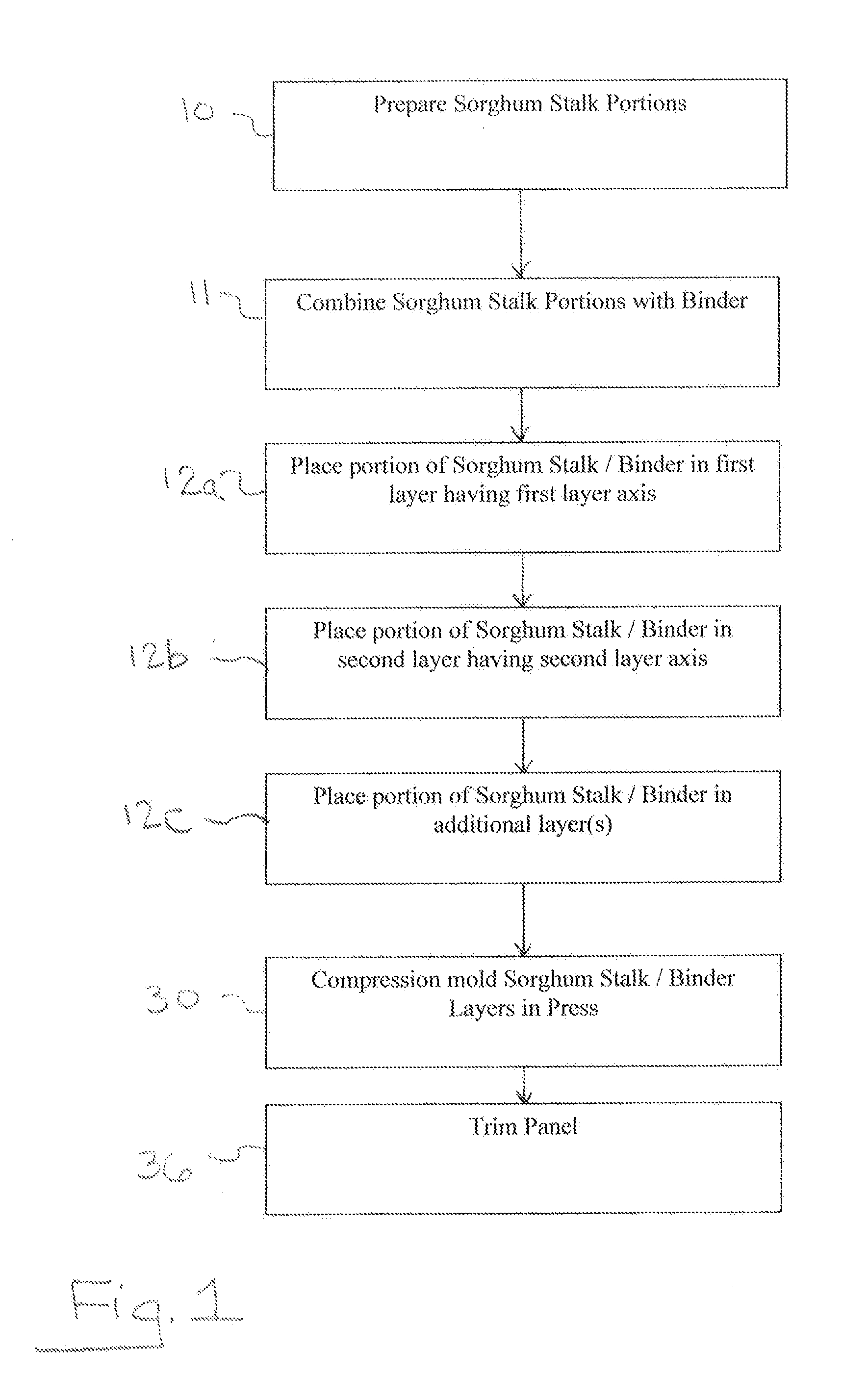

Method used

Image

Examples

example

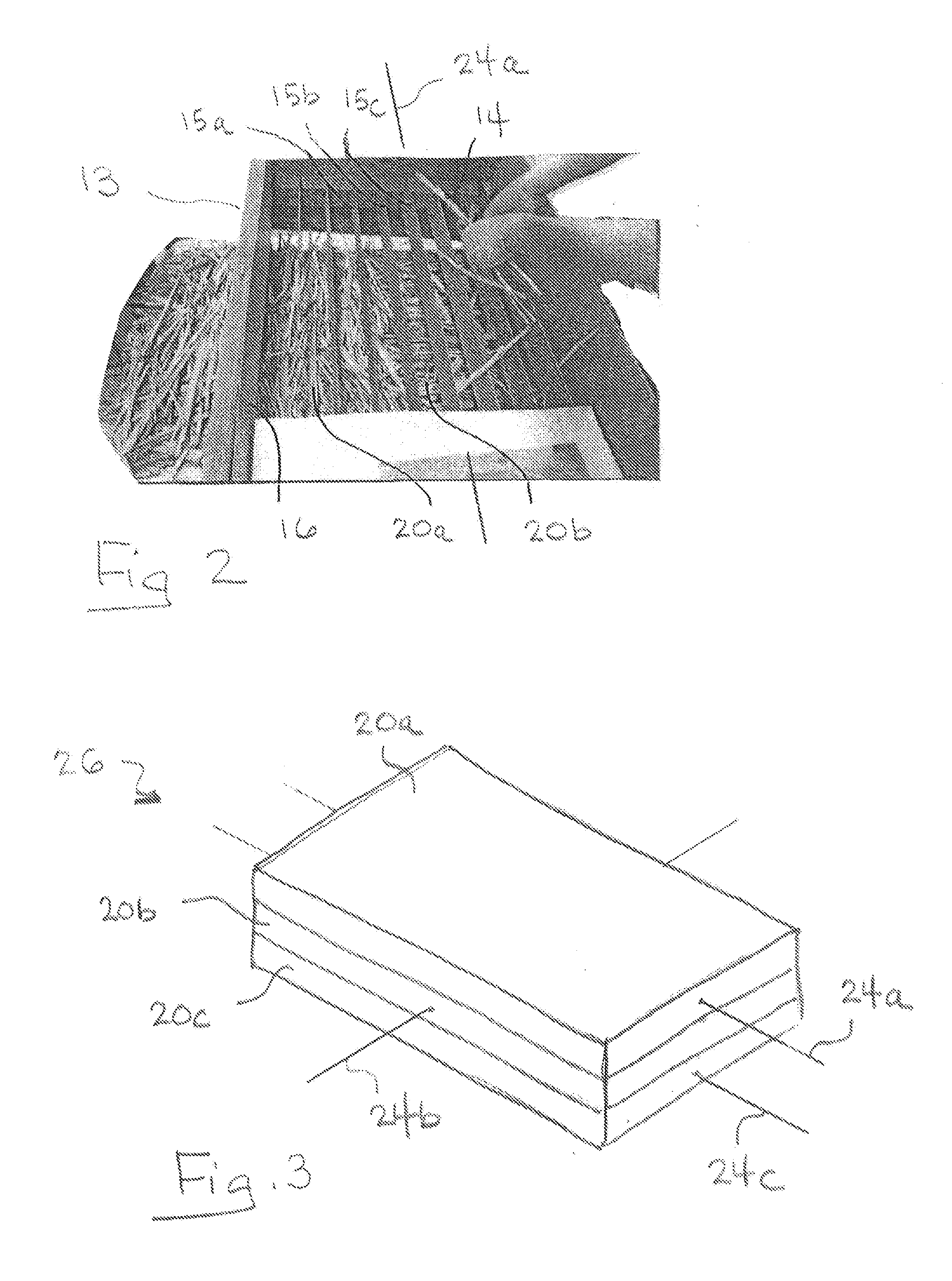

[0059]Single layer and three layer OSSB boards containing sorghum stalk material were prepared using stalks from energy Sorghum plants: 96% by weight, MIDI; 4% by weight and a final Density: 43.2 lb / ft3. Processing parameters for the three layers composites were:[0060]Hot-pressing temperature: 350 F[0061]Duration: 6 min[0062]Closing time: 4 min[0063]Moisture content: 6%

Processing parameters for the one layer composites were:[0064]Hot-pressing temperature: 350 F[0065]Duration: 5 min[0066]Closing time: 3 min[0067]Moisture content: 8%

[0068]FIGS. 8-13 show density modified properties of the one layer and three layer boards. MOR, MOE and IP properties are influenced by density, and the data shown has been normalized by density.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com