Procedures for rapid build and improved surface characteristics in layered manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

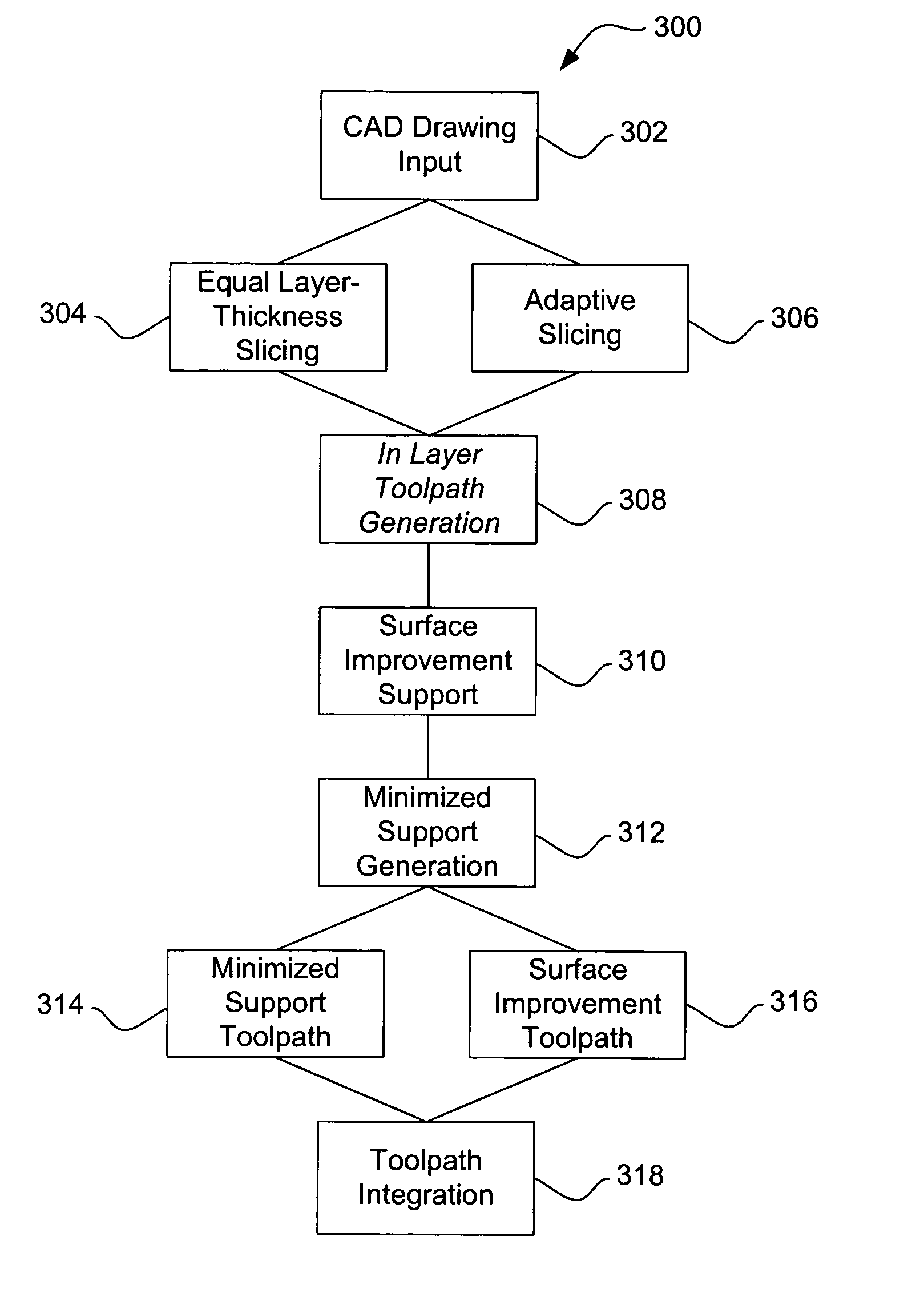

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

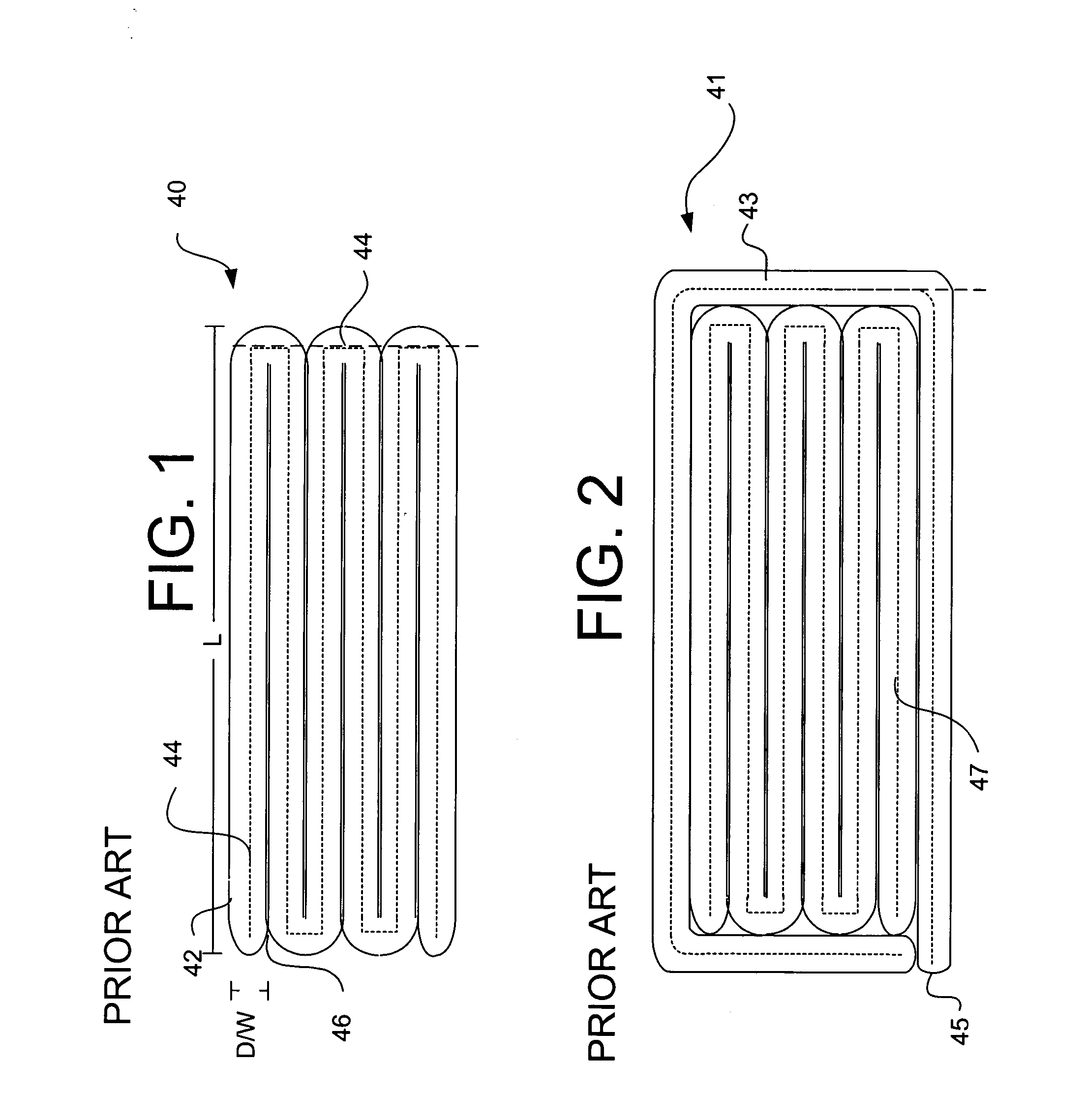

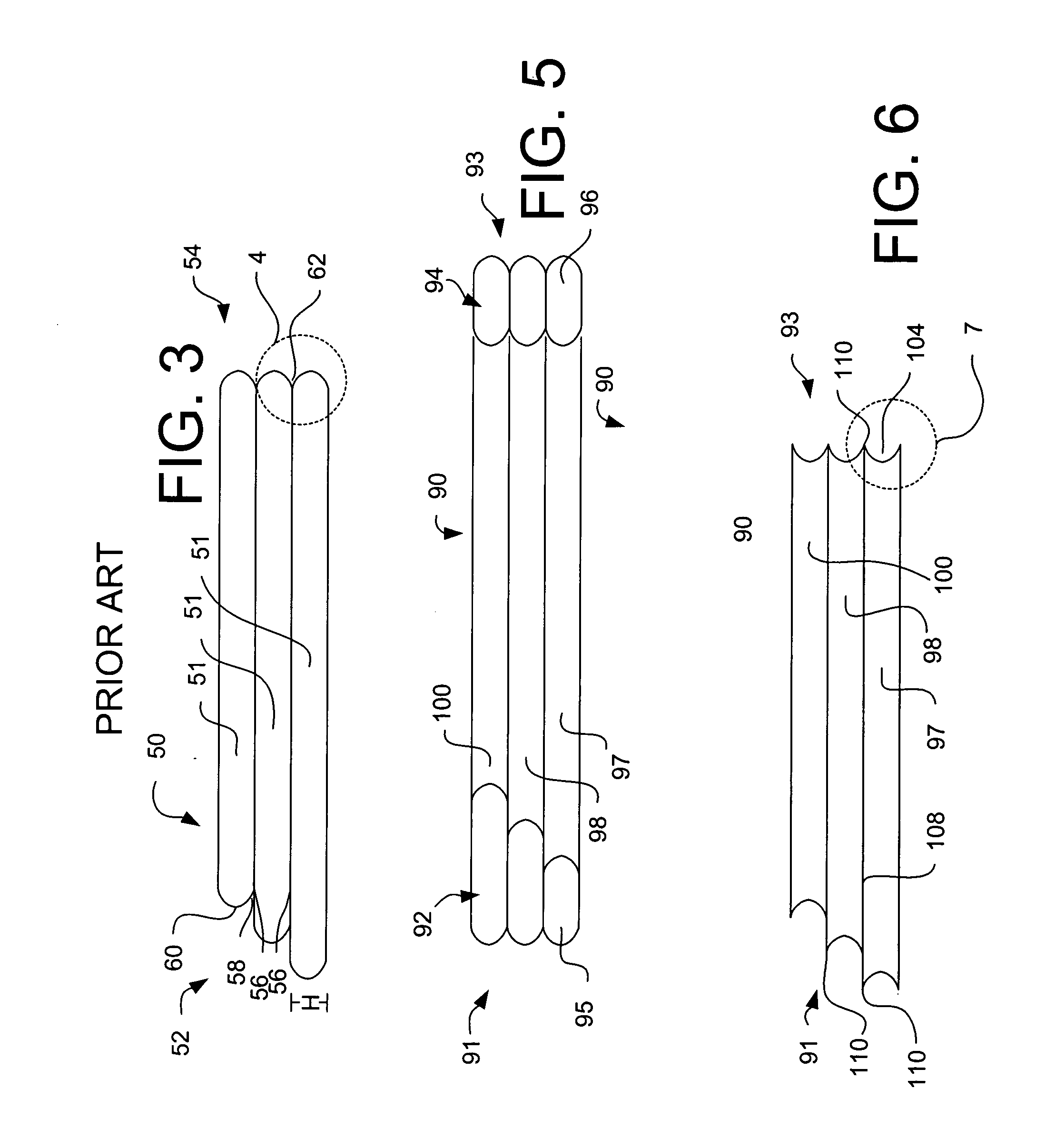

[0058]FIG. 1 illustrates a top view of a single layer of an object 40 made using layered manufacturing techniques. Object 40 is formed from a single bead 42 laid along a tool path 44, having a zigzag pattern to substantially fill a rectangular area. Bead 42 has a diameter or width indicated at D / W and a length indicated at L. Bead 42 may be seen to flow together at inter-bead region 46 where adjacent sections of the bead abut one another. Bead 42 and object 40 may be formed using any suitable manufacturing technique, for example, fused deposition techniques, multi-phase jet solidification techniques, or laser-engineered net shaping techniques. Bead 42 can be a ceramic suspension or slurry, a molten plastic, a powder-binder mixture, a polymeric material ready for curing or hardening, a molten metal, or other suitable materials which harden with time and / or exposure to an external stimulus. Bead 42 can also represent a curable strip of polymer or pre-polymer with polymerization initia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Structure | aaaaa | aaaaa |

| Electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com