Patents

Literature

36results about How to "Increase material rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

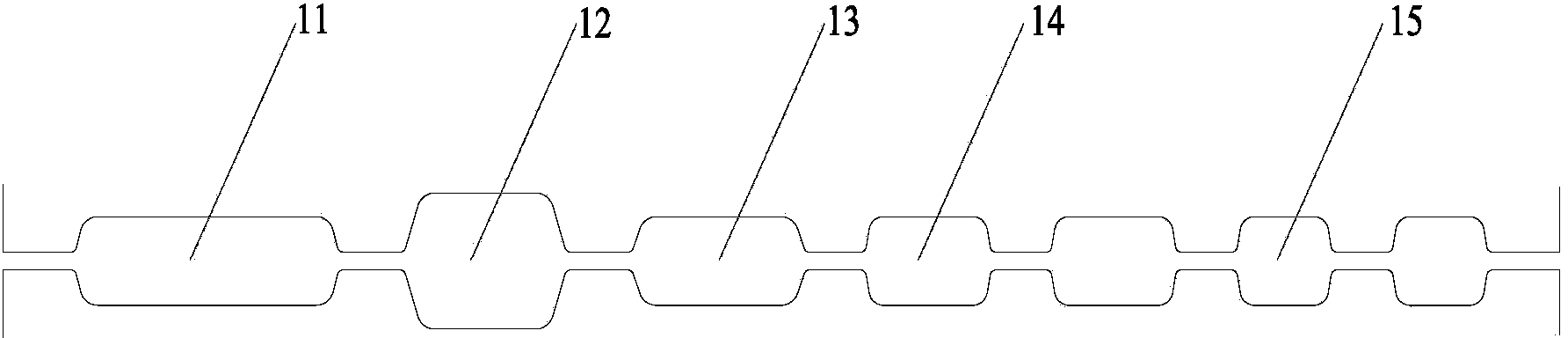

Two-roller reversible mill roller device and technology using continuous casting round billets for carrying out rolling production

ActiveCN103801560AIncrease the amount of steelImprove rolling yieldRollsMetal rolling arrangementsOne passMetallurgy

The invention discloses a two-roller reversible mill roller device and technology using continuous casting round billets for carrying out rolling production. Four types of hole patterns including a transition hole pattern, a supporting hole pattern, a before-finished-product hole pattern and a finished product hole pattern are designed on a pair of rollers. The rolling technology comprises the steps of using the transition hole pattern (1) for rolling the continuous casting round billets, and turning over steel after rolling is accomplished, wherein the rolling reduction ranges from 40 mm to 90 mm per pass; using the supporting hole pattern for continuously rolling the drum-shaped rolled pieces obtained in the previous step to obtain rectangular or square rolled pieces which have regular shapes, and turning over the steel after rolling is accomplished, wherein the rolling reduction ranges from 40 mm 90 mm per pass; using the before-finished-product hole pattern (3) for rolling the rolled pieces to obtain rectangular or oval rolled pieces with reserved rolling reduction and reserved broadening quantity, and turning over the steel billets after rolling is accomplished, wherein the rolling reduction ranges from 20 mm to 90 mm per pass; using the finished product hole pattern for rolling one pass to obtain rolled pieces which are high in dimensional accuracy and product quality, wherein the rolling reduction of square or rectangular steel finished products ranges from 40 mm to 60 mm per pass, and the nominal rolling reduction of round steel ranges from 10 mm to 40 mm per pass.

Owner:HUATIAN ENG & TECH CORP MCC

Natural mineral-based high-temperature anti-oxidation decarbonization coating

InactiveCN102786822AGood dispersionImprove high temperature resistanceCoatingsPhysical chemistrySlurry

Owner:NANJING UNIV OF INFORMATION SCI & TECH

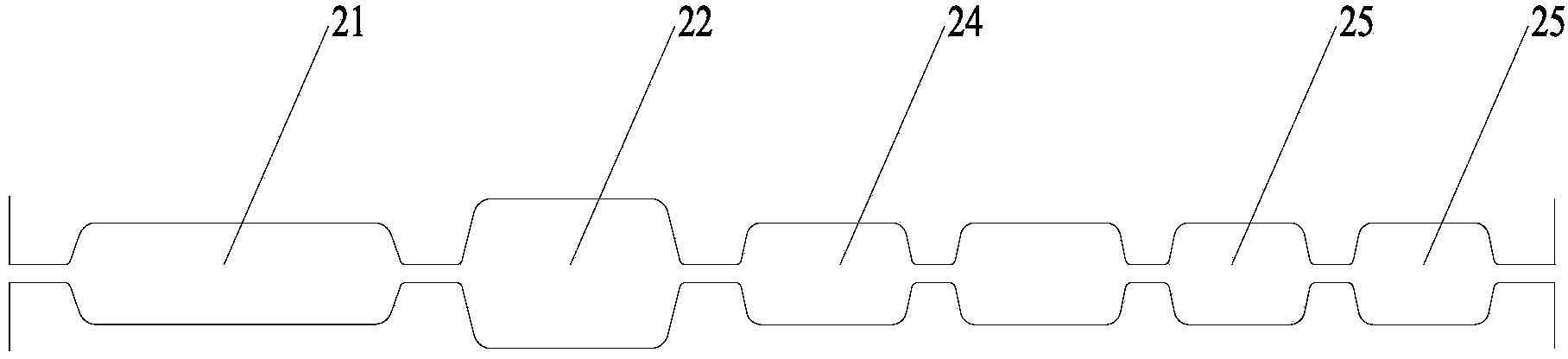

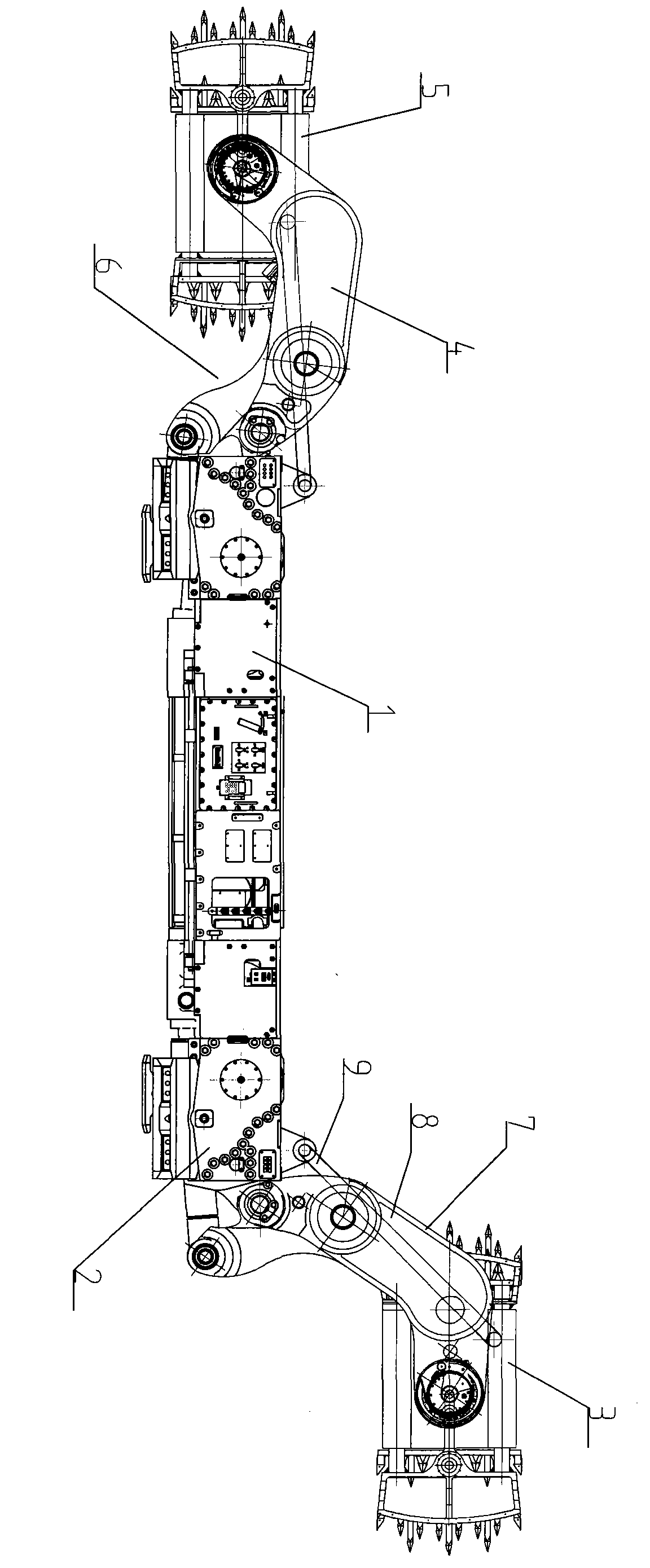

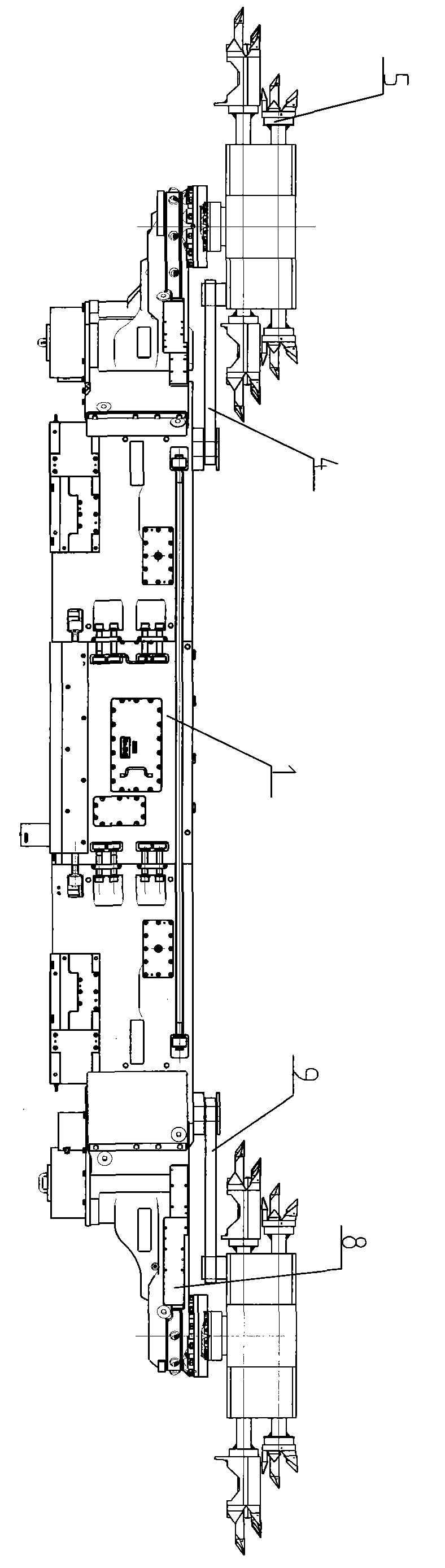

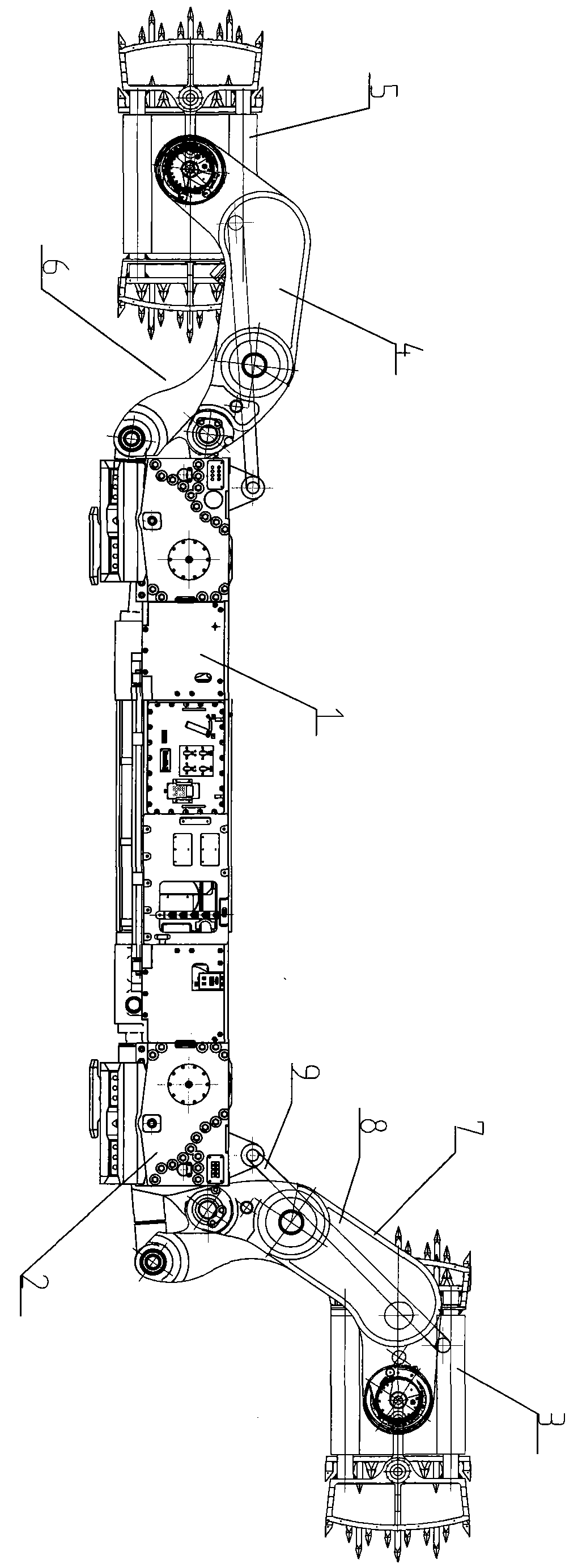

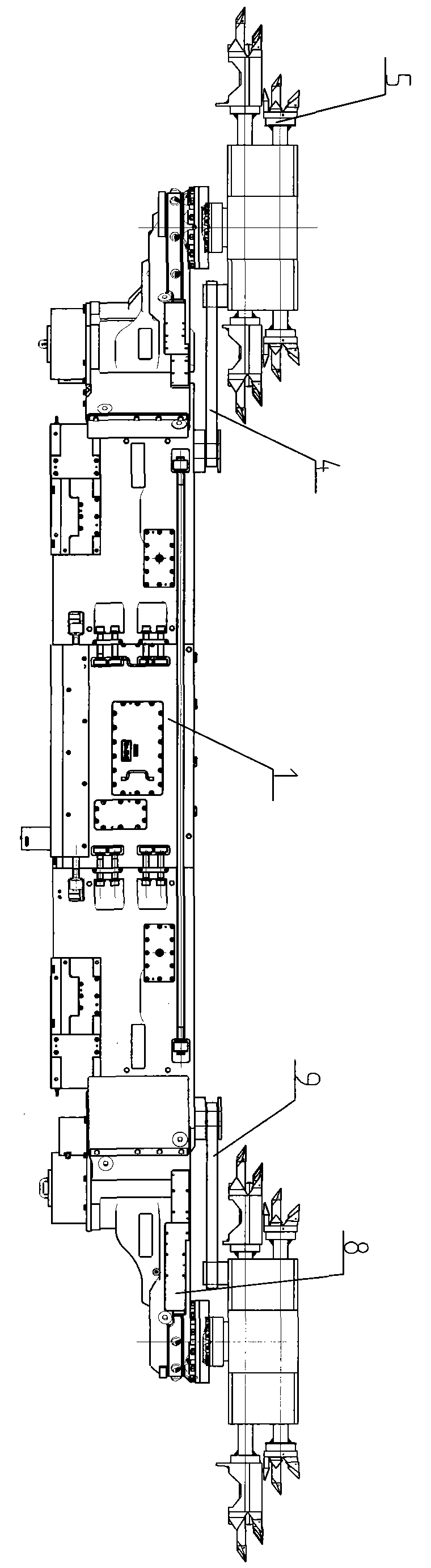

Mining machine with rocker arm provided with coal-passing space

ActiveCN103498671AReduce frictional resistanceLess wearing partsDriving meansCutting machinesMachineRocker arm

The invention provides a mining machine with a rocker arm provided with coal-passing space, which comprises a machine body and a walking portion, and is characterized in that the mining machine with a rocker arm provided with coal-passing space also comprises a rocker arm, and cutting heads; the walking portion is disposed at the lower part of the machine body; the cutting heads are disposed at two ends of the machine body; the rocker arm is a rhomboid rocker arm or a single rocker arm; one end of the rocker arm is connected with the machine body, and the other end of the rocker arm is connected with the cutting heads; the rocker arm arches upwards to form the coal-passing space; the rocker arm is provided with the coal-passing space, which well solves the problem that coal falling by impact of a cutting head near a machine body of a reciprocating impact mining machine can not be conveyed out due to no coal-passing space between a straight rocker arm and a scraper conveyer, gives full play to advantages of high coal mining rate, high efficiency, energy saving, and environmental protection for reciprocating impact mining machines.

Owner:刘素华

A continuous casting billet hot delivery and hot charging process

The invention provides a continuous casting billet hot delivery and hot charging process and solves the problem that products in the prior art are not stable enough in performance. The quality of casting blanks is guaranteed while the effects of energy saving and environmental production are achieved, and meanwhile, the fuel consumption of a casting blank heating furnace is reduced and the output of the casting blank heating furnace is increased; the surface oxidation burning loss amount of casting blanks is reduced; the time for heating the casting blanks in the furnace is reduced and thus the surface oxidation burning loss amount of the casting blanks is reduced relatively; generally the burning loss amount of a cold charging furnace is 1.5%-2.0%, sometimes more than 2.5%; under the condition of a hot charging furnace, the burning loss amount can be reduced to 0.5%-0.7%, so that the yield of the casting blanks is increased.

Owner:张学一

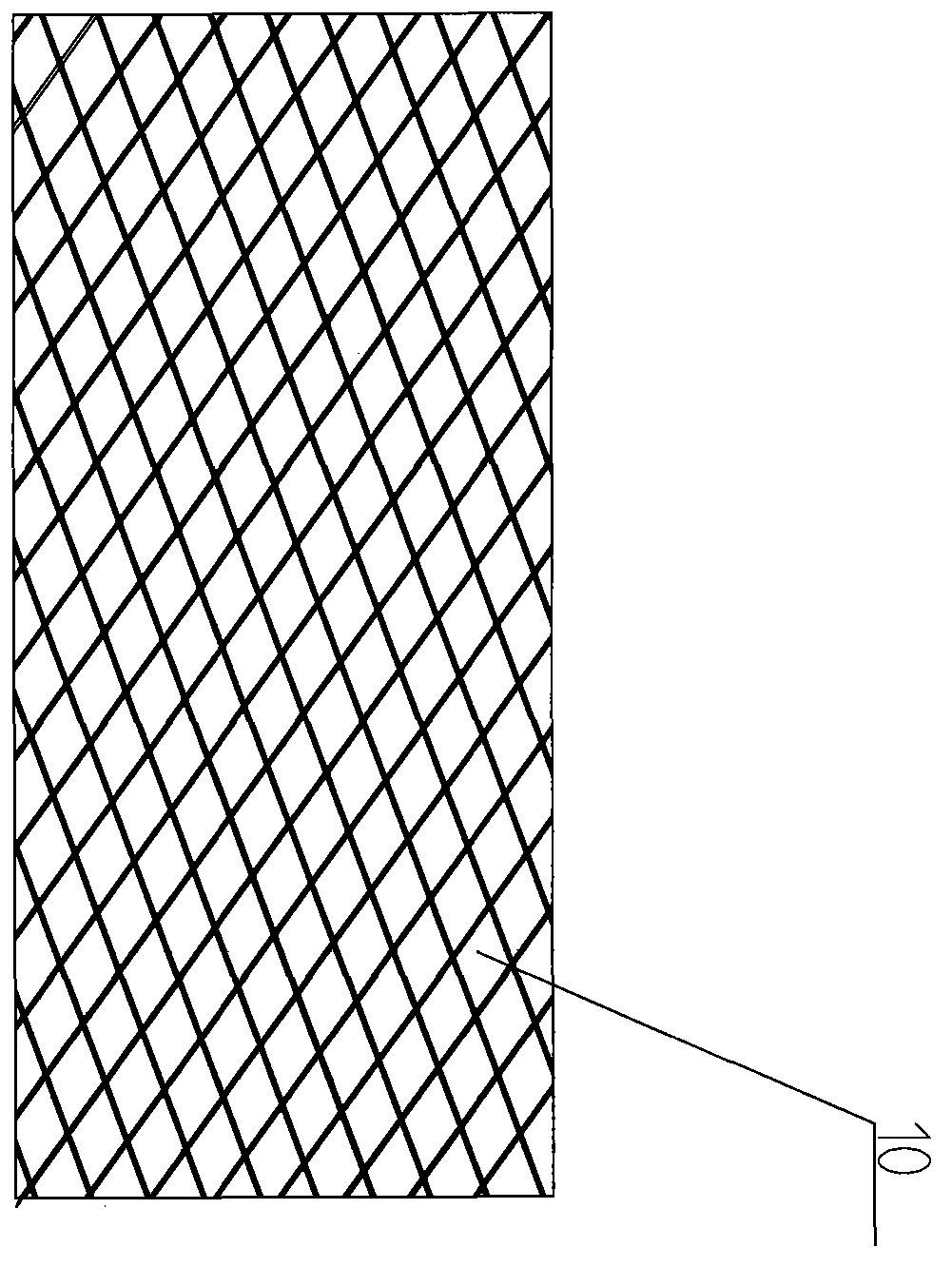

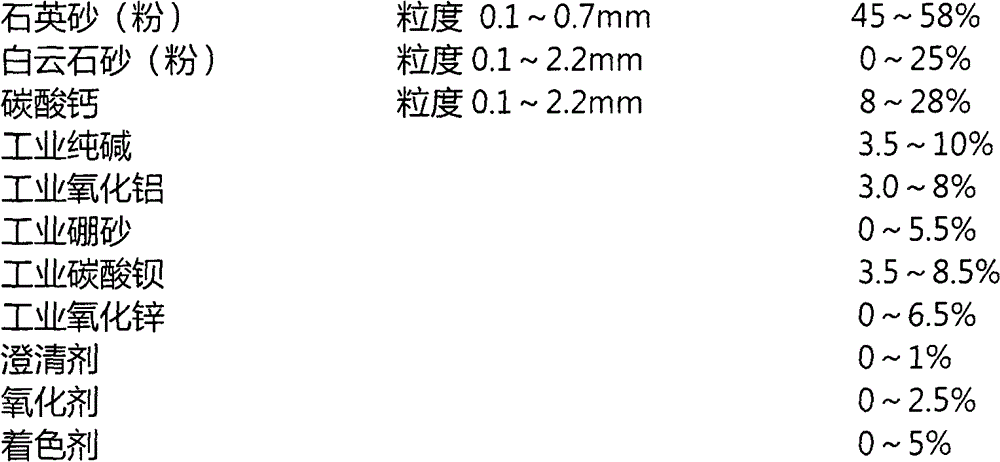

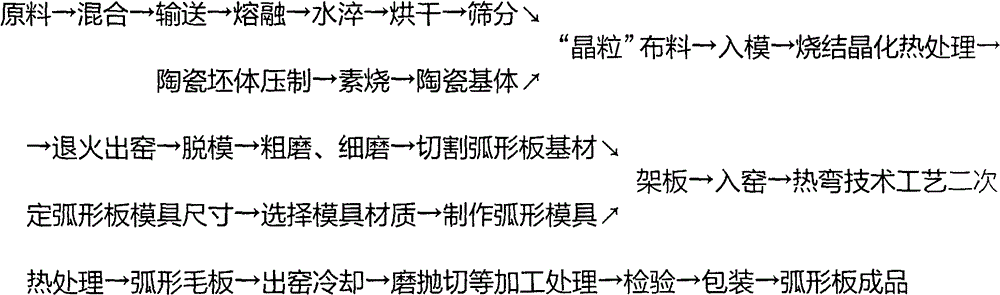

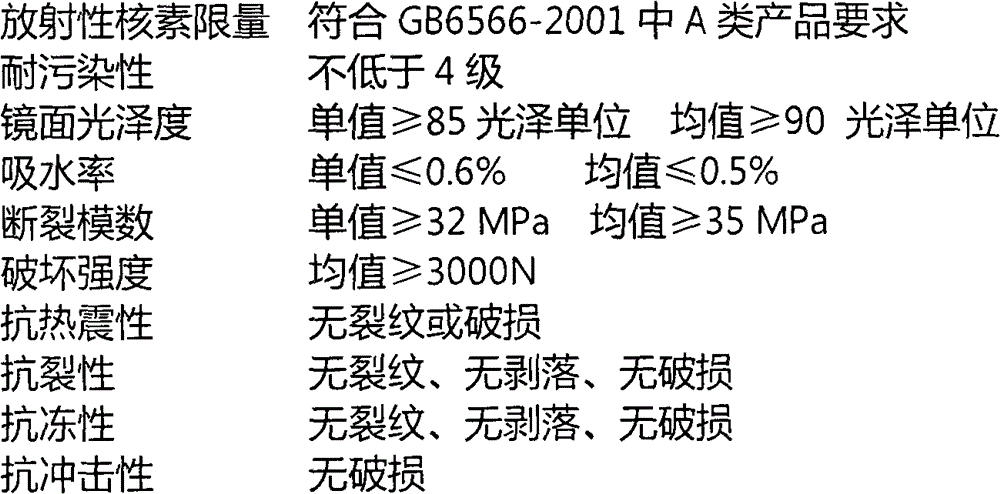

Production process of ceramic-based microcrystal composite arc-shaped plate

InactiveCN102795777APromote a deep revolutionInfluence and change the layoutGlass reforming apparatusComposite plateMaterial distribution

The invention provides a production process of a ceramic-based microcrystal composite arc-shaped plate. The production process takes a microcrystal grain material of a specific formula as a decorative layer and takes a specific ceramic-based blank as a base layer; a crystalline grain material distribution technology is adopted, and the microcrystal grain material and a ceramic base are sintered and crystallized in a crystallizing and sintering kiln at a specific temperature mechanism to form the ceramic-based microcrystal composite arc-shaped plate. The ceramic-based microcrystal composite arc-shaped plate is used as a substrate and is placed in a pre-designed mould; a specific hot bending technical process is utilized to obtain an arc-shaped rough board with a certain arc degree of a pre-set requirement by secondary heat treatment; and the arc-shaped rough board is subjected to milling, polishing and cutting machining and is checked and packaged to obtain an arc-shaped plate finished product. The color of the ceramic-based microcrystal composite arc-shaped plate can be adjusted by adding a coloring agent according to microcrystal grain materials; and the ceramic-based microcrystal composite arc-shaped plate has the characteristics that the batch production finished product rate is high, the manufacturing cost is greatly reduced, the resource is saved, the environment is protected and beautified, and greenness and health are advocated.

Owner:淄博钰晶新型材料科技有限公司 +1

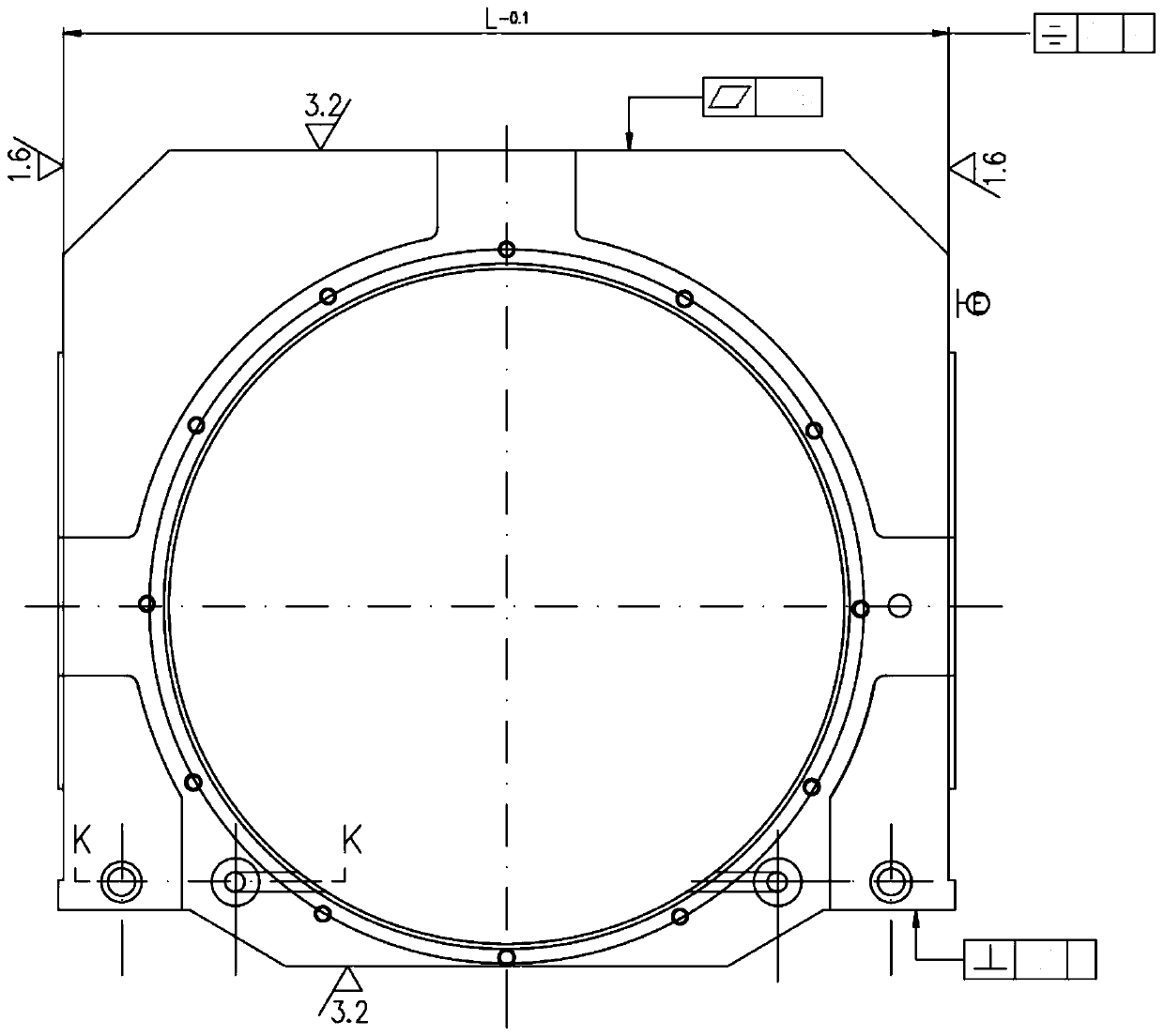

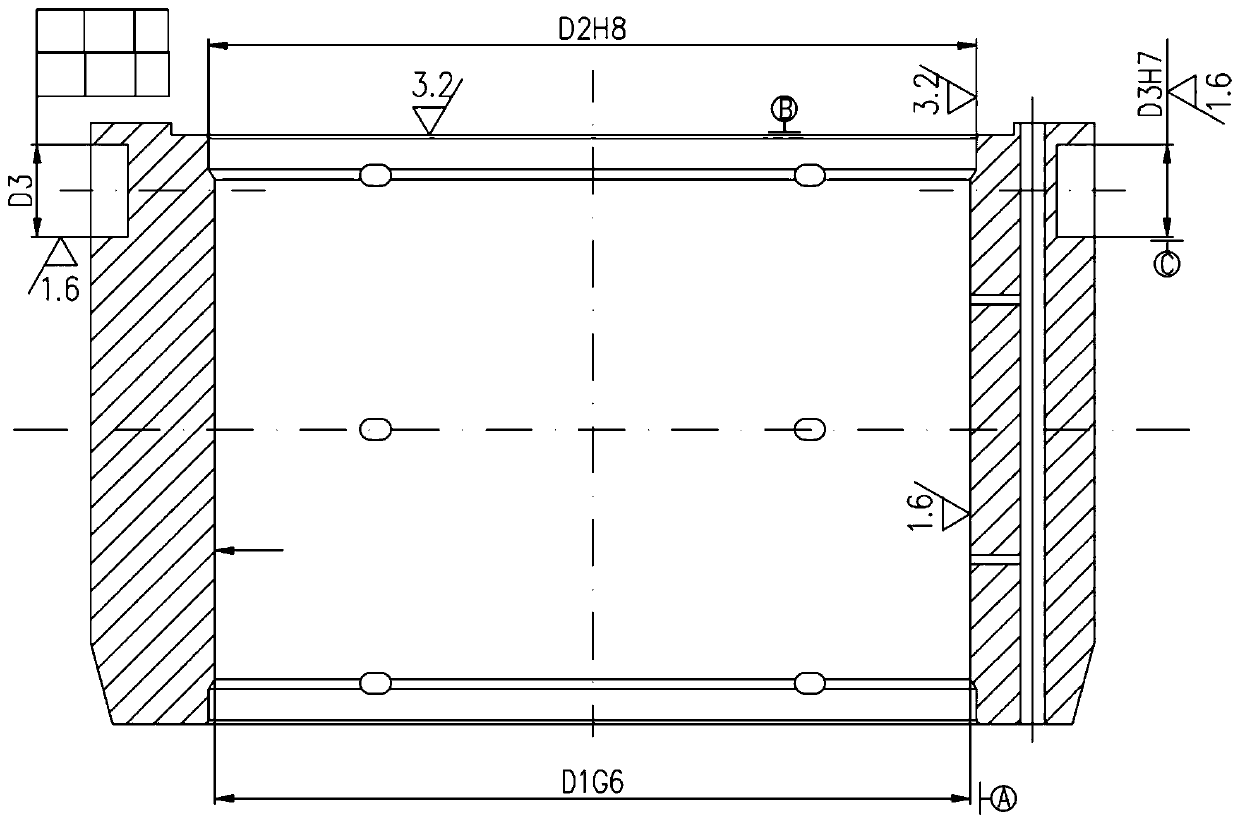

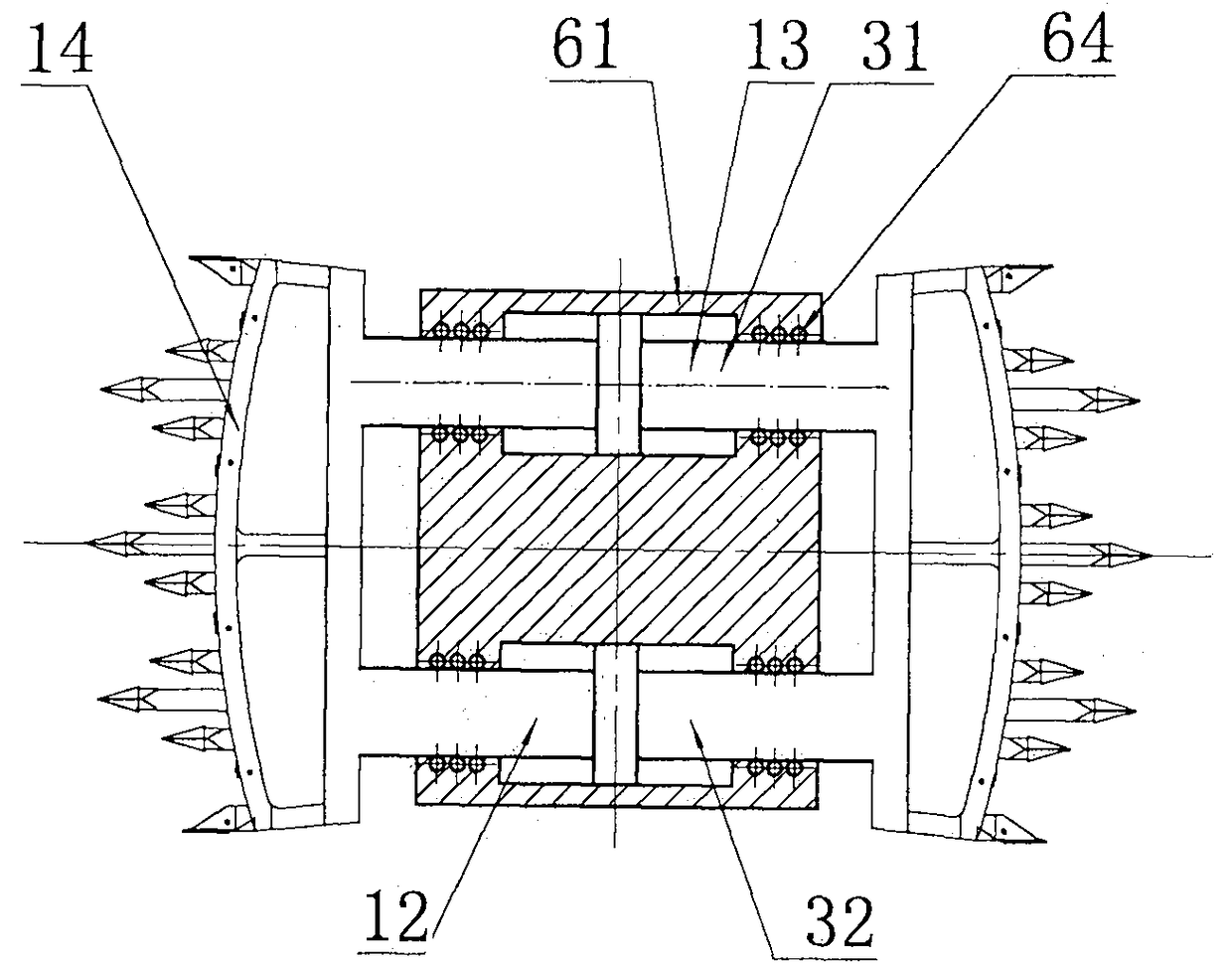

Rolling mill bearing base and manufacturing method thereof

ActiveCN109731916AMeet quick replacement requirementsAxial positioning is accurateMetal rolling stand detailsFurnace typesSurface roughnessSlide plate

The invention discloses a rolling mill bearing base and a manufacturing method thereof. The rolling mill bearing base is forged and processed from high-quality alloy steel, and is mounted at the two ends of a supporting roller of a symmetrical structure on a large rolling mill; the sliding surface which is in contact with a rolling mill memorial gate is equipped with a copper slide plate; precision of a bearing hole is G6, surface roughness of the bearing hole is Ra1.6 and cylindricity of the bearing hole is 0.03mm; precision of a bearing end cover matching hole is H8, surface roughness of thebearing end cover matching hole is Ra3.2, surface roughness of sliding surfaces at the two sides is Ra1.6, degree of symmetry on the bearing hole is 0.1 mm, flatness of an upper surface is 0.05mm, perpendicularity, to the sliding surfaces, of a lower surface is 0.2 mm, the two sliding surfaces are symmetrically equipped with dowel pin holes, precision of the dowel pin holes is H7, surface roughness of the dowel pin holes is Ra1.6, degree of symmetry on the bearing hole is 0.1 mm, and center perpendicularity to the bearing hole is 0.1 mm. An intensive lubricating system is adopted, and a ratioof hole depth to hole diameter of an oil inlet and outlet is 20 or higher. The rolling mill bearing base can meet the requirements of quickly replacing and interchanging a supporting roller, is accurate in positioning, is good in cooling and lubricating effect, is high in precision, reduces rolling mill faults, and guarantees the processing quality.

Owner:武汉钢铁有限公司

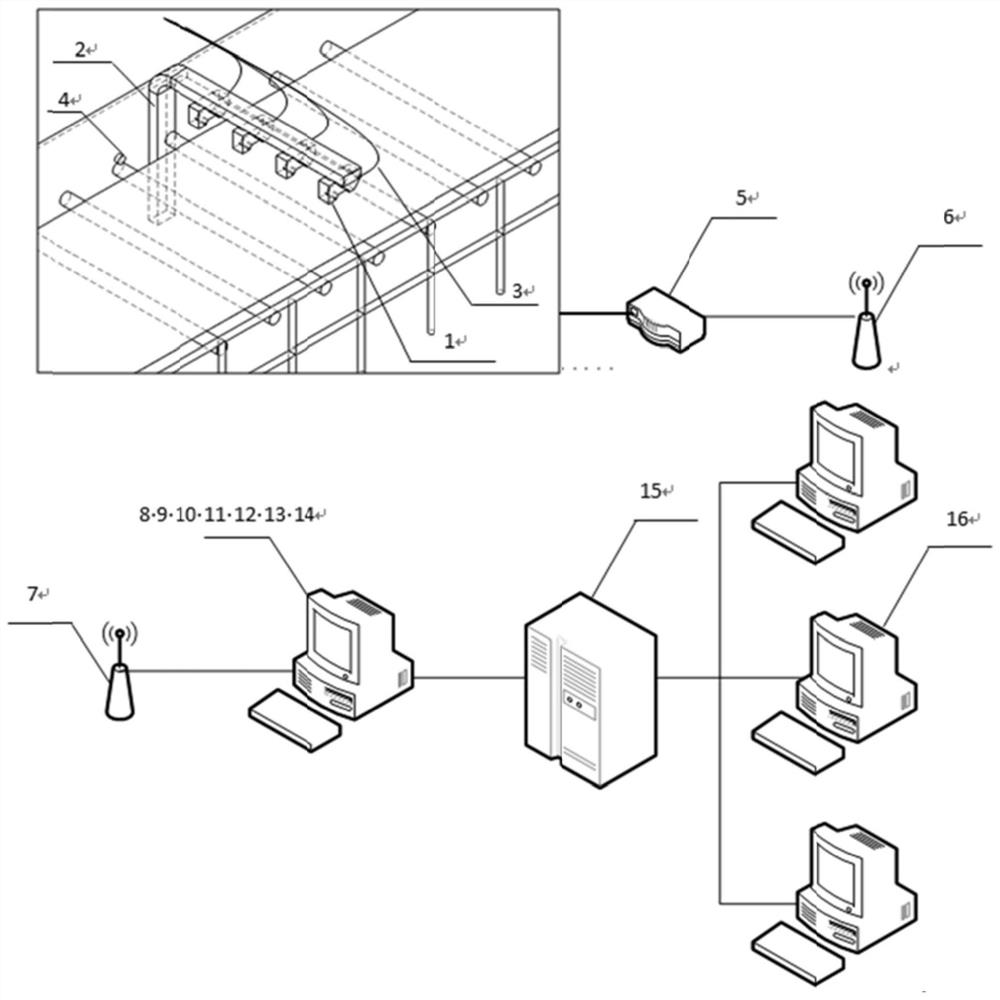

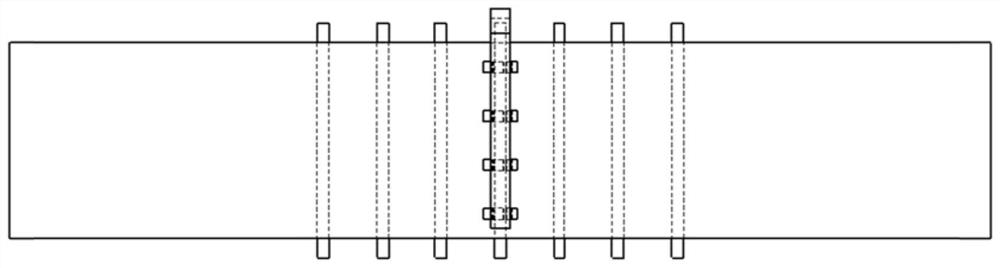

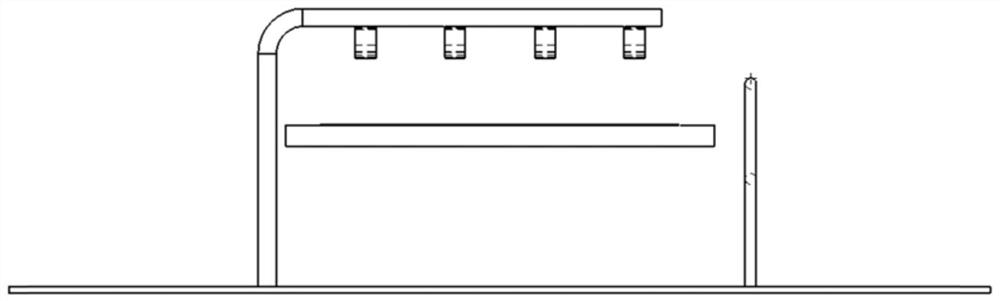

Online detection method and device for plate shape defects of oriented silicon steel finished product

PendingCN112113963AIncrease material rateLow costInvestigating moving sheetsOptically investigating flaws/contaminationHeight differenceEngineering

The invention discloses an online detection method and device for plate shape defects of oriented silicon steel finished products, and belongs to the technical field of measuring equipment. The devicecomprises a detection end, a processing end and a network end; the detection end is used for measuring the vertical height from each point on a steel belt to a laser head, calculating the height difference between each point and the reference surface by taking a unit roller way as the reference surface, and drawing steel belt contour data according to the difference value; the processing end is used for processing the steel belt contour data to obtain steel belt full-length contour data, correcting the steel belt contour information into plate shape information, storing the plate shape information into a plate shape database, automatically classifying defects and generating a slitting instruction according to the plate shape information, and uploading the slitting instruction to the network end; and the network end is used for checking the slitting instruction of a to-be-produced steel coil so as to carry out production through the slitting instruction. A non-contact laser contour scanning method is combined with steel strip jitter suppression suitable for oriented silicon steel, contour information is corrected into the plate shape defect information through laser joint correction, the manufacturing cost is low, and a steel strip coating layer cannot be damaged.

Owner:武汉钢铁有限公司

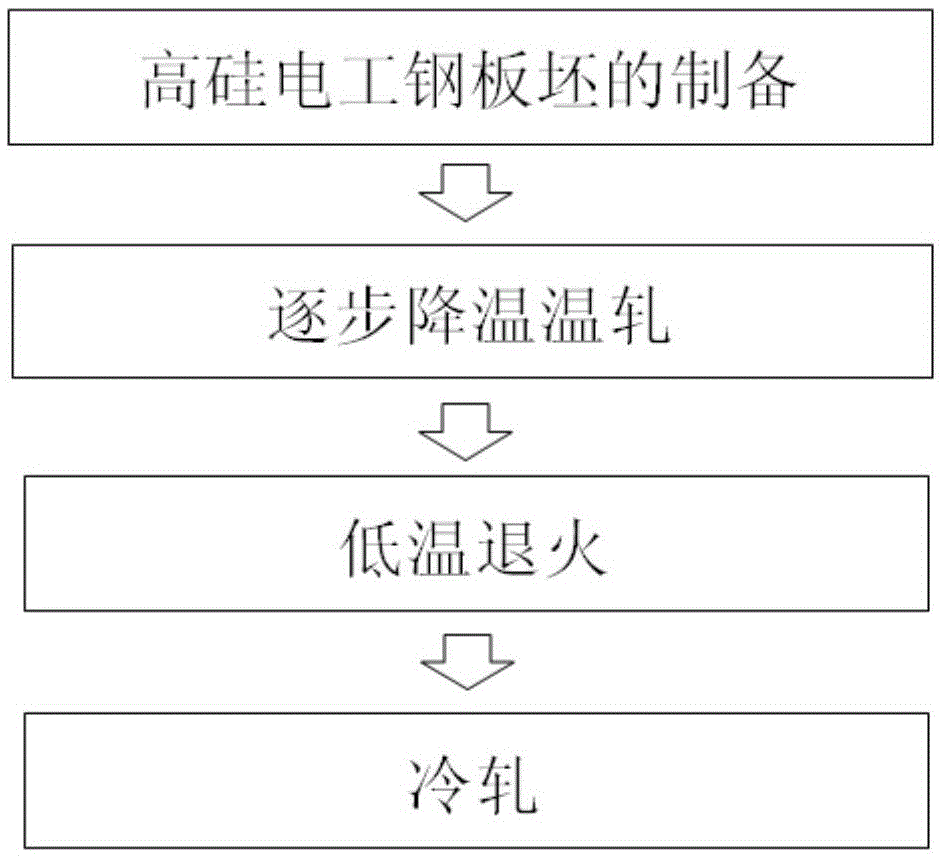

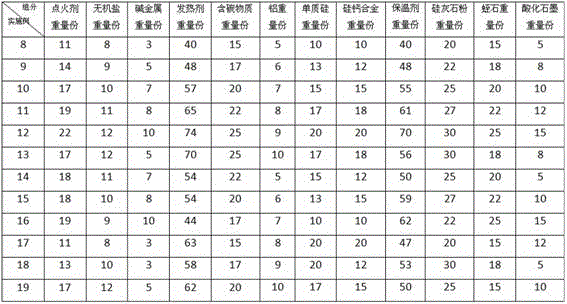

Rolling preparation method for high-silicon electrical steel thin strip

ActiveCN105598164ABright and smooth surfaceReduce orderMetal rolling arrangementsElectrical steelMetallic materials

The invention mainly belongs to the field of metal material preparation and machining and particularly relates to a rolling preparation method for a high-silicon electrical steel thin strip. The method comprises the steps of firstly, taking a high-silicon electrical steel casting blank heated in a furnace as the raw material, so that a high-silicon electrical steel plate slab is prepared and obtained, then conducting warm rolling on the high-silicon electrical steel plate slab in a stepwise-cooling mode, so that a high-silicon electrical steel warm-rolled strip is obtained, and conducting low temperature annealing and cold rolling on the high-silicon electrical steel warm-rolled strip, so that the high-silicon electrical steel thin strip is prepared and obtained. According to the rolling preparation method for the high-silicon electrical steel thin strip, warm rolling in a stepwise-cooling mode is adopted, the accumulated maximum warm rolling deflection is not influenced, meanwhile, the rolling temperature can be lowered, and a better toughening and plasticizing effect is obtained; after warm rolling is completed, annealing is conducted in the proper condition, residual tension of sides of the high-silicon electrical steel warm-rolled strip is effectively lowered, meanwhile, restoration of the ordered structure is avoided, and the cold rolling yield is raised.

Owner:UNIV OF SCI & TECH BEIJING

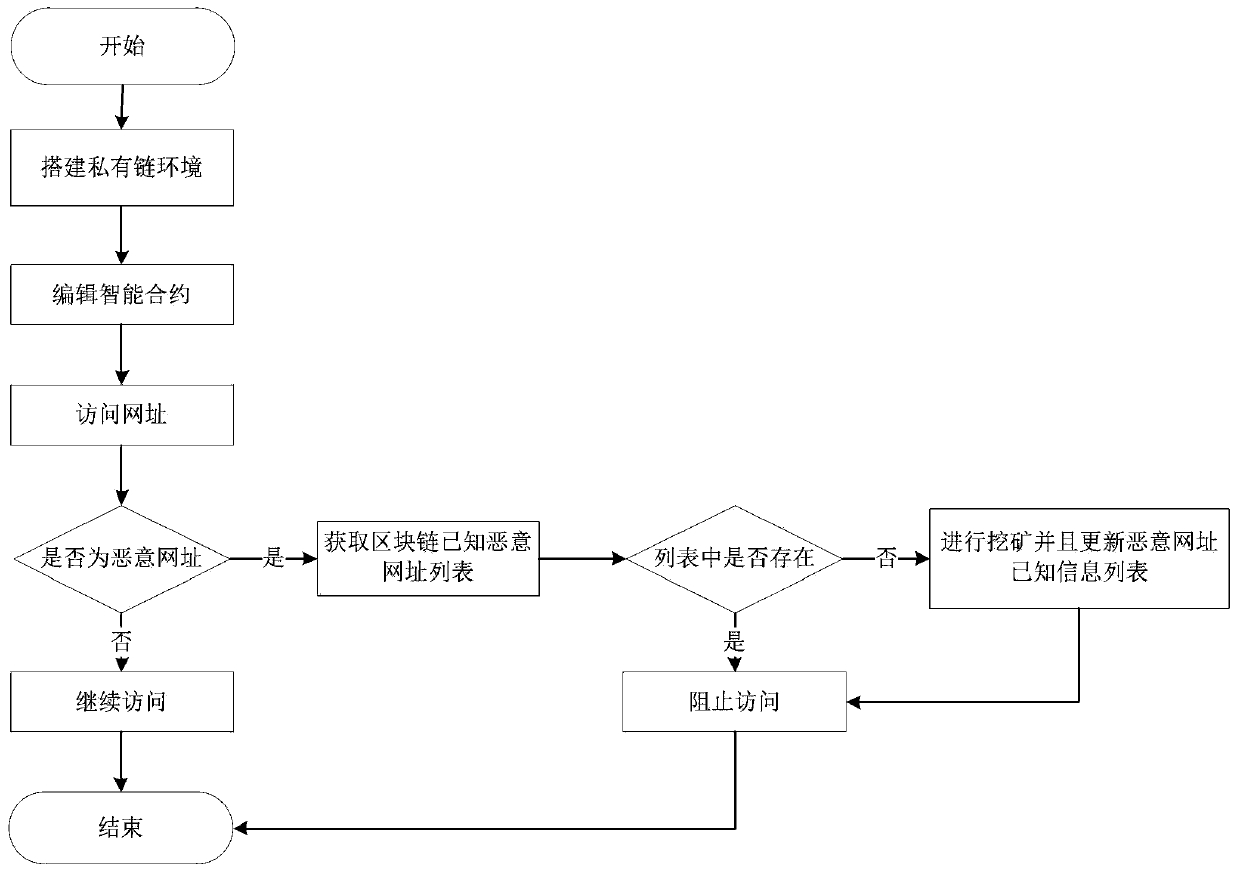

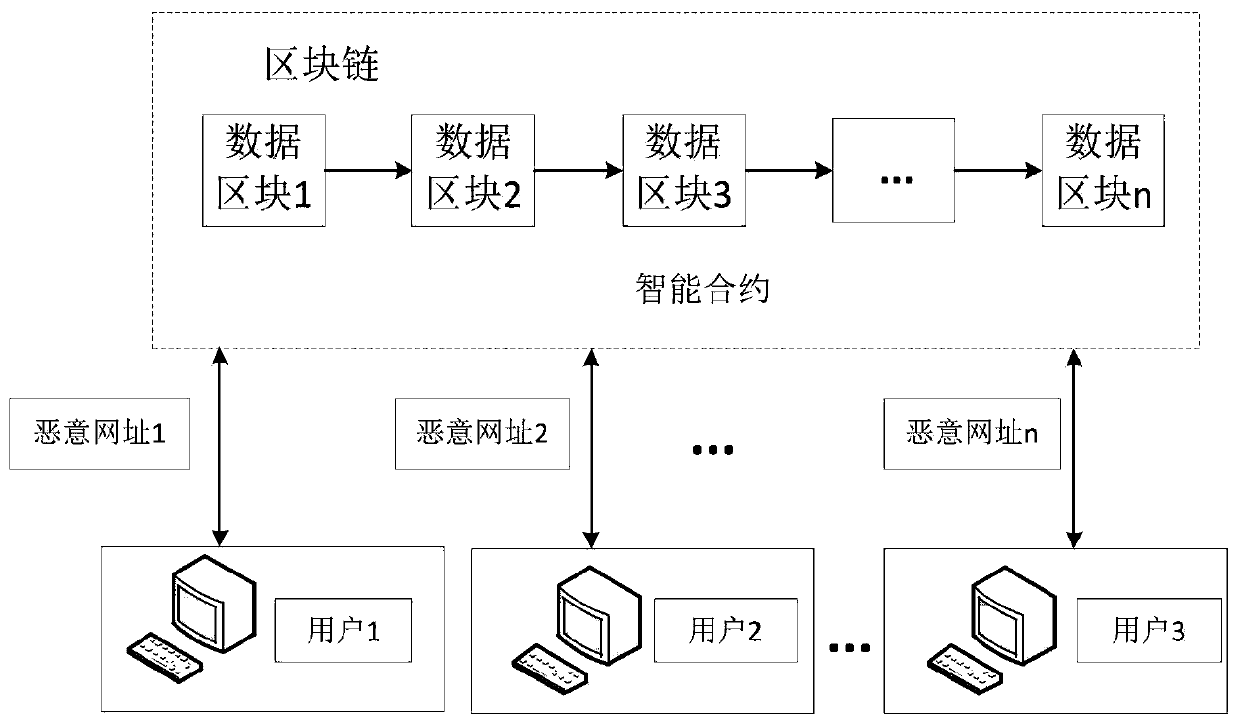

Malicious website collaborative detection strategy based on blockchain technology

InactiveCN110691065AImprove detection and defense efficiencyImprove securityTransmissionWeb siteInternet privacy

The invention discloses a malicious website collaborative detection strategy based on a blockchain technology, and the strategy mainly comprises the steps: firstly, a blockchain private chain is builtto form a collaborative detection synchronization environment; secondly, each node in the blockchain environment can be used as a participant and a beneficiary for malicious website collaborative detection; when a certain node accesses a malicious website, the detailed information of the accessed malicious website can be used as a record to be stored in the block chain through a workload certification mechanism; all nodes in the blockchain synchronize malicious website information detected by each blockchain node by jointly maintaining a data account book, and a warning is given when other nodes access existing malicious websites in the blockchain. According to the scheme, the block chain technology is combined, a malicious website detection environment based on the block chain technologyis formed through a workload proof mechanism, the effectiveness and tamper resistance of malicious website information are guaranteed, the collaborative defense effect is achieved, and the network security is effectively improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

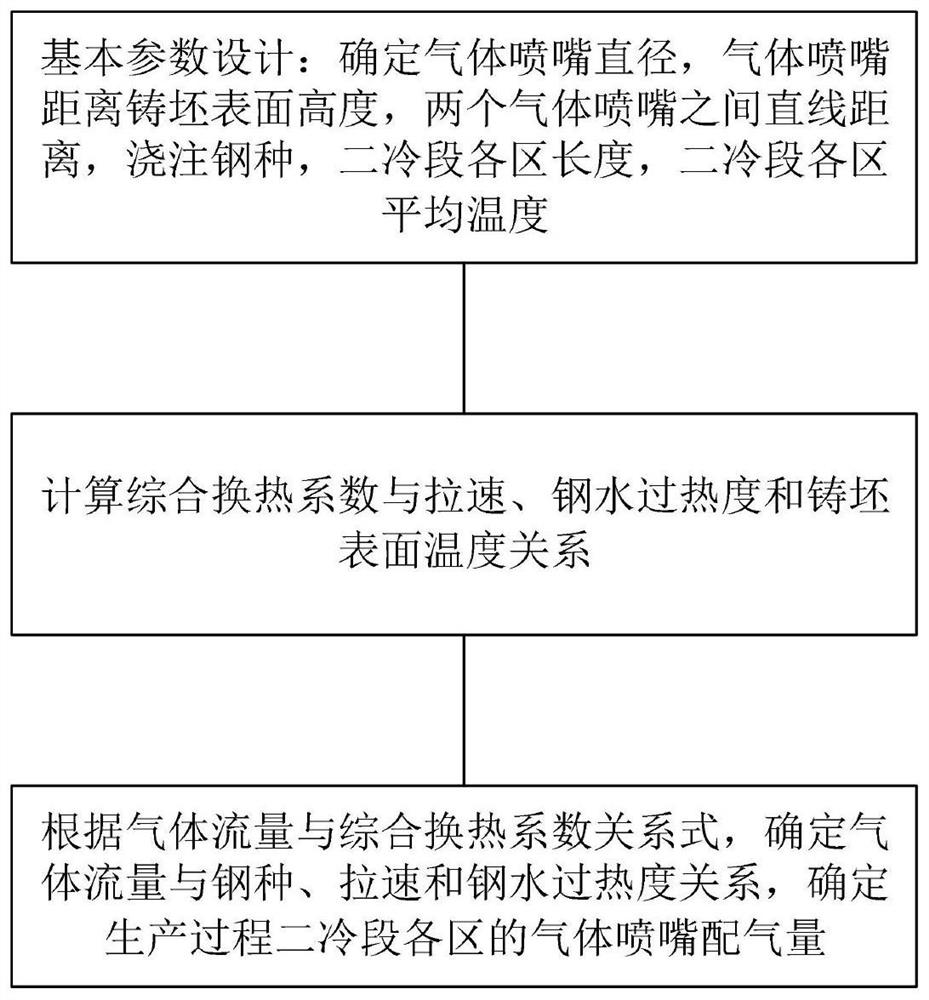

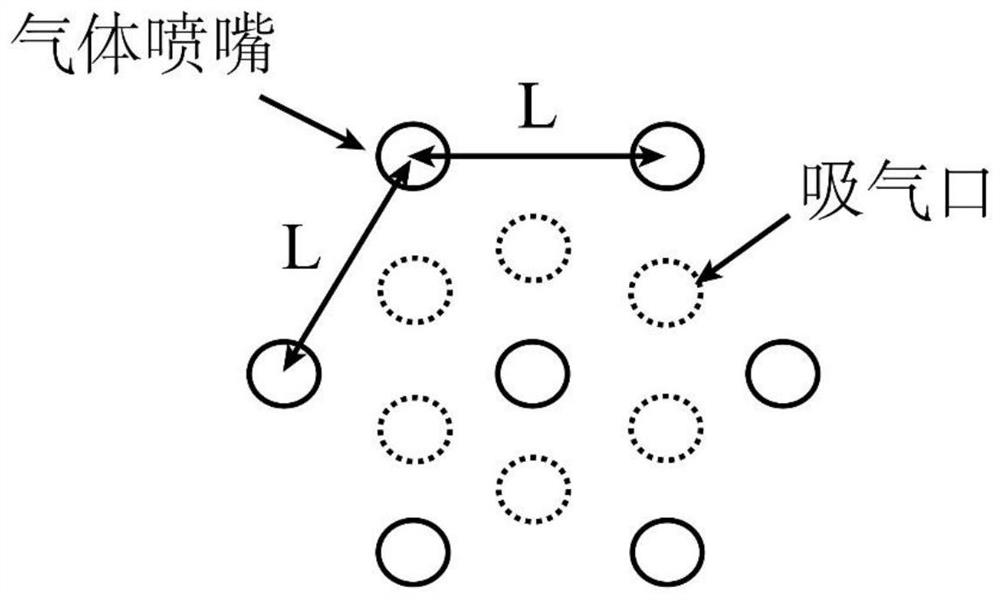

Method and system for full gas cooling of secondary cooling section of continuous casting

The invention relates to a method for full gas cooling of the secondary cooling section of continuous casting. The method uses gas that does not undergo oxidation reaction with the high-temperature slab, and the gas is sprayed to the secondary cooling section of continuous casting at a certain speed through a gas nozzle. On the surface of the high-temperature slab, forced convective heat transfer and radiation heat transfer occur on the surface of the high-temperature slab to realize solidification and cooling of the high-temperature slab. According to the difference in pouring steel type, slab casting speed, molten steel superheat and high-temperature slab surface temperature, the flow rate of cooling gas ejected from the gas nozzle is adjusted accordingly to realize the process of dynamic gas distribution in the secondary cooling section of continuous casting. The cooling gas used in the method is recovered by an air suction port and cooled by a gas cooling device, and the cooled cooling gas is delivered to a gas nozzle to realize recycling of the cooling gas. The invention eliminates the oxidation problem of the billet surface in the secondary cooling section of continuous casting, improves the cooling uniformity of the billet and increases the heat exchange efficiency.

Owner:UNIV OF SCI & TECH BEIJING

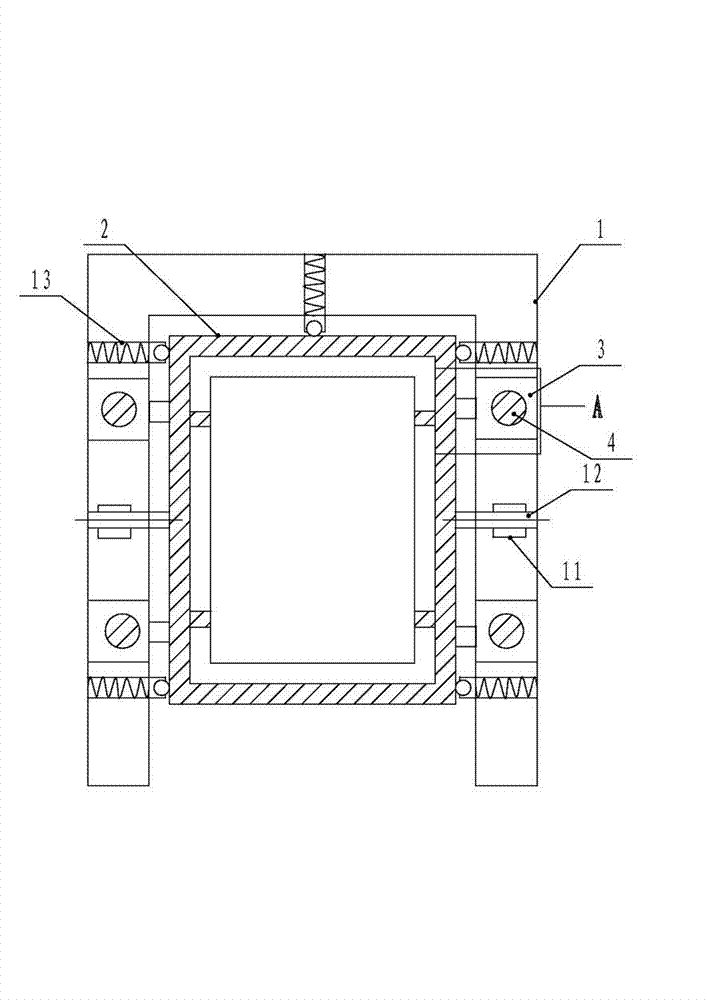

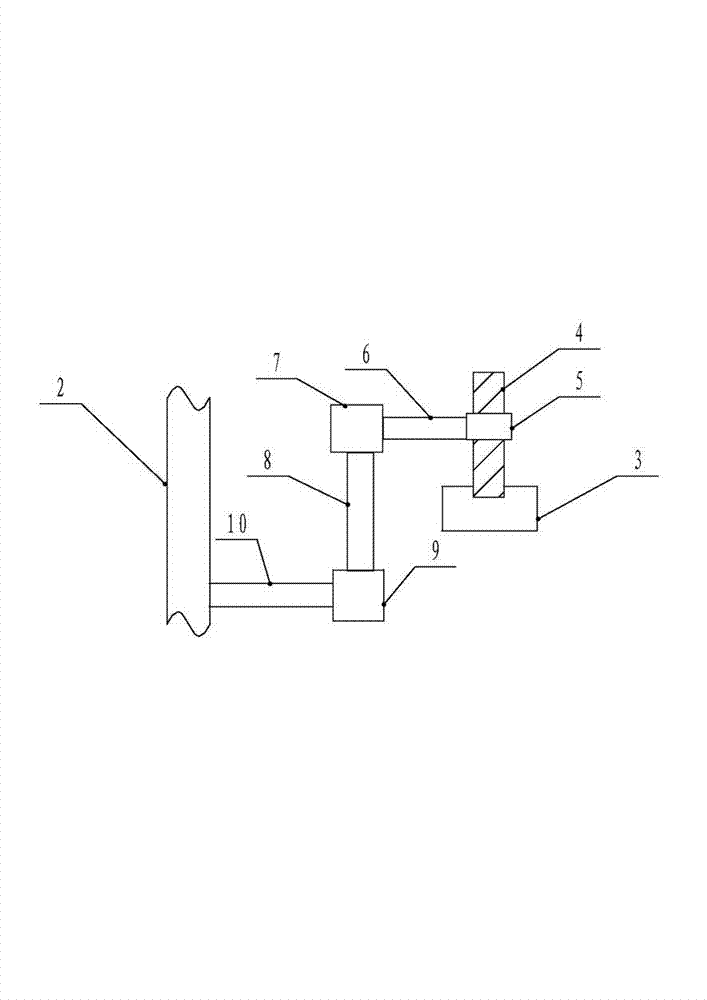

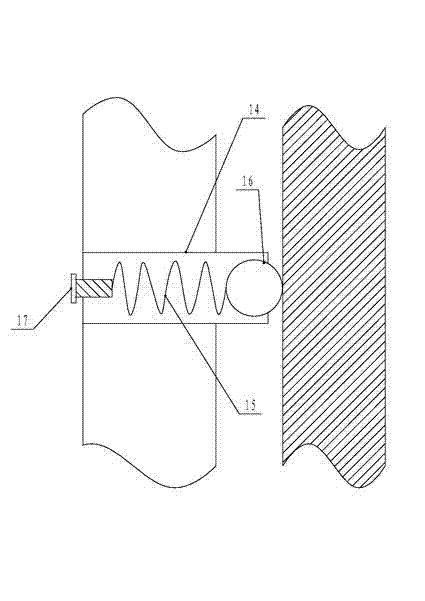

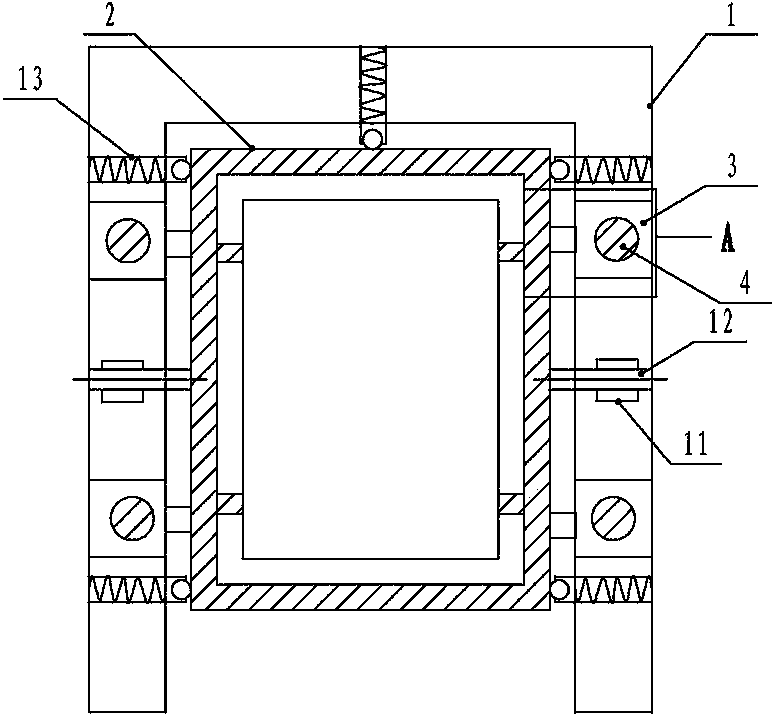

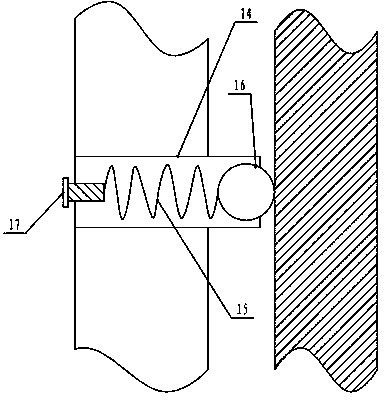

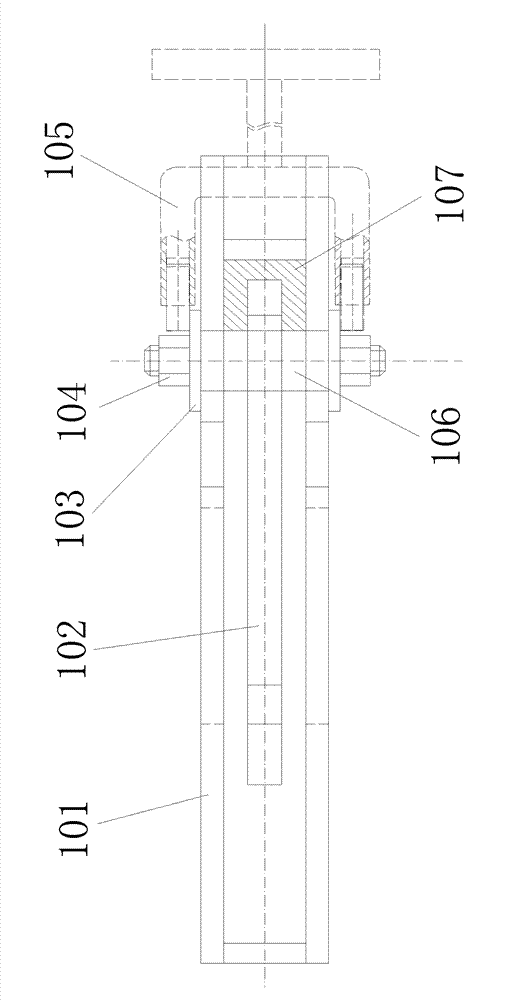

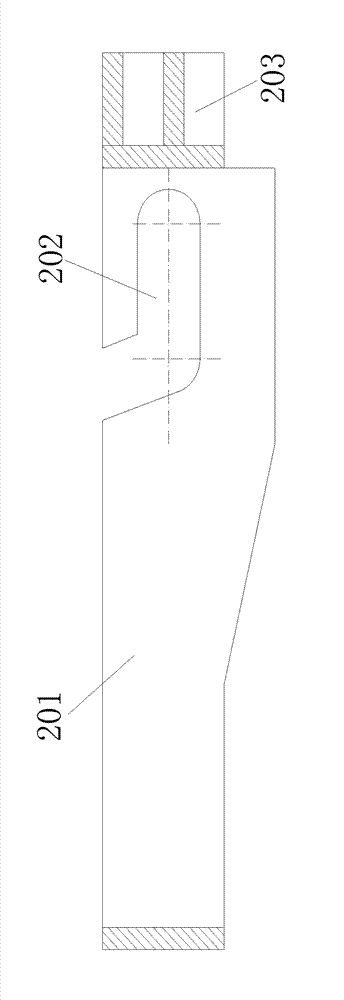

Nozzle adjusting device in amorphous belt building machine

The invention discloses a nozzle adjusting device in an amorphous belt building machine, comprising a fixed frame and a movable frame which is movably arranged in the fixed frame, wherein the two sides of the fixed frame are respectively provided with middle universal sections; the two middle universal sections are internally and respectively provided with middle shafts; the middle shafts are horizontally and transversely arranged; the end parts of the two middle shafts are respectively fixed with middle parts of the two sides of the movable frame; two sides of the fixed frame are respectively provided with two screw rods and a motor for driving the screw rods to rotate; the two screw rods at the same side are symmetrical relative to the middle shaft of the side; meanwhile, the screw rods of the two sides are symmetrical relative to a vertical symmetrical axis of the movable frame; the screw rods are provided with screw rod nuts and each screw rod nut is connected to an upper universal section through a transverse transmission rod; the upper universal section is connected to a lower universal section through a vertical transmission rod; and the lower universal section is connected to the movable frame through a connection rod. The nozzle adjusting device disclosed by the invention has the advantages of simple structure and low cost, and can simply and rapidly adjust the distance between a nozzle and a cooling roller, so that the belt building cost is reduced and the belt building yield is higher.

Owner:张家港市清大星源微晶有限公司 +1

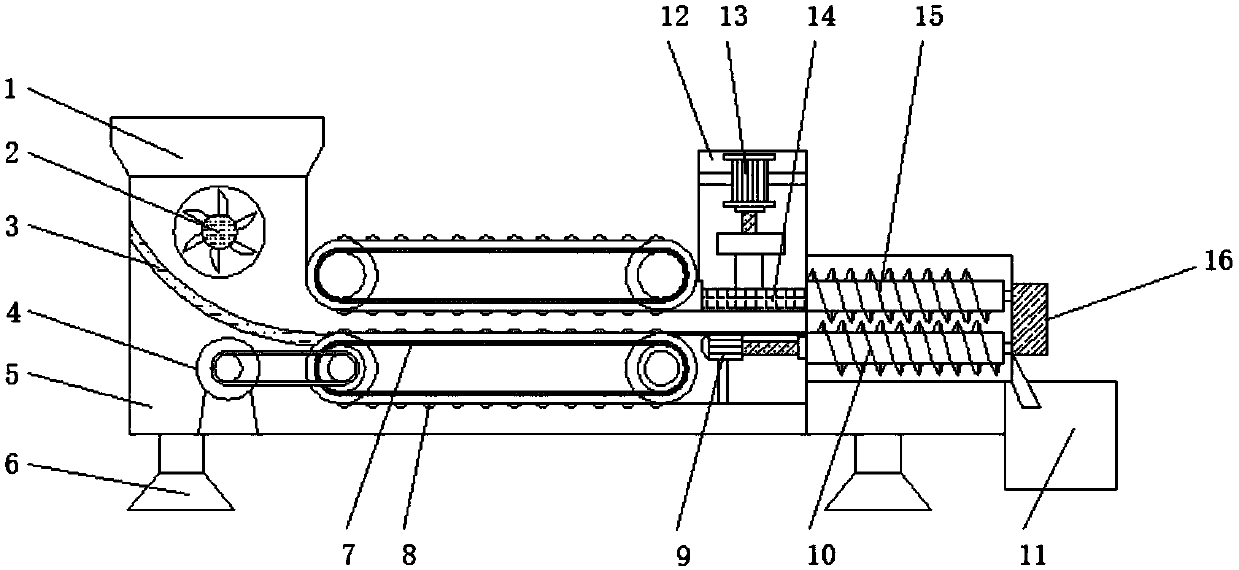

Powerful medicinal material smashing device achieving thorough smashing

InactiveCN107597374ASmash thoroughlyImprove crushing efficiencyGrain treatmentsElectric machineryEngineering

The invention discloses a powerful medicinal material smashing device achieving thorough smashing. The powerful medicinal material smashing device achieving thorough smashing comprises a storage bin,a first screw rod and a second screw rod. The top end of the storage bin is provided with a material inlet. A fan is arranged in the storage bin and located below the material inlet. A feeding rail isarranged below the fan. Two conveying rails are arranged on one side of the feeding rail. One side of one conveying rail is connected with a first motor in a transmission manner through a conveyer belt. According to the powerful medicinal material smashing device achieving thorough smashing, the fan is arranged above the feeding rail, one side of the feeding rail is provided with the conveying rails used for conveying medicinal materials, one side of the conveying rails is provided with a squeezing plate used for squeezing, an XTL100 electric telescopic rod drives squeezing, so that the fan can be used for conducting air drying the medicinal materials at the material inlet, then the medicinal materials are conveyed to the squeezing plate to be squeezed, and then the medicinal materials become crisp due to the arrangement; and in this way, the medicinal materials are smashed more thoroughly during squeezing and smashing, and the smashing efficiency is higher.

Owner:弘毅天承知识产权股份有限公司

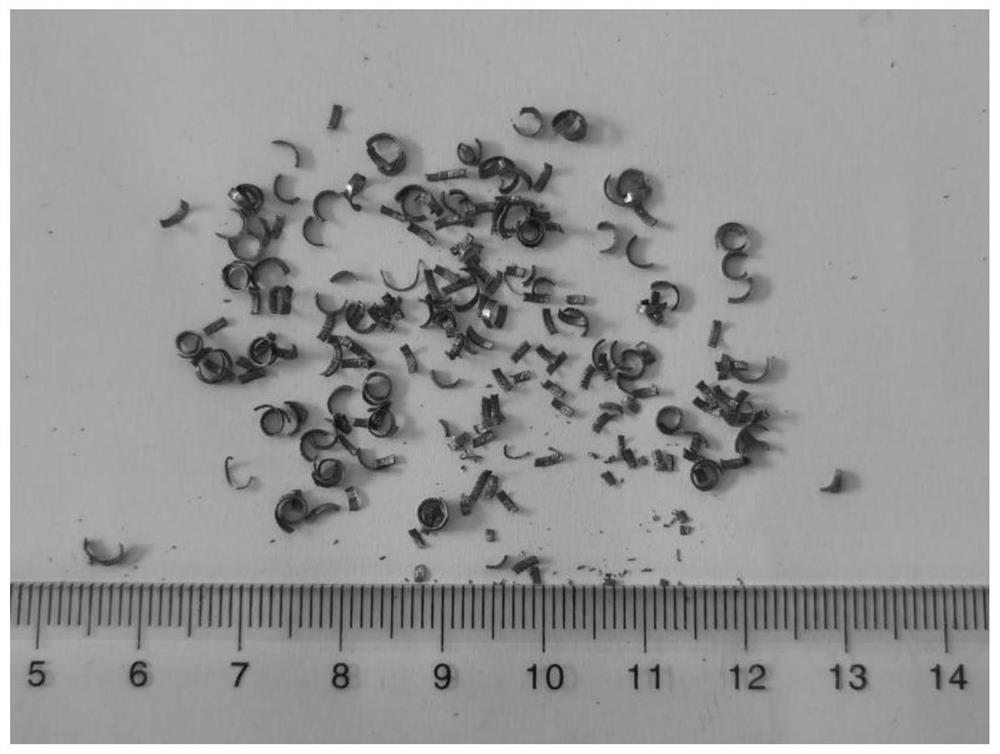

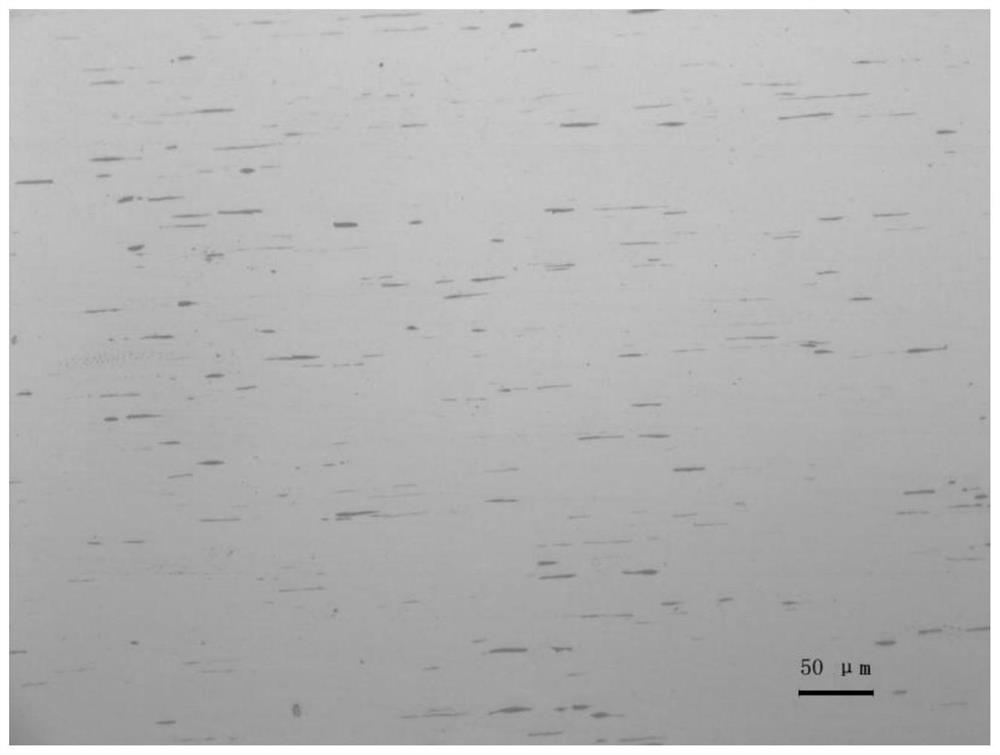

Sulfur-containing tellurium-containing free-cutting ferritic stainless steel and manufacturing method thereof

ActiveCN114182177AImprove turning performanceImprove plasticity and corrosion resistanceTemperature control deviceProcess efficiency improvementElectric furnacesCorrosion

The invention relates to free-cutting ferritic stainless steel, in particular to free-cutting ferritic stainless steel containing sulfur and tellurium and a preparation method of the free-cutting ferritic stainless steel. The free-cutting ferritic stainless steel containing sulfur and tellurium comprises the following components in percentage by mass: less than or equal to 0.10% of C, less than or equal to 1.0% of Si, less than or equal to 1.25% of Mn, less than or equal to 0.03% of P, 0.20-0.30% of S, less than or equal to 0.60% of Ni, 17.0-18.0% of Cr, less than or equal to 0.60% of Mo, less than or equal to 0.05% of N, 0.005-0.015% of Te, 0.001-0.005% of B and the balance of iron and inevitable impurities. The sulfur-containing tellurium-containing free-cutting ferritic stainless steel is prepared through electric furnace smelting, AOD furnace refining, LF furnace refining, continuous casting, rolling and annealing, the turning performance, corrosion resistance and plasticity of the sulfur-containing tellurium-containing free-cutting ferritic stainless steel are completely superior to those of a common 430F material, and the sulfur-containing tellurium-containing free-cutting ferritic stainless steel has a wider industrial application prospect.

Owner:浙江青山钢铁有限公司 +1

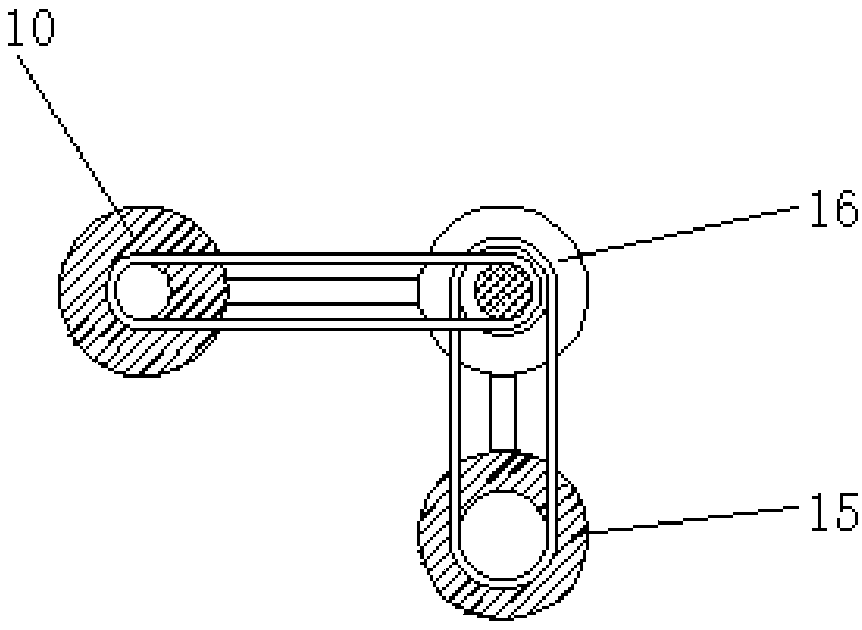

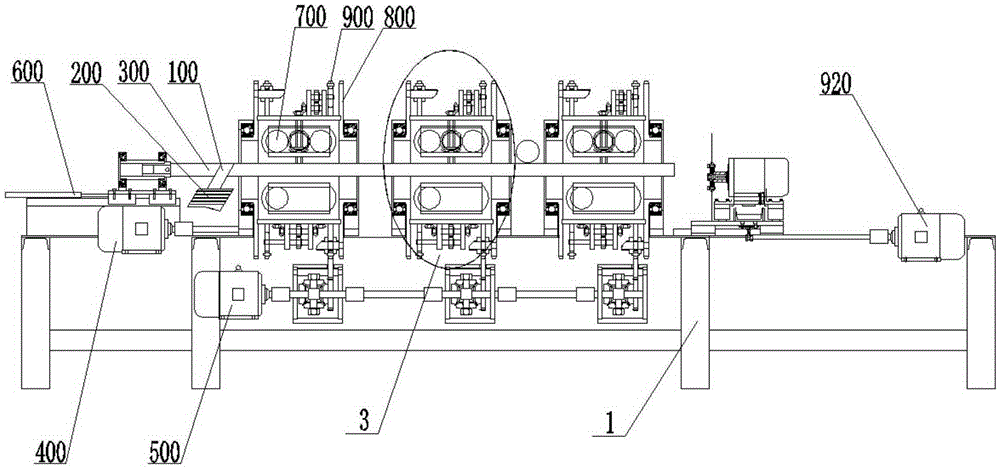

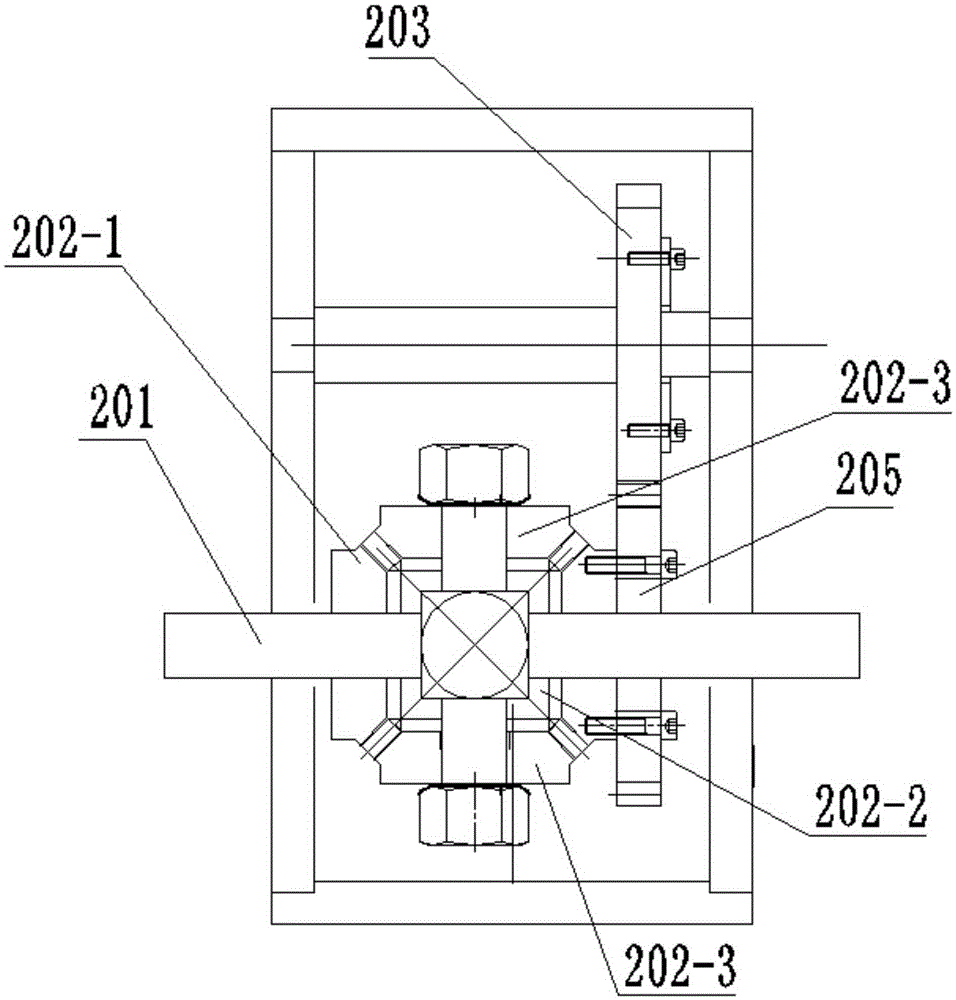

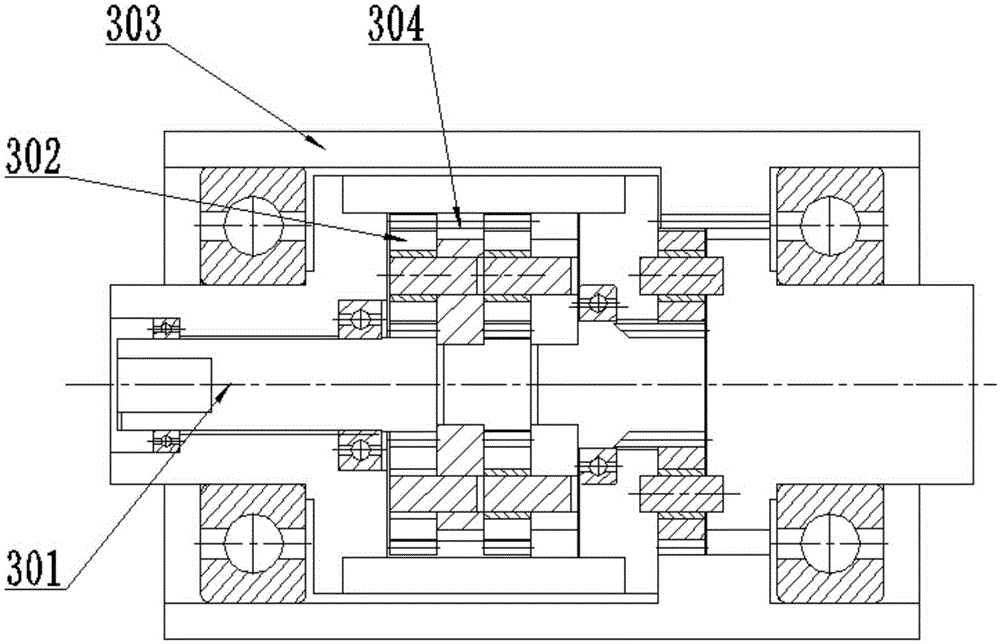

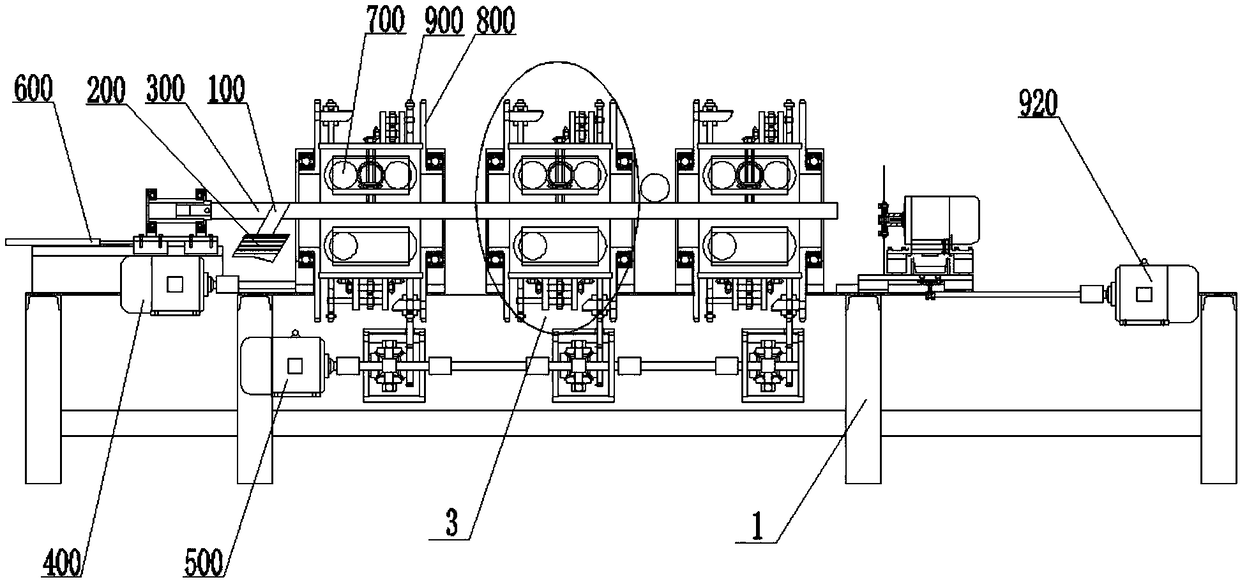

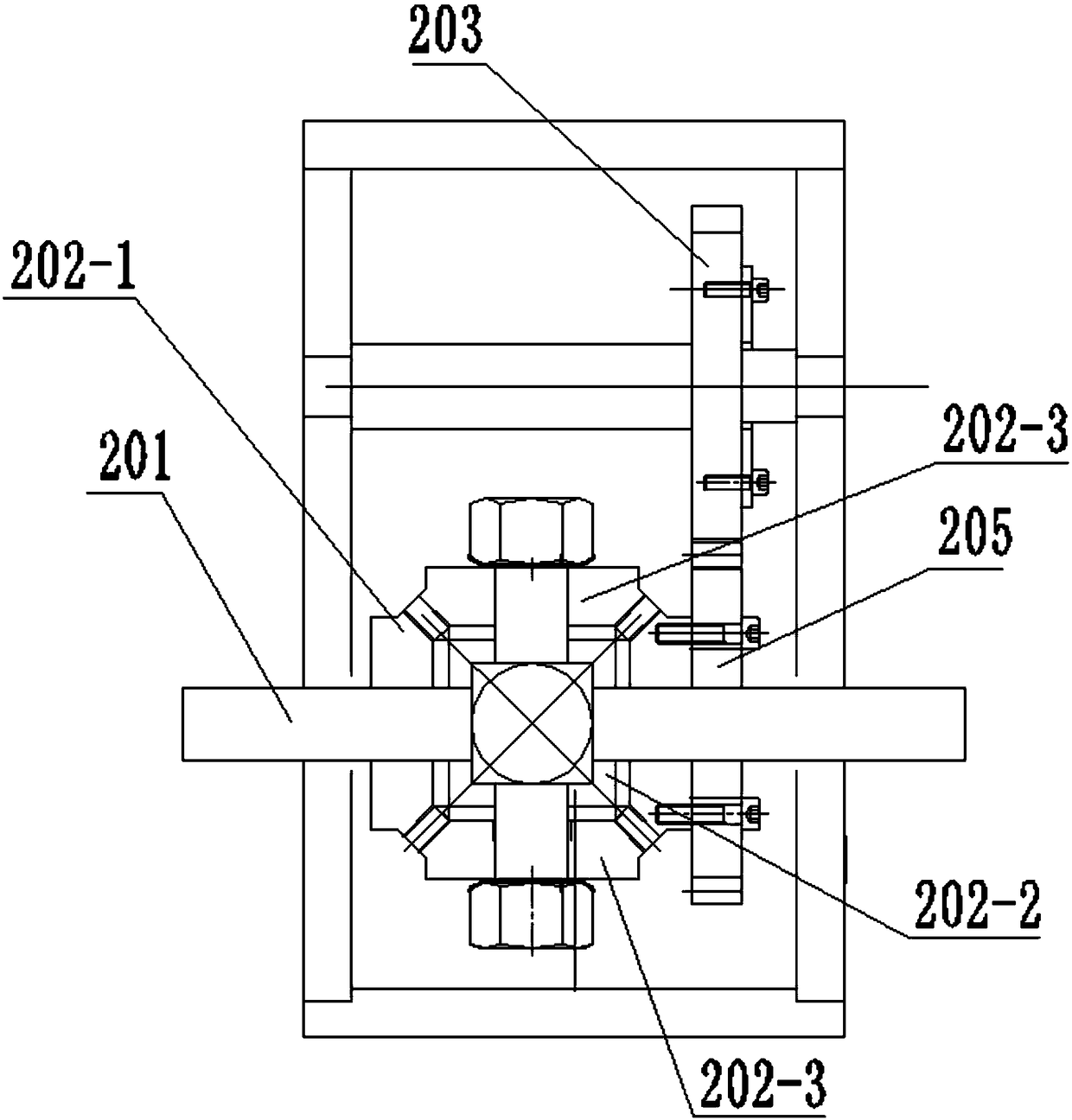

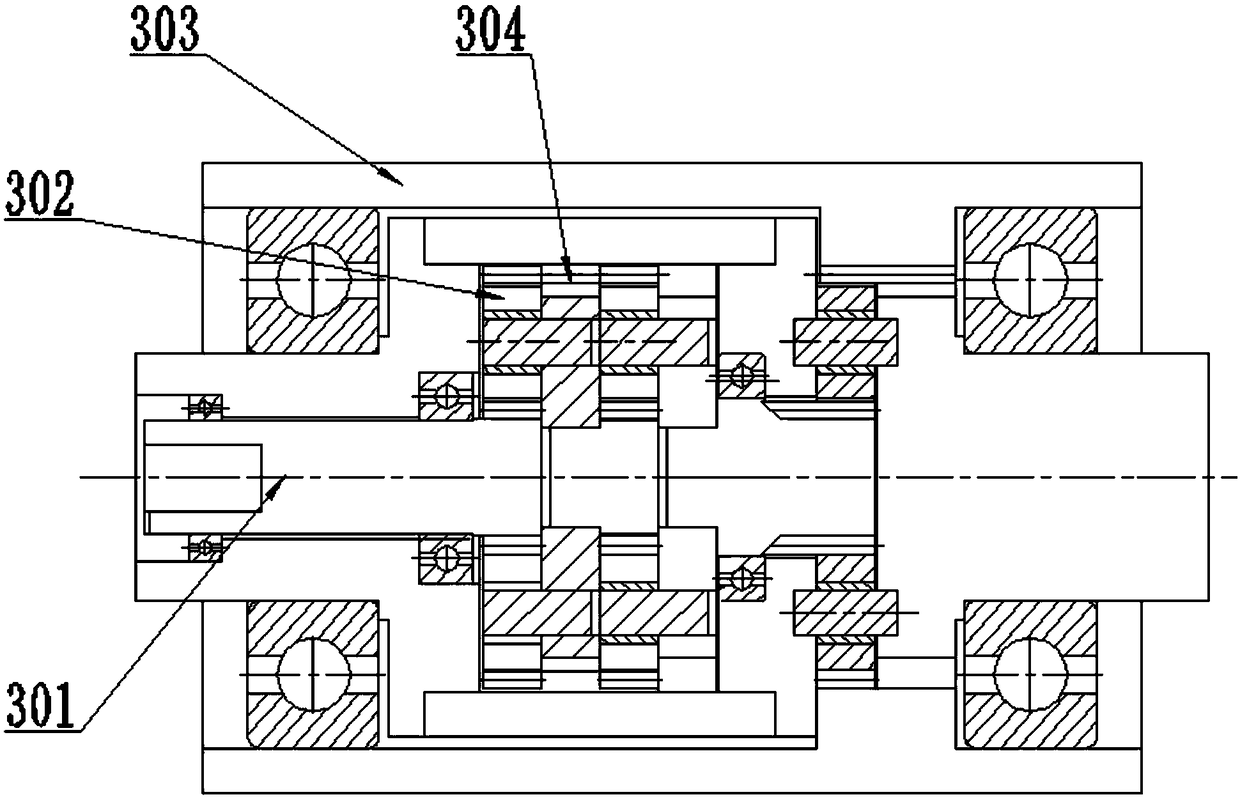

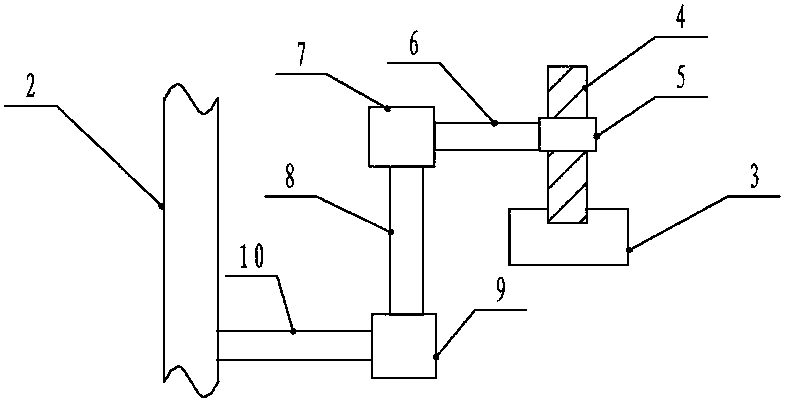

Equipment for processing N-edge-shaped paper tubes

ActiveCN105398091AEasy to adjustIncrease material ratePaper/cardboard wound articlesNumerical controlMotor drive

The invention relates to the field of numerical control machinery, in particular to equipment for processing N-edge-shaped paper tubes. The equipment is used for producing paper strips to paper tubes, and is characterized by comprising a frame, a clamping fixture, at least two paper tube forming sets, a rotating servo motor and a traction servo motor, wherein the paper strips are wound on the clamping fixture in a staggered manner in sequence; the paper tube forming sets are used for forming the paper tubes, and comprise gears, gear rings and traction pressing wheel mechanisms; the traction pressing wheel mechanisms include upper and lower pressing wheels and traction wheels; the paper tube forming mechanisms transfer power through couplings, and produce the paper tubes with different shapes through changing relative positions of key slots of the couplings; the rotating servo motor is used for driving the gears to peripherally rotate in Y direction; and the traction servo motor drives the gear rings of the paper tube forming sets to peripherally rotate in Y direction through a differential transmission mechanism. The equipment can be used for producing the paper tubes with various shapes (such as triangles, rectangles and hexagons), is simple in dimension adjustment, needs no secondary cutting, and is high in yield, fast in production speed, high in efficiency and low in cost.

Owner:王群

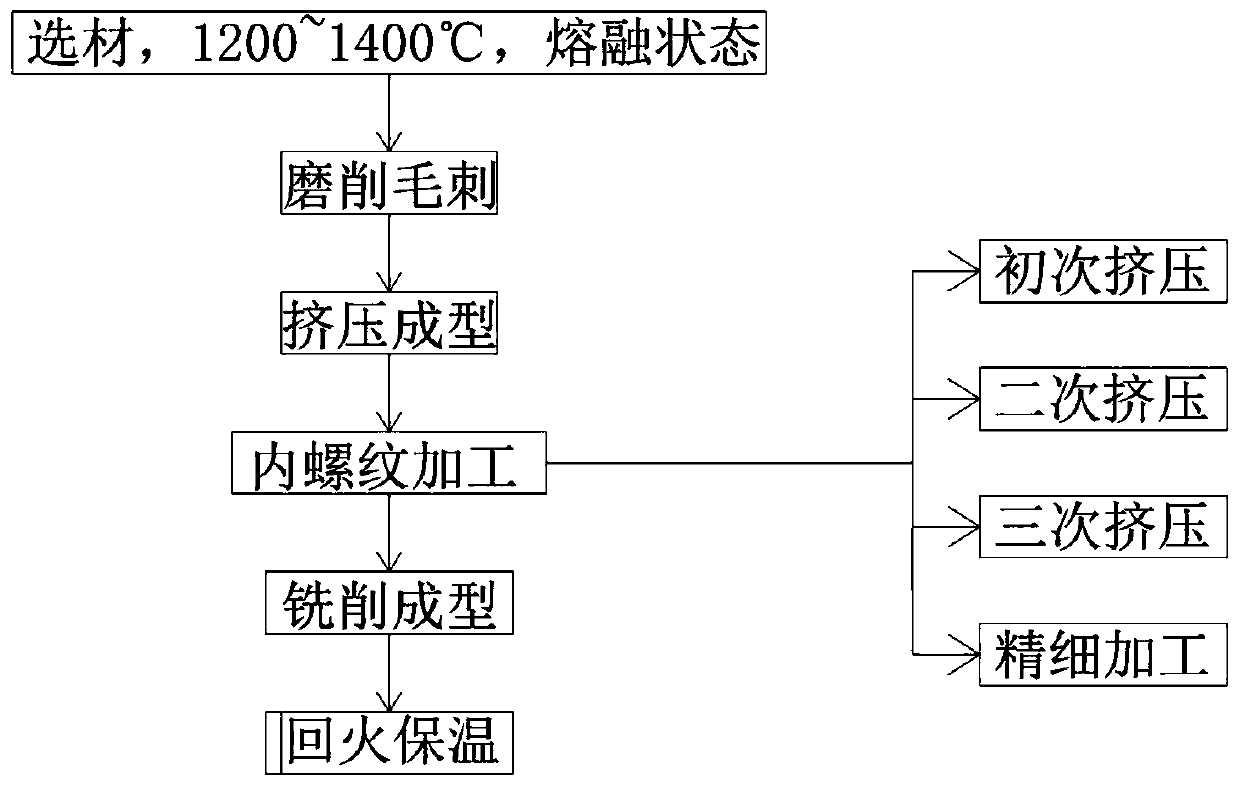

Production technology of semicircle groove internal threaded steel pipe

InactiveCN110549081AEasy to processIncrease material rateScrew-threads articlesScrew threadSteel tube

The invention discloses a production technology of a semicircle groove internal threaded steel pipe, belongs to the technical field of production of semicircle groove internal threaded steel pipes, and particularly provides an internal threaded steel pipe preset with semicircle grooves. The production technology comprises the following steps of (1) material selecting; (2) abrasive machining; (3) extrusion forming; (4) internal thread machining; (5) milling; and (6) tempering. Machining of the steel pipes is simple, the yield is high, the service life is long, if a screw thread is broken, the problem that continuous fastening is hard due to breaking of the screw thread can be relieved through the semicircle grooves formed oppositely, the technical effect of one pipe for durable using is achieved in real sense, and meanwhile the advantages of increasing the heat transfer area and improving the heat dissipation performance of an existing internal threaded steel pipe are also inherited.

Owner:CHANGZHOU SHENGTAK SEAMLESS STEEL TUBE

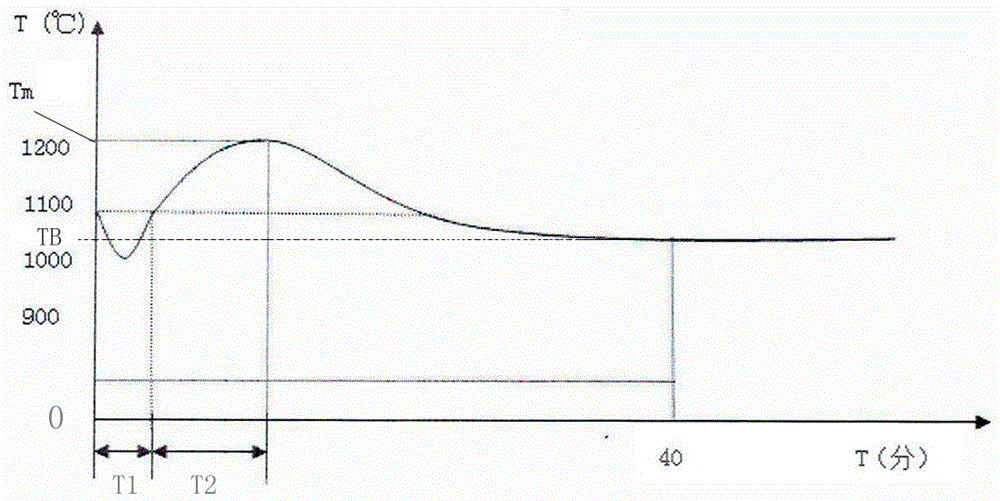

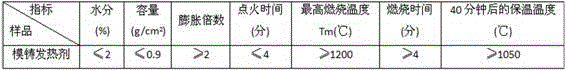

Heating agent for die casting

InactiveCN106141093ACreate pollutionProlong clotting timeFoundry mouldsFoundry coresMetallurgyDie casting

A die-casting exothermic agent relates to casting auxiliary materials, and the weight parts of each component are: ignition agent 11-22, exothermic agent 40-75, heat preservation agent 40-70. The exothermic agent of the invention is composed of three parts: ignition agent, exothermic agent and heat insulating agent, which can heat and keep warm the molten steel at the riser without causing pollution to the molten steel, thus greatly prolonging the solidification of the molten steel at the riser Time, reducing the head shrinkage of the ingot and improving the yield of the slab.

Owner:ZHENGZHOU DONGSHENG METALLURGY NEW MATERIAL

A rolling preparation method of high-silicon electrical steel thin strip

ActiveCN105598164BFlat surfaceReduce orderMetal rolling arrangementsMaterials preparationSheet steel

Owner:UNIV OF SCI & TECH BEIJING

A device for processing "n" polygonal paper tubes

ActiveCN105398091BEasy to adjustIncrease material ratePaper/cardboard wound articlesNumerical controlMotor drive

The invention relates to the field of numerical control machinery, in particular to equipment for processing N-edge-shaped paper tubes. The equipment is used for producing paper strips to paper tubes, and is characterized by comprising a frame, a clamping fixture, at least two paper tube forming sets, a rotating servo motor and a traction servo motor, wherein the paper strips are wound on the clamping fixture in a staggered manner in sequence; the paper tube forming sets are used for forming the paper tubes, and comprise gears, gear rings and traction pressing wheel mechanisms; the traction pressing wheel mechanisms include upper and lower pressing wheels and traction wheels; the paper tube forming mechanisms transfer power through couplings, and produce the paper tubes with different shapes through changing relative positions of key slots of the couplings; the rotating servo motor is used for driving the gears to peripherally rotate in Y direction; and the traction servo motor drives the gear rings of the paper tube forming sets to peripherally rotate in Y direction through a differential transmission mechanism. The equipment can be used for producing the paper tubes with various shapes (such as triangles, rectangles and hexagons), is simple in dimension adjustment, needs no secondary cutting, and is high in yield, fast in production speed, high in efficiency and low in cost.

Owner:王群

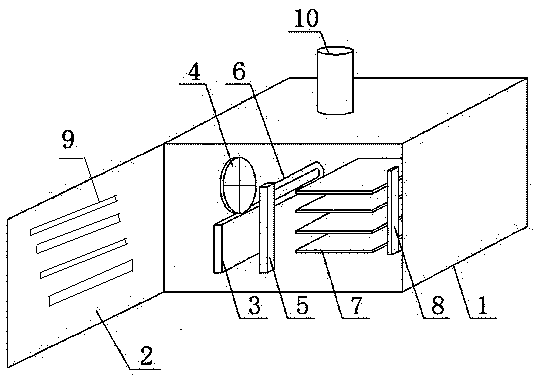

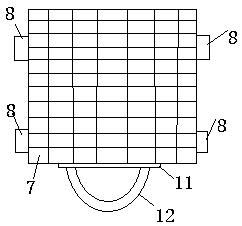

Drying device of dried sweet potatoes

InactiveCN107593887AIncrease material rateEvenly heatedFruits/vegetable preservation by dehydrationElectricityEconomic benefits

The invention relates to the technical field of processing of agricultural products, in particular to a drying device of dried sweet potatoes. The drying device specifically comprises a drying chamberdoor, a fan supporting frame, a fan, an electric heating pipe supporting frame, an electric heating pipe, metal nets, one or more supporting plate, material taking openings, an exhaust pipe, materialtaking opening baffles and metal net handles. According to the drying device of dried sweet potatoes disclosed by the invention, the material taking openings are formed, so that the material yield ofdrying the dried sweet potatoes is increased; the material taking opening baffles are arranged to seal the material taking openings, so that the electric energy is saved; mutual cooperation of the fan and the electric heating pipe is adopted, so that the sweet potatoes are heated uniformly, the drying effect is good, and the made sweet potatoes are uniform in color, good in mouth feel, good in outward appearance and high in economic benefits; and the handle is arranged on the door and an exhaust pipe switch is arranged, so that convenience is enhanced.

Owner:灵川县龙达种植专业合作社

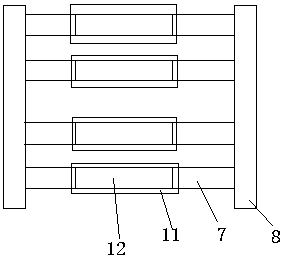

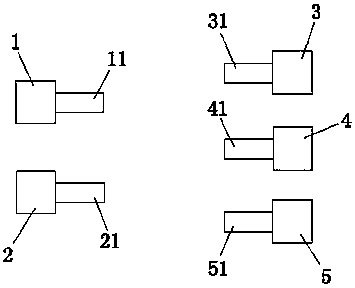

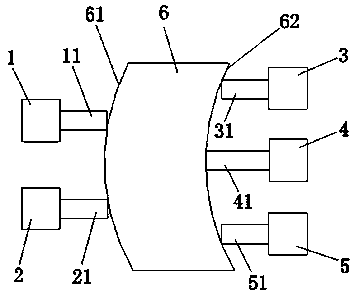

Automatic positioning equipment for cutting

InactiveCN105710934BAvoid lostAvoid Quality ComplaintsGuide fencesAutomatic test equipmentEngineering

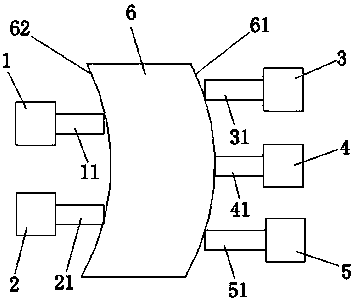

The invention discloses automatic positioning equipment for cutting. The automatic positioning equipment is used for positioning a cut part and comprises a first air cylinder, a second air cylinder, a third air cylinder, a fourth air cylinder and a fifth air cylinder; the first air cylinder and the second air cylinder are arranged on one side of the cut part, and the third air cylinder, the fourth air cylinder and the fifth air cylinder are arranged on the other opposite side of the cut part; a driving mechanism drives the first air cylinder, the second air cylinder, the third air cylinder, the fourth air cylinder and the fifth air cylinder; the front end of the first air cylinder is provided with a first push rod, the front end of the second air cylinder is provided with a second push rod, the front end of the third air cylinder is provided with a third push rod, the front end of the fourth air cylinder is provided with a fourth push rod, and the front end of the fifth air cylinder is provided with a fifth push rod; joint pressure of the first air cylinder and the second air cylinder is slightly larger than or equal to that of the third air cylinder, the fourth air cylinder and the fifth air cylinder; and the first push rod and the second push rod independently move, and the third push rod and the fifth push rod jointly move. When the cut part is positioned, the cut part cannot rotate or shift all the time, the cutting position is always vertical and cannot incline, and positioning is accurate.

Owner:湖州亿盒包装材料科技有限公司

Nozzle adjusting device in amorphous belt building machine

The invention discloses a nozzle adjusting device in an amorphous belt building machine, comprising a fixed frame and a movable frame which is movably arranged in the fixed frame, wherein the two sides of the fixed frame are respectively provided with middle universal sections; the two middle universal sections are internally and respectively provided with middle shafts; the middle shafts are horizontally and transversely arranged; the end parts of the two middle shafts are respectively fixed with middle parts of the two sides of the movable frame; two sides of the fixed frame are respectively provided with two screw rods and a motor for driving the screw rods to rotate; the two screw rods at the same side are symmetrical relative to the middle shaft of the side; meanwhile, the screw rods of the two sides are symmetrical relative to a vertical symmetrical axis of the movable frame; the screw rods are provided with screw rod nuts and each screw rod nut is connected to an upper universal section through a transverse transmission rod; the upper universal section is connected to a lower universal section through a vertical transmission rod; and the lower universal section is connected to the movable frame through a connection rod. The nozzle adjusting device disclosed by the invention has the advantages of simple structure and low cost, and can simply and rapidly adjust the distance between a nozzle and a cooling roller, so that the belt building cost is reduced and the belt building yield is higher.

Owner:张家港市清大星源微晶有限公司 +1

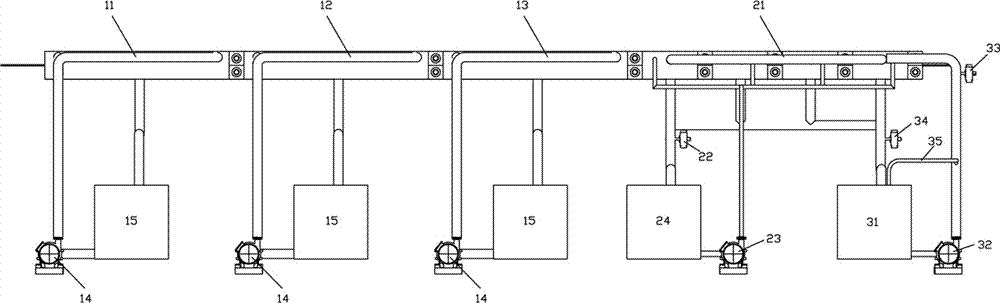

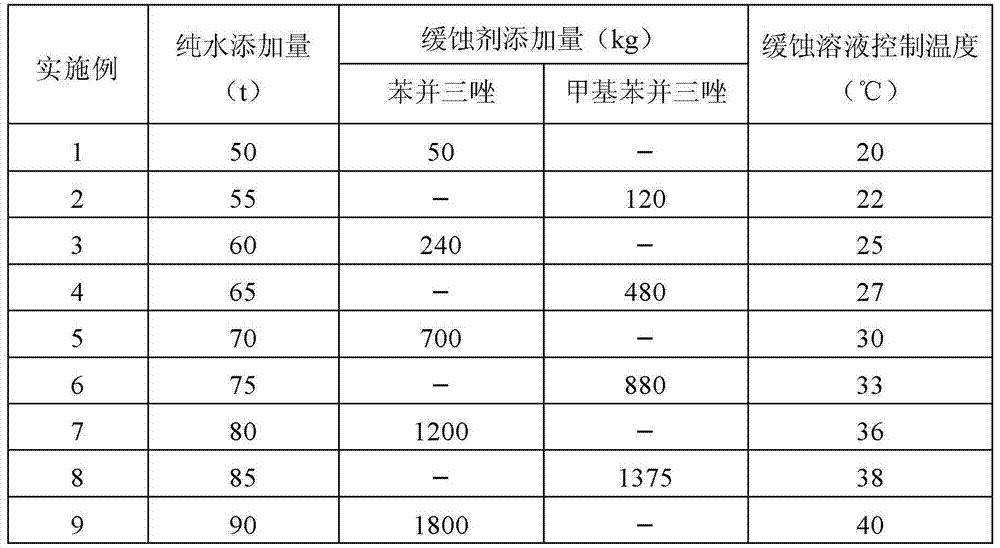

Stop spot control method for shallow slot turbulent pickling line

A stop spot control method for a shallow slot turbulent pickling line comprises the following steps: 1) strip steel sequentially enters an acid bath for pickling and then enters a bleaching bath, so the residual chloridion on the surface can be rinsed; 2) corrosion inhibition solution is prepared in a corrosion inhibition solution tank in advance, pure water and corrosion inhibitor are sequentially added to the corrosion inhibition solution tank, and the addition volume of the corrosion inhibitor is 0.1wt%-2.0wt% of the addition volume of the pure water; 3) when the pickling line stops, a bleaching water pump stops operating, and the bleaching water is drained completely; 4) the corrosion inhibition solution in the corrosion inhibition solution tank is injected to the bleaching bath by a solution feed pump until the strip steel is completely immersed; 5) the pickling line is restarted, a corrosion inhibition solution emptying valve is opened, the corrosion inhibition solution is emptied to the corrosion inhibition solution tank, and then the corrosion inhibition solution emptying valve is closed; and a bleaching water reflow valve is opened, the bleaching water pump starts to operate and clean the strip steel by spraying again. the stop spot control method can effectively prevent the stop spot from being formed on the surface of the strip steel, the pickling efficiency is greatly improved, and the pickling line plate yield and rate of quality products are also improved.

Owner:BAOSHAN IRON & STEEL CO LTD

The rocker arm is equipped with a coal-passing space mining machine

ActiveCN103498671BIncrease material rateImprove efficiencyDriving meansCutting machinesFuselageRocker arm

The invention provides a mining machine with a rocker arm provided with coal-passing space, which comprises a machine body and a walking portion, and is characterized in that the mining machine with a rocker arm provided with coal-passing space also comprises a rocker arm, and cutting heads; the walking portion is disposed at the lower part of the machine body; the cutting heads are disposed at two ends of the machine body; the rocker arm is a rhomboid rocker arm or a single rocker arm; one end of the rocker arm is connected with the machine body, and the other end of the rocker arm is connected with the cutting heads; the rocker arm arches upwards to form the coal-passing space; the rocker arm is provided with the coal-passing space, which well solves the problem that coal falling by impact of a cutting head near a machine body of a reciprocating impact mining machine can not be conveyed out due to no coal-passing space between a straight rocker arm and a scraper conveyer, gives full play to advantages of high coal mining rate, high efficiency, energy saving, and environmental protection for reciprocating impact mining machines.

Owner:刘素华

Continuous casting method of steel for sulfuric acid dew point corrosion resistance

The invention discloses a continuous casting method for steel resistant to sulfuric acid dew point corrosion. The technology comprises the following steps: (1) whole-process protection pouring is adopted in the continuous casting process, argon seal protection pouring is adopted for a large ladle long nozzle, wherein argon flow is 30~50 L / min, and an immersion type nozzle adopts a concave type nozzle, wherein the argon flow is 5~8 L / min; (2) the components of a covering agent adopted by the molten steel level of a middle ladle comprise, by weight, CaO and MgO with the total content greater than or equal to 52.0% but less than or equal to 58.2%, SiO2 with the content less than or equal to 30%, Al2O3 with the content less than or equal to 15%, T(C) with the content less than or equal to 3.5%, H2O with the content less than or equal to 0.5%, TFe with the content less than or equal to 2.0% and the balance ash with the density of 0.93+ / -0.05g / cm<3>; (3) a crystallizer uses low-carbon high-alkalinity casting powder, the content of free C is less than or equal to 1.0%, and binary basicity R is equal to CaO / SiO2, namely1.05~1.20; and (4) a pulling speed is controlled with 0.70~0.85m / min, the liquid level of the crystallizer is detected in a full-automatic mode, liquid level fluctuation is within 3.0mm, a continuous casting secondary cooling zone adopts a combination mode of electromagnetic stirring, light pressing and heavy pressing, and a cooling mode adopts front weak cooling and rear strong cooling. According to the continuous casting method, a surface crack of a casting blank can be reduced, a peeling process caused by the defect of the casting blank can be eliminated, the yield of the cast blank is improved, and the production cost is effectively reduced.

Owner:TANGSHAN IRON & STEEL GROUP +1

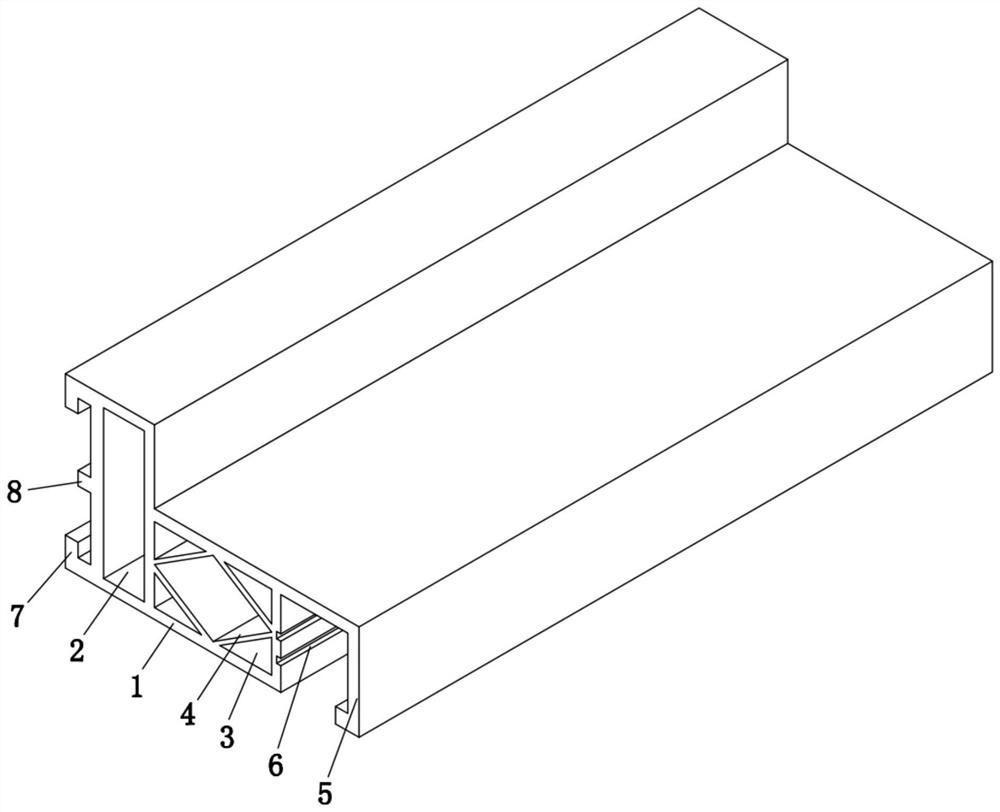

Bright anti-corrosion aluminum profile and preparation method thereof

InactiveCN112483875AReduce cleanup costsWill not polluteElectrophoretic coatingsConstructions elementsAfter treatmentStructural engineering

The invention relates to the technical field of aluminum profiles, in particular to a bright anti-corrosion aluminum profile and a preparation method thereof. The bright anti-corrosion aluminum profile comprises a main frame, a first cavity and a second cavity which are distributed in a horizontal structure are arranged in the interior of the main frame in a preset mode, four reinforcing ribs which can be distributed in an annular structure are integrally formed in the interior of the second cavity, every two adjacent reinforcing ribs are connected end to end, an open edge is integrally formedon outer wall of one side, close to the second cavity, of the main frame, and two clamping hooks distributed in an up-down structure are integrally formed on the outer wall of the side, close to thefirst cavity, of the main frame. The bright anti-corrosion aluminum profile and the preparation method thereof have the beneficial effects that HF, Fe < 3 + > and NO < 2 - > are added to the interiorof a bright degreasing solution, so that the soaking treatment time is greatly shortened, the operation can be directly carried out at room temperature, the material rate is improved, the cost is reduced, a subsequent treatment tank is not polluted after treatment is finished, the cleaning cost of the subsequent treatment tank is greatly reduced, and the bright anti-corrosion aluminum profile is more practical.

Owner:肇庆新联昌金属实业有限公司

High temperature common mild steel anti-oxidation coating and application thereof

InactiveCN100532466CGood anti-oxidation effect at high temperatureEasy to peel offLiquid surface applicatorsCoatingsMetallurgySlurry

The invention relates to a high-temperature ordinary low-carbon steel anti-oxidation coating, which grinds ore powder, metallurgical waste, carbon-containing reducing agent, and inorganic binder including Al2O3, SiO2, Fe2O3, and other components to less than 100 meshes. , mix evenly, and then fully mix with water and stir evenly. The amount of water added is to finally adjust the density of the coating slurry to 1100-1500kg / m3. The coating can be directly sprayed on hot (below 1000°C) steel slabs before hot rolling into the furnace for heating, and can form a continuous protective coating under high temperature, which can effectively reduce the stress of slab transportation and soaking process before hot rolling. High-temperature oxidation burns, does not change the original properties of the billet substrate, and the coating has a strong ability to peel off naturally after heating; at the same time, the raw materials of the anti-oxidation coating are easy to obtain, the cost is low, and the preparation process is simple, which can be widely used in various steels at 800~ Anti-oxidation when heated at 1300°C / 2-10 hours.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

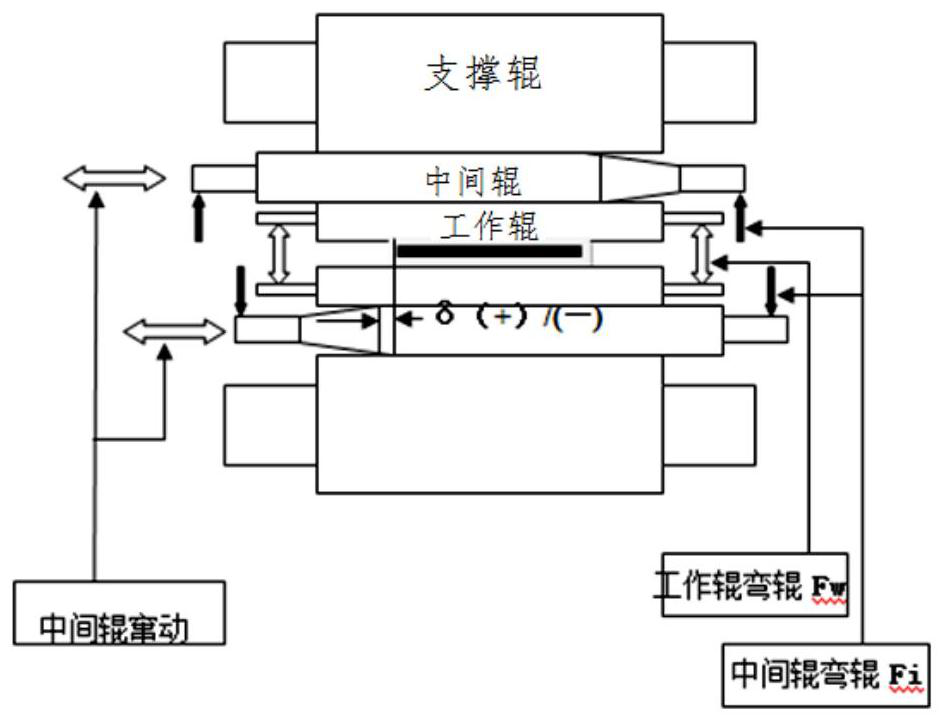

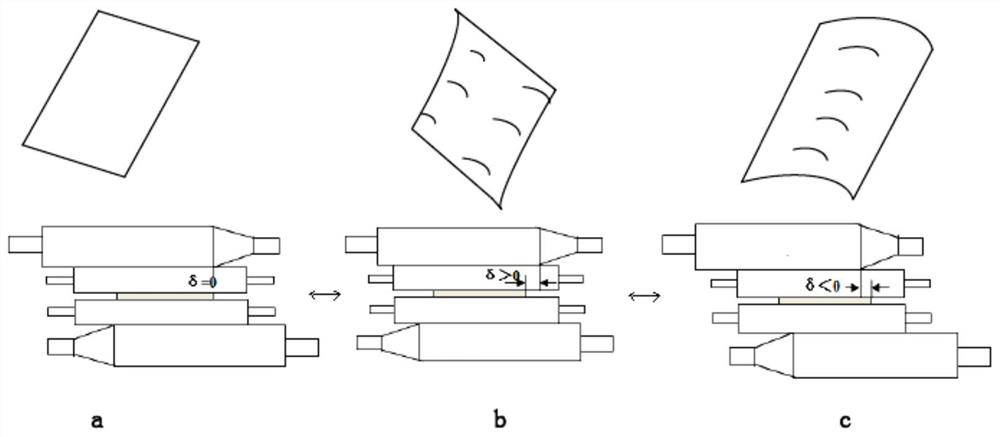

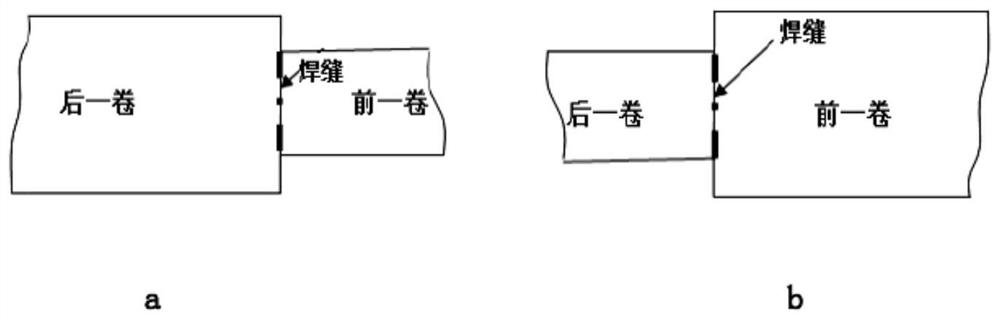

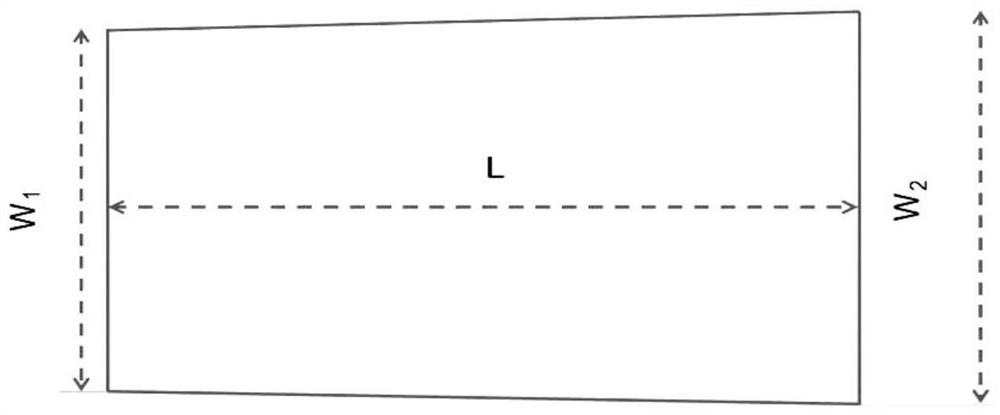

A strip shape control method for dynamically changing strip width in cold tandem mill

ActiveCN109759453BReasonable designImprove control efficiencyProfile control deviceWork rollStructural engineering

The invention discloses a strip shape control method for dynamically changing the specification of the steel strip width of a cold tandem rolling mill, which comprises the following steps: during the control process of the dynamic specification changing of the strip steel width of a cold tandem rolling mill, the roll shifting mode of the middle roll is carried out in two stages ; The shifting of the intermediate rolls is to perform a roll shifting at the positions before and after the welding seam between the front and rear coils of strip steel respectively. The roll shifting method of the intermediate roll is implemented in two steps on the front and rear coils, and combined with the combined control strategy of bending force compensation, the control effect of the work roll and intermediate roll bending is improved, so that the cold-rolled steel coil can be rolled in the width The shape of the strip during the transition period is controlled; the ability to adjust the shape on-line can be improved to achieve the purpose of continuous rolling, and at the same time, the number of abnormal off-line rolls can be indirectly reduced, and the slab ratio of the unit can be improved.

Owner:MAANSHAN IRON & STEEL CO LTD

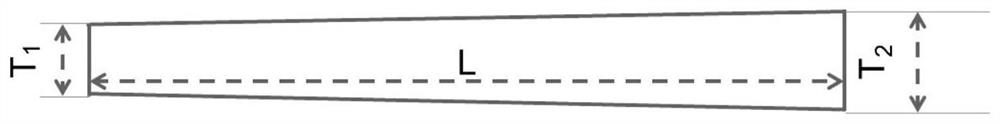

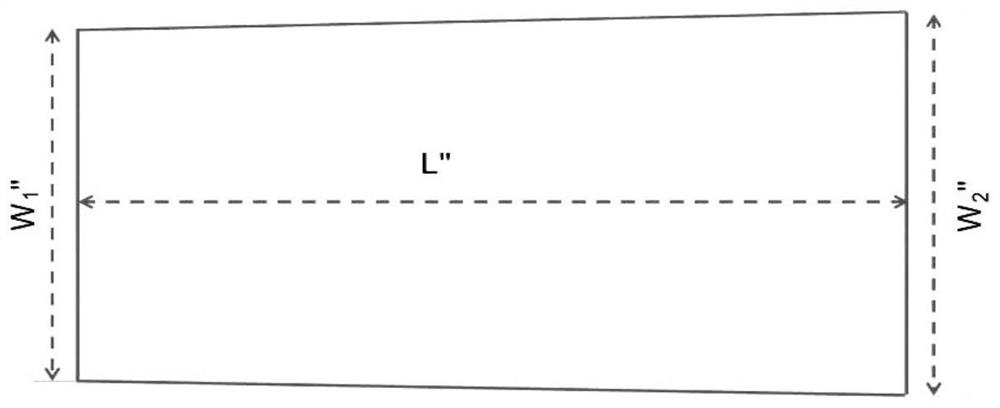

Rolling method of wedge-shaped blank

PendingCN114472509AIncrease material rateMaximize efficiencyRoll mill control devicesMetal rolling arrangementsMechanical engineeringRaw material

The invention discloses a rolling method of a wedge-shaped blank, which is characterized in that the thickness difference of a plate blank is firstly eliminated through several passes before longitudinal rolling, and then the width difference of the plate blank is further eliminated through a reverse plate blank thickness difference caused by a subsequent longitudinal rolling pass. According to the method, the rolling process is optimized, the rolling yield of the wedge-shaped blank is increased by about 15%, the efficiency is maximized when the wedge-shaped blank is rolled, and the raw material utilization rate of the wedge-shaped blank is effectively increased.

Owner:NANJING IRON & STEEL CO LTD

Auxiliary processing device

InactiveCN102513357BPrevent tamperingAvoid unqualifiedRoll mill control devicesMetal rolling arrangementsRelative displacementEngineering

The invention discloses an auxiliary processing device, comprising a base, a locating shaft, a carrier rod and a pin, wherein the base comprises a first supporting part provided with a sliding chute having an opening, and a second supporting part located at the end of the first supporting part; the first supporting part comprises at least two first supporting plates provided with the sliding chute; the locating shaft is movably arranged on the base through the sliding chutes; the carrier rod comprises a main cross rod, a first mounting part and a clamping part; the first mounting part and the clamping part are respectively arranged at both ends of the main cross rod; the carrier rod is fixedly connected with the locating shaft by the first mounting part; the pin is detachably inserted between the locating shaft and the second supporting part; and the pin is of a wedged structure. The auxiliary processing device provided by the invention can avoid the movement of the processing device, and the relative displacement of two processing devices or two components of the same processing device, thereby improving the yield of the device.

Owner:LAIWU IRON & STEEL GRP

Heating method of hollow ingot

The invention discloses a heating method of a hollow ingot. The heating method comprises the following steps that (1) a graphite rod is placed in the hollow ingot, wherein the length of the graphite rod is the same as that of the hollow ingot, and the diameter of the graphite rod is 2mm-8mm smaller than the inner diameter of the hollow ingot; (2) the hollow ingot with the graphite rod is placed ina copper ingot heating furnace to be heated; and (3) after the hollow ingot with the graphite rod reaches the process temperature, the hollow ingot is pushed out of the copper ingot heating furnace and conveyed to an extruder, and the hollow ingot is extruded after the graphite rod in the hollow ingot is taken out. The heating method of the hollow ingot effectively solves the problem of oxidationof the inner surface of the hollow ingot in the heating process, so that the pipe yield is greatly increased; the method is simple, convenient to operate, good in using effect and capable of reducingmetal loss; and according to the heating method of the hollow ingot, the one-time yield of pipes is greatly improved, and obvious economic benefits can be obtained.

Owner:JINCHUAN GROUP LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com