Stop spot control method for shallow slot turbulent pickling line

A control method and technology of turbulent acid, which is applied in the field of strip pickling, can solve the problems of quality and yield loss, reduce parking spot defects, and reduce machine composition rate, so as to improve yield and genuine product rate, and eliminate parking spots Defect, pickling efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The method for controlling the parking spot of the shallow groove turbulent flow pickling unit of the present invention comprises the following steps:

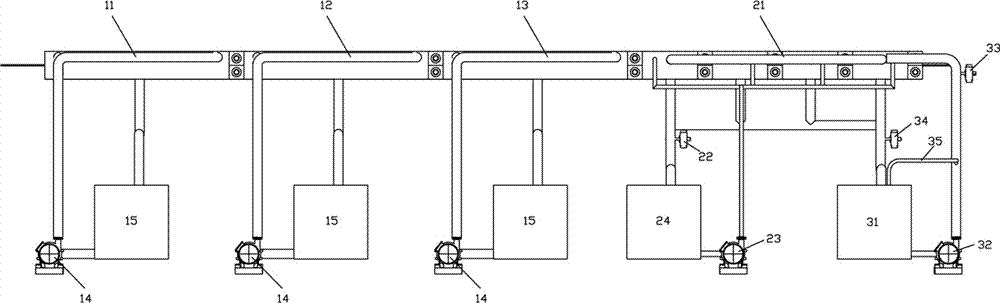

[0028] 1) After stretching and leveling, the strip steel enters the three-stage acid tank 11, 12, and 13 to start pickling, and the acid tank 15 pickling solution is recycled through the circulation pump 14; then it enters the four-stage rinse tank 21 to clean the residual Chloride.

[0029] When the pickling unit is in normal operation, the return valve 22 of the rinsing tank 21 is always open. The return valve 22 is an automatic valve, and its opening / closing action is interlocked with the operation signal of the pickling unit.

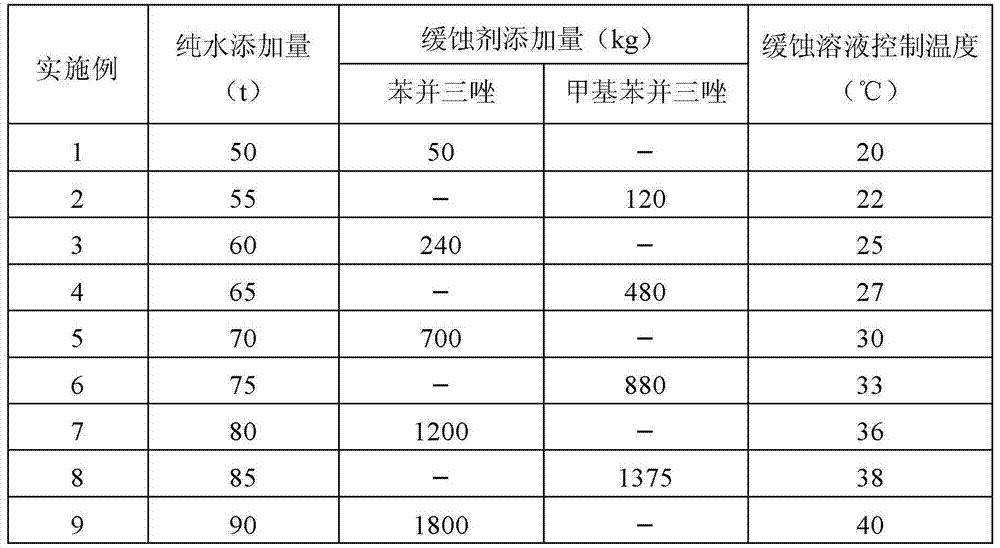

[0030] 2) Configure the corrosion inhibition solution in the corrosion inhibition solution tank 31, add pure water first, and then add the adsorption film type corrosion inhibitor according to the ratio of 0.1wt% to 2.0wt% of the pure water addition; turn on the corrosion inhibition solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com