A rolling preparation method of high-silicon electrical steel thin strip

A high-silicon electrical steel and high-silicon technology, applied in metal rolling and other directions, can solve problems such as reducing the cold rolling processability of high-silicon electrical steel, reduce subsequent cold rolling edge cracks, have a bright and smooth surface, and improve cold rolling. The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

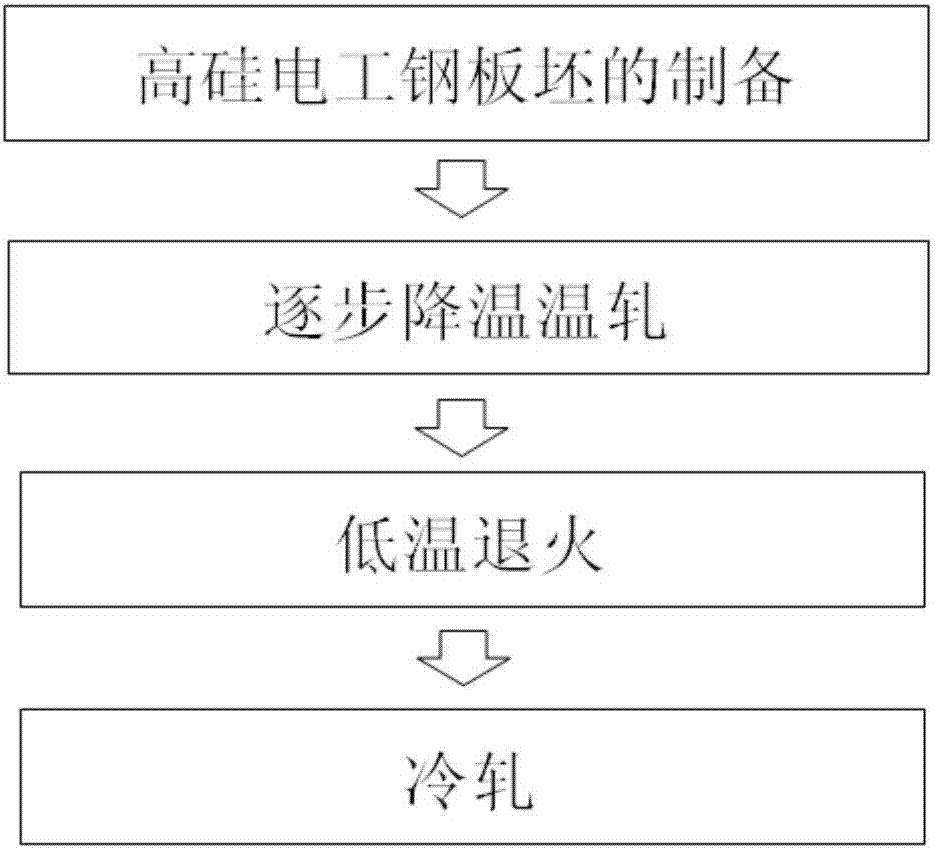

[0030] Such as figure 1 Shown, a rolling preparation method of high-silicon electrical steel thin strip, the method first uses the high-silicon electrical steel slab heated with the furnace as raw material to prepare a high-silicon electrical steel slab, and then the high-silicon electrical steel slab is prepared The electrical steel slab is gradually cooled and rolled to obtain a high-silicon electrical steel warm-rolled strip, and the high-silicon electrical steel warm-rolled strip is subjected to low-temperature annealing and cold rolling to prepare a high-silicon electrical steel thin strip; the prepared obtained The thickness of the high-silicon electrical steel thin strip is 0.1-0.5mm; the high-silicon electrical steel cast slab includes the following components in weight percentage: silicon 4.5-6.8wt%, boron 0.001-0.05wt%, and the balance is iron and unavoidable impurity elements.

[0031] Gradually lowering the temperature of the high-silicon electrical steel slab to ...

Embodiment 2

[0042] A high-silicon electrical steel ingot with a silicon content of 6.8 wt% (mass percentage), a B content of 0.02 wt% (mass percentage), and iron and unavoidable impurity elements as the balance was prepared by vacuum induction melting. The raw materials are: industrial pure iron with an iron content of 99.65 wt% (mass percentage), metal silicon with a purity of 99.95 wt% (mass percentage), and ferroboron with a B content of 20 wt% (mass percentage). Melting adopts intermediate frequency vacuum induction furnace, pouring high-silicon electrical steel billets weighing 21-25kg. The high-silicon electrical steel slab was heated to 1200°C with the furnace and then forged. The final forging temperature was 900°C to obtain a high-silicon electrical steel slab with a thickness of 20mm.

[0043] After heating the high-silicon electrical steel slab to 700°C, roll it for 3 passes with a deformation of 30% until the thickness of the slab is about 7mm, and heat the slab back to 700°C ...

Embodiment 3

[0047] A high-silicon electrical steel ingot with a silicon content of 6.5wt% (mass percent), a B content of 0.02wt% (mass percent), and iron and unavoidable impurity elements as the balance was prepared by vacuum induction melting. The raw materials are: industrial pure iron with an iron content of 99.65 wt% (mass percentage), metal silicon with a purity of 99.95 wt% (mass percentage), and ferroboron with a B content of 20 wt% (mass percentage). Melting adopts intermediate frequency vacuum induction furnace, pouring high-silicon electrical steel billets weighing 21-25kg. The high-silicon electrical steel slab was heated to 1100° C. with the furnace and then hot-rolled to obtain a high-silicon electrical steel slab with a thickness of 5 mm.

[0048] The hot-rolled high-silicon electrical steel slab is pickled to remove the surface oxide layer. The pickling condition is to immerse in 10-20% hydrochloric acid for 5-10 minutes, then brush to remove the surface oxide layer, and ri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com