Automatic positioning equipment for cutting

An automatic positioning and equipment technology, applied in the direction of sawing equipment, sawing components, wood processing equipment, etc., can solve the problems of large manual errors, unsightly furniture, low yield rate, etc., to solve the problem of large manual errors and avoid quality Complaints and the effect of high yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to facilitate a better understanding of the purpose, structure, features, and effects of the present invention, the present invention will now be further described in conjunction with the accompanying drawings and specific embodiments.

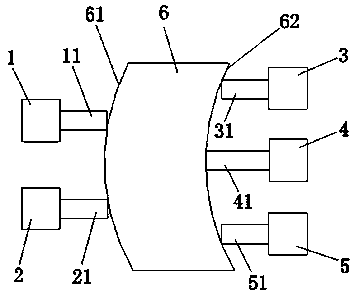

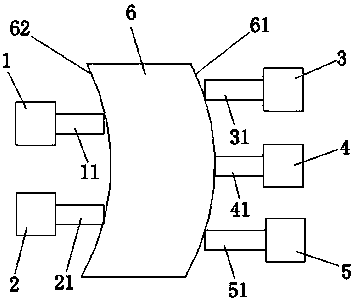

[0024] See figure 2 with image 3 , the automatic positioning equipment for cutting of the present invention is used to position the cut piece 6, the cut piece 6 is wood, and the cut piece 6 has a first surface 61 and a second surface 62 opposite, the first surface 61 is The structure is convex, and the second surface 62 is concave.

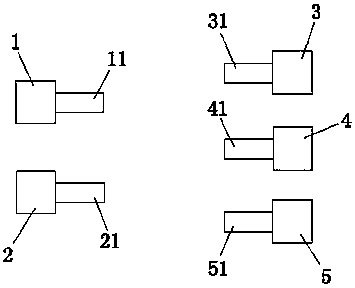

[0025] See Figure 1 to Figure 3 The automatic positioning equipment for cutting includes a first cylinder 1 and a second cylinder 2 arranged on one side of the cut piece 6, a third cylinder 3, a fourth cylinder 4 and a fourth cylinder 4 arranged on the other side. A fifth cylinder 5, the fourth cylinder 4 is located between the third cylinder 3 and the fifth cylinder 5. A driving mechanism (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com