Sulfur-containing tellurium-containing free-cutting ferritic stainless steel and manufacturing method thereof

A kind of stainless steel and ferrite technology, applied in the direction of manufacturing tools, metal rolling, temperature control, etc., can solve problems such as poor turning performance, and achieve the effect of improving turning performance, uniform metallographic structure, and improving corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The present invention provides a method for preparing the above free-cutting ferritic stainless steel containing sulfur and tellurium, comprising the following steps: electric furnace smelting→AOD furnace refining→LF furnace refining→continuous casting→rolling→annealing, wherein:

[0067] Electric furnace smelting: melting raw materials into molten steel in an electric furnace;

[0068] AOD furnace refining: molten steel is decarburized and chromium-preserved in the AOD furnace, so that the C content in molten steel after decarburization and chromium preservation is not higher than the target value; argon gas is blown and stirred throughout the refining process to ensure that the N content is not higher than the target value;

[0069] LF furnace refining: add materials according to the target value of each component in the molten steel in the next step, then add ferroboron to make the B content the target value, and then feed tellurium wire to make the Te content the tar...

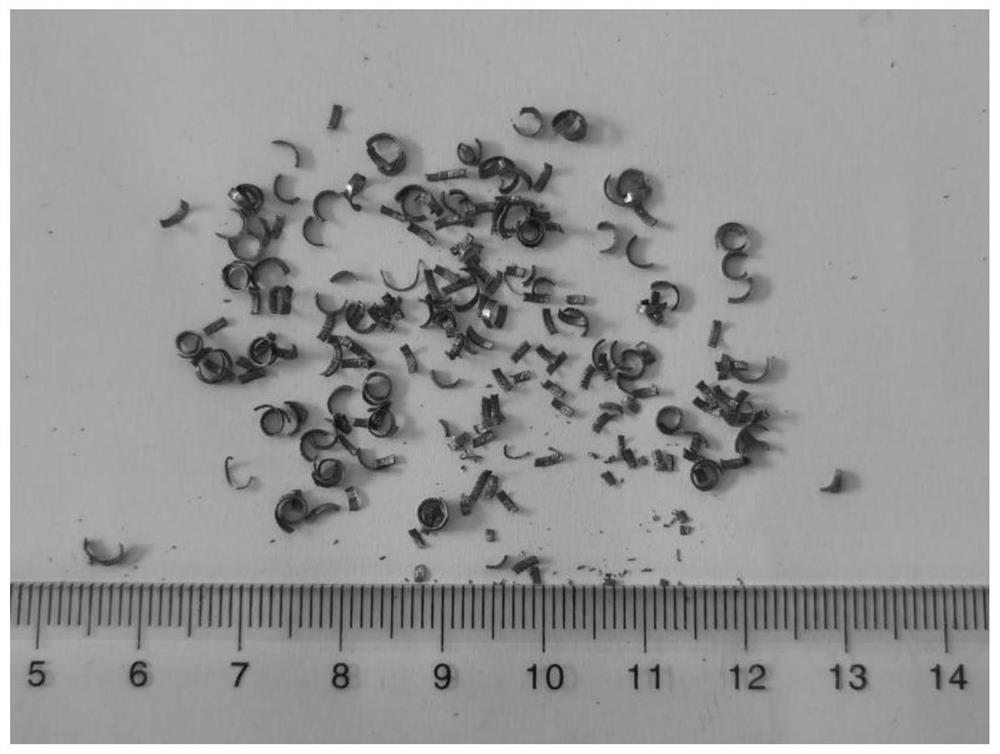

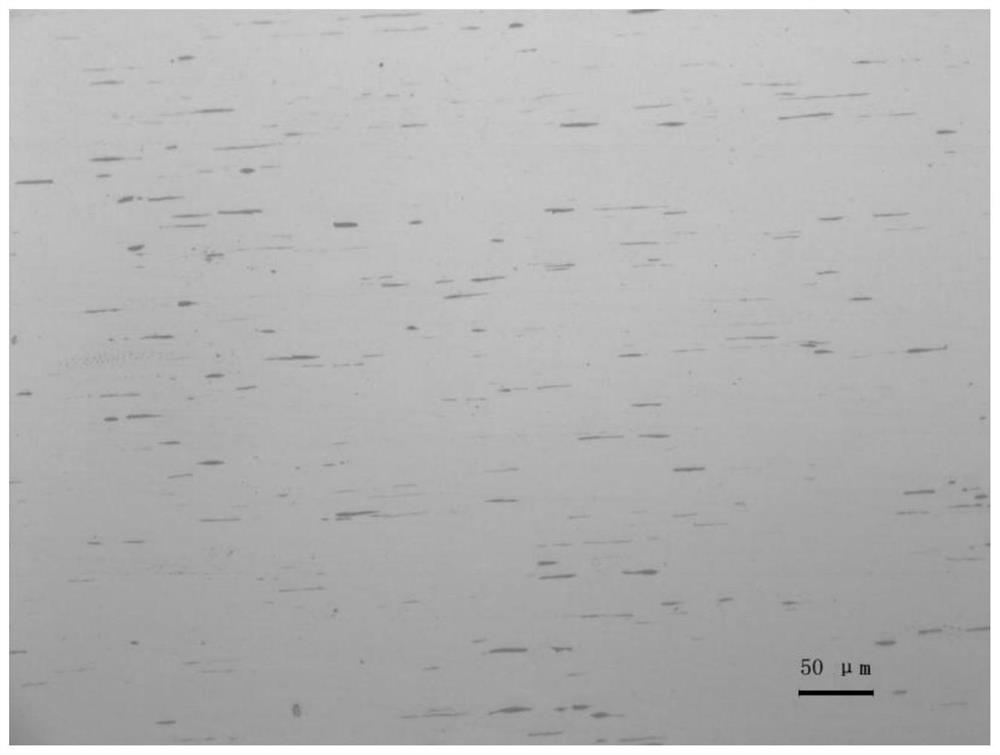

Embodiment 1

[0097] The sulfur-containing and tellurium-containing free-cutting ferritic stainless steel described in this embodiment comprises, by mass percentage: C: 0.042%, Si: 0.40%, Mn: 0.81%, P: 0.023%, S: 0.25%, Ni: 0.22%, Cr: 17.23%, Mo: 0.26%, N: 0.018%, Te: 0.0081%, B: 0.0019%, and the rest are iron and unavoidable impurities. The production process of the above-mentioned free-cutting ferritic stainless steel containing sulfur and tellurium is: electric furnace→AOD→LF→continuous casting→rolling→annealing, specifically:

[0098] Electric furnace: 30 tons of electric furnace is used for smelting, and the raw materials are 34 tons of waste stainless steel with low P and five harmful elements (Pb, Sn, As, Sb, Bi). Add 14 tons of small pieces of raw materials. After complete melting, the P content is 0.023%, and the content of other elements is: C: 0.806%, Si: 0.14%, Mn: 0.68%, S: 0.017%, Ni: 0.22%, Cr: 16.99 %, Mo: 0.26%, N: 0.072%, adjust the temperature to 1670°C, pull out 2 / 3 of ...

Embodiment 2

[0106] The sulfur-containing and tellurium-containing free-cutting ferritic stainless steel described in this embodiment comprises, by mass percentage: C: 0.049%, Si: 0.51%, Mn: 0.99%, P: 0.014%, S: 0.28%, Ni: 0.30%, Cr: 17.33%, Mo: 0.32%, N: 0.009%, Te: 0.0062%, B: 0.0021%, and the rest are iron and unavoidable impurities. The production process of the above sulfur-containing and tellurium-containing free-cutting ferritic stainless steel is: electric furnace→AOD→LF→continuous casting→rolling→annealing, specifically:

[0107] Electric furnace: 30 tons of electric furnace is used for smelting, and the raw materials are 33 tons of scrap stainless steel with low P and low five harmful elements (Pb, Sn, As, Sb, Bi). Add 8 tons of small pieces of raw materials. After complete melting, the P content is 0.014%, and the content of other elements is: C: 0.780%, Si: 0.16%, Mn: 0.61%, S: 0.016%, Ni: 0.32%, Cr: 16.81 %, Mo: 0.34%, N: 0.016%, adjust the temperature to 1675°C, pull out 2 / 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com