Method for manufacturing double metal composite wear-resistant metallurgical rollers

A technology of a metallurgical roll and a manufacturing method, which is applied in the manufacture of rolls and the manufacture of bimetal composite wear-resistant metallurgical rolls, can solve the problems of low over-steel amount, frequent occurrence of roll breakage, long manufacturing period, etc. The effect of improving the quantity, considerable economic benefits, and avoiding the accident of roller breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

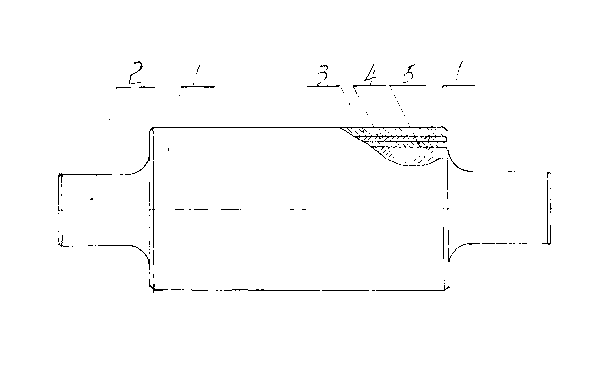

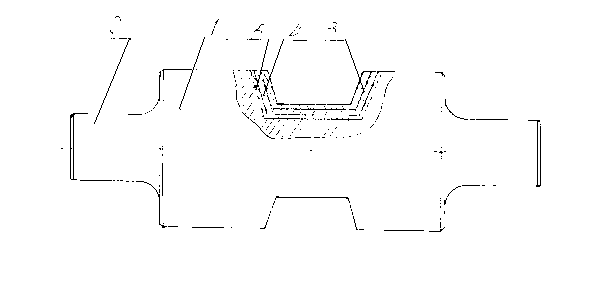

[0020] A method for manufacturing a bimetallic composite wear-resistant metallurgical roll, comprising a roll core processing step, a preheating step, a surfacing composite layer step, a finishing step and a heat treatment step, wherein:

[0021] The processing steps of the roller core are as follows: forging and quenching and tempering steel materials with excellent tensile strength, yield strength and impact resistance to make a roller core blank, and then rough machining the roller core blank to the size of the reserved surfacing composite layer;

[0022] The preheating step is to preheat the roller core to a suitable welding temperature of 380C°±5C°.

[0023] The step of surfacing the composite layer is to fill up the reserved surfacing composite layer with flux-cored welding wire on the surface of the preheated roller core by submerged arc welding;

[0024] The finishing step is to process the bimetal composite wear-resistant metallurgical roll blank to the designed size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com