Blooming down-the-hole pattern design method used on continuous rolling mill

A design method and continuous rolling mill technology, applied in design optimization/simulation, roll, metal rolling, etc., can solve problems such as low roll body utilization, long roll body length, and large pass outer width, etc., to achieve Reduced roll weight, improved utilization, and reduced roll diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

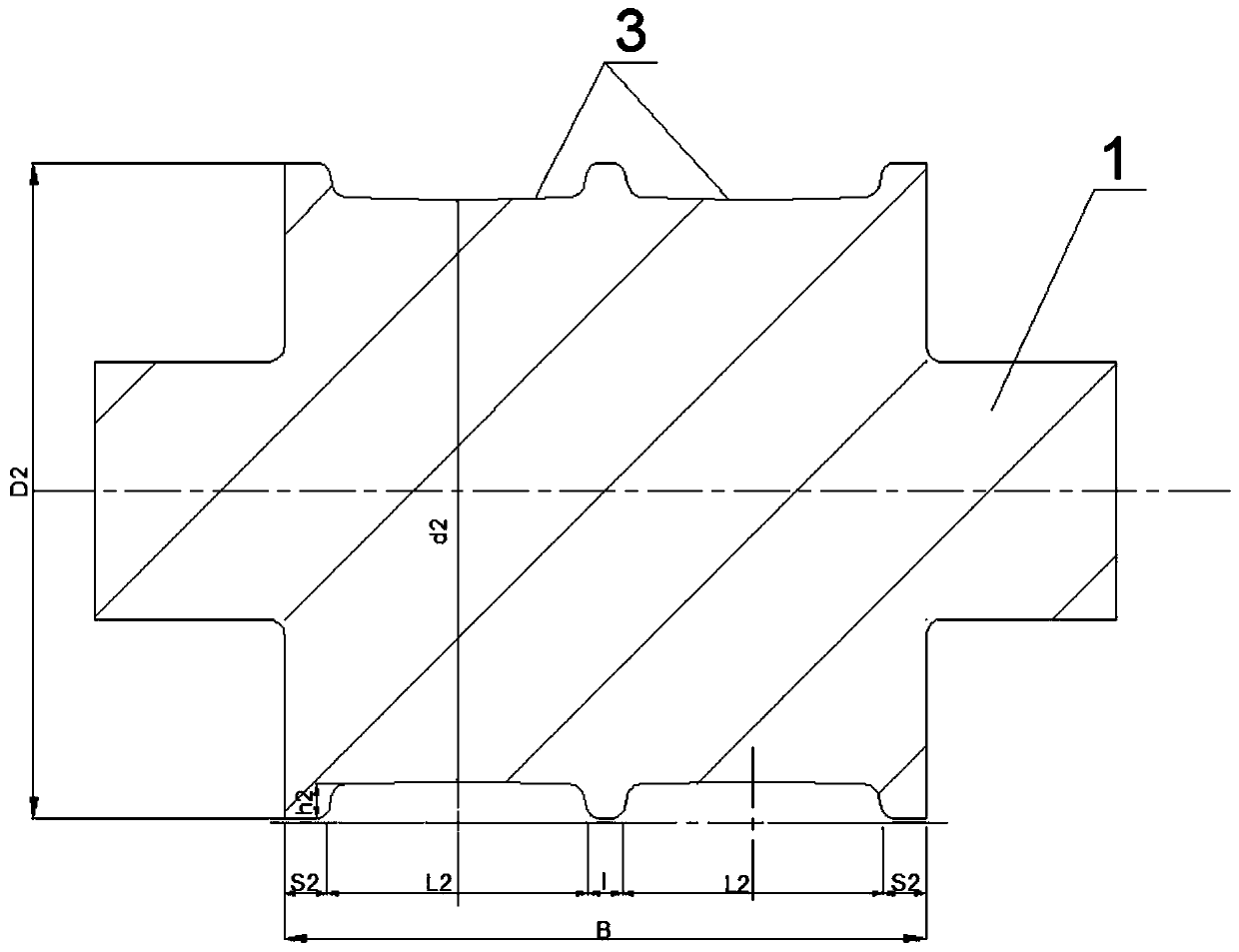

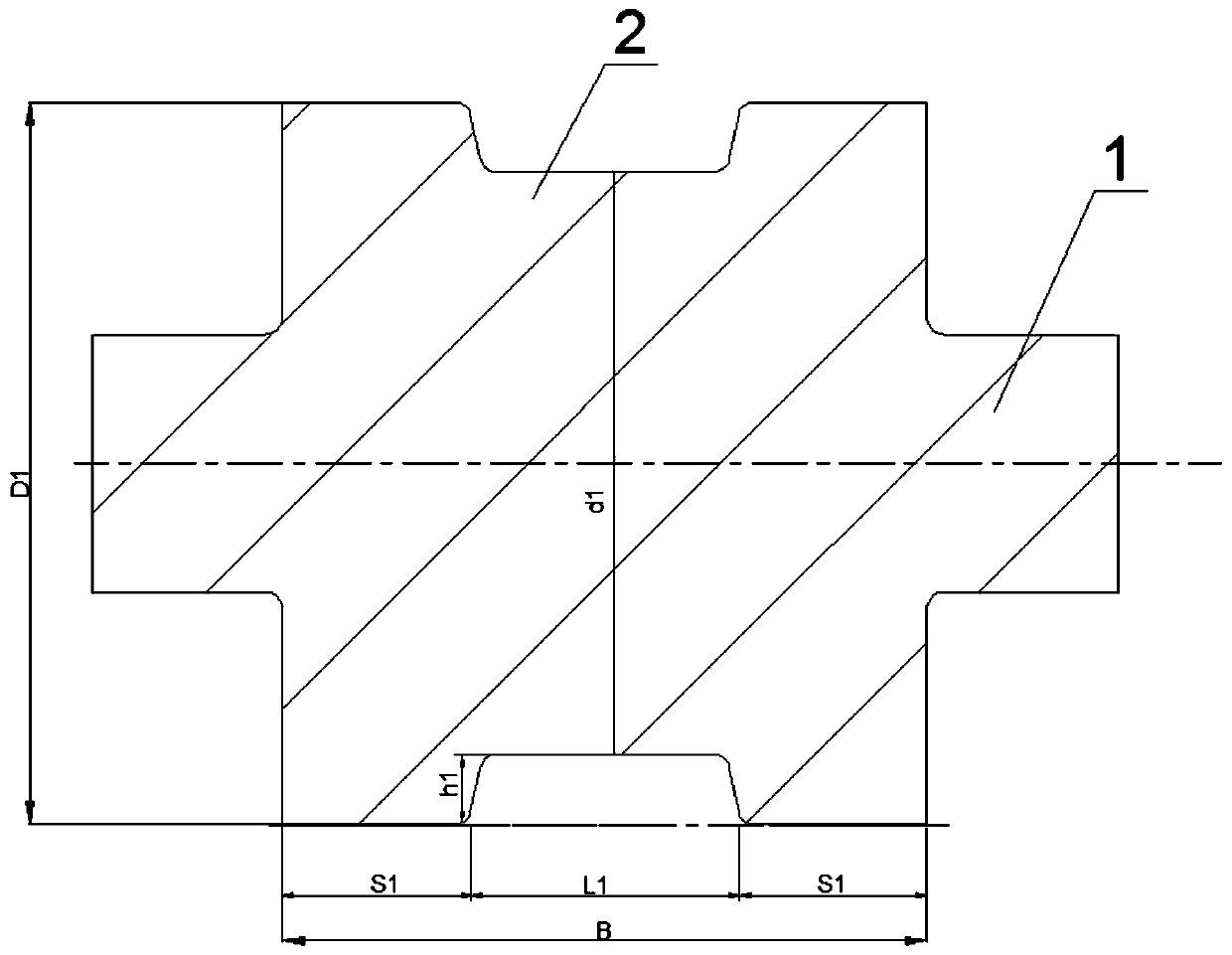

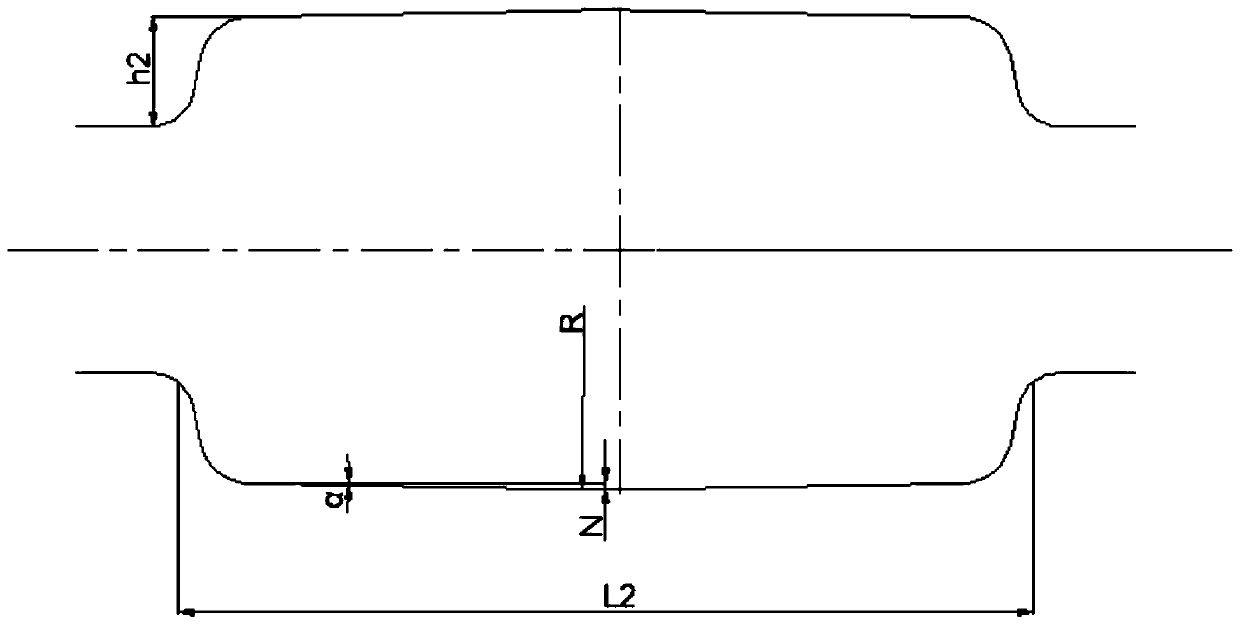

[0037] Such as figure 1 with Figure 5 As shown, the present invention is a design method for the blooming submerged pass type used on the continuous rolling mill. A box-shaped pass type is processed on the surface of the roll 1, and the side wall of the pass type is inclined, and specifically includes The following steps:

[0038] Step 1: According to the groove depth of the existing hole type 2, the groove depth of the submerged hole type 3 is determined by the following formula. The slope of the side wall of the submerged hole type 3 is the same as that of the existing hole type 2, namely :

[0039] h 2 = 1 / 2h 1

[0040] Where: h 2 is the groove depth of down-the-hole type, h 1 Notch depth for existing pass pattern

[0041] Due to the reduced groove depth of DTH type 3, the roll body diameter D 2 and roll working diameter d 2 The difference is reduced by half compared with the original design, so that the groove bottom of submerged hole type 3 is located at a high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com