A kind of metal-ceramic coating continuous casting crystallizer copper tube and preparation method thereof

A cermet coating and continuous casting mold technology, which is applied in metal material coating process, coating, fusion spraying and other directions, can solve the problem of inability to prepare cermet coating with HVOF spray gun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of R6-160*160*900 metal ceramic coating continuous casting mold copper tube adopts HVAF process, and the process steps are as follows:

[0040] step 1:

[0041] (1) Straightening the surface of the copper tube: Use a press to straighten the copper tube. The radius of the curved surface on one side is 6000mm±1mm, and the flatness on the straight side is less than 1mm to obtain the straightened copper tube.

[0042] (2) Degreasing the surface of the copper tube: Use industrial alcohol to deoil the surface of the straightened copper tube, and use acetone to purify the surface to be sprayed before spraying.

[0043] Step 2: Sandblasting and preheating the surface of the copper pipe

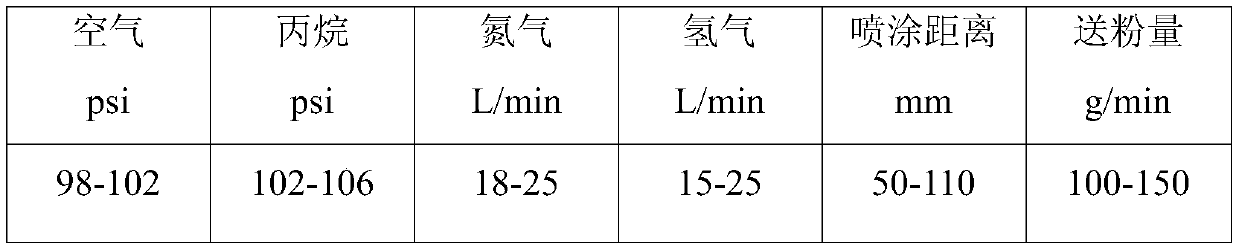

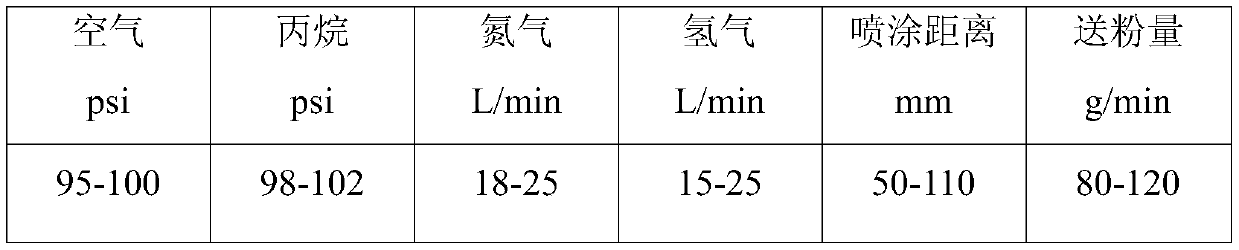

[0044] Set the robot program, use the HVAF inner hole spray gun, start the HVAF spraying system, ignite and send the sandblasting powder. The thermal temperature is 90-120°C. The surface roughness Ra after sandblasting is 2.5 to 4 μm. The relevant parameters of sandblas...

application example 1

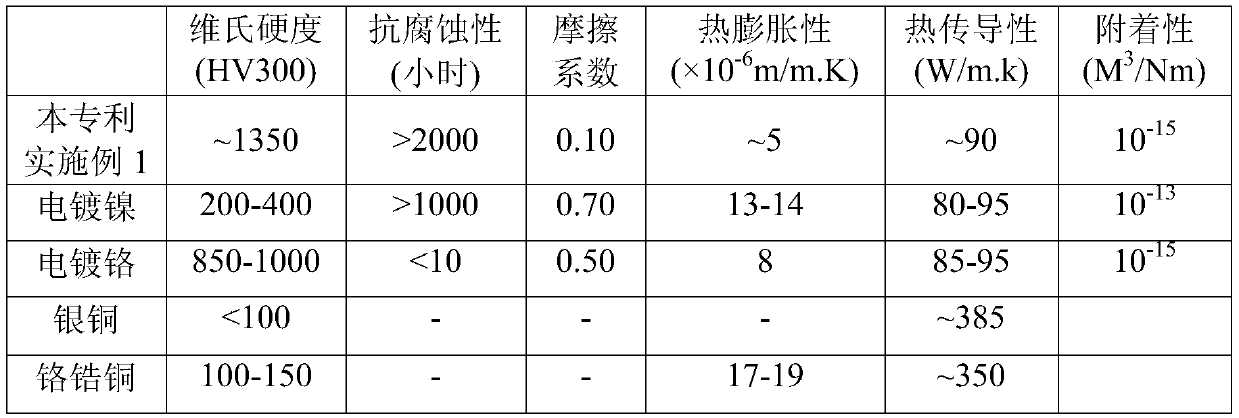

[0062] In February 2018, a steel mill used the cermet coating continuous casting mold copper tube prepared in Example 1 of the present invention. After use, it was found that the cermet coating continuous casting mold copper tube of the present invention has the following advantages:

[0063] 1. Over 36,000 tons of steel, the maximum wear amount is 0.4mm, which is much smaller than the wear amount of 2-3mm when the electroplated copper tube passes over 7,500 tons of steel;

[0064] 2. Because there is almost no wear and tear, the taper of the narrow copper pipe is well maintained;

[0065] 3. Reduce the workload of disassembly and repair;

[0066] 4. Extend the life of copper tube.

application example 2

[0068] In May 2018, a steel mill used the cermet coating continuous casting mold copper tube prepared in Example 1 of the present invention. After use, it was found that the cermet coating continuous casting mold copper tube of the present invention has the following advantages:

[0069] 1. The average amount of steel passing is increased by 4.5 times;

[0070] 2. A single copper tube is used twice on average, and its service life reaches 80,000 tons, an increase of 11 times;

[0071] 3. The shape of the corners of the billet is stable, which greatly reduces cracks;

[0072] 4. The heat flow is stable and the rotten edges are reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com